3 | M5751

Table of Contents

1Notes, Warnings, and Cautions .................................................................................................................... 5

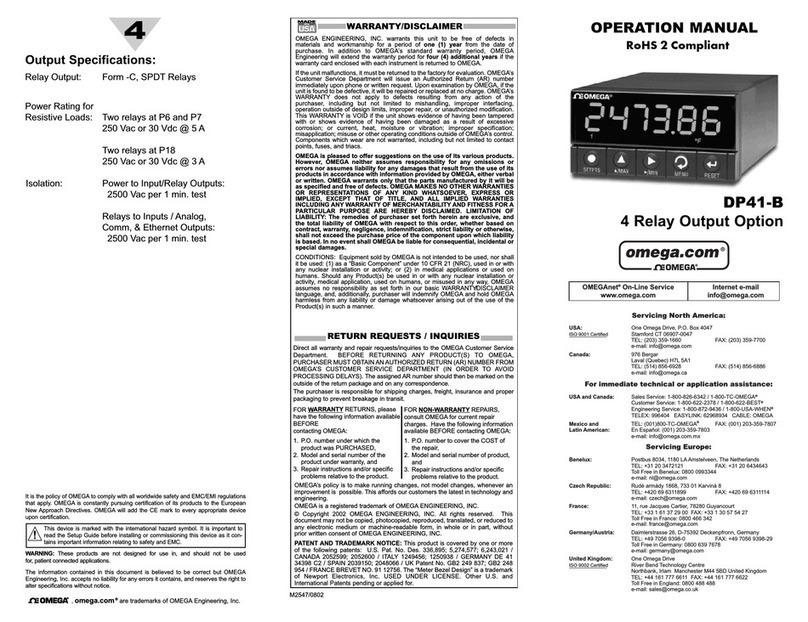

2Introduction................................................................................................................................................. 6

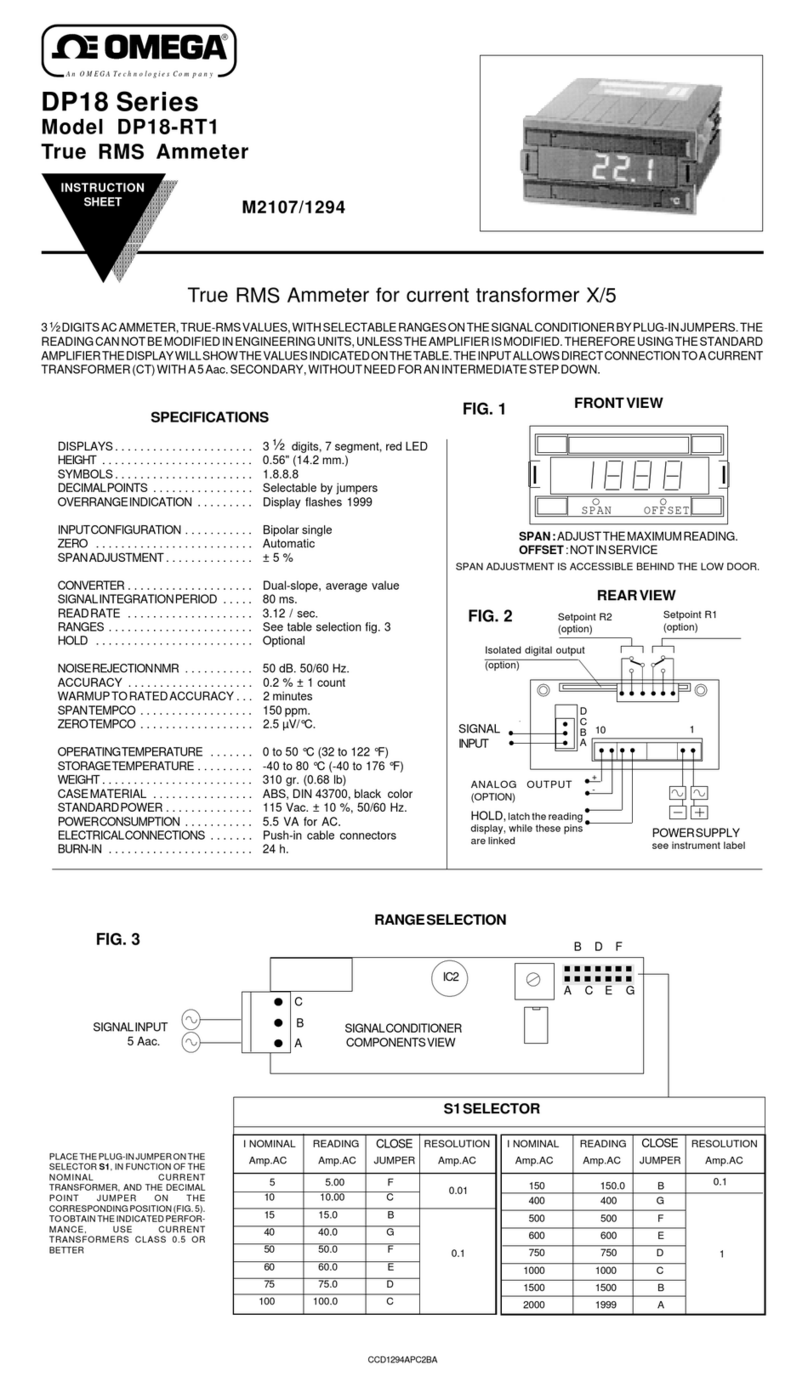

3Specifications............................................................................................................................................... 7

4Hardware Setup........................................................................................................................................... 8

4.1 Connecting to your Layer N Smart Interface ...................................................................................................... 8

4.2 Digital Input Wiring Diagram ............................................................................................................................ 8

4.3 Discrete I/O ..................................................................................................................................................... 8

5SYNC Configuration...................................................................................................................................... 9

5.1 Connecting to SYNC - Automatic Detect ............................................................................................................ 9

5.2 Connecting to SYNC – Manual........................................................................................................................... 9

5.2.1 Communication Interface.................................................................................................................................... 9

5.3 Input Configuration.........................................................................................................................................11

5.3.1 Digital Inputs Interface...................................................................................................................................... 11

5.3.1.1 Pulse Measurements................................................................................................................................................... 12

5.3.2 Mixed Input Interface........................................................................................................................................ 16

5.3.2.1 Digital Inputs (Mixed Mode)........................................................................................................................................ 17

5.3.2.2 Process Inputs (Mixed Mode)...................................................................................................................................... 17

5.3.3 Discrete Input/Output (DIO) ............................................................................................................................. 18

5.3.3.1 Setting DIO as an Input................................................................................................................................................ 19

5.3.4 Advanced Scaling Options ................................................................................................................................. 19

5.4 Output Configuration ......................................................................................................................................21

5.4.1 Device Output Range/Types.............................................................................................................................. 22

5.4.1.1 ON/OFF Output Type .................................................................................................................................................. 22

5.4.1.2 Pulse-Width Modulation (PWM) Output Type............................................................................................................. 22

5.4.1.3 SERVO Output Type .................................................................................................................................................... 22

5.4.2 Sensor Output Mapping .................................................................................................................................... 23

5.4.3 ON/OFF Control Module ................................................................................................................................... 24

5.4.4 Setting an Alarm................................................................................................................................................ 25

6Pairing a Sensing Device to a Layer N Gateway .......................................................................................... 26

6.1 Wireless Pairing ..............................................................................................................................................26

6.2 Wired Pairing..................................................................................................................................................26

7Appendix: SP-013 Registers........................................................................................................................ 27

7.1 Digital Descriptor ............................................................................................................................................27

7.1.1 Digital Descriptor .............................................................................................................................................. 27

7.1.1.1 Digital Measurement Types......................................................................................................................................... 28

7.1.1.2 Digital Data Type/Format ............................................................................................................................................ 28

7.1.1.3 Digital Configuration ................................................................................................................................................... 28

7.1.2 Digital Input Device Byte ................................................................................................................................... 29

7.1.3 Digital Sensor Parameters ................................................................................................................................. 29

7.1.3.1 IPSO Digital Definition................................................................................................................................................. 30

7.1.3.2 Digital Resolution........................................................................................................................................................ 30

7.1.3.3 Sensor Trigger Function .............................................................................................................................................. 30

7.2 Process Input ..................................................................................................................................................30

7.2.1 Process Descriptor ............................................................................................................................................ 30

7.2.1.1 Process Measurement Types....................................................................................................................................... 31

7.2.1.2 Process Input Data Type/Format................................................................................................................................. 31

7.2.1.3 Process Input Configuration ........................................................................................................................................ 31

7.2.2 Process Device Byte .......................................................................................................................................... 32