Tempco TEC-4100 User manual

Instruction Manual

TEC-4100 / 7100 / 8100 / 9100

Auto-Tune Fuzzy / PID Process

Temperature Controller

Manual TEC-100 evision 9/2013

Agency Approvals

TEMPCO Electric Heater Corporation

607 N. Central Avenue • Wood Dale, IL 60191-1452 USA

Tel: 630-350-2252 • Toll Free: 800-323-6859

Fax: 630-350-0232 • E-mail: [email protected]

Web: www.tempco.com

Serving Industry Since 1972

NOTES

Using the Manual

Installers . . . . . . . . . . . . . . . . . . . . . . . . . . . Read Chapter 1, 2

System Designer . . . . . . . . . . . . . . . . . . . . . Read All Chapters

xpert User . . . . . . . . . . . . . . . . . . . . . . . . . Read Page 11

OTE:

It is strongly recommended that a process should incorporate

a LIMIT CONTROL such as the TEC-910 which will shut

down the equipment at a preset process condition in order to

preclude possible damage to products or system.

Information in this user's manual is subject to change without

notice.

Copyright © 2012, Tempco lectric Heater Corporation, all

rights reserved. No part of this publication may be reproduced,

transmitted, transcribed or stored in a retrieval system, or trans-

lated into any language in any form by any means without the

written permission of Tempco lectric Heater Corporation.

CO TE TS

age No

Chapter 1 Overview

1-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Ordering Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Programming Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4 Keys and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-5 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-6 Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 Installation

2-1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-5 Sensor Installation Guidelines . . . . . . . . . . . . . . . . . . . 9

2-6 Sensor Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-7 Control Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-8 Alarm Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-9 Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3 Programming

3-1 Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-2 Signal Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-3 Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-4 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-5 Configuring User Menu . . . . . . . . . . . . . . . . . . . . . . . 15

3-6 Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-7 Dwell Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-8 PV Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-9 Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-10 Failure Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-11 Auto-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-12 Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-13 Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-14 Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-15 Process Variable (PV) Retransmission. . . . . . . . . . . . 18

Chapter 4 Applications

4-1 Heat Only Control With Dwell Timer . . . . . . . . . . . . . 19

4-2 Cool Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-3 Heat-Cool Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 5 Calibration . . . . . . . . . . . . . . . 21

Chapter 6 Specifications . . . . . . . . . . . 23

Chapter 7 Modbus Comm. . . . . . . . . . . 25

7-1 Functions Supported . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7-2 xception Responses . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7-3 Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7-4 Data Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7-5 Communication xample . . . . . . . . . . . . . . . . . . . . . . . 29

Appendix

A-1 rror Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

A-2 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

FIGURES & TABLES

age No

Figure 1.1 Fuzzy Control Advantage. . . . . . . . . . . . . . . . . . 1

Figure 1.2 Programming Port Overview . . . . . . . . . . . . . . . 3

Figure 1.3 Front Panel Description . . . . . . . . . . . . . . . . . . 3

Figure 1.4 Display during Power UP . . . . . . . . . . . . . . . . . 3

Figure 2.1 Mounting Dimensions . . . . . . . . . . . . . . . . . . . . 7

Figure 2.2 Lead Termination for T C-4100,

T C-8100 and T C-7100 . . . . . . . . . . . . . . . . . 8

Figure 2.3 Lead Termination for T C-9100 . . . . . . . . . . . . 8

Figure 2.4 Rear Terminal Connection for

T C-4100 and T C-8100 . . . . . . . . . . . . . . . . . 8

Figure 2.5 Rear Terminal Connection for T C-7100 . . . . . 8

Figure 2.6 Rear Terminal Connection for T C-9100 . . . . . 8

Figure 2.7 Power Supply Connections . . . . . . . . . . . . . . . . 9

Figure 2.8 Sensor Input Wiring . . . . . . . . . . . . . . . . . . . . . 9

Figure 2.9 Output 1 Relay or Triac (SSR) to

Drive Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2.10 Output 1 Relay or Triac (SSR) to

Drive Contactor . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2.11 Output 1 Pulsed Voltage to Drive SSR . . . . . 10

Figure 2.12 Output 1 Linear Current . . . . . . . . . . . . . . . . . 10

Figure 2.13 Output 1 Linear Voltage . . . . . . . . . . . . . . . . . 10

Figure 2.14 Output 2 Relay or Triac (SSR) to

Drive Load . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2.15 Output 2 Relay or Triac (SSR) to

Drive Contactor . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2.16 Output 2 Pulsed Voltage to Drive SSR . . . . . . 10

Figure 2.17 Output 2 Linear Current . . . . . . . . . . . . . . . . . 10

Figure 2.18 Output 2 Linear Voltage . . . . . . . . . . . . . . . . . 10

Figure 2.19 Alarm Output to Drive Load . . . . . . . . . . . . . 11

Figure 2.20 Alarm Output to Drive Contactor . . . . . . . . . . 11

Figure 2.20.1 Dwell Timer Function . . . . . . . . . . . . . . . . . 11

Figure 2.21 RS-485 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2.22 RS-232 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2.23 Configuration of RS-232 Cable . . . . . . . . . . . 11

Figure 3.1 Conversion Curve for Linear Type

Process Value . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 3.2 Heat Only ON-OFF Control . . . . . . . . . . . . . . . 13

Figure 3.3 Output 2 Deviation High Alarm . . . . . . . . . . . . 14

Figure 3.4 Output 2 Process Low Alarm . . . . . . . . . . . . . . 14

Figure 3.5 RAMP Function . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3.6 Dwell Timer Function . . . . . . . . . . . . . . . . . . . . 15

Figure 3.7 PV Shift Application . . . . . . . . . . . . . . . . . . . . . 16

Figure 3.8 Filter Characteristics . . . . . . . . . . . . . . . . . . . . . 16

Figure 3.9 ffects of PID Adjustment . . . . . . . . . . . . . . . . 17

Figure 4.1 Heating Control xample . . . . . . . . . . . . . . . . . 19

Figure 4.2 Cooling Control xample . . . . . . . . . . . . . . . . . 19

Figure 4.3 Heat-Cool Control xample . . . . . . . . . . . . . . . 20

Figure 5.1 RTD Calibration . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5.2 Cold Junction Calibration Setup . . . . . . . . . . . . 22

Table 1.1 Display Form of Characters . . . . . . . . . . . . . . . . 3

Table 3.1 Heat-Cool Control Setup Value . . . . . . . . . . . . . 12

Table 3.2 PID Adjustment Guide . . . . . . . . . . . . . . . . . . . . 17

Table A.1 rror Codes and Corrective Actions . . . . . . . . . 30

NOTES

1

1–1 General

Tempco’s T C-x100 Series Fuzzy Logic plus PID microproces-

sor-based controllers incorporate two bright easy to read 4-digit

LD displays, indicating process value and set point value. The

process value (PV) display is always the top digital display. The

setpoint (SV) display is always the bottom display. Fuzzy Logic

technology enables a process to reach a predetermined set point

in the shortest time with a minimum of overshoot during power-

up or external load disturbance.

T C-9100 is a 1/16 DIN size panel mount controller. T C-7100

is a 72×72 DIN size panel mount controller. T C-8100 is a 1/8

DIN size panel mount controller and T C-4100 is a 1/4 DIN size

panel mount controller. These units are powered by 11–26 or

90–250 VDC/VAC 50/60 Hz supply, incorporating a 2 amp con-

trol relay output as standard. The second output can be used as a

cooling control or an alarm. Both outputs can select triac, 5V

logic output, linear current, or linear voltage to drive an external

device. There are six types of alarm plus a dwell timer that can

be configured for the third output. The units are fully program-

mable for PT100 RTD and thermocouple types J, K, T, , B, R,

S, N, and L with no need to modify the unit. The input signal is

digitized by using an 18-bit A to D converter. Its fast sampling

rate allows the unit to control fast processes.

Digital communications RS-485 or RS-232 (excluding T C-

7100) are available as an additional option. These options allow

the units to be integrated with supervisory control systems and

software.

A programming port is available for automatic configuration,

calibration, and testing without the need to access the keys on the

front panel.

By using proprietary Fuzzy modified PID technology, the con-

trol loop will minimize overshoot and undershoot in a short time.

The following diagram is a comparison of results with and with-

out Fuzzy technology.

High accuracy

This series is manufactured with custom

designed ASIC (Application Specific

Integrated Circuit) technology which

contains an 18-bit A to D converter for

high resolution measurement (true 0.1°F

resolution for thermocouple and PT100)

and a 15-bit D to A converter for linear

current or voltage control output. The

ASIC technology provides improved

operating performance, low cost,

enhanced reliability and higher density.

Fast sampling rate

The sampling rate of the input A to D

converter is 5 times/second. The fast

sampling rate allows this series to control

fast processes.

Fuzzy control

The function of Fuzzy control is to adjust

PID parameters from time to time in

order to make manipulation of the output

value more flexible and adaptive to vari-

ous processes. The result is to enable a

process to reach a predetermined set point

in the shortest time, with the minimum of

overshoot and undershoot during power-

up or external load disturbance.

Digital communication

The units are equipped with an optional

RS-485 or RS-232 interface cards to pro-

vide digital communication. By using

twisted pair wires, up to 247 units can be

connected together via RS-485 interface

to a host computer.

Programming port

A programming port can be used to con-

nect the unit to a PC for quick configura-

tion. It also can be connected to an AT

system for automatic testing and calibra-

tion.

Auto-tune

The auto-tune function allows the user to

simplify initial setup for a new system.

An advanced algorithm is used to obtain

an optimal set of control parameters for

the process, and it can be applied either as

the process is warming up (cold start) or

when the process is in a steady state

(warm start).

Lockout protection

Depending on security requirements, one

of four lockout levels can be selected to

prevent the unit from being changed

without permission.

Bumpless transfer

Bumpless transfer allows the controller to

continue to control if the sensor breaks by

using its previous value. Hence, the

process can be controlled temporarily as

if the sensor is normal.

Soft-start ramp

The ramping function is performed dur-

ing power up as well as any time the set

point is changed. It can be ramping up or

ramping down. The process value will

reach the set point at a predetermined

constant rate.

Digital filter

A first order low pass filter with a pro-

grammable time constant is used to

improve the stability of the process value.

This is particularly useful in certain

applications where the process value is

too unstable to be read.

SEL function

The units have the flexibility to allow the

user to select those parameters which are

most significant to him and put these

parameters in the front of the display

sequence. Up to eight parameters can be

selected to allow the user to build his own

display sequence.

Chapter 1 Overview

Figure 1.1 Fuzzy Control Advantage

2

1–2 Ordering Code

Data Communication Accessories:

TEC99001 Smart Network Adapter for third party SCADA software

which converts 255 channels of RS-485 or RS-422 to RS-

232 Network.

TEC99003 Smart Network Adapter for connecting the programming

port to the RS-232 PC serial port. Allows downloading and

reading of configuration information directly from a person-

al computer. Can be used with T C-4100, T C-7100, T C-

8100 and T C-9100.

TEC99030 "Tempco Config Set" PC software for use with T C99003

Smart Network Adapter. (can be downloaded at no charge

from www.tempco.com)

Minimum System Requirements:

Microsoft Windows 2000, 98, 95, NT4.0

Pentium 200 MHz or faster

32 MB RAM (64 MB recommended)

Hard disk space: 2 MB

TEC99011 Programming port cable for T C-4100, T C-7100, T C-

8100 and T C-9100. Connects the controller to the

T C99003 Smart Network Adapter.

Power Input

4 = 90-250 VAC

5 = 11-26 VAC/VDC

9 = Other

Signal Input

Universal, can be

programmed in the field

for item 5 or 6

5 = TC: *J,K,T, ,B,R,S,N,L

0-60 mV

6 = RTD: *PT100 DIN,

PT100 JIS

7 = 0-1 VDC

8 = *0-5, 1-5 VDC

A = 0-10 VDC

B = *4-20, 0-20 mA

9 = Other

*indicates default value

Output 1

1 = Relay: 2A/240 VAC

2 = Pulse dc for SSR drive:

5 Vdc (30 mA max)

3 = Isolated, 4-20 mA (default)

0-20 mA

4 = Isolated, VDC, 1-5 (default)

0-5, 0-1

5 = Isolated, VDC, 0-10

6 = Triac-SSR output

1A/240 VAC

C = Pulse dc for SSR drive:

14 Vdc (40 mA max)

9 = Other

Output 2

0 = None

1 = Relay: 2A / 240 VAC

2 = Pulse dc for SSR drive: 5 Vdc (30 mA max)

3 = Isolated, 4-20 mA (default), 0-20 mA

4 = Isolated VDC, 1-5 (default), 0-5, 0-1

5 = Isolated VDC, 0-10

6 = Triac-SSR output 1A / 240 VAC

7 = Isolated 20V @ 25 mA DC, Output Power Supply

8 = Isolated 12V @ 40 mA DC, Output Power Supply

9 = Isolated 5V @ 80 mA DC, Output Power Supply

C = Pulse dc for SSR drive: 14 VDC (40 mA max)

A = Other

Power Input

4 = 90-250 VAC

5 = 11-26 VAC/VDC

9 = Other

Signal Input

Universal, can be programmed in the field

for item 5 or 6

5 = TC: *J,K,T, ,B,R,S,N,L 0-60mV

6 = RTD: *PT100 DIN, PT100 JIS

7 = 0-1 Vdc

8 = *0-5, 1-5 VDC

A = 0-10 VDC

B = *4-20, 0-20 mA

9 = Other

*indicates default value

Output 1

1 = Relay: 2A / 240 VAC

2 = Pulse dc for SSR drive: 5 VDC (30 mA max)

3 = Isolated, 4-20 mA (default), 0-20 mA

4 = Isolated, VDC, 1-5 (default), 0-5, 0-1

5 = Isolated, VDC, 0-10

6 = Triac-SSR output 1A/240 VAC

C = Pulse dc for SSR drive:14 VDC (40 mA max)

9 = Other

Output 2

0 = None

1 = Relay: 2A/240 VAC

2 = Pulse dc for SSR drive: 5 VDC (30 mA max)

3 = Isolated, 4-20 mA (default), 0-20 mA

4 = Isolated VDC, 1-5 (default), 0-5, 0-1

5 = Isolated VDC, 0-10

6 = Triac-SSR output 1A/240 Vac

7 = Isolated 20V @ 25 mA DC, Output Power Supply

8 = Isolated 12V @ 40 mA DC, Output Power Supply

9 = Isolated 5V @ 80 mA DC, Output Power Supply

C = Pulse dc for SSR drive: 14 VDC (40 mA max)

A = Other

Alarm

0 = None

1 = Relay: 2A / 240 VAC, SPDT

9 = Other

Communication

0 = None

1 = RS-485 Interface

2 = RS-232 Interface

3 = Retransmission 4-20 mA (default), 0-20 mA

4 = Retransmission 1-5 VDC (default), 0-5 VDC

5 = Retransmission 0-10 VDC

9 = Other

Case Options

0 = Panel mount standard

1 = Panel mount with N MA 4X/IP65 front panel

2 = DIN rail mount

Alarm

0 = None

1 = Relay: 2A/240 VAC,

SPDT

9 = Other

Communication

0 = None

1 = RS-485 Interface

2 = RS-232 Interface

(not available for T C-7100)

3 = Retransmission 4-20 mA

(default), 0-20 mA

4 = Retransmission 1-5 Vdc

(default), 0-5 VDC

5 = Retransmission 0-10 VDC

9 = Other

NEMA 4X / IP65

0 = No

1 = Yes

TEC-4100-

TEC-7100-

TEC-8100-

TEC-9100-

3

1–4 Keys and Displays

EYPAD OPERATION

SCROLL EY:

This key is used to select a parameter to be viewed or adjusted.

UP EY:

This key is used to increase the value of the selected parameter.

DOWN EY:

This key is used to decrease the value of the selected parameter.

RESET EY:

This key is used to:

1. Revert the display to show the process value.

2. Reset the latching alarm, once the alarm condition is removed.

3. Stop the manual control mode, auto-tuning mode, and calibra-

tion mode.

4. Clear the message of communication error and auto-tuning

error.

5. Restart the dwell timer when the dwell timer has timed out.

6. nter the manual control menu when in failure mode.

ENTER EY: Press for 5 seconds or longer.

Press for 5 seconds to:

1. nter setup menu. The display shows .

2. nter manual control mode—when manual control mode

is selected.

3. nter auto-tuning mode—when auto-tuning mode is

selected.

4. Perform calibration to a selected parameter during the calibra-

tion procedure.

Press for 6.2 seconds to select manual control mode.

Press for 7.4 seconds to select auto-tuning mode.

Press for 8.6 seconds to select calibration mode.

R

The T C99011 cable and T C99003

network adapter can be used to con-

nect the programming port to a PC

for automatic configuration.

The programming port is used for

off-line automatic setup and testing

procedures only. Don't attempt to

make any connection to these pins

when the unit is used for a normal

control purpose.

1–3 Programming Port

Table 1.1 Display Form of Characters

Display program code of the product for

2.5 seconds.

The left diagram shows program number 6

for T C-9100 with version 12.

The program no. for T C-7100 is 13, for

T C-8100 is 11 and for T C-4100 is 12.

4

1–5 Menu Overview

5

1–6 Parameter Descriptions

Continued…

6

Parameter Descriptions, Continued…

7

Dangerous voltages capable of causing death are some-

times present in this instrument. Before installation or

beginning any troubleshooting procedures, the power to all

equipment must be switched off and isolated. Units suspected of

being faulty must be disconnected and removed to a properly

equipped workshop for testing and repair. Component replace-

ment and internal adjustments must be made by a qualified main-

tenance person only.

This instrument is protected throughout by double insula-

tion to minimize the possibility of fire or shock hazards,

do not expose this instrument to rain or excessive moisture.

Do not use this instrument in areas under hazardous con-

ditions such as excessive shock, vibration, dirt, moisture,

corrosive gases or oil. This control is not to be used in hazardous

locations as defined in Articles 500 and 505 of the National

lectrical Code. The ambient temperature of the area should not

exceed 122°F.

Remove stains from this instrument using a soft, dry

cloth. To avoid deformation or discoloration do not use

harsh chemicals, volatile solvent such as thinner, or strong deter-

gents to clean this instrument.

2–1 Unpacking

Upon receipt of the shipment, remove the unit from the carton

and inspect the unit for shipping damage.

If there is any damage due to transit, report it and file a claim

with the carrier. Write down the model number, serial number,

and date code for future reference when corresponding with

Tempco. The serial number (S/N) and date code (D/C) are

labeled on the box and the housing of the control.

2–2 Mounting

Remove mounting clamps or screws and insert the controller into

the panel cutout. Reinstall the mounting clamps or screws.

Gently tighten the screws or clamp until the front panel of the

controller fits snugly in the cutout.

Figure 2.1 Mounting Dimensions

Chapter 2 Installation

NOT :

The T C-9100 Series may be supplied with either mounting

screws (2) or mounting clamps (2). The mounting clamps

are the newer type.

In clamp mounting, to remove the clamps before installation

lift under one of the edges and pull up (un-peel). To install

just snap back on and push the clamps towards the front of

the control until they are snug.

8

Before wiring, verify the correct model

number and options on the label. Switch

off the power while checking.

Care must be taken to ensure that the

maximum voltage rating specified on

the label is not exceeded.

It is recommended that the power for

these units be protected by fuses or cir-

cuit breakers rated at the minimum

value possible.

All units should be installed inside a

suitably grounded metal enclosure to

prevent live parts from being accessible

to human hands and metal tools.

All wiring must conform to appropriate

standards of good practice and local

codes and regulations. Wiring must be

suitable for the voltage, current, and

temperature rating of the system.

Beware not to over-tighten the terminal

screws. The torque should not exceed

1 n-m (8.9 in-lb.)

Unused control terminals should not be

used as jumper points as they may be

internally connected, causing damage

to the unit.

Verify that the ratings of the output

devices and the inputs as specified in

chapter 6 are not exceeded.

xcept for the thermocouple wiring, all

wiring should be stranded copper with a

maximum gauge of 18 awg.

2–3 Wiring Precautions

*Or low voltage (11-26 VAC/VDC) when ordered as specified. Non-polarized.

NOTE: ASTM thermocouples (American) the

red colored lead is always negative.

II

9

Proper sensor installation can eliminate many problems in a con-

trol system. The probe should be placed so that it can detect any

temperature change with minimal thermal lag. In a process that

requires fairly constant heat output, the probe should be placed

close to the heater. In a process where the heat demand is variable,

the probe should be close to the work area. Some experimentation

with probe location is often required to find the optimum position.

In a liquid process, the addition of agitation will help to eliminate

thermal lag. Since the thermocouple is basically a point measuring

device, placing more than one thermocouple in parallel can provide

an average temperature readout and produce better results in

most air heated processes.

Proper sensor type is also a very important factor in obtaining

precise measurements. The sensor must have the correct temper-

ature range to meet the process requirements. In special processes,

the sensor might have requirements such as leak-proof, anti-

vibration, antiseptic, etc.

Standard sensor limits of error are ±4°F (±2°C) or 0.75% of the

sensed temperature (half that for special) plus drift caused by

improper protection or an over-temperature occurrence. This

error is far greater than controller error and cannot be corrected

on the sensor except by proper selection and replacement.

Note: A 2-wire RTD temperature sensor can be used if a short is

placed across the “B” terminals.

xample: For a T C-9100 Controller, connect the 2-wire RTD to

terminals 4 & 5, and a short across terminals 5 & 6.

The controller is designed to operate at 11–26 VAC/VDC or

90–250 VAC. Check that the installation voltage corresponds to

the power rating indicated on the product label before connect-

ing power to the controller. The controller power input should be

equipped with a fuse and switch as shown below in figure 2.7

This equipment is designed for installation in an enclo-

sure which provides adequate protection against electric

shock. The enclosure must be connected to earth ground.

Local requirements regarding electrical installation should be

rigidly observed. Consideration should be given to prevent unau-

thorized personnel from accessing the power terminals.

2–4 Power Wiring

2–5 Sensor Installation Guidelines

2–6 Sensor Input Wiring 2–7 Control Output Wiring

Control Output Wiring, continued…

10

Control Output Wiring, continued…

11

2–9 Data Communication

2–8 Alarm Wiring

If you use a conventional 9-pin RS-232 cable instead

of T C 99014, the cable must be modified according

to the following circuit diagram.

12

Chapter 3 Programming

Press for 5 seconds and release to enter the setup menu.

Press to select the desired parameter. The upper display indi-

cates the parameter symbol, and the lower display indicates the

selected value of the parameter.

3–1 Lockout

There are four security levels that can be selected using the

LOCK parameter.

If NONE is selected for LOCK, then no parameter is locked.

If SET is selected for LOCK, then all setup data are locked.

If USER is selected for LOCK, then all setup data as well as

user data (refer to section 1-5) except the set point are

locked to prevent them from being changed.

If ALL is selected for LOCK, then all parameters are locked to

prevent them from being changed.

3–2 Signal Input

IN T: Selects the sensor type or signal type for signal input.

Range: (thermocouple) J-TC, K-TC, T-TC, -TC, B-TC,

R-TC, S-TC, N-TC, L-TC

(RTD) PT.DN, PT.JS

(Linear) 4–20mA, 0–20mA, 0–60mV, 0–1VDC,

0–5VDC, 1–5VDC, 0–10VDC

UNIT: Selects the process unit

Range: °C, °F, PU (process unit). If the unit is set for nei-

ther °C nor °F, then it defaults to PU.

D : Selects the resolution of process value.

Range: (For T/C and RTD) NO.DP, 1-DP

(For linear) NO.DP, 1-DP, 2-DP, 3-DP

INLO: Selects the low scale value for the linear type input.

INHI: Selects the high scale value for the linear type input.

How to use the conversion curve for linear type

process values, INLO and INHI;

If 4–20mA is selected for INPT, SL specifies the input signal low

(i.e., 4mA), SH specifies the input signal high (i.e., 20mA), S

specifies the current input signal value, and the conversion curve

of the process value is shown as follows:

3–3 Control Outputs

There are four kinds of control modes that can be configured as shown in table 3.1.

SL = Setpoint Low Limit SH = Setpoint High Limit

Table 3.1 Heat-Cool Control Setup Value

Figure 3.1

Conversion Curve

for Linear Type

Process Value

13

The ON-OFF control may introduce excessive process oscillation

even if hysteresis is minimized. If ON-OFF control is set (i.e.,

PB=0), TI, TD, CYC1, OFST, CYC2, CPB, and DB will be hid-

den and have no function in the system. The auto-tuning and

bumpless transfer functions will be disabled as well.

Heat only (or D) control: Select R VR for OUT1, set TI to

0. OFST is used to adjust the control offset (manual reset). O1HY

is hidden if PB is not equal to 0. OFST function: OFST is meas-

ured by % with a range of 0–100.0%. In the steady state (i.e.,

process has been stabilized), if the process value is lower than the

set point by a definite value, say 5°C, while 20°C is used for PB,

that is lower by 25%, then increase OFST 25%, and vice-versa.

After adjusting OFST value, the process value will be varied and

eventually coincide with set point.

Refer to section 3-12 “manual tuning” for the adjustment of PB

and TD. Manual reset (adjust OFST) is not practical because the

load may change from time to time and OFST may need to be

adjusted repeatedly. PID control can avoid this situation.

Heat only ID control: If R VR is selected for OUT1, PB and

TI should not be zero. Perform auto-tuning for the new process,

or set PB, TI, and TD with historical values. See section 3-11 for

auto-tuning operation. If the control result is still unsatisfactory,

then use manual tuning to improve control. See section 3-12 for

manual tuning. The unit contains a very advanced PID and Fuzzy

Logic algorithm to create a very small overshoot and very quick

response to the process if it is properly tuned.

Control Outputs, continued…

Heat only ON-OFF control: Select R VR for OUT1. Set PB

(proportional band) to 0. O1HY is used to adjust dead band for

ON-OFF control. The output 1 hysteresis (O1HY) is enabled

in case PB=0. The heat only on-off control function is shown

in the following diagram:

3.3 & 3.4 Alarm Figures, next page…

Cool only control: ON-OFF control, P (PD) control, and PID

control can be used for cool control. Set OUT1 to DIRT (direct

action). The other functions for cool only ON-OFF control,

cool only P (PD) control, and cool only PID control are the

same as for heat only control except that the output variable

(and action) for cool control is inverse to heat control.

NOTE: ON-OFF control may result in excessive overshoot and

undershoot problems in the process. P (or PD) control will

result in a deviation of process value from the set point. It is

recommended to use PID control for heat-cool control to produce

a stable and zero offset process value.

Other setup required: O1TY, CYC1, O2TY, CYC2, O1FT

and O2FT are set in accordance with the types of OUT1 and

OUT2 installed. CYC1 and CYC2 are selected according to the

output 1 type (O1TY) and output 2 type (O2TY). Generally,

select 0.5~2 seconds for CYC1 if SSRD or SSR is used for

O1TY; 10~20 seconds if relay is used for O1TY. CYC1 is

ignored if a linear output is used. Similar conditions are applied

for CYC2 selection.

You can use the auto-tuning program for the new process or

directly set the appropriate values for PB, TI, and TD accord-

ing to historical records for the repeated systems. If the control

behavior is still inadequate, use manual tuning to improve the

control. See section 3-12 for manual tuning.

C B (Cooling roportional Band) rogramming: The cool-

ing proportional band is measured by % of PB with a range of

50-300. Initially set 100% for CPB and examine the cooling

effect. If the cooling action should be enhanced, then decrease

CPB, if the cooling action is too strong, then increase CPB. The

value of CPB is related to PB and its value remains unchanged

throughout the auto-tuning procedures.

Adjustment of CPB is related to the cooling medium used. If air

is used as the cooling medium, adjust CPB to 100%. If oil is

used as the cooling medium, adjust CPB to 125%. If water is

used as the cooling medium, adjust CPB to 250%.

DB (Heating-Cooling Dead Band) rogramming: The

adjustment of DB is dependent on the system requirements. If

a more positive value of DB (greater dead band) is used, an

unwanted cooling action can be avoided but an excessive over-

shoot over the set point will occur. If a more negative value of

DB (greater overlap) is used, an excessive overshoot over the

set point can be minimized, but an unwanted cooling action will

occur. It is adjustable in the range -36.0% to 36.0% of PB. A

negative DB value shows an overlap area over which both out-

puts are active. A positive DB value shows a dead band area

over which neither output is active.

Output 2 ON-OFF control (alarm function): Output 2 can

also be configured with an alarm function. There are four kinds

of alarm functions that can be selected for output 2. These are:

D .HI (deviation high alarm), D .LO (deviation low alarm),

PV.HI (process high alarm), and PV.LO (process low alarm).

Refer to figure 3.3 and figure 3.4 for descriptions of the devia-

tion alarm and the process alarm.

14

3.3 & 3.4 Alarm Figures 3–4 Alarm

The controller has one alarm output. There are six types of

alarm functions and one dwell timer that can be selected, and

four kinds of alarm modes (ALMD) are available for each

alarm function (ALFN). Output 2 can be configured as

another alarm in addition to the alarm output. But output 2

only provides four kinds of alarm functions and only normal

alarm mode is available for this alarm. When output 2 is used

as an alarm, SP2 sets the trigger point. SP3 sets the trigger

point for Alarm.

A process alarm sets absolute trigger levels. When the

process is higher than SP3, a process high alarm (PV.HI)

occurs, and the alarm is off when the process is lower than

SP3-ALHY. When the process is lower than SP3, a process

low alarm (PV.LO) occurs, and the alarm is off when the

process is higher than SP3+ALHY. A process alarm is inde-

pendent of the set point.

A deviation alarm alerts the user when the process deviates

from the set point. When the process is higher than SV+SP3,

a deviation high alarm (D .HI) occurs, and the alarm is off

when the process is lower than SV+SP3-ALHY. When the

process is lower than SV+SP3, a deviation low alarm

(D .LO) occurs, and the alarm is off when the process is

higher than SV+SP3+ALHY. The trigger level of the devia-

tion alarm moves with the set point.

A deviation band alarm presets two trigger levels relative to

the set point. The two trigger levels are SV+SP3 and SV-SP3

for alarm. When the process is higher than (SV+SP3) or

lower than (SV-SP3), a deviation band high alarm (DB.HI)

occurs. When the process is within the trigger levels, a devi-

ation band low alarm (DB.LO) occurs.

There are four types of alarm modes available for each alarm

function. These are: normal alarm, latching alarm, holding

alarm and latching/holding alarm. They are described as fol-

lows:

Normal alarm: ALMD=NORM

When a normal alarm is selected, the alarm output is de-ener-

gized in the non-alarm condition and energized in an alarm

condition.

Latching alarm: ALMD=LTCH

If a latching alarm is selected, once the alarm output is ener-

gized, it will remain unchanged even if the alarm condition

is cleared. The latching alarm is reset when the R S T key

is pressed after the alarm condition is removed.

Holding alarm: ALMD=HOLD

A holding alarm prevents an alarm when the control is pow-

ering up. The alarm is enabled only when the process reach-

es the set point value. Afterwards, the alarm performs the

same function as a normal alarm.

Latching/holding alarm: ALMD=LT.HO

A latching/holding alarm performs both holding and latching

functions. The latching alarm is reset when the R S T key

is pressed after the alarm condition is removed.

Alarm failure transfer is activated as the unit enters failure

mode. The alarm will go on if ALFT is set for ON and go off

if ALFT is set for OFF. The unit will enter failure mode when

a sensor break occurs or if the A-D converter of the unit fails.

Figure 3.4 Output 2 Process Low Alarm

Figure 3.3 Output 2 Deviation High Alarm

15

3–5 Configuring User Menu

Most conventional controllers are designed with a fixed order in

which the parameters scroll. The x100 series have the flexibility

to allow you to select those parameters which are most significant

to you and put these parameters at the front of the display

sequence.

SEL1~SEL8: Selects the parameter for view and change in the

user menu.

Range: LOCK, INPT, UNIT, DP, SHIF, PB, TI, TD, O1HY,

CYC1, OFST, RR, O2HY, CYC2, CPB, DB, ADDR, ALHY

When using the up and down keys to select the parameters, you

may not see all of the above parameters. The number of visible

parameters is dependent on the setup condition. The hidden

parameters for the specific application are also blocked from the

S L selection.

xample:

OUT2 set for D .LO PB= 100.0 S L1 set for INPT

S L2 set for UNIT S L3 set for PB S L4 set for TI

S L5~S L8 set for NON

Now, the upper display scrolling becomes:

3–6 Ramp

Ramp

The ramping function is performed during power up as well as

any time the set point is changed. If MINR or HRR is chosen for

RAMP, the unit will perform the ramping function. The ramp rate

is programmed by adjusting RR. The ramping function is dis-

abled as soon as failure mode, manual control mode, auto-tuning

mode or calibration mode is entered.

Example without dwell timer

Select MINR for RAMP, select °C for UNIT, select 1-DP for DP,

set RR=10.0. SV is set to 200°C initially, and changed to 100°C

30 minutes after power-up. The starting temperature is 30°C.

After power-up, the process runs like the curve shown below:

Note: When the ramp function is used, the lower display will

show the current ramping value. The ramping value is an artifi-

cially determined setpoint created and updated by the control to

match the ramp rate set by the user. However, it will revert to

show the set point value as soon as the up or down key is touched

for adjustment. The ramping value is initiated to process value

either on power-up or when RR and/or the set point are changed.

Setting RR to zero means no ramp function.

3–7 Dwell Timer

The alarm output can be configured as a dwell timer by selecting

TIMR for ALFN (alarm function). As the dwell timer is config-

ured, the parameter SP3 is used for dwell time adjustment. The

dwell time is measured in minutes ranging from 0.1 to 4553 min-

utes. Once the process reaches the set point the dwell timer starts

to count down to zero (time out). The timer relay will remain

unchanged until time out. For the dwell timer to control the

heater, the heater circuit (or contactor) must be wired in series

with the alarm relay. Note the following diagram located below

and also Figure 2.20.1 on page 11. When the dwell timer times

out, the heater will be turned off. The dwell timer operation is

shown in the following diagram.

After time out, the dwell timer can be restarted by pressing the

R S T key.

The timer stops counting during manual control mode, failure

mode, the calibration period and the auto-tuning period.

If the alarm is configured as a dwell timer, ALHY and ALMD are

hidden.

Dwell Timer Function Wiring Diagram

Figure 3.6 Dwell Timer Function

Figure 3.5 RAMP Function

16

3–8 PV Shift

In certain applications it is desirable to shift the

controller display value (PV) from its actual value.

This can easily be accomplished by using the PV

shift function.

The SHIF function will alter PV only.

xample: A process is equipped with a heater, a

sensor, and a subject to be warmed up. Due to the

design and position of the components in the sys-

tem, the sensor could not be placed any closer to the

part. Thermal gradient (differing temperatures) is

common and necessary to an extent in any thermal

system for heat to be transferred from one point to

another. If the difference between the sensor and the

subject is 35°C, and the desired temperature at the

subject to be heated is 200°C, the temperature at the

sensor should be 235°C. You should enter -35°C to

subtract 35°C from the actual process display. This

in turn will cause the controller to energize the load

and bring the process display up to the set point

value.

3–9 Digital Filter

In certain applications, the process value is too unstable to be

read due possibly to electrical noise. A programmable low-

pass filter incorporated in the controller is used to improve

this. It is a first-order filter with the time constant specified by

the FILT parameter. The default value of FILT is set at 0.5 sec-

onds before shipping. Adjust FILT to change the time constant

from 0 to 60 seconds. 0 seconds means no filter is applied to

the input signal. The filter is characterized by the following

diagram:

Note

The filter is available only for PV, and is performed for the

displayed value only. The controller is designed to use unfil-

tered signal for control even if the filter is applied. A lagged

(filtered) signal, if used for control, may produce an unstable

process.

The controller will enter failure mode if

one of the following conditions occurs:

1. SBER occurs due to input sensor break

or input current below 1mA if 4–20 mA

is selected or input voltage below 0.25V

if 1–5V is selected.

2. ADER occurs due to the A-D converter

of the controller failing.

Output 1 and output 2 will perform the fail-

ure transfer function as the controller

enters failure mode.

Output 1 failure transfer, if activated,

will perform:

1. If output 1 is configured as proportion-

al control (PB≠ 0), and BPLS is select-

ed for O1FT, then output 1 will perform

bumpless transfer. Thereafter, the previ-

ous averaging value of MV1 will be

used for controlling output 1.

2. If output 1 is configured as proportion-

al control (PB≠ 0), and a value of 0 to

100.0% is set for O1FT, then output 1

will perform failure transfer. Thereafter,

the value of O1FT will be used for con-

trolling output 1.

3. If output 1 is configured as ON-OFF

control (PB=0), then output 1 will be

driven OFF if OFF is set for O1FT and

will be driven ON if ON is set for

O1FT.

Output 2 failure transfer, if activated,

will perform:

1. If OUT2 is configured as COOL, and

BPLS is selected for O1FT, then output

2 will perform bumpless transfer.

Thereafter, the previous averaging

value of MV2 will be used for control-

ling output 2.

2. If OUT2 is configured as COOL, and a

value of 0 to 100.0% is set for O2FT,

then output 2 will perform failure trans-

fer. Thereafter, the value of O1FT will

be used for controlling output 2.

3. If OUT2 is configured as alarm func-

tion, and O2FT is set to OFF, then out-

put 2 will go off. Otherwise, output 2

will go on if O2FT is set to ON.

Alarm failure transfer is activated as the

controller enters failure mode. Thereafter,

the alarm will transfer to the ON or OFF

state preset by ALFT.

3–10 Failure Transfer

Figure 3.7 PV Shift Application

Figure 3.8 Filter Characteristics

This manual suits for next models

3

Table of contents

Other Tempco Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Galvin Engineering

Galvin Engineering CliniMix 100.91.10.20 Installation guidelines

Minco

Minco CT425 Technical user guide

Auber Instruments

Auber Instruments WSD-1500H-W Operation & instruction manual

2VV

2VV ESSENSSE NEO COMFORT Installation and operation instractions

Powtier Controls

Powtier Controls TC308 instruction manual

SMC Networks

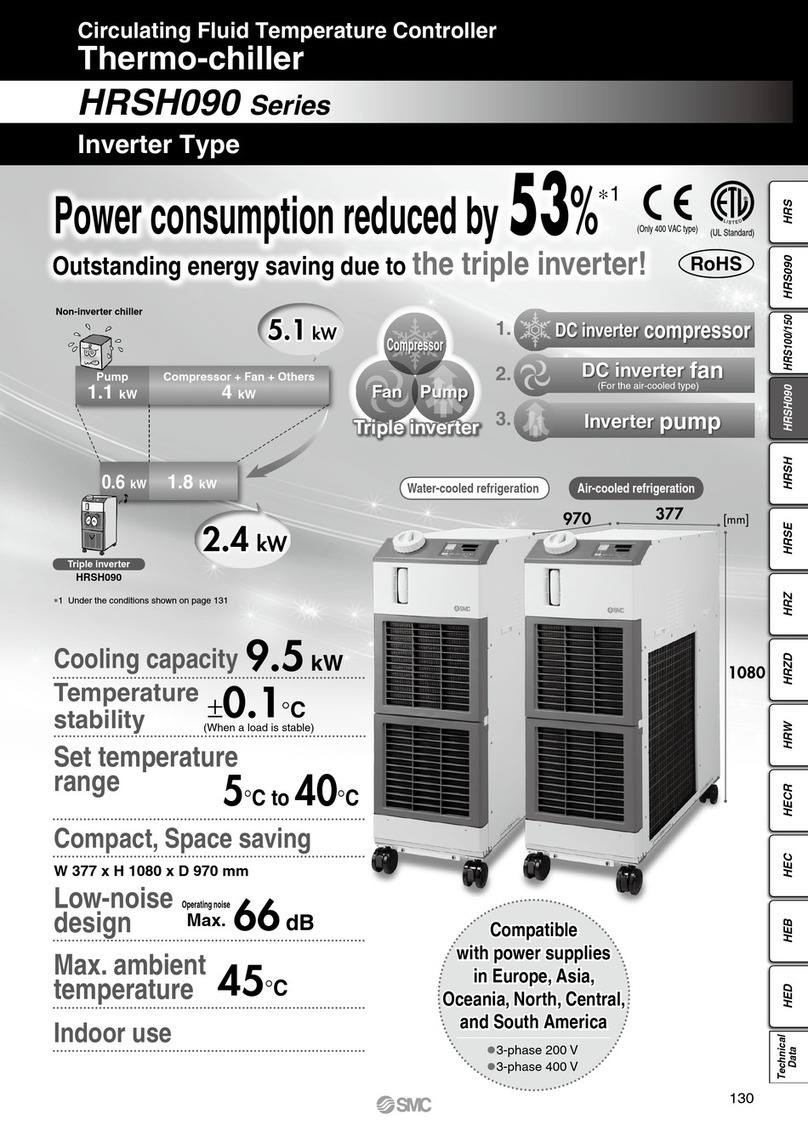

SMC Networks HRSH090 Series Technical data