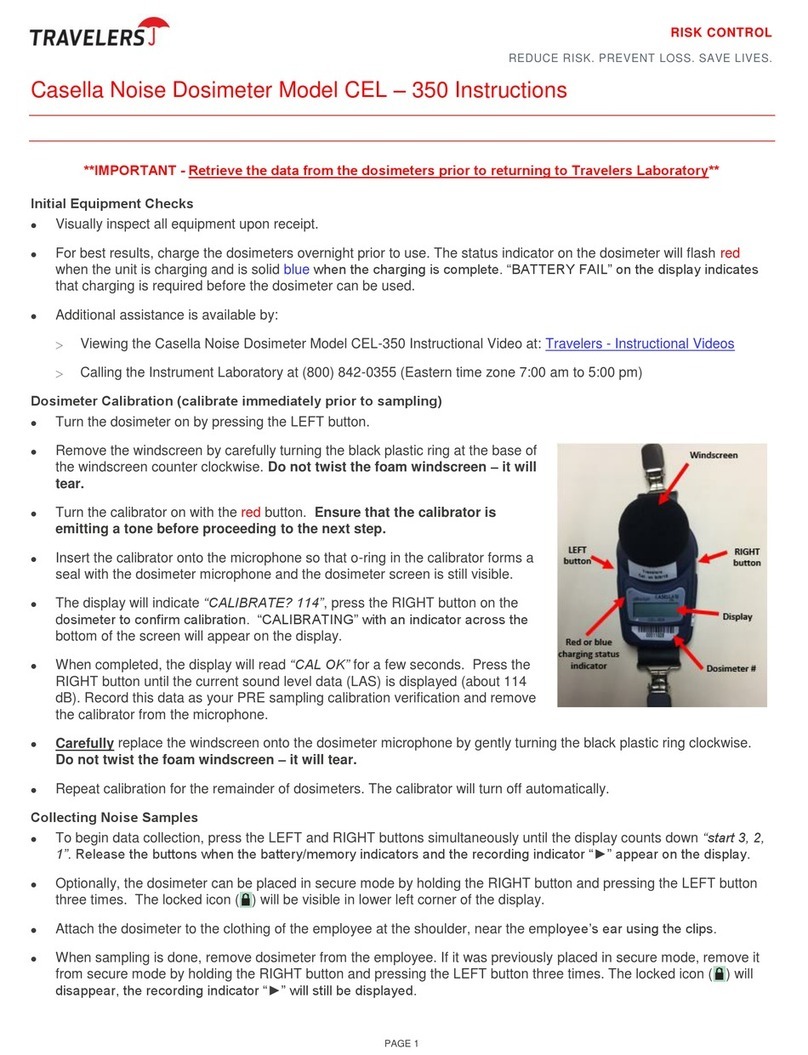

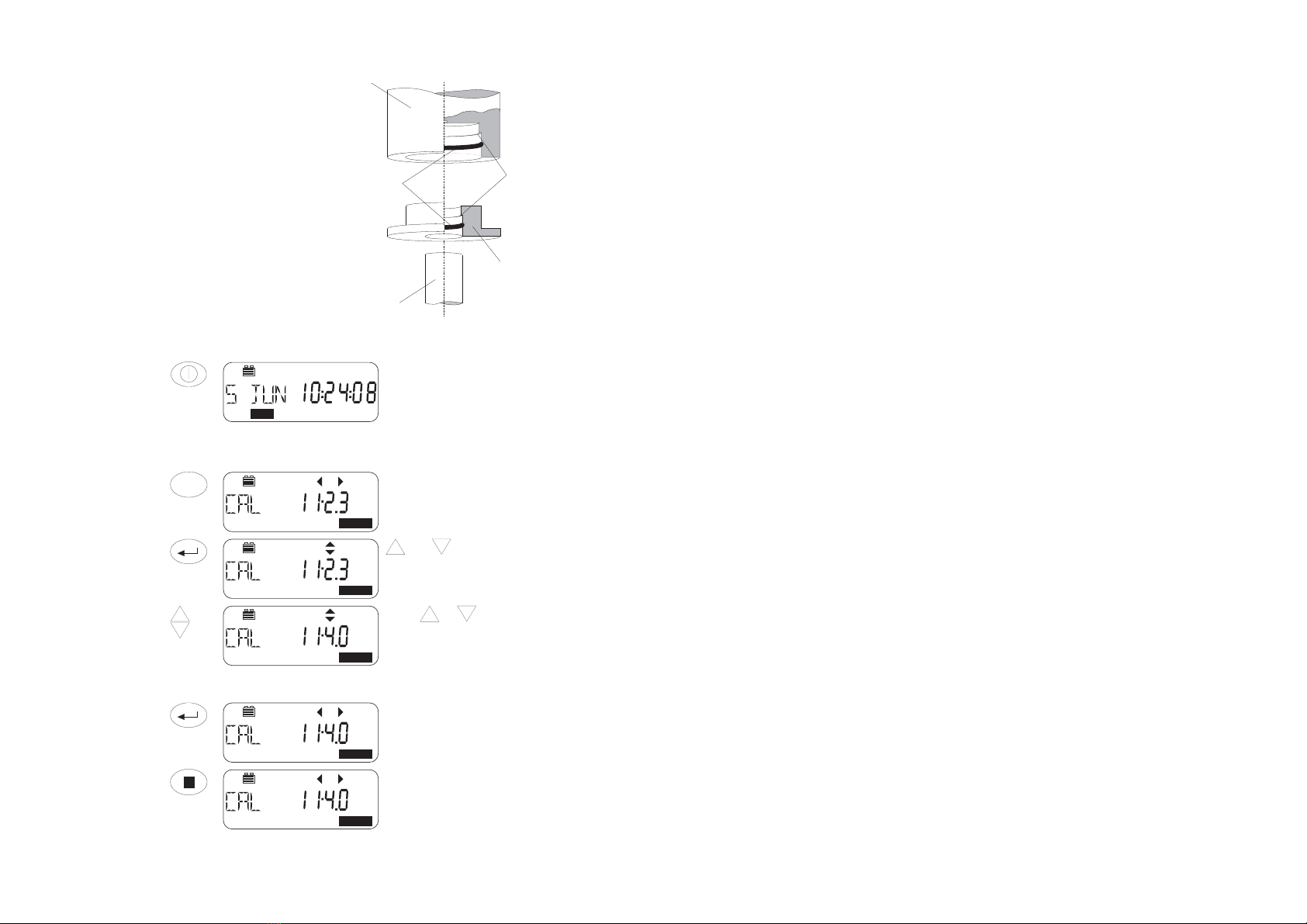

However, all sound

level measurement

parameters can be set from

the keypad. There are three

overlapping measurement

ranges: 30 - 100, 50-120 &

70-140 dB, A & C RMS

weightings, Linear & C Peak

weightings, Fast, Slow &

Impulse time weightings, and

energy exchange rates (Q) of

3, 4, 5 & 6. In dose measure-

ment mode, they display %

dose, % dose projected for

an 8 hour period, peak level

and measurement duration.

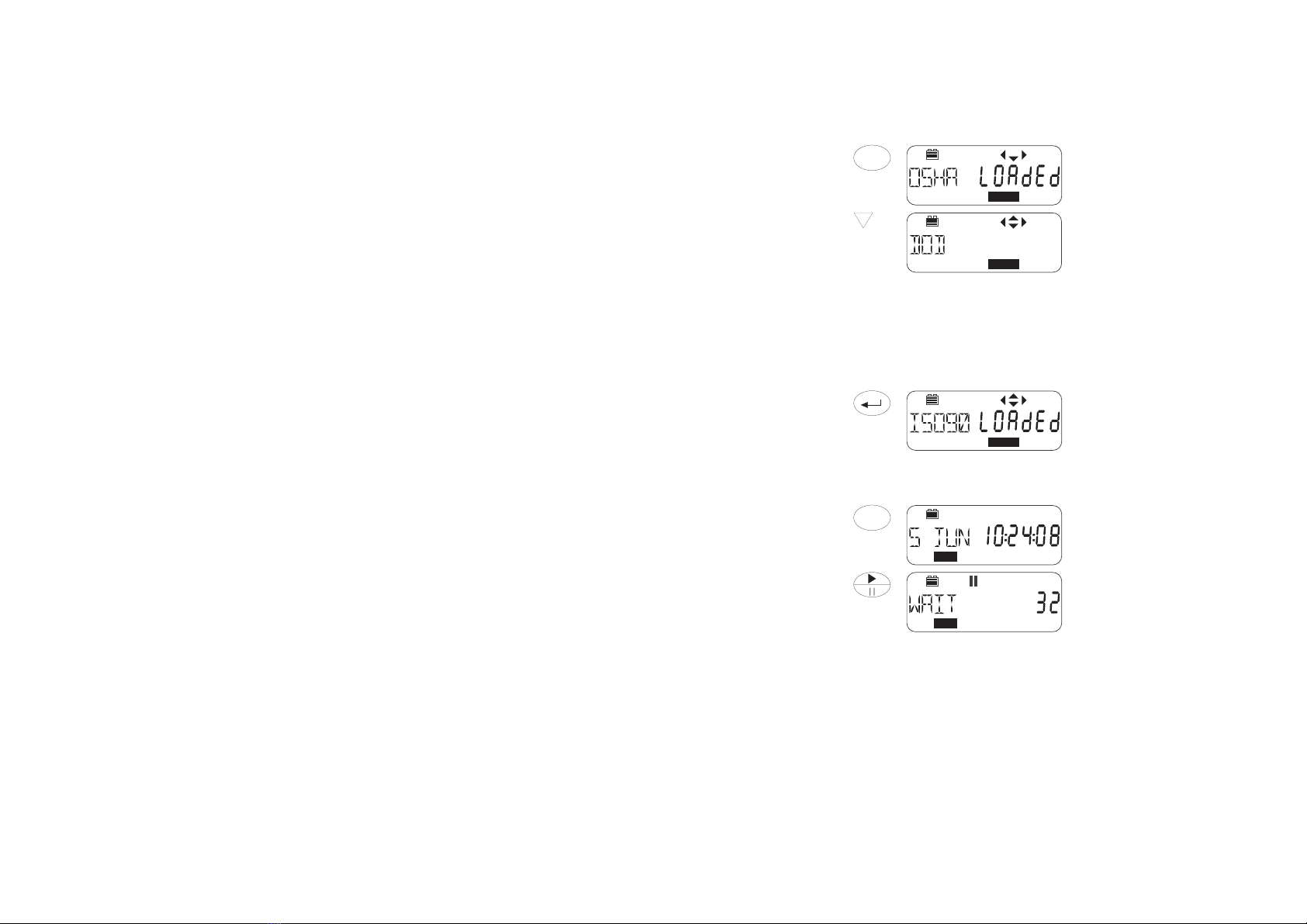

For countries that are subject to European Union regulations or

the equivelent ISO standards, these instruments measure the daily

sound exposure level (LAeq,8hr Pa2h according to IEC 1252, which is

identical with the LEX,8h required by ISO 1999), while for USA

OSHA/MSHA regulations they measure the Time Weighted Average

level (TWA).

When used as a sound level meter they display sound level,

maximum sound level, minimum sound level, peak, time-averaged (LAeq

or LAvg) sound levels and sound exposure level (SEL).

4.3 CEL-360/360S Logging Noise Dosimeters

In addition to the features available to the CEL-320 Dosimeters, the

following additional features apply to the CEL-360 and CEL-360S. These

instruments are recommended for detailed measurements as they

include extended processing and memory functions.

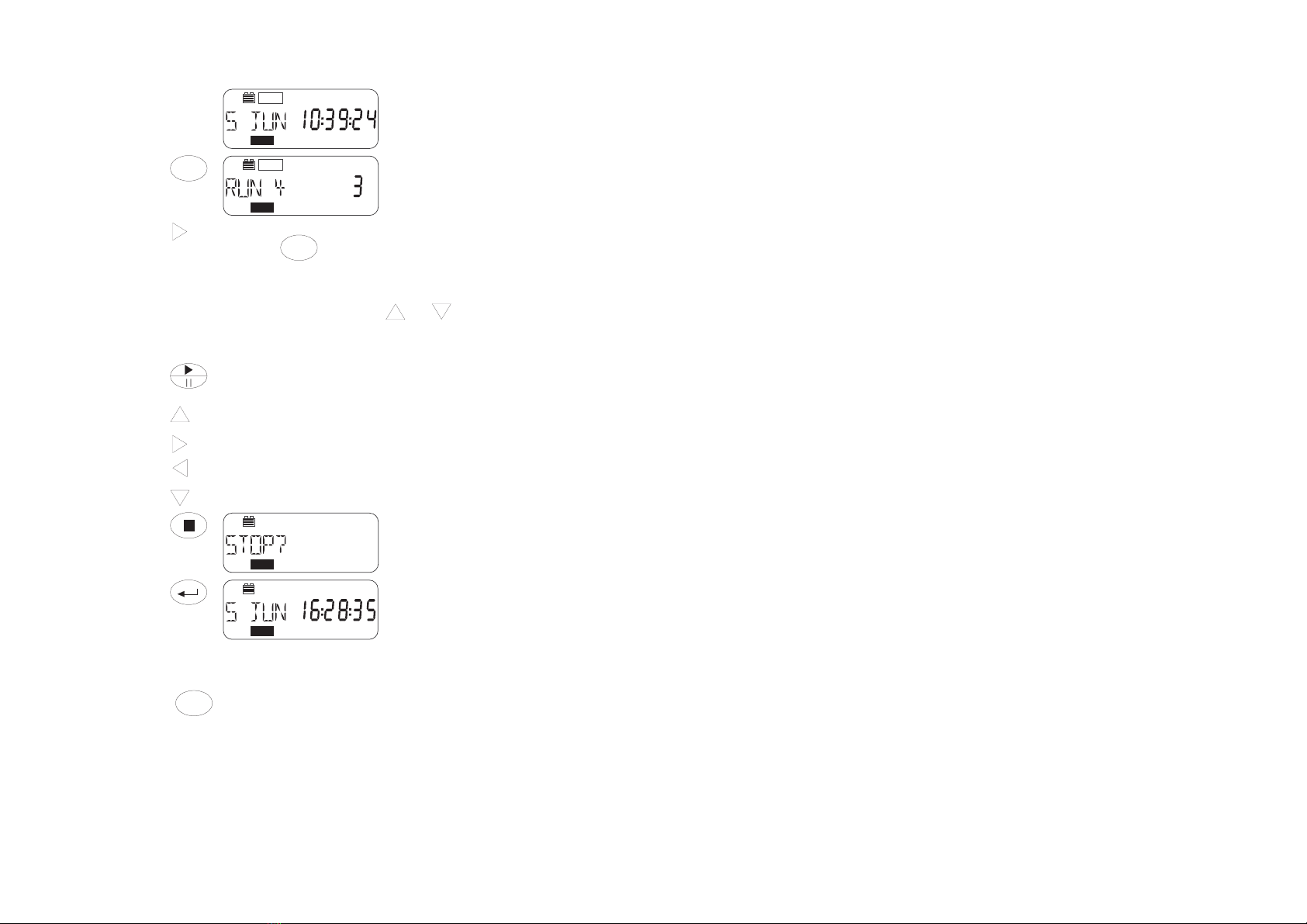

There are automatic run timing facilities controlled by the built-in

clock and time-history recording capabilities that allow up to 10 profiles

to be saved with each dose (DATA) result set, in a separate profile store.

Sampling times can be specified between 1 s and 1 hour by dB10 and

dB12 software, while profile storage is in excess of 220 000 data points,

where any single run can use up to 99 999 points.

The instruments are able to measure and save up to five user

specified Lnvalues (exceedance level percentiles). Run durations

specified via instrument keys, by dB10 or dB12, and start and stop times

preset via dB10 or dB12 can be switched on or off from the instrument

keys. Other settings can be changed only by dB10 and dB12 Software.

Table 2: Setups and Configuration Files

Parameter settings that do not modify preset

measurement protocols can be changed by using

the instrument keys.

All available parameter settings can be changed

from a PC by means of dB10 or dB12 Software.

Parameter settings that modify preset measure-

ment protocols must first be saved by dB10 or

dB12 under a new setup identity in an instrument

“configuration file”.

A“configuration file” contains a complete

instrument set of setups, i.e. seven fixed dose

setups, up to 13 user defined setups, one SLM

setup, and one timer setup common to all dose

setups.

Parameter settings on an instrument can be

changed ONLY by using dB10 or dB12 to replace

the configuration file in the instrument by another

configuration file loaded from the PC.

Page 6 - CEL-320/360 Getting Started