µAligna Manual

5 Advanced Operation

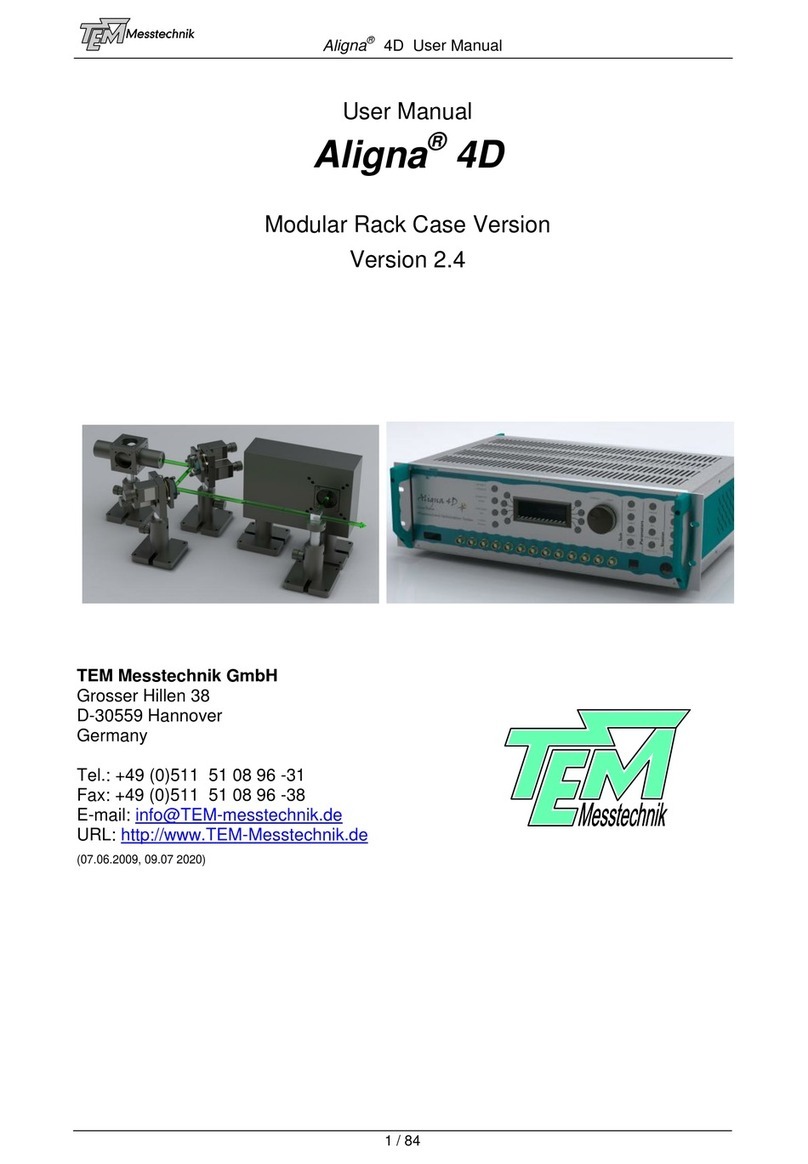

5.1 PSD

The detector delivered with a µAligna system measures the beam pointing in four dimensions,

namely beam angle (Axand Ay) and beam position (Bxand By). To this end, it contains two

separate detector chips, Aand B. In addition to these four pointing values, the detector measures

the intensities at both chips, labelled SumAand SumB. These are used for normalization of the

pointing signals, i.e., to make them independent of intensity fluctuations. The sum signals also

indicate whether the laser hits both detector chips, and they allow the PSD-4D to be used to

monitor the optical power. The detector returns its signals in the form of analog voltages to the

µAligna electronics, with ranges of ±10 V for the pointing signals and 0−10 V for the sum signals.

These signals can be monitored on an oscilloscope without disturbing the normal operation of the

system (use the add-on “Aligna Con”, which breaks out the signals to BNC connectors).

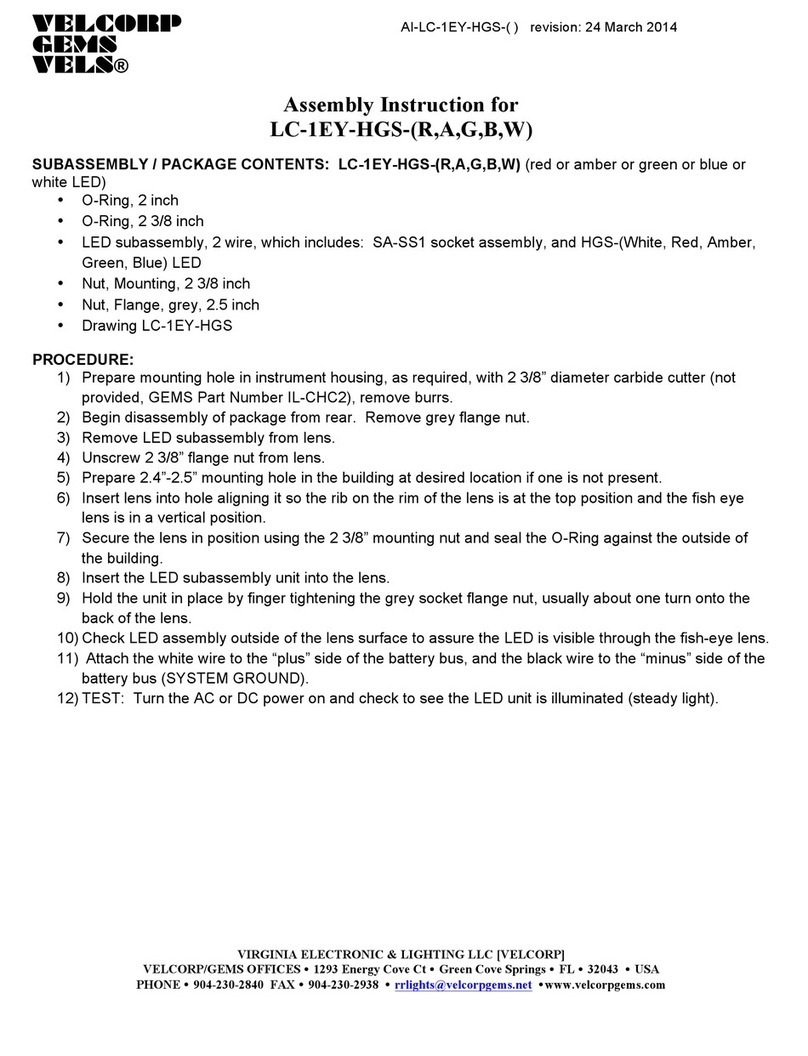

5.1.1 Beam Sampling

In almost all applications, the PSD-4D is placed behind a beam sampler which splits a sample beam

off the main beam. The sample beam then enters the PSD-4D and the main beam continues to

the target. The optical power required for good detector signals is about 100

µ

W for the visible

spectrum and about 500

µ

W for near UV (say 355 nm) and near IR (say 1064 nm).

Clearly, for the Aligna system to work well, the sample beam’s pointing must be a faithful rep-

resentation of the main beam’s pointing. Large intensity fluctuations in the sample beam can be

mis-interpreted as pointing drifts by the Aligna system. Therefore, the beam sampling is crucial to

the performance. In most applications, beam sampler glass plates with parallel surfaces or beam

splitter cubes are not recommended, since they can suffer from interference effects. It is also very

important to mount the glass plates without mechanical stress to avoid birefringence and deforma-

tion of the surfaces. Similarly, very thin glass plates (less than 1mm) are not recommended. The

following general points should be observed:

A beam sampling glass plate or beam splitter cube located in the main beam path may influence

the beam quality if the flatness, the transmission properties or the polishing is non-perfect.

High-quality elements have to be used.

A glass plate may cause interference effects due to multiple reflections between surfaces. Glass

plates with a small angle (wedge plates) are preferred. However, they cause an angle deviation

in the main beam.

In femto-second laser applications, the glass in the beam path may cause unwanted dispersion

effects. However, the problem of interference will not appear with fs laser applications, since

the pulses are too short to interfere with reflected (and therefore delayed) pulses. Here it is

not necessary to use wedge plates. In this case thin plates (1...2mm) are preferred. In most

applications, dispersion effects can then be neglected.

An uncoated glass plate at 45◦splits approximately 1% of the beam for one polarization

direction (p-light) and 8 % for the other polarization direction (s-light). These values differ

by nearly one order of magnitude, which leads to a strong unwanted polarization dependence

of the test beam intensity.

µAligna Manual

February 19, 2020 17 / 34