Tell Manufacturing | A Division of Spectrum Brands Inc. 32

CODE CHANGE INSTRUCTIONS

The CL600 range offers signicant advantages over other similar mechanical digital locks by

allowing the code to be changed in seconds on the door.

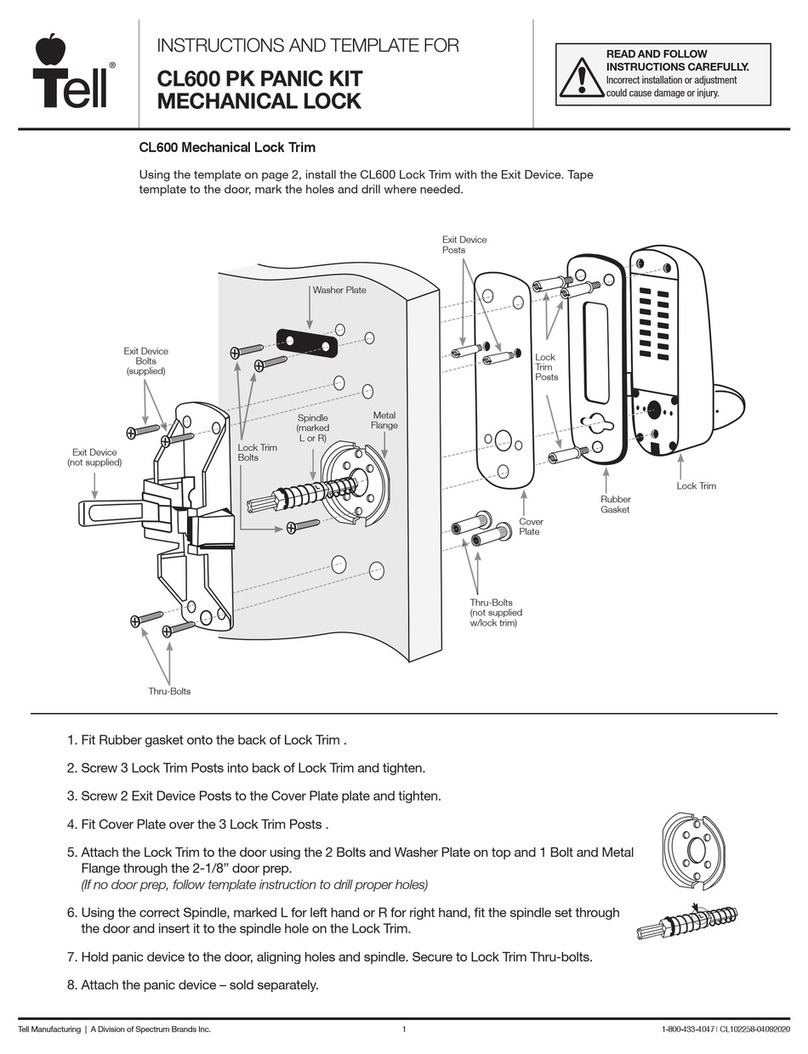

1. Choose your code.

2. Insert key and turn anticlockwise to stop for right hand hung doors, or clockwise to stop for left hand

hung doors. Fig 1.

3. Push the code change tool onto each button in turn, pushing in the buttons approx 3/32” (2mm) turn

anticlockwise 180°. All buttons should now be in the non code position.

4. Test that all buttons are in non code position (perform step 6 before testing buttons) then depress the

lever handle which should retract the latch. If latch cannot be retracted press ‘C’ button and repeat

step 3.

5. To select a button as a code button, push code tool over button. Press in button with tool approx 3/32”

(2mm) and turn clockwise 180°. Fig 2.

6. Now turn the key clockwise for right hand hung doors, or anticlockwise for left hand hung doors

retracting the latch which will re-lock the code buttons. Fig 3.

7. Return the key to center and remove.

8. Before closing door test code.

Note: Models 605, 615, 625 only – Before changing code press the ‘Z’ and ‘C’ button to ensure that the

lock is not in free passage mode.

1. Remove handle and cylinder cover.

2. Turn Key 90° anticlockwise and remove the

cylinder from boss

3. To replace cylinder, reinsert and turn 90°

clockwise. Replace the cylinder cover and

handle.

*If intending to use a cylinder from a different

manufacturer it is advisable to conrm

beforehand that the new cylinder will t the

boss.

Note that the CL600 uses a 6 pin screw cap

cylinder.

If using a screw cap cylinder other than

supplied, the tail piece from the Codelocks

screw cap cylinder will need to be tted as

follows:

4. Hold down the control pin in the end of the

cylinder and unscrew the cap.

Caution! Do not insert the key in the cylinder

once you have removed the screw cap!

5. Ret the tailpiece, hold down the control pin and

screw the cap on fully without tightening. Ensure

the control pin projects to lock the cap.

Test the key operation

If the key is difcult to insert, or tight when turning,

then the cap may be too tight. Loosen the cap one

notch at a time and try the key again. If the key

inserts and turns OK, but is difcult to remove, then

the cap may be too loose.

Tighten up the cap one notch at a time.

Adjust the cap until the key inserts, turns and

removes easily.

REMOVAL OF FRONT LOAD CYLINDERS TO RE-PIN OR REPLACE WITH CYLINDERS.