Tellabs 263DC User manual

7te11abs

technical manual

76-81263DC

rev A

practice section 81263DC-1

/81263DC-2/81263DC-3

©Tellabs, Inc., 1May

1984

all rights reserved, printed in USA

263DC

Data Station Termination Systems

-

figure

1.

2630C-1

OST

Sysfem

page 1

page 2

page 5

page

10

page

12

page

11

page

13

contents

section 1general description

section 2application

section 3installation

section 4

circuit

description

section 5

block

diagram

section 6specifications

section

7testing

and

troubleshooting

1.

general

description

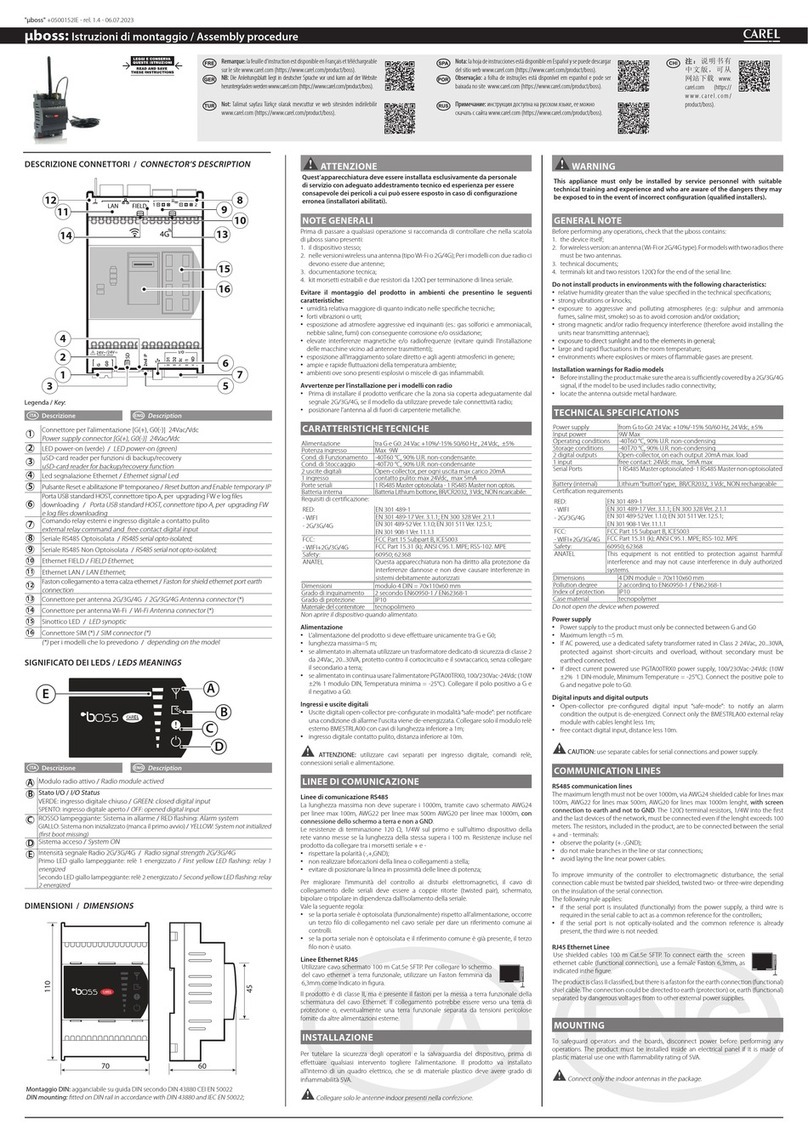

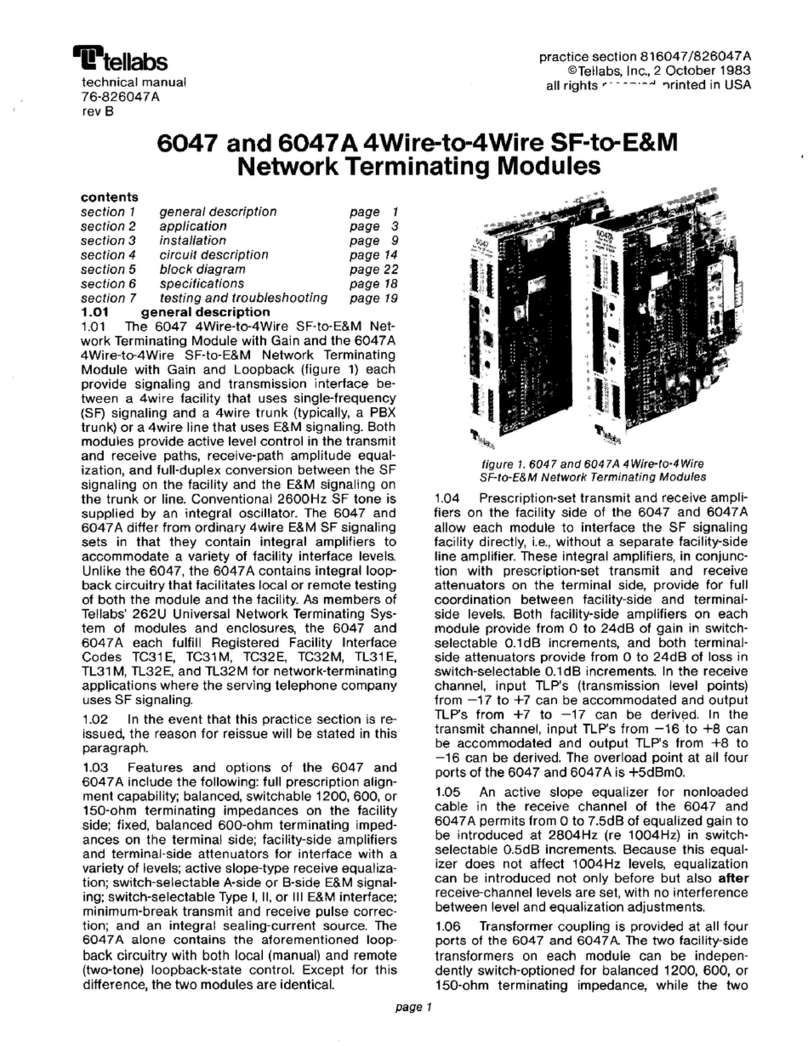

1.01 The Tellabs 263DC-1 (figure

1),

263DC-2,

and 263DC-3 Data Station Termination (DS1)

Systems interface

either

a2wire

or

a4wire data

set

with

a4wire transmission facility. All three

systems

are

compact, self-contained units that

provide data interface and

power

rectification/

regulation circuitry in an attractive enclosure that

can be wall mounted

or

placed on adesktop.

Power

for

these systems can be provided from

battery feed

or

sealing current derived from

the

units' simplex leads,

or

from an external source of

either

nominal 26Vac

or

-22

to

-56Vdc.

All three

systems feature prescription gain and loss in

the

receive channel, prescription loss in

the

transmit

the

263DC-2 and 263DC-3,

this

is in addition

to

channel, and manual

or

two-tone

loopback

In

any provided by

the

receive equalizer) for long

addition, both

the

263DC-2 and 263DC-3 provide sections of nonloaded cable. The facility-side trans-

prescription active equalization in

the

receive formers can also be optioned

to

derive normal

channel. All

three

units also include a20mA simplex leads,

to

provide an internal source of

sealing current source

to

provide sealing current sealing current

to

the

facility,

or

to

provide areturn

for

the

4wire

facility. path for sealing current applied at

the

far

end

of

Note:

Throughout the rest

of

this practice, the term

the

facility. (The

263DC

must be powered from an

2630C

refers to

all

three OST systems unless external source when

the

sealing-current source

otherwise

indicated. option is selected.)

1.02

In

the

event that this practice section is re- 1.05 On

the

station side,

the

263DC

can be

issued,

the

reason for reissue will be stated in this optioned

to

interface either a2wire

or

a4wire

paragraph. modem. In

either

mode,

the

station-side port(s) pro-

1.03 The

263DC

provides from

-24

to

+24dB

of vides capacitively-coupled, balanced, 600-ohm

gain in

the

receive channel and from 0

to

24dB

of terminating impedance.

loss in

the

transmit channel. Transmission levels in 1.06 The

263DC

provides loopback of

the

facility

both channels are prescription-set in 0.1dB incre- for testing and troubleshooting. The loopback func-

ments via DIP switches. The maximum input and tion can be activated either remotely by transmis-

output

level of each channel is

+5dBm.

While

the

sion of a2713Hz tone

or

locally via alocal loop-

263DC-1 provides no amplitude equalization,

the

back lead. When activated remotely,

the

263DC

263DC-2 and 263DC-3 both contain active pre- can be optioned

to

restore normal operation upon

scription equalizers in

their

receive paths. The receipt of asecond loopback

tone

or

automatically

263DC-2's equalizer is slope-type, providing up

to

at

the

end of a20-minute timeout period (receipt of

7.5dB of gain at

2804Hz

(re 1004Hz) in switch- asecond tone before

the

expiration

of

this

timeout

selectable 0.5dB increments. The 263DC-3's equal- period will also restore normal operation). The

izer is aslope/bump-type equivalent to the Western

263DC

system provides equal-level loopback with

Electric modei 309B. switch-selectable gain of 8

or

16dB in

the

loop-

1.04 Transformers· at both facility-side ports back path.

(receive

output

and transmit input) can be switch 1.07

Other

standard features

of

the

263DC

optioned

for

balanced 1200-, 600-,

or

150-ohm System include two 310-type

test

jacks and five

terminating impedance. The 150-ohm option pro- status-Indicating LEDs. The

test

jacks are opening-

vides approximately

2dB

of slope equalization (for type and face

the

DST system at

the

receive output

page

1

practice section 81263DC-1/81263DC-2/81263DC-3

and

transmit input

ports.

Four

of

the

LEDs

are

visible with

the

unit's cover in place. Ayellow

power

on LED lights when

power

is applied

to

the

unit. A

red loopback LED lights when

the

loopback cir-

cuitry

is activated. Two

other

yellow LEOs are

labeled data in and data out; these LEOs light

when data is present in

the

receive and transmit

channels, respectively. Afourth yellow LED located

on

the

unit's printed circuit board lights when

the

internal sealing current source

is

active and seal-

ing current is flowing.

One

optional feature is avail-

able on

the

263DC: apair of gas-tube lightning

protectors for

the

facility-side ports (Tellabs part

number

2630

L2).

1.08 The

263DC

can be powered remotely

(facility-powered) by sealing current

or

battery feed

applied at

the

far end

of

the

facility,

or

can be

powered locally by an external source

of

either

nominal 26Vac

or

-22

to

-56Vdc.

When facility-

powered,

the

263DC

derives its operating voltage

from

the

facility via its simplex leads. The

263DC

requires nominal 20mA sealing current

or

56Vdc

maximum battery feed

for

facility powered opera-

tion. The 263DC's internal sealing current source

cannot be used when the system

is

facility-powered.

When powered from an external source,

the

263DC

requires 18

to

28Vac

or

-22

to

-56Vdc

input. The nominal 26Vac can be supplied from a

commercial 120Vac, 60Hz outlet through use of a

Tellabs

8015

Transformer, which can be ordered at

the

same

time

as

the

263DC. The

263DC

con-

sumes amaximum of

30mA

of current under

normal operating conditions.

1.09 The 263DC is aself-contained DST system

housed in aplastic enclosure with aremovable

cover. Designed primarily for wall mounting,

the

263DC

is also equipped with rubber feet for desk-

top

placement. Ahole in

the

bottom

of

the

cover

(when wall mounted) allows access

to

the

unit for

external connections. Connections

to

the

facility

and

power

source are made at a17-position screw-

terminal strip. Connections

to

the

data

station are

made

to

the

terminal strip

or

to

amodular phone

jack

(similar

to

USOC RJ11C).

1.10 The 263DC can be equipped with

two

optional gas-tube lightning protectors for

the

facility-side ports (Tellabs part

number

2630

L2).

When

the

gas tubes are used,

the

PROT GND pin

on

TB1

must be

connected

to

earth ground for

proper protection from lightning strikes.

2.

application

2.01 The

263DC

DST System is used in applica-

tions

where

adata station communicates with

other

data stations

or

acentral processor unit

(CPU)

over

voice-grade

telephone

facilities. The

unit provides

the

necessary level coordination and

impedance matching

to

interface

the

modem

portion of

either

a4wire

or

2wire data

set

with a

4wire facility. If

the

data station is provided by the

customer,

the

263DC

acts as an interconnect

device,

providing end-termination

of

the

telco

facility.

Loopback

circuitry on

the

263DC

allows

either local (ground) activation

or

remote (two-tone)

activation of facility loopback, with switch-selectable

loopback-path gain of 8

or

16dB. The 263DC-2 and

263DC-3 versions of

the

system provide receive-

channel equalization. All

three

versions can supply

sealing current

to

the

facility.

2.02 Level coordination between

the

station and

the

facility is provided

independently

in each

channel of

the

263DC.

The

receive channel pro-

vides up

to

24dB of prescription gain

or

loss in

0.1dB increments, and

the

transmit channel pro-

vides up

to

24dB

of prescription loss, also in

0.1

dB

increments. The output levels

of

the

two

channels

are controlled by

the

transmit level and receive

level DIP switches (S13 and S19, respectively).

Adjacent

to

each DIP switch position is

the

value,

in

dB, of that switch position. These values are

cumulative;

the

total

amount

of gain

or

loss intro-

duced

into achannel is

the

sum of

that

channel's

DIP-switch positions set

to

in.

The maximum

input

and output level of both channels is

+5dBm.

These

level ranges allow

the

DST system

to

easily accom-

modate

the

-3

receive TLP (transmission level

point) and

+13

transmit TLP (assuming a

-13dBm

OTLP)

required by most modems.

2.03 Adata in and adata

out

LED on

the

cover

of

the

system light when data is present in

the

receive and transmit channels, respectively. The

level

detectors

that

drive

the

LEOs respond

to

data

levels

greater

than

-25dBm.

2.04 Both

the

263DC-2 and 263DC-3 provide

active prescription post-equalization of

the

facility

in

their

receive channels. The 263DC-2 uses a

slope-type amplitude equalizer

to

provide up

to

7.5dB

of

equalized gain at

2804Hz

(re 1004Hz) in

discrete 0.5dB increments. The frequency response

of

the

263DC-2's receive equalizer is

shown

graph-

ically in figure 2and in tabular form in

table

1.

The

263DC-3's equalizer is functionally equivalent

to

the

Western Electric model

309B

Prescription

Equalizer.

In

addition

to

providing slope-type

amplitude equalization,

the

263DC-3

provides

bump-type equalization with variable height and

bandwidth settings. Figures 3and 4

show

the

typical response curves for

the

263DC-3's equalizer

in

the

slope mode; figure 3shows

the

curves

for

loaded cable and figure 4shows the curves for non-

loaded cable. Table 2gives

the

1004Hz

reference

levels for figures 3and 4

for

various settings of

the

slope switch. Figures 5and 6

show

the

typical

response curves

for

the

263DC-3's equalizer in

the

bump mode; figure 5shows

the

curves represent-

ing various height settings versus awide bandwidth

setting and figure 6shows

the

curves represent-

ing various height settings versus anarrow band-

width setting. Table 3gives

the

1004Hz

reference

levels for figures 5and

6.

The equalization functions

of both

the

263DC-2 and 263DC-3 are controlled

by

DIP switches.

page 2

practice section

81263DC-1/81263DC-2/81263DC-3

7

:>dH

MAXIMUM

4KHZ

4KHZ

3KHZ

2KHZ

1KHZ

-2

table

2.

Equalized gam (m dB)

at

1004Hz

lor

263DC-3 equalizer in

slope

mode

-2

FREQUENCV

fjgure

6.

Typical response curves

for

263DC-3

receive-channel

equaiizer

in

bump

mode,

BW

switch

=3

HTSETTINGS

10

,.

6

8

..

C

z•

;;:

C>

2

00

10

HTSElTlNGS

8

,.

12

6

10

..

8

C

z•

"6

C>

2•

2

00

figure

5.

Typical response curves

for

263DC-3

receive-channel

equalizer

in

bump

mode,

BW

switch

=14

slope

loaded/nonloaded

switch

switch setting

setting

NL

L

a

0.0 0.0

(slope

disabled)

10.4 1.4

20.9 2.6

31.4 3.7

41.8 4.7

52.3 5.5

62.8 6.3

73.4 7.2

83.7

7.8

94.2

8.4

10

4.6 9.0

11

5.0 9.5

12

5.4

10.0

13

5.8 10.5

14

6.2

11.0

15

6.6 11.4

o

~d8

MINIMUM

0',

;0

,;

00

"

30

O~,HJ

2S

INCHlMlNTS

"

2804H, 3kHz

FRFOUFNCY

FREQUENCY

table

1.

TYPIcal

receIve-channel slope

equalization for 263DC-2

JOOlil

figure

2.

Typical response curves for 263DC-2

receive-channel

equalizer

'004

HI

o

C>

-2

Z

~2

'::,.

-3

~6

~15

figure

3.

Typical response curves for 263DC-3

receive-channel

equalizer

in slope mode,

loaded

cable

figure 4. Typical response curves

for

263DC-3

receive-channel equalizer in stope mode, nonloaded cable

..

C

Z-1

~

.,

~

1--+''-------1

receive

equalizer equalized gain (in dB)

introduced

at va,ious frequencies

,witch

setting (dB

300Hz

400Hz

500Hz

800Hz

1004Hz

1500Hz

1800Hz

2500Hz 2804Hz

0

00 00

00

00

0.0

00

0.0

00

0.0

0;

-

0.23

-0,19

-

0.15

-0,06

00

+0.1~

'0.24

+043

+0.50

,

.0

-0,~2

042

-0,33

0.13

00

+0.32

-.-0,52

+0.93 +1,07

,

.5

0.75

-0,60

0,49

-0,18

00

+0.46

-+0.74

+1.33 +1.54

"

-100

-0.80

-0.64

-0,24

0.0 +0.61 +0,98

-+1.76

-.-2,04

'.5

-1,22

0.98

-0.78

0.29 0.0 +0,75 +1,20 12.15 +2,49

3.0

-1.50

-1.20 -0.95

-0,36

00

+0,90

'1.45 +2,60 +3.01

35

1.71

-1,37

-1.09

-0,41

00

+1.03 -.-1.65 +2,97 +3,45

'.0

2.02

-1.63

-1.29

-0,49

0.0 -+1.22 +1,95 +3.54 +4.12

"

-2,25

1.79

-142

-

0.53

0.0 +1.33 +2.14

13.90

+4.56

50

-249

-1,98

-1.57

-0,59

00

-'-1,47

t2.36

+4,32 -+5.08

5.5

-268

-2.14 -

1,69

-0.63

0.0

,1.58

+2,53

'4.67

+5,51

6.0

-2.89

-2.30

-181

-0.68

0.0 +1.69 -+2.72 +5.05 +5,99

65

3.07

-2.44

1.93

-0.72

00

+1.79

1287

+5.38

1641

"

-3.29

2.61

-2.05 -0.76

00

1189

+3.05 +5.76 +6.90

75

-3.45

-2.74

-2,15

-0,78

0.0 +1.98

+319

+6.06 -.-730

"

•12

10

8

6

•SLOPE

2

SETTINGS

2

•

0

Z0

"

~

-2

page 3

practice

section

81263DC-1/81263DC-2/81263DC-3

HT

switch

BW

switch

setting**

setting*

6 7 8 9

10

11

12 13 14 15

2

0.0

0.0

0.0 0.0

0.0 0.0 0.0

0.1 0.1

0.2

3

0.0 0.0 0.0 0.0

0.0

0.0

0.1 0.1 0.1

0.3

4

0.0 0.0 0.0 0.0 0.0

0.1 0.1 0.1

0.2

0.4

5

0.0 0.0 0.0

0.1

0.1 0.1 0.1

0.2 0.3 0.5

6

0.0

0.0

0.1 0.1

0.1 0.1

0.2

0.2

0.4

0.7

7

0.0

0.1

0.1 0.1

0.1

0.2 0.2

0.3 0.5 0.9

8

0.0

0.1

0.1 0.1

0.2 0.2

0.3

0.4

0.7

1.2

9

0.0

0.1

0.1

0.2 0.2

0.3 0.4 0.5 0.8

1.5

10

0.0

0.1

0.2

0.2 0.2

0.3 0.4 0.6

1.0

1.7

11

0.1

0.1

0.2

0.2

0.3 0.4 0.5 0.7

1.2

2.0

12

0.1

0.1

0.2

03

0.3 0.4 0.6 0.9

1.4

2.4

13

0.1

0.2

0.3 0.3 0.4 0.6 0.8

1.1

1.7

2.8

14

0.1

0.2

0.3 0.4 0.5

0.7

0.9

1.3

2.0

3.3

15

0.2

0.3

0.4

0.5

0.7

0.9

1.2

1.7

2.5

3.9

*HT

switch position adisables

bump

function.

HT

switch position 1introduces

0.1dB

of gain or less

at

1

kHz.

**BW switch positions athrough 5introduce

0.1dB

of

gain

or

less

at

1kHz

for

all

HT

seltings.

table

3.

Equalized gain at 1004Hz for

263DC-3

equalizer

in

bump mode

2.05 The transformers

at

the

facility-side ports

of

permitting

the

maintenance

responsibility involved

the

263DC

can be switch-optioned

for

1200-ohm in a

particular

case

of

trouble

to

be determined.

terminating

impedance to

interface

loaded cable, 2.09 The

263DC's

loopback

circuitry

can be

for

600

ohms

to

interface

nonloaded cable

or

car- activated either remotely by transmission

of

nominal

rier,

or

for

150

ohms

to

provide approximately

2dB

2713Hz

loopback

tone

from

the

far

end

of

the

facil-

of

equalization (in addition

to

any provided by

the

ity

or

locally by

grounding

the

system's loop

back

263DC-2's

or

263DC-3's receive equalizer)

for

long lead.

Loopback

will

not

occur

accidentally

because

sections

of

nonloaded cable

through

the

deliberate

of

power

failure. When loop

back

is activated,

the

impedance mismatch. Both facility-side transformers loop

back

(LB) relay operates,

disconnecting

the

on the 263DC are center-tapped

to

derive balanced station from the data circuit and looping the receive

simplex leads. path

back

to

the

transmit path. Additional

contacts

2.06 The station-side

ports

of

the

263DC

can be

of

the

LB

relay electrically

disable

the

data

station

optioned

to

interlace

either

4wire

or

2wire data via

the

263DC's

TEK5 and TEK6 leads. The foop-

sets. In

the

2wire mode, an

electronic

hybrid pro-

back

LED on

the

system's

cover

lights

to

indicate

vides

the

necessary

4wire

to

2wire

conversion.

that

loopback

is activated.

Both

the

2wire

and

4wire

ports

provide fixed, 2.10 Remote

loopback

is

accomplished

by plac-

capacitively-coupled 600-ohm terminating imped- ing a

2713Hz

tone

on

the

receive pair

of

the

ances

toward

the

station.

263DC

for

at

least 1.6

seconds

and

then

removing

2.07 An option switch on

the

263DC

selects

the

tone. The

263DC

initiates

loopback

only

upon

either

internal sealing current, external sealing cur-

the

removal

of

the

tone. This prevents accidental

rent,

or

normal simplex leads. In

the

SOURCE looping

of

other

than

the

intended

loopback

point

position,

the

center-tapped leads

of

the

facility-side on amultipoint circuil. The

threshold

of

the

loop-

transformers are

connected

to

anominal

20mA

back-tone-detection

circuit

is

-30dBm

as meas-

integral sealing

current

source. In

the

SINK

posi- ured

at

the

receive input porI. The

loopback

tone

tion,

these

leads are

connected

together

to

pro-

detector's

center

frequency

is

2713Hz

±0.20/0

with

vide ade path

for

sealing

current

applied

at

the

far

amaximum bandwidth

of

75Hz. Asignal-to-guard

end

of

the

4wire

facility. The

SX

position provides ratio

of

6dB

prevents

either

raw data signals

or

normal simplex-lead derivation. An LED on the harmonics of

those

signals from initiating loopback,

263DC's

printed circuit board lights

when

the

thus allowing

the

263DC

to

operate

in

circuits

internal sealing-current source

is

active and cur-

where

similar units

might

be

prone

to

false

rent is flowing. loopback. Aswitch option allows remote

loopback

2.08 The

263DC

DST System can serve as a

to

be

deactivated

by asecond

2713Hz

loopback

testing and

troubleshooting

device

through its

tone

of

O.7-second duration

or

longer

(removal

of

ability

to

isolate

the

facility from

the

station via

the

tone

is not necessary

to

deactivate

loopback),

loopback. The loopback feature allows

the

voice-

or

automatically

after

a

20-minute

timeout

period.

frequency

characteristics

of

the

facility

to

be tested

2.11

Local

loopback

is initiated by placing a

from aremote location

(e.g.,

the

serving

CO).

Loop-

ground

on

the

local loop

back

lead (LOC

LB

back

also allows

the

source

of

trouble

to

be local- terminal

of

TBI).

Loopback

is maintained until

the

ized

to

either

the

facility

or

the

data station, thus

ground

is removed.

page

4

practice section

81263DC-l/81263DC-2/81263DC-3

clears

the

unit's chassis. The cover is replaced by

reversing this procedure.

mounting

3.03 The 263DC

is

wall mounted via three screws

(not supplied) inserted

through

holes

in

the

base

plate

of

the

unit. A

template

for

positioning

the

screws is proVided

at

the

end

of

this practice. Four

rubber feet are supplied

for

desktop

placement.

installer

connections

3.04 Before making any

connections

to

the

263DC, ensure that

power

is

not

applied

to

the

unit.

Power

should be

connected

to

the

unit

only

after

all

other

installer

connections

are made and

after

the

unit is properly optioned.

3.05

Make

all

telco

connections

(facility-side

ports and simplex leads)

to

the

263DC at 17-position

terminal block TBI. The modem connections (station-

side

ports

and

data disable leads), however, can be

made

at

TB

I

or

via

the

modular

phone

jack

(similar

to

USOC

RJllC),

J3, supplied with

the

unit. Access

to both

TB

Iand

J3

is through

the

bottom

of

the

unit. Connections to

the

263DC are listed in table

4.

Note:

When the 263DC is

equipped

with the

optional

gas-tube lightning protectors, the PROT

GND terminal on TB1

should

be

connected

to a

separate earth

ground

to provide maximum light-

ning

protection.

connect:

toTBl

pin:

facility:

XMTOUTTIP

............

...........

..

.............

IT

XMT

OUT

RING.

........

,-

...

TR

RCV

IN

TIP

....

-

..........................

.....

....

RT

RCVINRING

..............................

........

RR

simplex leads:

SX

TRANSM

IT

..........

.. ..

....................

..SXT

SX

RECEiVE

......

.

.................

~R

data station:

XMT

IN

TIP/2WIRE

TIP

...............

DIT/2WIRE

TIP

(or

J3

pin

4)

XMT

IN

RING/2WIRE

RING

........

DTR/2WIRE

RING

(or

J3

pin

3)

RCV

OUT

TiP

........................

DRT

(or

J3

pin

2)

RCVOUTRING

.....................

ORR

(or

J3

pin

5)

DATA

SET

DISABLE

................

TEK5

(or

J3

pin

1)

DATA

SET

DISABLE

................

TEK6

(or

J3

pin

6)

power:

AC

OR

DC

INPUT

......

.......

.

....................

AC

INPUT

GROUND

..........

..................

CKTGND

EARTH

GROUND

.............

....

.......

PROTGND

(only when optional

gas

tube

lightning

protectors

are used)

loopback:

local loopback

......

.

......................

LOC

LB

3.

installation

inspection

3.01 The 263DC Data Station Termination System

should

be

visually

inspected

upon arrival

to

find

any

damage

incurred

during

shipment.

If

damage

is

noted, aclaim should immediately be filed with

the

carrier. If stored,

the

unit should be visually inspected table

4.

External

connections

to

263DC

again

prior

to

installation. 3.06

To

power

the

263DC

from alocal external

cover

removal

source

of

either

nominal 26Vac

or

-22

to

-56Vdc,

3.02

To

instali

the

263DC

System, its protective make

power

connections

to

the

AC

terminals of

plastic

cover

must be removed. The cover is held in

TB

I(polarity need

not

be

considered

in

either

place by a

single

captive

screw

in

the

bottom

of

the

case). If

the

Tellabs

8015

Transformer is used

to

unit. To remove

the

cover, loosen

the

screw and supply

the

required

ac

voltage,

connect

terminals I

swing

the

bottom

of

the

cover

up

and

out

until it and 3

of

the

8015

to

the

AC

terminals

of

TBI, and

page

5

2.12 Equal-level

loopback

is provided by an

amplifier

in

the

263DC's

loopback

path. This ampli-

fier can be switch-optioned

to

insert

either

8

or

16dB

of

gain

between

the

receive

channel

and

the

transmit

channel

when

the

loop

back circuitry is

activated. Thus, in adata circuit with

either

an 8

or

16dB

difference

between

the

receive and transmit

TLPs, a

test

signal transmitted from

the

far

end

of

the

facility

at

the

normal data transmission level will

be returned

at

the

normal receive level. In data cir-

cuits

with

aTLP differential

other

than

8

or

16dB,

the

gain inserted

into

the

loopback

path must be

considered

when

making transmission level tests.

(Please

note

that

this problem can be avoided by

setting

the

amplifier

for

8dB

and inserting an addi-

tional

8dB

of

attenuation

into

the

transmit channel

via

the

xmt

level

switches

while

testing is in

progress.)

2.1

3The

263DC

can be powered locally from

an

external

source

of

either

nominal 26Vac

or

-22

to

-56Vdc,

or

it can be

powered

remotely from de

applied at

the

far

end

of

the

facility and derived

from

the

facility by

the

263DC's

simplex leads. The

power source is selected by aswitch option that con-

nects

the

input

of

the

263DC's

power

rectification/

regulation circuitry

to

the

AC

terminals

of

TB

I

or

to

the

simplex

leads. When

powered

externally,

the

263DC

requires 18

to

26Vac input

at

7.5VA

or

-22

to

-56Vdc

input at 15mA minimum. The required ac

input can be supplied from acommercial 120Vac,

60Hz

grounded

outlet

by using aTellabs

8015

Transformer (ordered separately). When powered

remotely,

Le.,

facility-powered,

the

263DC

requires

aminimum

of

20mA

dc, which can be supplied by a

regulated sealing-current source

or

by

direct

bat-

tery

feed

to

the

4wire

loop.

To

ensure

proper

opera-

tion

of

the

263DC

when

it is facility-powered,

the

ioop

length

between

the

263DC

and

the

power

source

should

not

exceed

1000

ohms

for

sealing

current

or

2000

ohms

for

battery

feed. Also, when

powered

by

battery

feed,

the

voltage across

the

263DC's

simplex

leads must

not

exceed

56Vdc. Both

facility-powering

schemes

are

shown

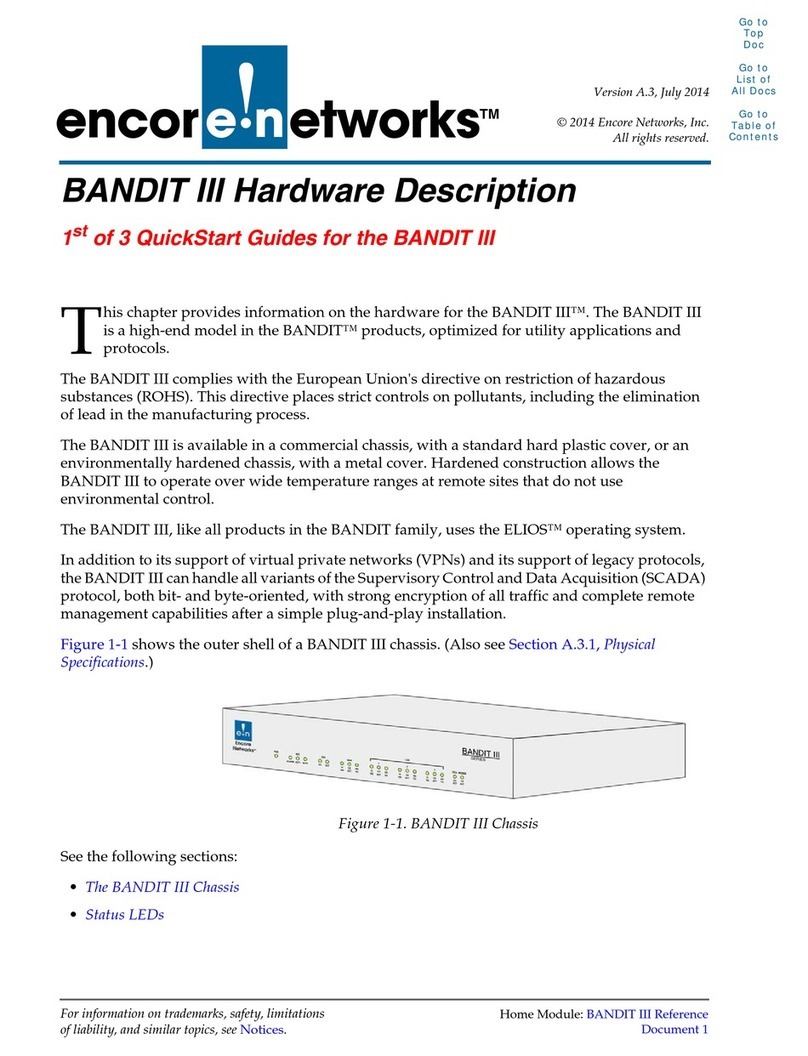

in figure

7.

Note:

The 263DC's

integral

sealing

current

source

can be

used

only

when the

263DC

is

powered

externally.

practice section

81263DC-l/81263DC-2/81263DC-3

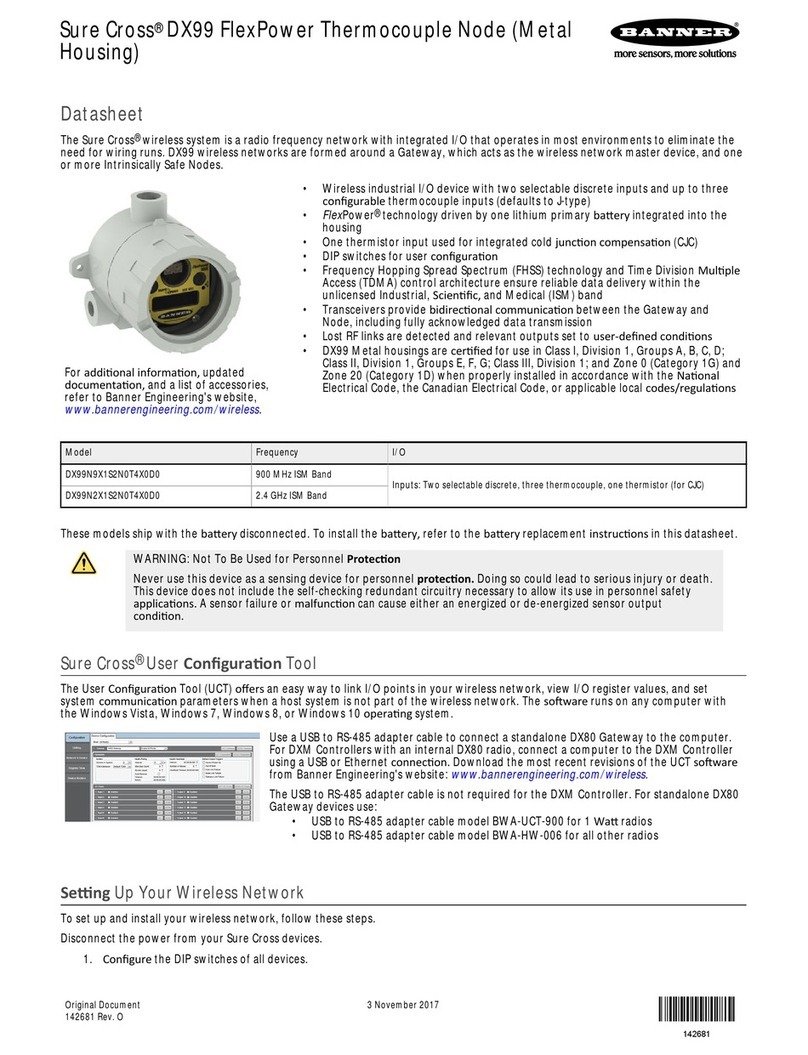

4WIRE

FACILITY

FAR-END

DST 263DC

((

RT [>

~

RCV

~

~

RCV

II

IN {

OU,

JJ

RR

FAC

NOMINAL

8AC

~

_-v

20mA POWER

EXT

PWR

*S17

RECTIFICATION/

MODEM

de

SEALING

CURRENT

AC C

REGULATION

"l

SOURCE

PWR

-

II

TT

-

~

XMT

{

<J

~

XMT

II

OUT

{

IN

JJ

TR

263DC/DC-2 line-powered

by

sealing current

4WIRE

FACILITY

FAR-END

DST 263DC

"RT

[>

~

"RCV {

~

RCV

."IN {

OUT

"

RR

FAC

MAXIMUM

...L

~

_-V

±56Vdc AC POWER

BATTERY

-EXTPWR*S17

RECTIFICATION/

MODEM

FEED AC C

REGULATION

""l

-BATT

PWR

-

II

-

TT

<J

~

XMT

oj

~

XMT

II

OUT

~

IN

"TR

263DC/DC-2

tine-powered by battery

feed

*517

mustbe

settothe

FAC

PWR position

for

facility

powering

of

the

263DC.

517

must be set to

the

EXT PWR position to

supply sealing current to the facility.

figure

7.

263DC

remote powering schemes

then plug

the

8015 into a

grounded

120Vac, 60Hz

outlet. When

the

263DC

is

facility-powered, con-

nect

aregulated source of 20mA sealing current

or

nominal 48Vdc battery across

the

facility at

the

far

end as shown in figure 7_Option switch S17 must

be set

to

the

proper

position

for

either

external

power

or

facility power; see paragraph 3.12. As

stated above, power

connections

to

the

263DC

should be made only

after

all

other

connections

are made and

after

the

unit

is

properly optioned.

optioning

3.07 Optioning

the

263DC

consists of selecting

the

facility-side impedance,

the

2wire

or

4wire data

set interface,

the

loopback path gain,

the

tone-

loopback

release option,

the

power

option, and

selecting external

or

internal sealing current

or

normal simplex-lead derivation. The locations of

the

option switches are shown in figure

8.

Table 5con-

tains a

brief

explanation of

the

functions and set-

tings of each option switch plus aconvenient

optioning checklist. The checklist can be filled

out

(by checking

the

appropriate box for each switch)

either

prior

to

installation

to

allow

for

prescription

optioning of the unit or as the unit is being optioned

to

provide arecord for

future

reference. Detailed

instructions

for

optioning

the

263DC

are provided

in

the

following paragraphs.

3.08 Switch

SII

selects balanced 1200-, 600-,

or 150-ohm impedance at

the

facility-side ports

(receive input and transmit output). Set S

11

to

the

1200, 600, or 150 position as required. Generally,

the

1200-ohm option is used

for

loaded cable,

the

600-ohm option is used

for

nonloaded cable

or

car-

rier, and

the

150-ohm option is used

to

provide a

small amount of slope equalization for long sections

of nonloaded cable through a

deliberate

imped-

ance mismatch.

3.09 Switch S14 selects

the

desired data-station

interface,

either

2wire

or

4wire.

Set

S14

to

the

2W

position

to

interface a2wire modem

or

to

the

4W

position

to

interface a4wire modem.

3.10 Position 1of switch S15

selects

the

amount

of gain inserted between

the

receive channel and

page

6

practice section

81263DC-1/81263DC-2/81263DC-3

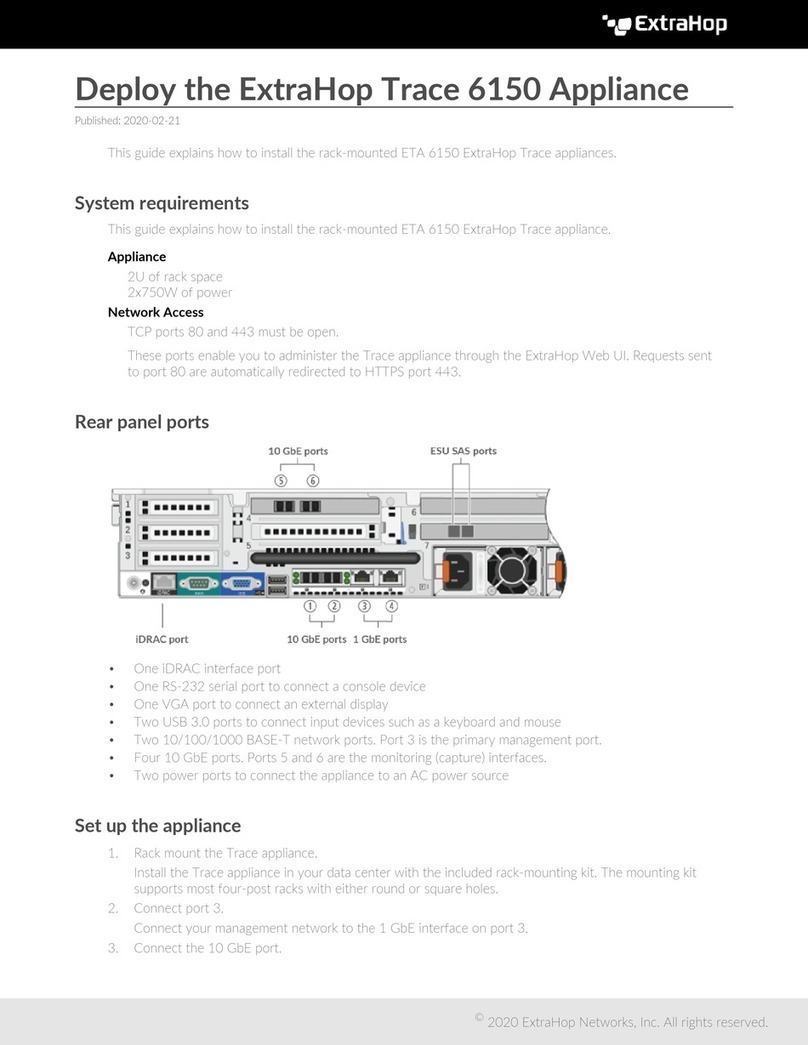

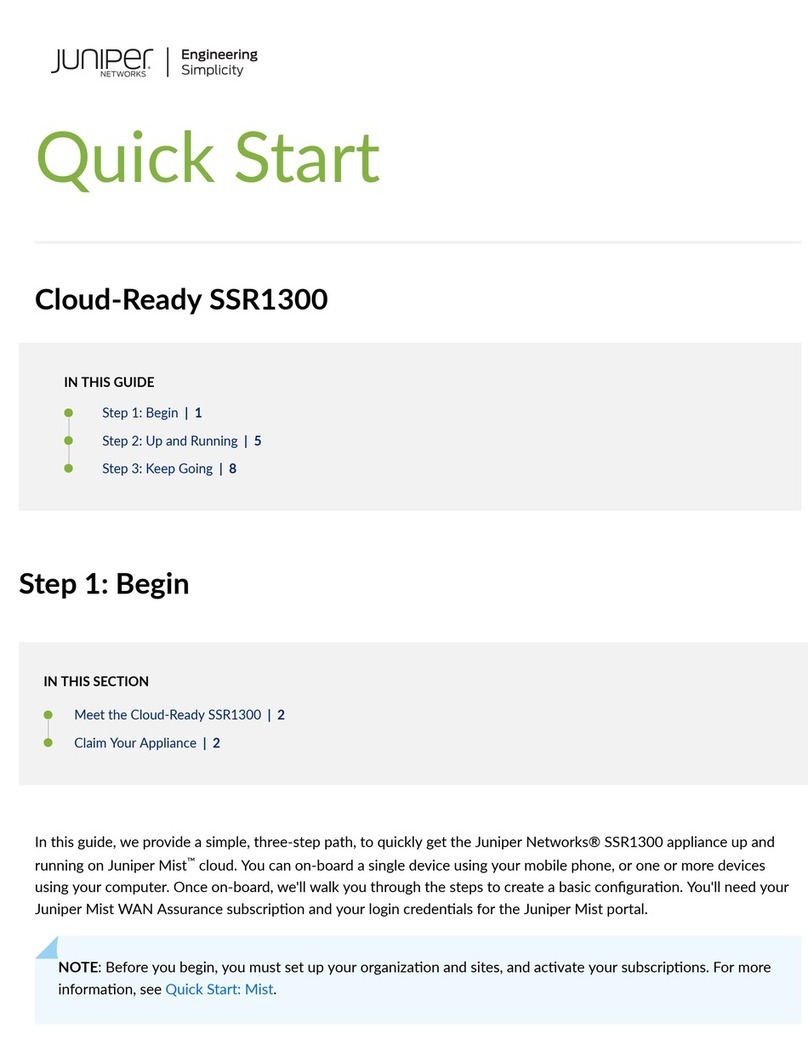

figure

8.

263DC

option

sWItch locatIOns

table

5.

263DC

option

summary

and

checklist

the

transmit channel when

the

unit is in loopback

(see paragraph 2.12).

To

insert

8dB

01

gain into

the

loopback path, set S15-1

to

the

8position.

To

insert

16dB of gain into

the

loopback path, set

S15-1

to

the

16

position.

check-

function switch selections settings list

facility-side

S11

150

ohms

150

port

impedances

(rev

out

and

600

ohms

600

xmt

in)

1200

ohms

1200

data-station

S14

2wire

2W

interface

4wire

4W

loop

back-path

S15-1

adS

gain 6

gain

16dB

gain

16

tone

loopback

S15-3

normal

(two

OFF

release

tone)

timeout

TO

(20 minutes)

tone

loopback

S15-2

enabled

n

disable

disabled

OFF

facility

or

S17

facility FAC PWR

external

power

via

power

SX leads

external EXT PWR

power

sealing

current

S18

internal

SOURCE

sealing-

current

source

de

return

SINK

path

for

far-end

source

normal

SX

simplex

leads

3.11 Position 3of S

15

selects

the

tone-Ioopback

release option. For normal two-tone operation

(Ioopback released by second loopback

tone

only),

set S

15-3

to

the OFF position. For timeout operation

(Ioopback released automatically

after

20

minutes

unless asecond tone is received prior

to

that

time),

set S15-3

to

the

TO

(on) position. Position

201

S15

disables the tone loopback circuit. For normal opera-

tion (tone loopback enabled) set S15-2

to

the

IT

(on)

position.

11

tone loopback is not desired, setS15-2

to

the

OFF position.

In

either

case, loopback can

still be activated locally via

the

local ioopback lead.

3.12 Switch S17 selects

either

facility

power

or

external power.

To

power

the

263DC

from sealing

current

or

battery feed via

the

simplex leads, set

S17

to

the

FAC

PWR

position.

To

power

the

263DC

from an external source of nominal 26Vac

or

of

-22

to

-56Vdc,

set S17

to

the

EXT

PWR

position.

Note:

The

263DC

must

be

powered

from an

external source when the 20mA sealing current

source is used.

3.13 Switch

SIB

selects

the

desired sealing cur-

rent option.

To

supply 20mA

of

sealing current

to

the

facility from

the

263DC's internal current

source, set S18

to

the

SOURCE position.

To

pro-

vide areturn path for sealing current supplied from

the

far

end

of

the

facility, set S18

to

the

SINK posi-

tion. If normal simplex lead derivation is desired,

set

SIB

to

the

SX position.

Note:

The

263DC's integral sealing current source

can

only

be used when the 263DC is powered from

an external source.

alignment

3.14 Alignment

01

all

three

versions of

the

263DC

consists of setting

the

transmit and receive

transmission levels and, for

the

263DC-2 and

263DC-3 only, setting the receive-channel amplitude

equalization if required. After all

options

on

the

unit

are selected,

two

methods of

alignment

are avail-

able: prescription

or

direct measurement (non-

prescription). With

the

prescription method,

the

unit's alignment switches are set according

to

the

specifications on

the

circuit layout record

or

on a

computer

printout.

In

cases where

the

information

supplied by

the

CLR

or

printout is inadequate

or

unavailable, it is necessary

to

perform

the

non-

prescription alignment procedure. The procedure

for prescription alignment of

the

263DC's transmit

and receive transmission level is given in para-

graph 3.15;

the

non-prescription alignment pro-

cedure is given in paragraphs 3.19 and 3.20 (long

form) and in figure 9(condensed form). The pre-

scription and non-prescription alignment procedures

for

the

receive-channel equalizer on

the

263DC-2

are given in paragraphs 3.16 and 3.21, respectively.

The prescription alignment procedure

for

the

263DC-3's receive-channel equalizer is given in

paragraph 3.17; information on non-prescription

alignment

01

the

263DC-3's equalizer is provided in

paragraph 3.22.

Note:

To

place the 263DC into loopback for test-

ing,

either

transmit a2713Hz tone

burst

at

alevel

of

page 7

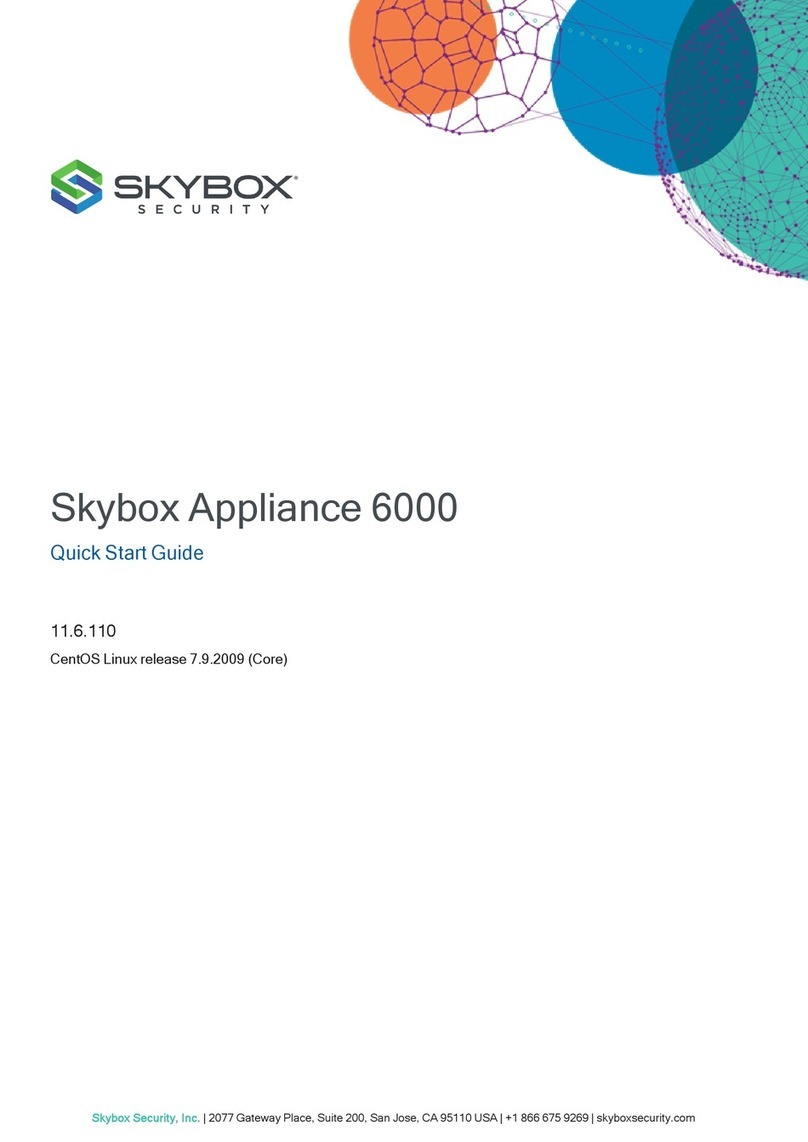

o

"~'"

.

OFF

TT

OFF

TO

o

LOOP

BO~

DATA

o

DATA

o

POWE~

o

practice section 81263DC-1

/81263DC-2/81263DC-3

515

16~8

OFF

TT

OFF

TO

1

Refer

to

the

CLR

and

determine

the

following:

facility

port

impedances, re-

Quired

receive

output

level,

and

transmit

input

level.

Ensure

that

811 (facility

port

impedance) is

set

correctly. Then pro-

ceed

to

step

2and

perform

the

alignment

procedures

in

numeric

order. The para·

graphs

referenced

in

the

procedure

headings

provide

a

more

detailed

ex-

planation

of

that

specific

procedure.

o

LOOP

BACK

o

DATA

IN

o

DATA

OUT

o

POWER

ON

o

GN~L5

.1 ~

.2

!!.

M

.4

~

@+~'I

~

12

B!

C6»~·.I-"

_IN

o

00

FAC

50:~~~

~

rjlt

150600

1200

~EXT

~

...

518

PWR

I~-

I

~

V1~t

::R

YQ

RR

10

CKT

V2~

~

~~D

Y

\y

SXT

®®

~~r.

4W

+- +-

<9

ORR

~OO

(Qj

(Q]

~

~~;

2W

RCV

OUT

I~~~

0TEK5

o

TEK6

~

0AC

oAC

J3_

~~~7,T

Receive

Level

(paragraph

3.19)

2

Arrange

the

receive

portion

of

the

TMS

for

600~ohm

terminated

measure-

ment

and

connect

it

to

the

RCVOUTjack

(XMT

IN/2W

jack

for

2wire

operation).

3

Have

the

far

end

transmit

1004Hz

test

tone

at

the

level

specified

on

the

CLR. Measure the received level.

4Ifthespecified receive level is higher

than themeasured level, set513-1 tothe

GNposition. If

the

specified level is

lower

than the measured level,

set

813·1

lathe

LS

position.

Then

set

the

rev

level

(813-2

through

813-9)

switches

in

the

proper

combination

to

achieve

the

specified

output

level.

Transmit

Level

(paragraph

3.20)

5

Arrange

the

transmit

portion

of

the

TMS

(terminated

at

600

ohms)

for

1004Hz

tone

output

at

the

CLR- speci-

fied

level,

and

connect

it

to

the

XMT

IN/

2Wjack.

6Have

the

far

end

measure

and re-

port

the

received

level. Then

set

the

xmt

level (819)

switches

in

the

proper

com·

bination

to

achieve

the

specified

level

at

the

far

end.

Receive

Equalization

(263DC·2

only;

see

paragraphs3.17

and

3.22

for

the

263DC-3)

(paragraph

3.21)

7

Connect

the

receive

portion

of

a

properlyterminatedTMS

tothe

RCVOUT

jack

(X

MT

I

N/2

WIRE

iack

for2wireopera-

tion). Have

the

far

end

send

1004Hz

and

2804Hz

test

tones

at

the

CLR-specified

level.

Measure

and

record

these

levels.

8

Subtract

the

2804Hz

level from

the

1004Hz

level.

9

Set

to

in

the

proper

combination

of

equalization

switches

on

the

equalizer

subassembly

that

most

closely

approx-

imates

the

amount

arrived

at

in

step

8.

figure 9.

Condensed

non-prescription

alignment

procedures

30dBm

or

higher

for

at

least 1.6-seconds

and

then switches to achieve the required levels. The specific

remove the tone (remote loopback),

or

apply

aamount

of

loss

or

gain (in dB)

introduced

by

each

ground to the local loopback lead.

To

restore normal DIP-switch position is indicated on

the

switch body

operation,

either

transmit a

second

tone burst for

at

adjacent

to

the

switch position. These switch posi-

least 0.7

second

or

remove the

ground

from the tions are cumulative;

the

total

amount

of flat loss

or

local

loopback

lead. gain introduced into achannel is

the

sum of that

prescription

transmit

and

receive

level

channel's DIP-switch positions set

to

in. Switch set-

adjustment

(263DC-1,

-2, -3) tings and achecklist for prescription level adjust-

3.15

To

adjust

the

transmit and receive levels on ment are provided in table

6.

the

263DC

via

the

prescription method, proceed as

263DC-2

prescription

receive

equalizer

tollows: From

the

CLR, determine

whether

gain

or

alignment

loss

is

required in

the

receive channel and set

the

3.16

To

adjust

the

receive equalization on

the

GN/L5

switch (513-1)

to

the

appropriate position 263DC-2 via

the

prescription method, proceed as

(L5

or

GN). Next, determine (from

the

CLR) the follows: From

the

CLR,

determine

the

amount

of

amount of loss

or

gain required in

the

receive chan- equalized gain required at

2804Hz

(re 1004Hz).

nel and

the

amount

of loss required in

the

transmit Equalization is introduced into

the

receive channel

channel. Then set to in

the

proper

combination of via

the

equalizer DIP switch on

the

equalizer sub-

transmit levei (519) and receive level (513) DIP assembly. The specific

amount

of equalized gain at

page

8

practice

section

81263DC-1

/81263DC-2/81263DC-3

table

8.

263DC-2

rounded

equalizer

SWitch

settings

263DC-3's receive equalizer consists

of

entering

the

pertinent

data into acomputer-controlled cir-

cuit design system

that

provides a

printout

specify-

ing

the

required equalizer switch settings. The

BW

and HT switches,

or

the

slope and loaded/nonloaded

switches

are then

set

as directed. The 263DC-3's

receive equalizer can also be aligned by determin-

ing

the

facility characteristics from

the

CLR and

then

setting

the

receive equalizer

switches

as indi-

cated in Tellabs practice

section

819908B

or

Bell

System Practice (BSP)

section

332-912-222. These

practices contain extensive listings of various facility

characteristics (including

combinations

thereof)

and

the

equalizer switch

settings

required

to

com-

pensate

for

these. The 263DC-3's equalizer switch

sellings

and achecklist

for

prescription equalizer

alignment

are given in

table

7.

post-alignment

testing

3.18

After

the

transmission levels and receive

equalization are set, it may be desirable

to

confirm

the

results via end-to-end tests.

Where

computer-

controlled

test

equipment

is used, a

subsequent

printout will verify

the

alignment results. Any devia-

tion from

the

required levels can

then

be adjusted

via

the

appropriate switches. If computer-controlled

test

equipment

is

not

available,

the

alignment

results can be confirmed

by

performing

the

mea-

surements

in

the

condensed

test

procedures

in

figure

9.

non-prescription

receive·

level

adjustment

(263DC-l,

-2, -3)

3.19

To

adjust

the

receive level

of

the

263DC

when prescription level

settings

are not given in

the

CLR

or

when

the

given

settings

do

not

produce

adequate

results, proceed as follows:

A.

Ensure

that

no

receive level DIP-switch posi-

tions are set

to

in. Also

ensure

that

the

facility-

side port impedance switch (SI1)

is

set correctly.

B.

Arrange

the

receive

portion

of

atransmission

measuring set (TMS)

for

600-ohm

terminated

measurement and

connect

it

to

the

ReV

OUT

jack

(XMT

IN/2Wfor

2wire

operation). Have

the

far end send 1004Hz test tone at

the

specified

level.

2804Hz

(re 1004Hz) introduced via each DIP-switch

position

is

indicated on

the

printed

circuit board

next

to

the

switch position. These switch positions

are cumulative;

the

total

amount

of

equalized gain

(0

to

7.5dB)

introduced

is

the

sum

of

those DIP-

switch

positions

that

are

set

to

in. The 263DC-2's

receive equalizer switch

settings

for

prescription

equalizer

alignment

and a

checklist

are given in

table

7.

Because

the

required

amount

of

equaliza-

tion

given in

the

CLR may be specified

to

the

nearest

0.1

dB

while

the

equalization switch is ar-

ranged in 0.5dB increments,

table

8gives

the

rounded switch sellings

fo

the equalizer's full range.

function

switch

settings(in dB) checklist

rev loss

S13-1

LS

or

gain

GN

rev level

S13-2

.1

through

.2

S13-9

.4

.8

1.5

3

6

12

xmt

level

S19-1

.1

through

.2

S19-8

.4

.8

1.5

3

6

12

table

6.

263

DC level

alignment

switches

and

checklist

DSTunit

function

switch

settings

checklist

263DC-2 receive slope

S1

0.5

equalization

1

gain at 2

2804Hz 4

(re 1004Hz)

263DC-3 loaded/non-

S1-1

NL

loaded cable L

slope

S1-2

1

through 2

S1-5

4

8

height

S2-1

1

through 2

S2-4

4

8

bandwidth

S2-5

1

through 2

S2-8

4

8

table

7.

263DC-2

and

263DC-3

receive

equalization

switches

and

checklist

263DC·3

prescription

receive

equalizer

alignment

3.17

Because

the

263DC-3's receive equalizer

switch

settings

are

totally

dependent

upon

the

characteristics

(e.g.,

cable

gauge

and length,

loaded

or

nonloaded, etc.) of

the

facility

to

which

the

unit

is connected, it is recommended

that

the

equalizer

be aligned via

the

prescription method

only. In most cases, prescription alignment of

the

page

9

1000Hz·2804Hz

difference

0.0

to

0.2d8

0.3

to

0.7d8

0.8

to

1.2d8

1.3

to

1.7dB

1.8

to

2.2dB

2.3

to

2.7d8

2.8

to

3.2dB

3.3

to

3.7dB

3.8

to

4.2dB

4.3

to

4.7dB

4.8

to

5.2dB

5.3

to

5.7dB

5.8

to

6.2dB

6.3

to

6.7dB

6.8

to 7.2d8

7.3

to

7.7dB

amount

of

equalized

gain

required

O.OdB

0.5d8

1.0dB

1.5dB

2.0dB

2.5dB

3.0d8

3.5dB

4.0dB

4.5dB

5.0dB

5.5dB

6.0dB

6.5dB

70d8

7.5dB

practice section 81263DC-1/81263DC-2/81263DC-3

C.

Now

have

the

far end send

2804Hz

test

tone at

the

level specified on

the

CLR. Measure and

record

the

received

2804Hz

level.

Subtract

the

2804Hz

level from

the

1004Hz

level recorded

in step

B.

D.

Set

to

in that combination of equalizer DIP

switch positionswhich approximates as closely as

possibie

the

measured difference (see table

8).

263DC-3

non-prescription

receive

equalization

adjustment

3.22 For anon-prescription

alignment

procedure

for

the

263DC-3's receive equalizer, please refer

to

BSP 332-912-221.

4.

circuit

description

4.01

This circuit description is

intended

to

famil-

iarize you with

the

263DC

Data Station Termination

System

for

engineering and application purposes

only. Attempts

to

troubleshoot

the

unit internally

are not recommended and may void

your

warranty.

Troubleshooting procedures should be limited

to

those prescribed in section 7of

this

practice. Refer

to

the

263DC

block

diagram, section 5

of

this

prac-

tice, while reading this circuit description.

4.02 The unit's

power

supply consists of afull-

wave bridge rectifier, acapacitor

input

filter, and a

series voltage regulator. The full-wave bridge rectifier

allows

the

unit

to

be powered from

either

ac

or

de

input voltage. The capacitor input filter provides

isolation from ac signals present on

the

line, and,

when ac

power

is used, eliminates

60Hz

interfer-

ence from

the

signal path. The series voltage regu-

lator is used

to

derive astable de voltage for

the

internal circuitry.

4.03 Transformers at the facility-side ports (receive

input and transmit output) are

tapped

to

provide

switch-selectable 1200-, 600-,

or

150-ohm termi-

nating impedance. Asilicon voltage-transient sup-

pressor on

the

secondary

side

of each

transformer

limits transient potentials

to

asafe level and pro-

vides surge protection. Both transformers are

center-tapped

to

derive balanced simplex leads. A

20mA current source provides an internal source of

nominal 20mA sealing current. The 20mA current

source can be switch-optioned

to

provide sealing

current

to

the

facility via

the

unit's simplex leads,

to

provide areturn path

for

sealing

current

supplied at

the far end of the facility,

or

to

derive normal simplex

leads. Aseal

curr

LED on

the

unit lights when

the

internal 20mA current source is

selected

and cur-

rent is flowing.

4.04 The station side of

the

263DC

can be op-

tioned

to

interface either a2wire

or

4wire

data

station as selected by switch S14. An

electronic

hybrid circuit provides

the

necessary 2wire-to-

4wire conversion in

the

2wire mode.

4.05 Levels between

the

facility and

the

data

station are coordinated by

the

receive

amplifier

and

the

receive-level-control circuit. DIP

switches

in

the

receive-level-control circuit introduce controlled

feedback

into

the

receive amplifier circuitry

to

pro-

page 10

C.

If

the

level measuredat

the

RCVOUT(orXMT

IN/

2

W)

jack

is

the

sameas

that

specifiedon

the

CLR,

proceed

to

the

transmit level adjustment pro-

cedure

(paragraph 3.20). If

the

measured level is

lower than

the

specified level, set

the

GN/LS

switch(SI3-1)

tothe

GN position; if

the

measured

level is higher than

the

specified level, set S13-1

to

the

LS position. Then set

to

in

that

combination

of receive level DIP switch positions which equals

the

required

amount

of gain

or

loss

(i.e.,

the

dif-

ference between

the

specified level and

the

measured level).

Note:

The

amount

of

gain

or

loss introduced by

each position

of

the receive level switch is indicated

on the switch body. These switch positions are

cumulative; the total

amount

of

gain

or

loss intro-

duced

is the sum

of

those switch positions set to

in.

non-prescription

transmit-level

adjustment

(263DC-1,

-2, -3)

3.20

To

adjust

the

transmit level of

the

263DC

when prescription level settings are not given in

the

CLR

or

when

the

given settings

do

not pro-

duce adequate results, proceed as follows:

A.

Ensure

that

no transmit level DIP-switch posi-

tions

are

set

to

in. Also ensure

that

the

facility-

side port impedance switch

(SII)

is set correctly.

B.

Arrange

the

transmit portion of aTMS (properly

terminated at

600

ohms)

to

output

1004Hz

toneatOdBm

(or

other

datalevel specified by

the

CLR), and

connect

it

to

the

XMT

IN/2W

jack.

C.

Have personnel at

the

far

end

measure and

report

the

received ievel;

the

difference between

the

measured level and

the

specified level is

the

amount

of loss required in

the

transmit

channel of

the

DST unit.

Set

to

in

that

combi-

nationoftransmit

level(SI9)

DIPswitch

positions

which equal the required amount of attenuation.

Note:

The

amount

of

loss introduced

by

each

position

of

the transmit level switch

is

indicated on

the switch body. These switch positions are cumula-

tive; the total

amount

of

gain

or

loss introduced is

the sum

of

those switch positions set to

in.

263DC-2

non-prescription

receive

equalization

adjustment

3.21

To

determine

the

need for receive-channel

equalization

(I.e.,

post-equalization at

the

local end

of

the

4wire facility) and

to

make

the

required

adjustments when

the

263DC-2 is used, proceed

as follows:

A.

Ensure

that

none of

the

four equalizer DIP-

switch positions are set

to

in. Also ensure that

the

facility-side port impedance switch

(SII)

is

set correctly.

B.

Arrange

the

receive portion of aTMS for 600-

ohm terminated measurement and connect it

to

the

RCVOUTjack(XMT

IN/2

Wfor

2wire

opera-

tion). Have

the

far end send

1004Hz

test

tone

at

the

level specified on

the

CLR. Verify

the

pres-

ence

of test

tone

and record

the

measured

level.

practice

section

81263DC-l

/81263DC-2/81263DC-3

envelope delay distortion

less than 100 microseconds,

400

to 3000Hz

peak/average ratio

greaterthan 98

I

receive

channel

I

level range

o

to

24dB

of

gain

or

loss in switch selectable 0.1dB

increments,

with

gain or loss selected via switch

option

input impedance

150ohms ±15%, 600 ohms ±10%, or

1200

ohms

±10%,

balanced, switchable

total harmonic distortion

1%

maximum, 300

to

4000Hz

2630C-2

equalization

up

to

7.5dB

of

active slope equalization

at

2804Hz

(re 1004Hz) in switch-selectable0.5dB increments

2630C-3

equalization

slope/bump equalizer for loaded or nonloaded cable

-equivalent

to

Western Electric 30gB

-30dBm.

Aminimum

6dB

guard

band prevents

remote

loopback

activation

by

other

than

the

in-

tended

signal. Local

loopback

is

deactivated

by

removing the ground from the

LOC

LB

lead. Remote

loop

back

is deactivated in

either

of

two

ways: upon

receipt

of

asecond

2713Hz

tone

burst

of

0.7

second

or

longer, or automatically after a20-minute

timeout

period. The method

of

remote

loopback

de-

activation is selected via switch option. When

the

timeout

method

is selected,

loopback

can still be

deactivated by transmission

of

a

second

2713Hz

tone

before

the

timeout

period expires. An option

switch is also available

to

disable

the

remote-Ioop-

back

function

completely

when

desired.

4.12 Aloopback amplifier in

the

loopback

path

can be switch-optioned

to

provide

either

8

or

16dB

of

gain

between

the

receive

and

transmit

channels

when

the

unit

is in

the

loopback

mode. In circuits

with

either

an 8

or

16dB

differential

between

the

receive and transmit TLPs, this feature allows a

test

signal received at

the

normal data level

to

be re-

turned

to

the

remote location

at

the

same

level as

in normal operation.

specifications continued on page

13

specifications

noise

10dBrnCO maximum

maximum input level

+5dBm

maximum output level

+5dBm

6.

vide

up

to

24dB

of

gain or loss in

the

receive

channel

in

O.ldB

increments.

One

of

the

DIP switch

positions determines whether gain

or

loss is inserted

by

the

receive amplifier.

4.06

Both

the

263DC-2 and 263DC-3 provide

active post-equalization

of

the

facility via integral

prescription

amplitude

equalizers in

their

receive

channels. The 263DC-2's receive equalizer is

slope-type, providing

up

to

7.5dB

of

equalized gain

at

2804Hz

(re 1004Hz) in discrete 0.5dB increments.

The

263DC-3's

receive equalizer is functionally

equivalent

to

the

Western Electric model

309B

Prescription Equalizer. In addition

to

providing

slope-type equalization,

the

263DC-3 provides bump-

type equalization with variable height and bandwidth

settings. The equalization

functions

of

both

the

263DC-2

and

the

263DC-3

are controlled by DIP

switches

on

the

receive equalizer subassemblies.

4.07 The receive level

detector

responds

to

the

presence

of

data in

the

receive channel

at

levels

greater

than

-25dBm

by lighting

the

data in LED.

The location

of

the

receive level

detector

in

the

circuit-following

the

receive

amplitier

and receive-

level-control circuit and, on

the

263DC-2 and

263DC-3, the receive

equalizer-makes

it avaluable

troubleshooting

aid

because

it provides a

check

on

virtually all active circuitry in

the

receive channel.

4.08 Level coordination

between

the

data sta-

tion

and

the

facility is provided by

the

transmit

amplifier

and

the

transmit-level-control circuit. A

five-step

attenuator

in

the

transmit-level-control cir-

cuit provides

up

to

24dB

of

flat loss in

0.1

dB incre-

ments. This loss is inserted

into

the

transmit

channel

via an eight-position

01

Pswitch.

4.09 The transmit level

detector

performs

the

same

functions

for

the

transmit

channel as

the

receive level

detector

does

for

the

receive channel,

responding

to

the

presence

of

data signals above

-25dBm

by lighting

the

data

out

LED. The transmit

level

detector

is similarly located at apoint in

the

circuit

where

it provides a

check

of

the

maximum

amount

of

active transmit-channel circuitry.

4.10

The

loopback

control

circuitry provides

the

detection,

timing, and logic

functions

for

loopback

operation

of

the

263DC. The

loopback

circuitry can

be activated

either

locally via

ground

or

remotely

via

2713Hz

tone

(see paragraph 4.11). When loop-

back

is activated by

either

method,

the

loopback

(LB)

relay operates, opening

the

transmit

and re-

ceive

channels

toward

the

modem and

connecting

the

receive

channel

to

the

transmit channel. The

LB

relay also provides data-set-disable leads (TEK5

and TEK6)

to

disable

the

associated data

set

during

loopback. The

loopback

LED on

the

unit's cover

iights

when

the

unit is in loopback. I I

transmit

channel

4.11

Loopback

is

activated locally by applying .

ground

to

the

LOC

LB

lead. Remote

loopback

is level range

activated by application

of

a

2713Hz

tone

burst 1.6 0

to

24dB

of

loss in switch-selectable0.1dB

seconds

or