TEM Aligna 4D User manual

Aligna® 4D User Manual

1 / 84

User Manual

Aligna®4D

Modular Rack Case Version

Version 2.4

TEM Messtechnik GmbH

Grosser Hillen 38

D-30559 Hannover

Germany

Tel.: +49 (0)511 51 08 96 -31

Fax: +49 (0)511 51 08 96 -38

E-mail: [email protected]

URL: http://www.TEM-Messtechnik.de

(07.06.2009, 09.07 2020)

Aligna® 4D User Manual

2 / 84

Aligna® 4D User Manual

3 / 84

Table of Contents

1Introduction ....................................................................................................... 7

2Block Diagram Aligna®4D.............................................................................. 10

3Short Description of the Front Panel Elements............................................ 11

4Principles of Laser Pointing Stabilization..................................................... 12

4.1 Reasons of Pointing Instabilities................................................................. 12

4.1.1 Thermal properties of the laser itself .................................................................12

4.1.2 Thermal movement by the laser cooling system................................................12

4.1.3 Drifts of alignment and folding mirrors...............................................................12

4.1.4 Air turbulences and temperature gradients in the air .........................................12

4.1.5 Thermal effects of optical elements...................................................................13

4.1.6 Mechanically moved optical elements (delay lines, e.g.) ...................................13

4.1.7 Movement of the experimental (optical) tables or vacuum chambers ................13

4.2 2D or 4D Stabilization?............................................................................... 14

4.3 Positioning of Actuator and Detectors........................................................ 17

4.3.1 Setup 1: Two Beam Samplers...........................................................................17

4.3.2 Setup 2: Second Mirror Acts as Beam Sampler.................................................17

4.3.3 Problems with Beam Sampler Plates ................................................................17

4.3.4 Setup 3: High Reflecting Mirror Acts as Beam Sampler.....................................18

4.3.5 Setup 4: Only One Beam Sampler Mirror..........................................................19

4.3.6 Setup 5: Compact 4D Sensor "PSD 4D"............................................................19

4.3.7 Setup 6: "PSD 4D" with Beam Sampler Wedge Plate........................................19

4.3.8 Distance between A1 and A2............................................................................20

4.3.9 Position of the Detector(s).................................................................................20

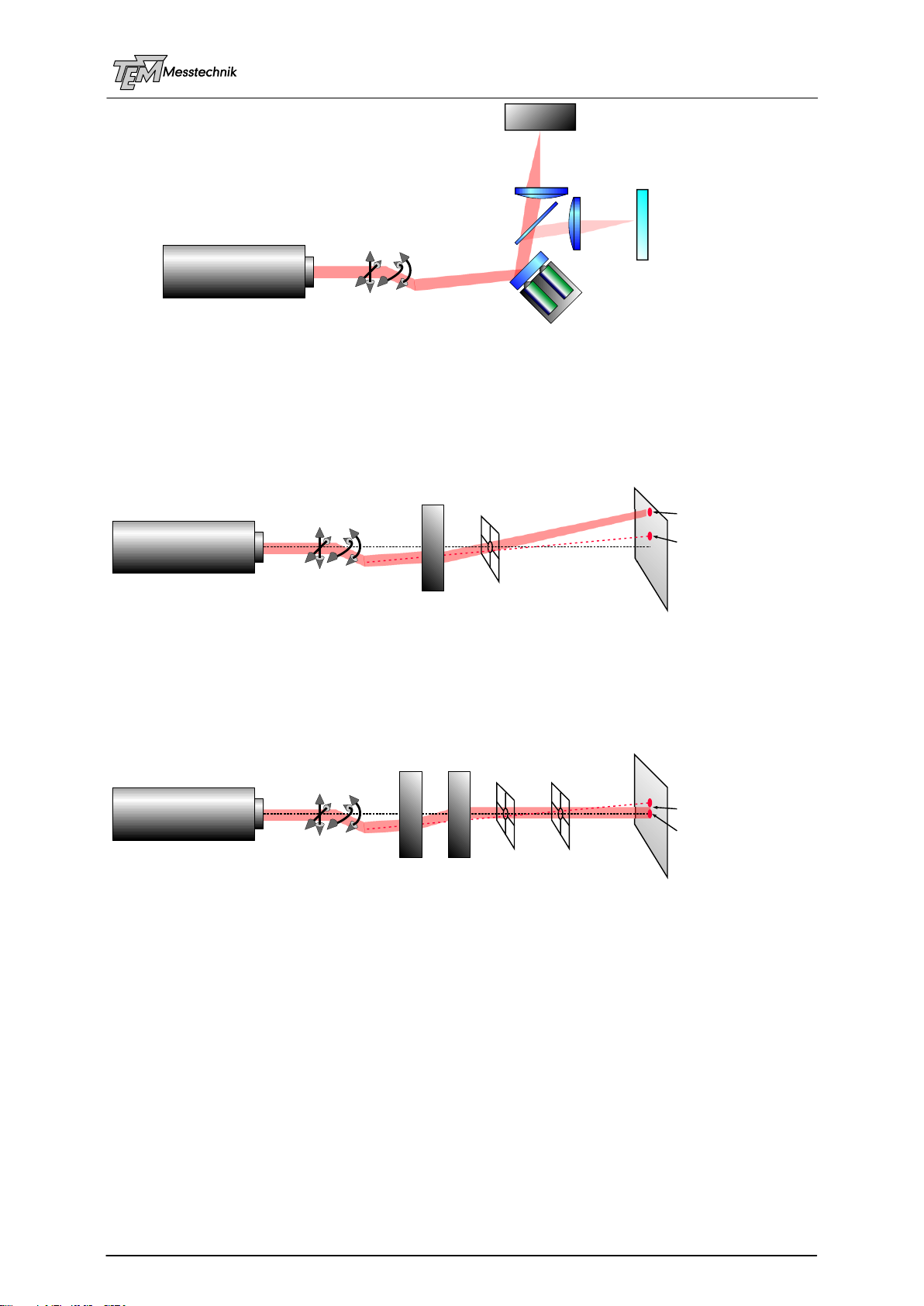

5Some Typical Configurations......................................................................... 25

5.1 2D System (Angle Stabilization)................................................................. 25

5.2 2D System (Long Path).............................................................................. 25

5.3 4D System.................................................................................................. 26

5.4 4D System with Long Beam Path............................................................... 26

5.5 Auto-Alignment and 2D stabilization........................................................... 27

5.6 Auto-Alignment and 4D stabilization........................................................... 28

5.7 Overlaying Two or More Laser Beams Independently................................ 28

5.8 Overlaying Two Laser Beams, Commonly Stabilized Path ........................ 29

5.9 Overlaying Three Laser Beams with Commonly Stabilized Path................ 30

5.10 Comparison of some Setups...................................................................... 31

6Pulsed Lasers.................................................................................................. 32

Aligna® 4D User Manual

4 / 84

6.1 Repetition Rate Categories ........................................................................ 32

6.1.1 CW Lasers........................................................................................................32

6.1.2 CW Lasers with Intensity modulation (5 kHz to 200 kHz) ..................................33

6.1.3 Pulsed Lasers with Slow Repetition Rates (1 Hz … 3 kHz) ...............................33

6.1.4 Pulsed Lasers with medium repetition rates (3 kHz … 15 kHz) .........................33

6.1.5 Pulsed Lasers with high repetition rates (>15 kHz … > 1 GHz) .........................34

7Input CrossLink Matrix (ICL) .......................................................................... 35

8Output CrossLink Matrix (OCL)...................................................................... 35

9Setting up an Aligna®Test System................................................................ 36

9.1.1 Cable Connections:...........................................................................................38

10 Setting up the Aligna®System by Help of Kangoo....................................... 41

10.1 Some basic Kangoo features ..................................................................... 41

10.1.1 Installation of Kangoo........................................................................................41

10.1.2 Buttons and Devices .........................................................................................41

10.1.3 Sections............................................................................................................42

10.1.4 Hotkeys.............................................................................................................42

10.1.5 Further Kangoo Functions.................................................................................43

10.2 Main Aligna®Configurations....................................................................... 44

10.2.1 Configuration "Aligna User Menu" ("BL Menu") .................................................44

10.2.2 Configuration "BeamLock Basic".......................................................................45

10.3 Some Common Sections............................................................................ 47

10.3.1 PSD Input Section.............................................................................................47

10.3.2 PSD Input Section.............................................................................................48

10.3.3 "Physical Units" Section....................................................................................51

10.3.4 "Calibration" Section..........................................................................................51

10.3.5 "3D Beam" Section............................................................................................52

10.3.6 "3D Beam" Section............................................................................................53

10.3.7 "Thresholds" Section.........................................................................................53

10.3.8 "Hidden Parameters" Section............................................................................54

10.3.9 "OCLM" (Motors Output Crosslink Matrix) Section.............................................55

10.3.10 Alignment of the "OCLM" Matrix (Output CrossLink Matrix of Motorized

Actuators) 57

10.3.11 Alignment of the Piezo OCL Matrix OCLP (Piezo’s Output Crosslink Matrix) .65

10.4 Storing and Recall of the Individual Parameters......................................... 68

10.4.1 Recall of the (User-Specific) Default Parameters ..............................................68

10.4.2 Storing the actually defined Parameters as Default Parameters (into the µC's

FlashEEPROM)...............................................................................................................68

10.4.3 Defining the Hardware-Specific Parameters......................................................69

Aligna® 4D User Manual

5 / 84

10.5 Configuration "Beam Alignment Scope"..................................................... 72

11 Safety Instructions .......................................................................................... 73

12 Delivery content............................................................................................... 74

12.1 Delivery content Aligna®:........................................................................... 74

12.2 Delivery content PSD 2D:........................................................................... 74

12.3 Delivery content PSD 4D e:........................................................................ 74

12.4 Delivery content PSD 4D i:......................................................................... 74

12.5 Delivery content BeamScan OneInch:........................................................ 74

12.6 Delivery content Motorized Mirror Mounts (MMMs):................................... 75

13 Technical Data................................................................................................. 76

13.1 Environmental conditions: .......................................................................... 76

13.2 Aligna®4D Module Rack Case Properties ................................................. 76

13.3 Detector properties PSD 2D (Detector A, or Detector B)............................ 77

13.4 Detector properties PSD 4D i..................................................................... 77

13.5 Actuator properties BeamScan 2D One Inch ............................................. 77

13.6 Aligna 60 Motorized Mirror Mount .............................................................. 78

13.7 Aligna 40 Motorized Mirror Mount .............................................................. 78

13.8 Used Mirrors............................................................................................... 79

14 Connectors and Cables .................................................................................. 80

14.1.1 Mains power cable ............................................................................................80

14.1.2 Connection of the Detectors and Actuators.......................................................80

15 Customer service ............................................................................................ 81

Aligna® 4D User Manual

6 / 84

Aligna® 4D User Manual

7 / 84

1 Introduction

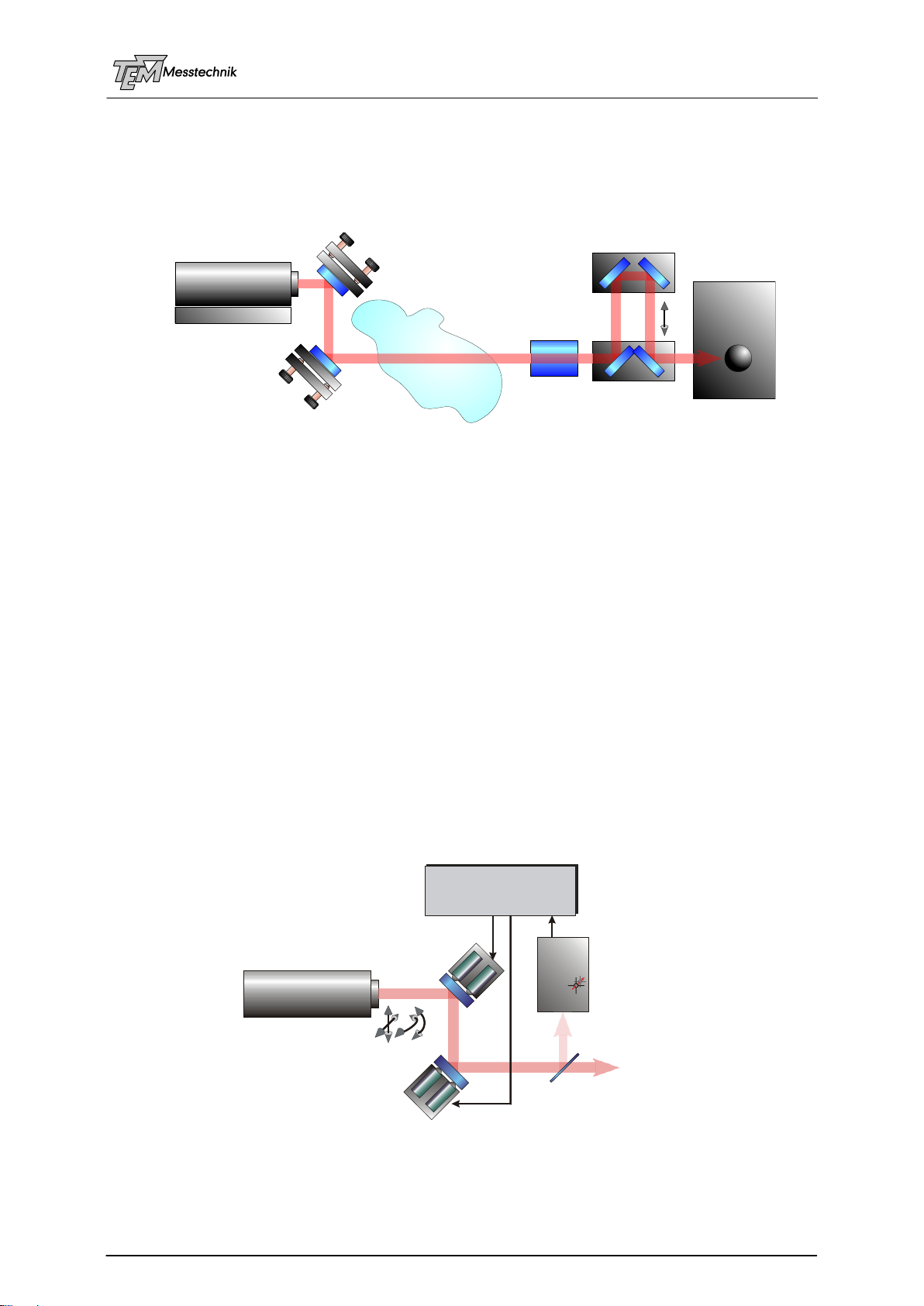

Laser beams, used in an experiment or in industrial applications, can move in space by many

reasons:

1. Thermal properties of the laser itself

2. Thermal movement by the laser cooling system

3. Drifts of alignment and folding mirrors

4. Air turbulences and temperature gradients in the air

5. Thermal effects of optical elements

6. Mechanically moved optical elements (delay lines, switching mirrors, motorized tele-

scopes, …)

7. Movement of the experimental (optical) tables or vacuum chambers

(In the chapter “Reasons of Pointing Instabilities” these topics will be discussed in more detail.)

The laser beam pointing stabilization system Aligna®compensates for all of these disturb-

ances. The laser beam position and its angle are measured by the 4D position sensitive detec-

tor PSD 4D in four degrees of freedom (two beam positions “X” and “Y”, and two angles “”

and “”). The position of a (collimated) laser beam is characterized by these four values, like a

line in space. The measured deviation signals of the laser axis with respect to the reference

axis are processed continuously by the Aligna®electronics. Herein control signals for four

piezo actuators of the BeamScan mirrors and/or motorized mirror mounts (Aligna60, e.g.) are

generated. Two 2D movable mirrors, which control these four degrees of freedom in four fast

closed lock loops keep the laser beam exactly at the reference axis.

Aligna®is a modular system, consisting of different elements, which can be adapted to the

individual application: Different types of scanners (with various values of displacement, beam

diameters, mirror types, movement speeds) and different types of PSDs (Position Sensitive

Laser

Cooling System

1: thermal drifts

inside the laser,

movements by

frequency detuning,

by power variation

2: thermal drifts

of cooling system

and mechanical mounts

3: drifts of alignment

and folding mirror

holders 4: air fluctuations and

temperature gradients

6: moved optical elements

(delay lines, switching mirrors,

motorized telescopes,...)

7: Movement of the experimental

(optical) tables or vacuum chambers

5: thermal effects in

optical elements and

mirrors

Target

Laser

BeamScan 2D

1PSD 4D

BeamLock®

electronics

BeamScan 2D

2

XY

Beam Splitter

to Experiment

Aligna® 4D User Manual

8 / 84

Detectors) with various types of sensors (wavelength, beam diameter, resolution, dimensions,

QUAD detectors, duo/tetra lateral PSDs, or CCD/CMOS cameras) are available.

In some applications a 2D stabilization (instead of 4D) may be suitable. In this case only one

2D scanner BamScan 2D is necessary. (This reduction, however, can be more critical and

takes more effort in positioning the PSD. Please refer to chapter “2D or 4D stabilization”!)

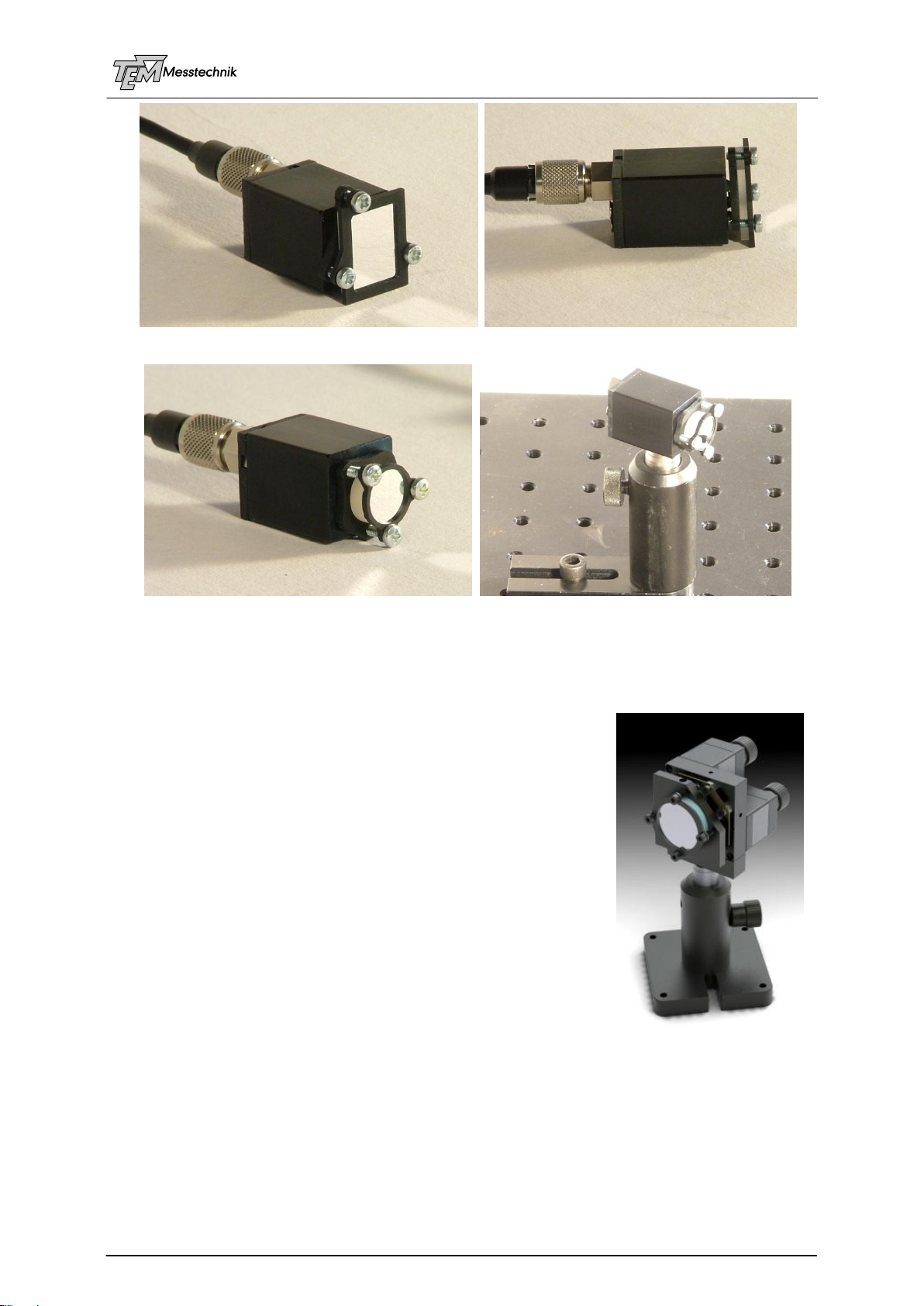

Aligna®4D electronics 4D detector PSD 4D e

BeamScan2D with different mirror shapes, 1-inch and square bodies

Elliptical mirror 22 x 32 mm, (5mm thick), fitting into std 1-inch mirror holder

Aligna® 4D User Manual

9 / 84

rectangular broadband mirror 15 x 20 x 2.5 mm, in rectangular corpus

Half-inch mirror, rectangular corpus

Aligna®also can be controlled by a PC or by other electronic

devices within a control system. In this case both the 2D beam

position and the 2D beam direction can be set by the control

system; a very precise stabilized 2D or 4D fast scanning of the

laser beam is possible.

Via the USB or serial interface, the following parameters can be

set and controlled:

Switching each servo channel on or off

control of the set points (position X, Y, and angle , )

Gain of the PSD amplifiers (sensor sensitivity)

…

For detailed information please consult the Software Manual.

In addition all relevant signals (4D position signals, 4D error signals, 4D regulation signals,…)

can be read as analog signals or via USB interface.

Aligna® 4D User Manual

10 / 84

2 Block Diagram Aligna®4D

In the following, the block diagram of the Aligna®4D electronics is described.

Note: This chapter is preliminary: It still contains additional information related to former ver-

sions.

Two 2D sensors “PSD 2D” (or one 4D sensor “PSD 4D”) detect both 2D position (“X”, “Y”)

and 2D angle (“”, “”) of a laser beam. The detector electronics contain (dependent on the

detector type):

The position sensitive chip: A variety of detector sizes and types is available: 2x2 mm,

4x4 mm, 9x9 mm, 12x12 mm, others on request, as well as quadrant detectors of different

sizes. Different speed options are available, please refer to PSD manual.

The detectors are located at a small PCB, which also contains transimpedance amplifiers

and filter networks to achieve very linear low noise robust signals.

The detectors are connected with the cables “PSD 1” to “PSD 4” with the Aligna®4D electron-

ics, which contains following functions.

signal range and clip check for each channel Ax, Ay, Bx, By

Input Cross-link Matrix circuitry (ICL Matrix) (calculation of pure Angle and BeamPosition

signals)

Set point definition (SetpAx, SetpAy, SetpBx, SetBy), fixed, external analog control or digital

control (including test generator)

Error calculation (4D actual position –4D set position)

Gain and regulator control logic

Four PIDT2regulators

Output Cross-link Matrix circuitry (OCL Matrix) (calculation of the combination movement)

Monitor multiplexer for observation of all relevant signals

HV Piezo amplifiers

Motor Drivers

MicroController Module, including USB Interface, Serial Interface, (Ethernet optionally)

Power Supply

Aligna® 4D User Manual

11 / 84

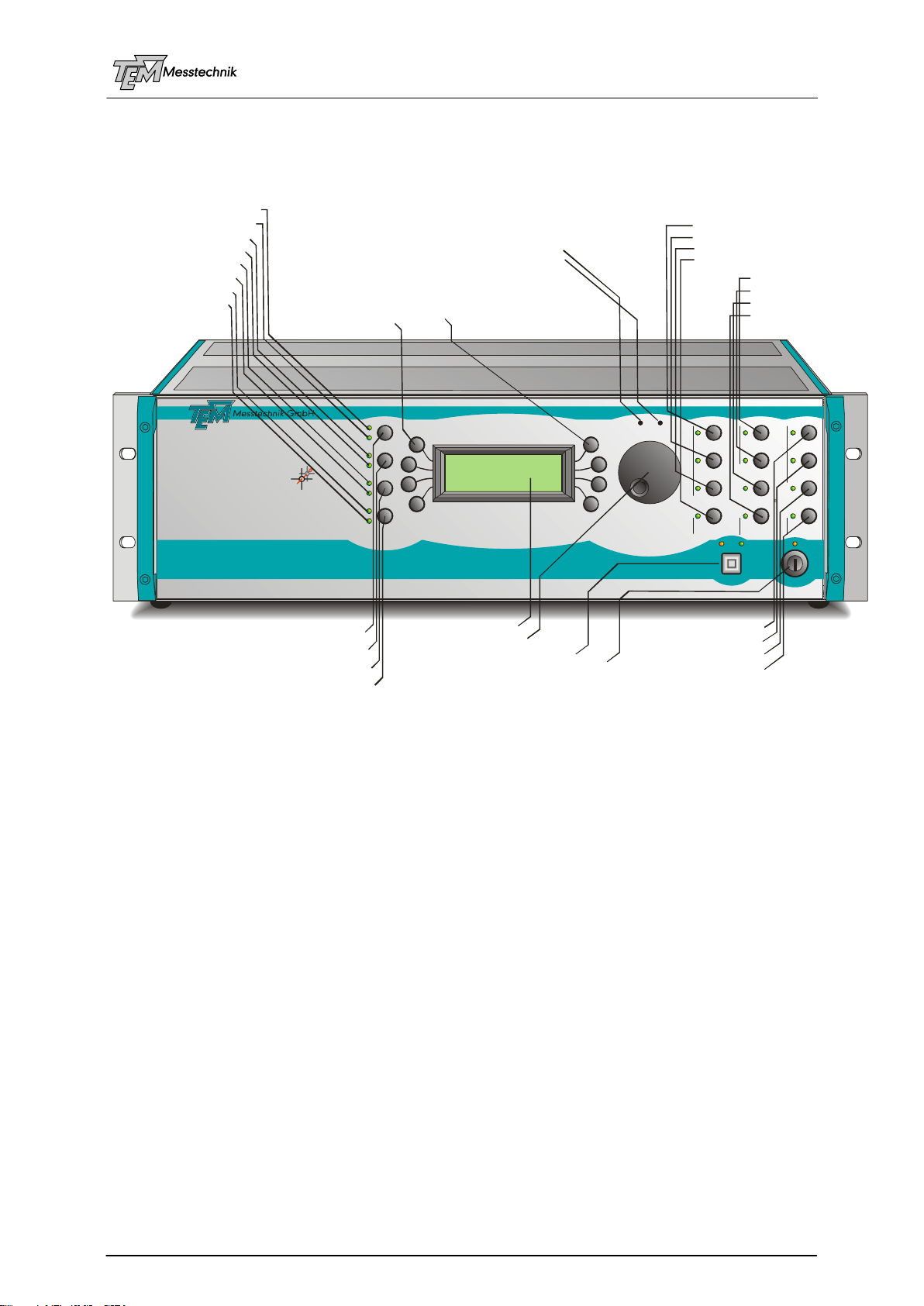

3 Short Description of the Front Panel Elements

Station

Parameters

Task

volume

brightness

station 3

manual

station 2

station 1

here is 0!

aux

auto detect

piezo enableoptimize!

center!

search!

intensity A

position OK

piezo active

A active

intensity B

locked

aux

B active regulate!

4DBeamLock System

Aligna two-point-O

Modular Laser Beam

Alignment andStabilizationSystem

USB

TR

power

®

®

www.TEM-Messtechnik.de

Aligna 4D 3.1

TEM Messtechnik GmbH

SN 2033 (Demo DPG10)

Release 16.02.2010

start procedure "search"

12 programmable user key buttons

LED "intensity OK" detectorA

(spec. key#0)

(spec. key#1)

reset/set error bit

activate servos A, B, A+ B

LED "intensity OK" detectorB

LED "position OK" all detectors

LED "locked" all servos

LED "piezo servo(s) active"

LED "aux" (errorbit, e.g.)

LED servo(s) Aare active

LED servo(s) Bare ac tive 8 menu keys

LCD menu display

trim LCD illumination brightness

trim loudspeaker volume (beep, key click,...)

start procedure "center"

start procedure "optimize"

switch on/off regulation (servos)

select manual access

auxillary userkey

enable piezo servo(s)

"here iszero"key

select station/tool # 1

select station/tool # 2

select station/tool # 3

automatic station detection

front panel USBinterface

selection wheel

front panel supply key switch

Pinnings of connectors are described in appendix “Connectors and Cables”.

Aligna® 4D User Manual

12 / 84

4 Principles of Laser Pointing Stabilization

4.1 Reasons of Pointing Instabilities

Laser beams, used in an experiment or in industrial applications, can move in space by many

reasons. Even small movements at the laser outlet may result in rather large movements of

the laser spot, depending on the distance to the target, and on the optical components in the

beam path. In the following, some of the most important reasons of pointing instabilities will be

named.

Reasons of Pointing Instabilities

4.1.1 Thermal properties of the laser itself

Often a high local power is dissipated in a small spatial region; even small thermal movements

can be transformed by collimating lenses of short focal lengths to relatively large angle move-

ments. Local heating may be caused by pump diodes, by gas discharges, flash lamps, or by

electrical excitation of the laser medium itself.

4.1.2 Thermal movement by the laser cooling system

If the laser medium is producing heat the laser is often cooled by Thermo-Electric Coolers

(TEC, Peltier elements), by fans or by a water cooling system. Those techniques produce

temperature gradients within the mechanical setup. If the development of the device is not

done in a perfectly temperature compensated manner, position and angle changes will result.

Even if the laser medium itself is stabilized and held at an exact constant temperature the

cooling system has to react on changing temperatures of the environment and it has to com-

pensate for the temperature change of the heat sinks. This will lead to pointing drifts.

4.1.3 Drifts of alignment and folding mirrors

Adjustment tools and element holders typically consist of different materials: Aluminum, stain-

less steel, brass and other materials, with different thermal expansion coefficients each.

Caused by a change of the environment temperature the different thermal expansions can

lead to position and –more critical- angle movements of the laser beam. The strength of these

effects strongly depends on the construction, the materials, and –of course- on the tempera-

ture variations of the environment.

4.1.4 Air turbulences and temperature gradients in the air

Air fluctuations may cause large pointing fluctuations, particularly at long distances. But even

one meter distance can produce pointing fluctuations in the order of some ten microns, which

may be too much for critical applications. Air fluctuations often play the main role in beam

pointing instabilities, especially at long distances between laser and target of several meters or

even several tens or even hundreds of meters. Using evacuated tubes for beam guiding over

Laser

Cooling System

1: thermal drifts

inside the laser,

movements by

frequency detuning,

by power variation

2: thermal drifts

of cooling system

and mechanical mounts

3: drifts of alignment

and folding mirror

holders 4: air fluctuations and

temperature gradients

6: moved optical elements

(delay lines, switching mirrors,

motorized telescopes,...)

7: Movement of the experimental

(optical) tables or vacuum chambers

5: thermal effects in

optical elements and

mirrors

Target

Aligna® 4D User Manual

13 / 84

long distances helps, of course, but even small effects at the path from the laser outlet to the

vacuum tube will be transformed to large effects at the end of the (long) tube. Please note,

using evacuated tubes may cause drifts depending on local air pressure variations.

In addition, evacuated tubes are expensive, bulky and inconvenient to handle.

If a laser is lead between different rooms through holes in the wall temperature and pressure

differences between these rooms may lead to strong local air density gradients and thus to

strong pointing drifts. Local pressure differences between the rooms (by air conditioning sys-

tems or by laminar flow systems, e.g.) will cause a strong air flow and air density turbulences.

4.1.5 Thermal effects of optical elements

Every optical element absorbs a distinct amount of the laser beam, which is true for both re-

flecting and transmitting elements. So-called thermal lenses lead to well-known influences of

the collimation properties of the laser beam. With high quality of the materials and coatings

and/or at low intensities the focusing/defocusing effect may be negligible.

But: the (very small) absorbed power leads to a local change of the temperature itself and thus

the temperature gradient, which leads to a pointing deviation. The related time constants can

be very slow, no equilibrium may be reached in many hours.

4.1.6 Mechanically moved optical elements (delay lines, e.g.)

Sometimes optical elements have to be moved within the application:

4.1.6.1 Delay Lines

In short pulse laser systems (ps or fs durations) so-called delay lines are often used to match

or shift two laser pulses in time with respect to each others. A set of several mirrors is moved

by a motorized sleigh which has to be aligned to be exactly parallel to the optical path. This

can only be done to a certain extent; it is difficult to align better than some ten micro radiants.

In addition, the motorized rail is not perfectly straight; there will be curvatures in the order of

typically some ten up to some 100 microns, depending on the length and the price of the rail.

4.1.6.2 Motorized or Manual Telescopes or Zoom Expanders

In some applications, setups of optical lenses have to be moved (telescopes, zoom telescopes,

expanders,…). It is impossible to position and move these elements exactly at the optical axis.

Thus, a beam pointing movement will be observed during the movement of the optical element.

4.1.6.3 Switching Mirrors

In some applications, the laser beam is switched between two paths of the experiment by a

manually operated or by a motorized switching mirror. The reproducibility of the mirror position

may be very high, but will not be perfect. Residual uncertainties of approx. ten µradiant are

typical.

4.1.7 Movement of the experimental (optical) tables or vacuum chambers

Often the laser and the experimental target are mounted at different optical tables. Many ex-

periments are located in small or large vacuum chambers. Those components will be at differ-

ent and changing temperature values. This leads to relative pointing drifts, even if each ele-

ment is very stable by itself.

Aligna® 4D User Manual

14 / 84

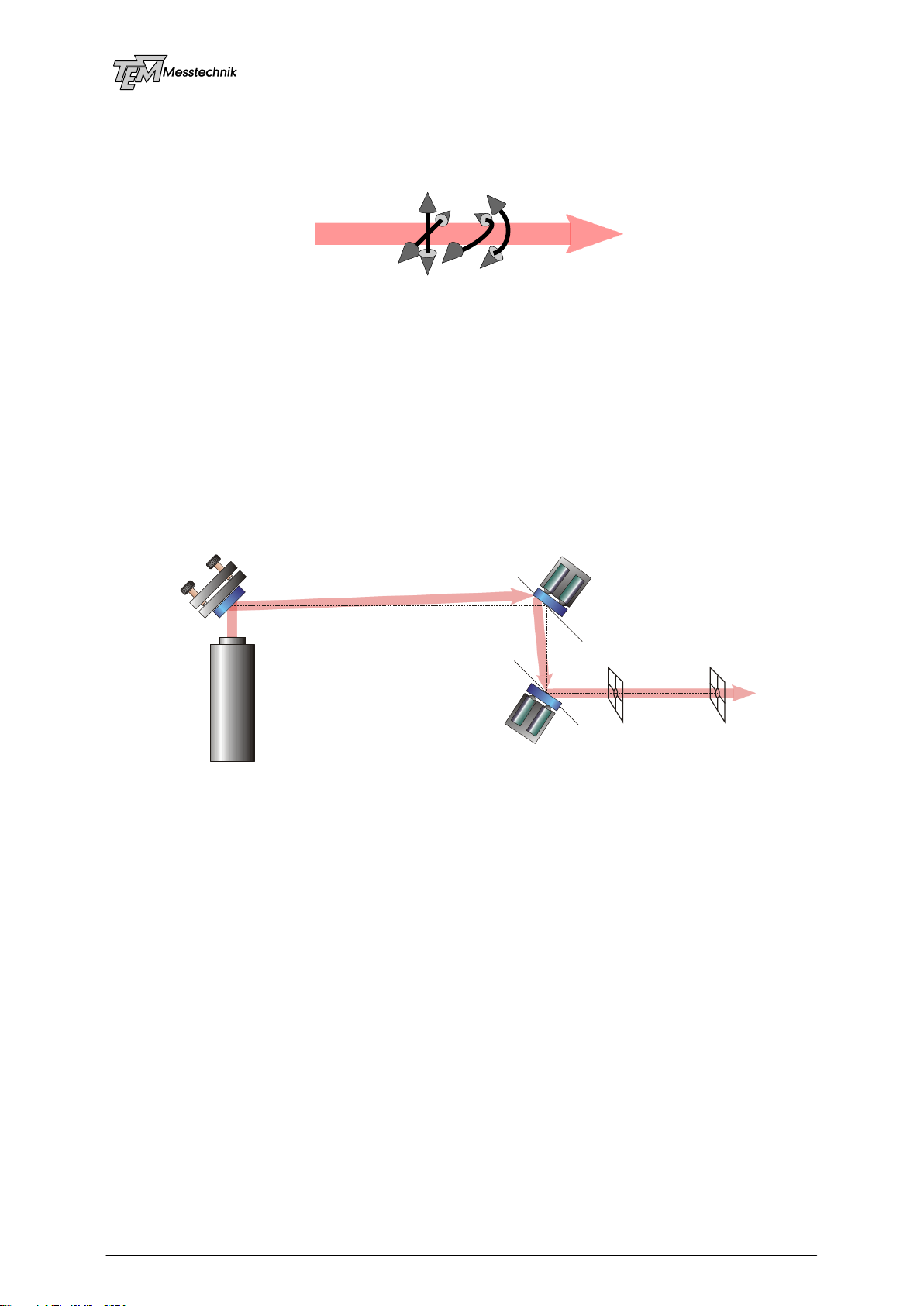

4.2 2D or 4D Stabilization?

The movement of a collimated beam can be separated into four dimensions: two translational

("X", "Y") and two rotational ("", "")

These degrees of freedom are not really independent: If, for example, one mirror holder drifts

by 100 µrad due to the change of the room temperature the translation error of some µm will

be negligible compared to the beam diameter of let's say some mm close to the mirror. After

one meter free propagation, however, this leads to a movement of 0.1 mm, after 10 meters

this is 1 mm, which is really not negligible any more. (Note: the angle drift is not directly de-

pendent on the propagation length in this example. In reality, however, angle fluctuations due

to air fluctuations increase with the length with a factor of sqrt(L))

Even if the nature of the drift (in this example) is a pure angle drift (just 2D) it leads to a com-

bination of angle and position movement after a distance of propagation (near the experiment)

and cannot be compensated for by one single 2D moving mirror. It has to be compensated for

with a combination of position and angle correction, e.g. by two 2D moved mirrors.

In many applications it is not really necessary to keep the laser beam fixed both in position

AND direction at the place of the experimental target. In the case of laser material processing,

for example, it is very important to keep the focused laser spot at an exactly defined position at

the target surface. The angle, however, is not that critical. So one could think, a 2D correction

might be sufficient. A beam splitter (also called beam sampler) separates a small part of the

main beam. This part is handled exactly as the main beam (distances, focusing elements, etc.).

If the laser spot is actively held fixed by the actuator at the detector position, it will be fixed in

the plane of the target, too.

XY

Laser

drifting mirror angle

compensation by a combination

of position and angle reference direction

and position

Aligna® 4D User Manual

15 / 84

In principle this works. But: The detector has to be positioned in an exact (!) image of the

target. Therefore it has to be aligned mechanically very well. Often it is difficult to find the

correct Z-position for the detector. If this Z-position of the detector is wrong the stabilization

can even ENLARGE the pointing fluctuations, compared to the situation WITHOUT any stabili-

zation!

This shows: the fixed point of a laser beam has to be well matched with the target require-

ments. In normal cases this needs additional optics in the detection path, corresponding to the

main optics and distances in the main path, and it needs a precise and critical alignment of the

detector and the related optics.

With a 4D stabilization, in contrast, two points of the beam are fixed in space, instead of one

point in case of 2D. As a result, ALL points of the output beam are fixed. For this it is not im-

portant WHICH two points are fixed. They only have to have a certain distance from each

other to get enough resolution for the angle measurement. The Z-positions of the detectors are

not critical. They can be positioned within a coarse spatial range and need not to be aligned

precisely.

If PSDs are used (not quadrant detectors, see description on "detectors", “PSDs or QUAD

detectors”) it is not important to hit exactly the center of the detectors: PSDs create a linear

signal proportional to the spot position within the detector area, independent of the spot size

and of the spot shape. (In contrast, quad detectors can only be used exactly in the physical

center of the detectors; they show a strong dependence of the position error signal from the

spot size and shape.) Thus PSDs do not have to be aligned precisely in X and Y position,

because the servo loop (the user, respectively) can select the working point by applying an

electronical DC set point signal (X and Y, and ) to the regulator electronics. (Thus even the

stabilized beam can be scanned quickly and precisely.)

XY

Laser

Target

Beam Splitter

Pointing Drifr and Fluctuations

2D Position Detector

in the position

of an image of the target

XY

Laser

2D steering element

(tilting mirror, e.g.)

ONE fixed point

of the beam

without stabilization

with stabilization

XY

Laser

two 2D steering element

(tilting mirrors, e.g.)

two fixed points

of the beam

without stabilization

with 4D stabilization

Aligna® 4D User Manual

16 / 84

As a result, the PSD 4D detector box has to be aligned just coarsely. It can be fixed firmly

without the need of precision alignment mechanics. The exact reference optical axis can be

controlled by electronic signals, instead of fine mechanical alignment!

Of course a 4D lock system needs a little bit higher effort in the electronic system, compared

to a 2D system (two 2D detectors, two actuator mirrors), but:

A 4D stabilization leads to a much more robust and easy to handle system, without the

necessity of mechanical fine alignment and very low mechanical drift!

It compensates for both angle AND position shifting effects.

Both position AND angle will be corrected without optimizing for one of them, without de-

tailed analysis of the movements and drifts.

No fine adjustment of the detectors is necessary.

Aligna®4D gives you both possibilities: It can be switched to 2D or to 4D stabilization. Even in

the 2D mode you have the advantage of watching both, position and direction, by help of the

4D detector.

In addition, a 2D stabilization can be performed by a combination movement of all four actua-

tors.

Moreover, the servo speeds may be selected different for angle and position stabilization,

which leads to higher precision, as described later.

Aligna® 4D User Manual

17 / 84

4.3 Positioning of Actuator and Detectors

In the following, we will discuss different setups to get the best setup of positions of the piezo-

controlled mirrors, the motorized mirror mounts, and the 4D detector system.

It is obvious that the detection of the beam movement has to be located BEHIND the actuators.

Otherwise a movement of the actuators cannot be observed by the detectors for pointing

correction in a closed servo loop.

In addition, it is obvious that the detectors should be located near the target (or experiment).

Then, all disturbances appearing at the path from the laser, passing maybe many folding

mirrors and optical elements, will be detected and compensated for.

It is NOT the case that both actuators should be located in the near of the experiment. The two

actuators may be located anywhere in the path up to the detectors. Of course, different posi-

tions have advantages and disadvantages, which will be discussed now:

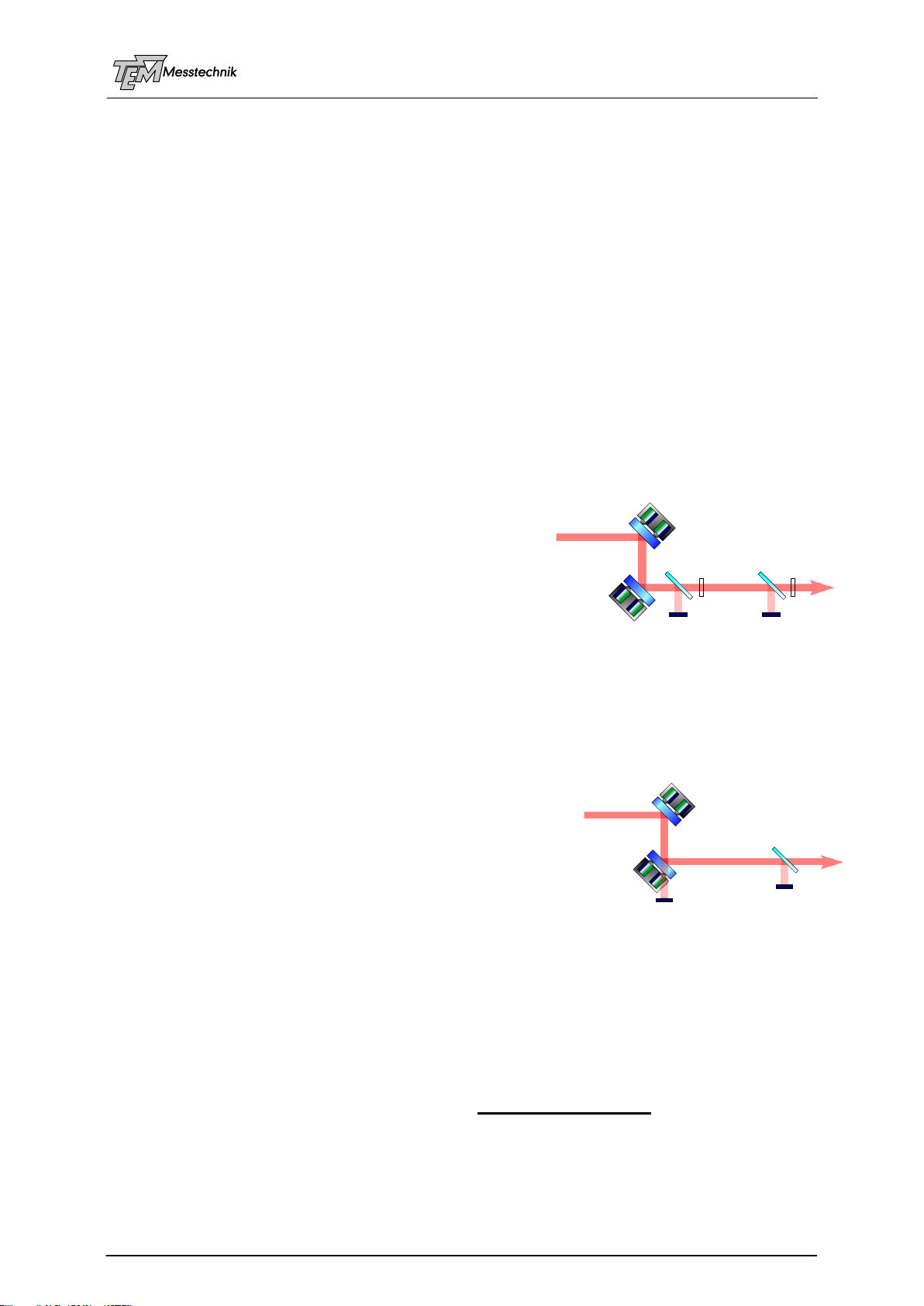

4.3.1 Setup 1: Two Beam Samplers

We will start with the perhaps most easy to understand setup:

Two mirrors are mounted at piezo-controlled mirror holders. Four piezos can control four de-

grees of freedom: Two translational (X, Y), two rotational

(, ).

Two 2D detectors represent two points of the laser beam.

The electronics keeps the beam exactly in the center of

both detectors. That means that two points of the beam

are fixed. Thus the complete beam will be fixed (as far

as no disturbance will happen BEHIND the detectors).

The position resolution is directly given by the position sensitivity of D1. A large distance be-

tween D1 and D2 leads to a high angle resolution. (The angle deviation is the difference of

both position deviations.) On the other hand, both detectors should be placed near by the

experiment. Therefore, a good compromise has to be found.

4.3.2 Setup 2: Second Mirror Acts as Beam Sampler

In the practical use it might be somewhat inconvenient to

use two beam samplers. We can use the second actuator

mirror as a beam sampler, because even very highly reflect-

ing mirrors will transmit a small amount of light. We only

need power in the order of some microwatts.

In this setup, detector D1 only observes the movement of

actuator A1. In fact, a movement of A2 will also cause a very

little beam movement at D1 due to beam shifting. However, this effect is negligible under

nearly all conditions. Detector D2, in contrast, observes a movement of A1 AND A2.

4.3.3 Problems with Beam Sampler Plates

A beam sampling glass plate (or a beam splitter cube), located in the main beam path, may

influence the beam quality, if the flatness, the transmission properties or the polishing is

non-perfect. High quality elements have to be used.

In most applications, beam sampler glass plates with parallel surfaces or beam splitter cubes

are NOT APPRECIATED:

D1 D2

A1

A2

D1

D1’ D1’

D2

A1

A2

Aligna® 4D User Manual

18 / 84

A glass plate may cause interference effects due to multiple reflections between surfaces.

Because of this effect, glass plates with a small angle (wedge plates) are preferred.

However, they cause a (very small) angle deviation from the original direction.

In femtosecond laser applications the glass in the beam path may cause unwanted disper-

sion effects.

However, the problem of interference will not appear with fs laser applications: A pulse of

50 fs, e.g., has an optical length of approx 15 microns. The optical path length difference

between both reflections of a 1 mm glass plate is 100 times longer! Therefore, both reflect-

ed pulses would not interfere. here it is not necessary to use plates with an angle.

In this case thin plates (1...2 mm) are preferred. In most applications, the dispersion effects

can then be neglected.

It is very important to mount the glass plates without mechanical stress to avoid birefrin-

gence and deforming of the surfaces. Note: The reflected beam will define the reference ax-

is for the pointing stabilization. Any movement of this reference beam will directly lead to

movements of the main beam! Thus, a very thin glass thickness of less than 1 mm is not

recommended.

An uncovered glass plate at 45° splits approx. 1% of the beam for one polarization direction

(p-light) and 12 % for the other polarization direction (s-light). Both values differ by more

than an order of magnitude, which leads to strong unwanted polarization dependence of the

test beam intensity.

In most applications both values (1% and 12%) lead to test beam intensities which are far

above the necessary intensities of some microwatt. These test beam intensities have to be

reduced by strong optical filters, and they are lost for the main beam.

With horizontally polarized laser light, it is possible to get very low reflection rates by using

a reflection angle of around Brewster’s angle, approx. 57°. This angle will be slightly more

difficult to align compared to a 45° angle.

One (or both) surfaces can be AR (anti-reflex coated) for the target wavelength at 45°

deflection. However, it is not easy (and thus not cheap) to get high quality broadband AR

coatings with well-defined reflection grades, while HR mirrors are more easy to get.

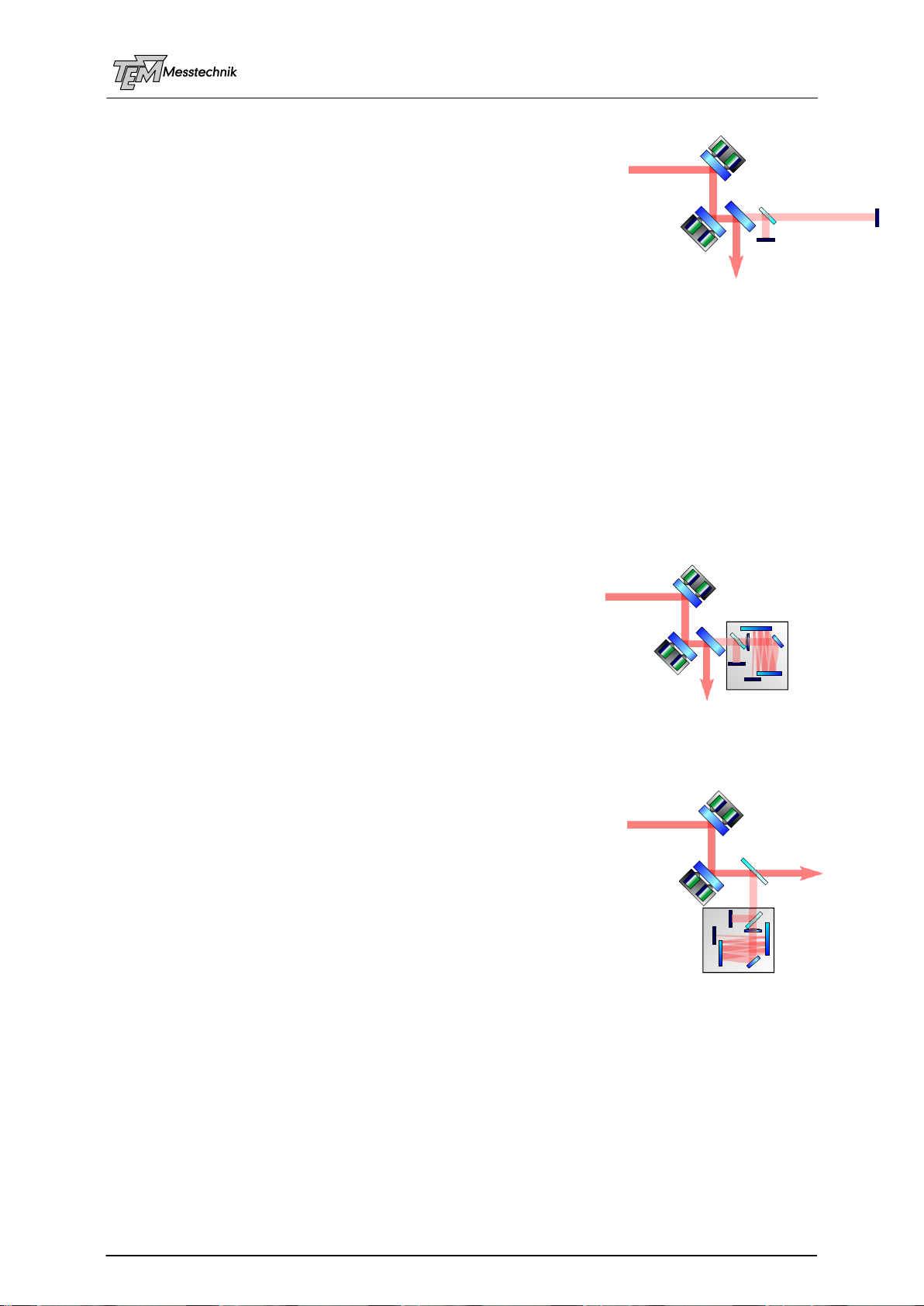

4.3.4 Setup 3: High Reflecting Mirror Acts as Beam Sampler

Because of these problems, it is usu-

ally better to use the transmission of a

HR (high reflecting) mirror as a beam

sampler. The transmissions are typi-

cally of the order of 1% down to

0.01%, which is by far enough in most

cases.

However, the polarization dependence of the transmitted beam can be

large. Especially high-bred mirrors for high-power or high energy fs pulse

lasers may have a polarization difference between s and p light by factor

of 100 or even 1000.

(Often HR mirrors for the target wavelength, in contrast to AR coated

substrates, are easier to get from stock.)

The distance between D1 and D2 defines the angle resolution.

In many applications, there are a lot of folding mirrors in the beam path.

One of the last mirrors before the experiment can be used as detection beam sampler for D2.

D1

D2

A1

A2

Aligna® 4D User Manual

19 / 84

4.3.5 Setup 4: Only One Beam Sampler Mirror

In a similar setup, a (nearly) non-polarizing 50% beam splitter

(plate or cube) is introduced behind a non-moved high reflecting

mirror, used for coupling out the test beam. This avoids the diffi-

culty of using the mirror at A2 both as mirror AND as beam sam-

pler. It leads to a smaller and more robust construction of A2. In

addition, it gives the advantage that the ratio of the intensities of

D1 and D2 only depends on the (known) properties of the detector

beam splitter, not on different transmissions of two HR mirrors.

Most of the problems with a beam sampler plate described before are not important here,

because the beam splitter is not located within the main beam path (dispersion, highest sur-

face quality and flatness, HQ AR coatings,...). Interference between surfaces has to be con-

sidered, as well.

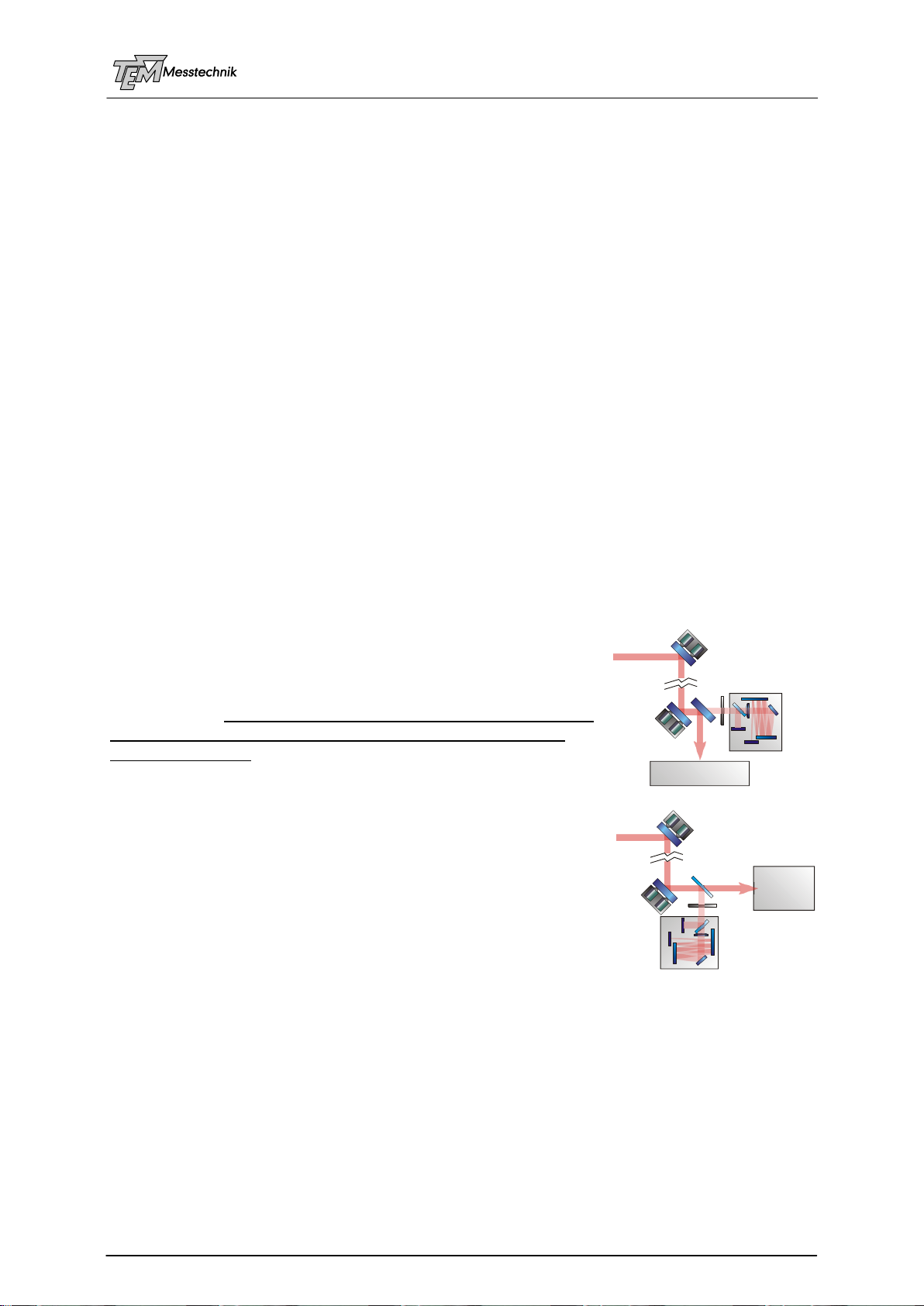

4.3.6 Setup 5: Compact 4D Sensor "PSD 4D"

The distance between D1 and D2 determines the angle resolution. The introduction of optical

elements can shrink down the necessary size of the detection setup:

1. A lens can create a far field image at the detector D2: If D2 is located in the focal plane of

a lens; the detector is imaged to infinity. This detector will not register a (parallel) transla-

tion of the beam at all, as the lens laws show. It only registers angle movements. Therefore,

this would be a pure angle detector, while detector D1 acts as a pure position detector.

However, at a given detector size the angle resolution will

increase with increasing the focal length. The optimum

resolution is reached, if the focused spot diameter has

nearly the detector size.

2. For getting a compact design the beam can be folded by

mirrors back and forth, which leads to a very compact 4D

detector, as realized in the "PSD 4D" detector box, which

has the dimensions of only 80 x 80 x 40 mm.

The sketched setup here is the mostly used one with Aligna®applications

4.3.7 Setup 6: "PSD 4D" with Beam Sampler

Wedge Plate

Of course it is also possible to use a glass beam sampler for the

creation of the test beam to be lead into PSD 4D. The setup

shown here is often used for testing purposes, because in many

cases no change of a pre-existing optical setup is necessary. It

has to be clarified that the beam sampler plate does not cause

problems (too high losses, dependence on polarization, disper-

sion, interference).

Excessively high intensities at the detector have to be handled

by optical filters.

D1

D2

A1

A2

D1 D2

PSD 4D

A1

A2

A1

A2

D1

D2

PSD 4D

Aligna® 4D User Manual

20 / 84

What is the Best Setup? Some Selection Rules

All of the described setups can be realized with the Aligna®4D (using PSD 2D or PSD 4D,

different types of beam samplers). The user may decide which fits best to his application.

However, there are some rules for selection:

4.3.8 Distance between A1 and A2

The distance between A1 and A2 defines the possible compensation of the beam translation

movement, while the possible rotation movement is independent on this distance.

Of course, in most cases a small and compact design is appreciated. What are the criteria?

If there is a large distance between the laser and the experiment, even small angle move-

ments are translated into large transversal movements. In these cases, a large distance be-

tween the mirrors A1 and A2 is recommended. If the distance from the laser to the experiment

is many meters, the optical path distance A1 to A2 should be 50 cm or more.

The standard actuators BeamScan 2D can move the mirror by an angle range of 2.3 mrad in

X and Y direction. That means with a distance between A1 and A2 of 1 meter a beam dis-

placement of up to over ± 2 mm can be compensated. This is quite sufficient for most applica-

tions.

One mm or more will only be necessary with very long laser beam distances of over 5…10

meters, depending on environmental properties, or with the use of delay lines and other mov-

ing optics. In fact, it is not easy and takes some time to align a delay line to much better than

some 100 microns of beam shift (depending on the moved rail length of course).

4.3.9 Position of the Detector(s)

The 4D detection should be located close to the experiment,

because only disturbances in the path BEFORE the detector can

be detected, and thus can be eliminated.

Even if a large variety of positions and distances can be handled

by Aligna®4D the best position of the 4D detector (or the first of

the two PSD 2Ds) is as close as possible behind the second

actuator mirror A2. (Of course, the necessary beam sam-

plers/mirrors and maybe filters for adjusting the detection beam

power have to be between A2 and the detector.)

In this case, the four servo loops can mostly be separated from

each other. This leads to a more stable and robust locking be-

havior.

D1 D2

PSD 4D

Experiment

Experi-

ment

A1

A1

A2

A2

Filter

Filter

D1

D2 PSD 4D

Table of contents

Other TEM Industrial Equipment manuals