Tempco TEC-9200 User manual

User's Manual

TEC-9200

Self-Tune Fuzzy/PID

Process/Temperature Controller

TEMPCO Electric Heater Corporation

607 N. Central Avenue

Wood Dale, IL 60191-1452 USA

Tel: 630-350-2252

800-323-6859

Fax: 630-350-0232

website: http://www.tempco.com

Copyright © 2003, Tempco Electric Heater Corporation, all rights reserved.

Revision 6/2003

Warning Symbol

This symbol calls attention to an operating procedure, practice, or the like which, if not correctly performed or adhered

to, could result in personal injury or damage to or destruction of part or all of the product and system. Do not proceed

beyond a warning symbol until the indicated conditions are fully understood and met.

CONTENTS

1. Introduction

2. Numbering System

3. Specifications

4. Installation

5. Operation

6. Recalibration

7. Error Messages and Diagnosis

Information in this user's manual is subject to change without notice.

Copyright © 2003, Tempco Electric Heater Corporation, all rights reserved. No part of this publication may be

reproduced, transmitted, transcribed or stored in a retrieval system, or translated into any language in any form by any

means without the written permission of Tempco Electric Heater Corporation.

1. Introduction

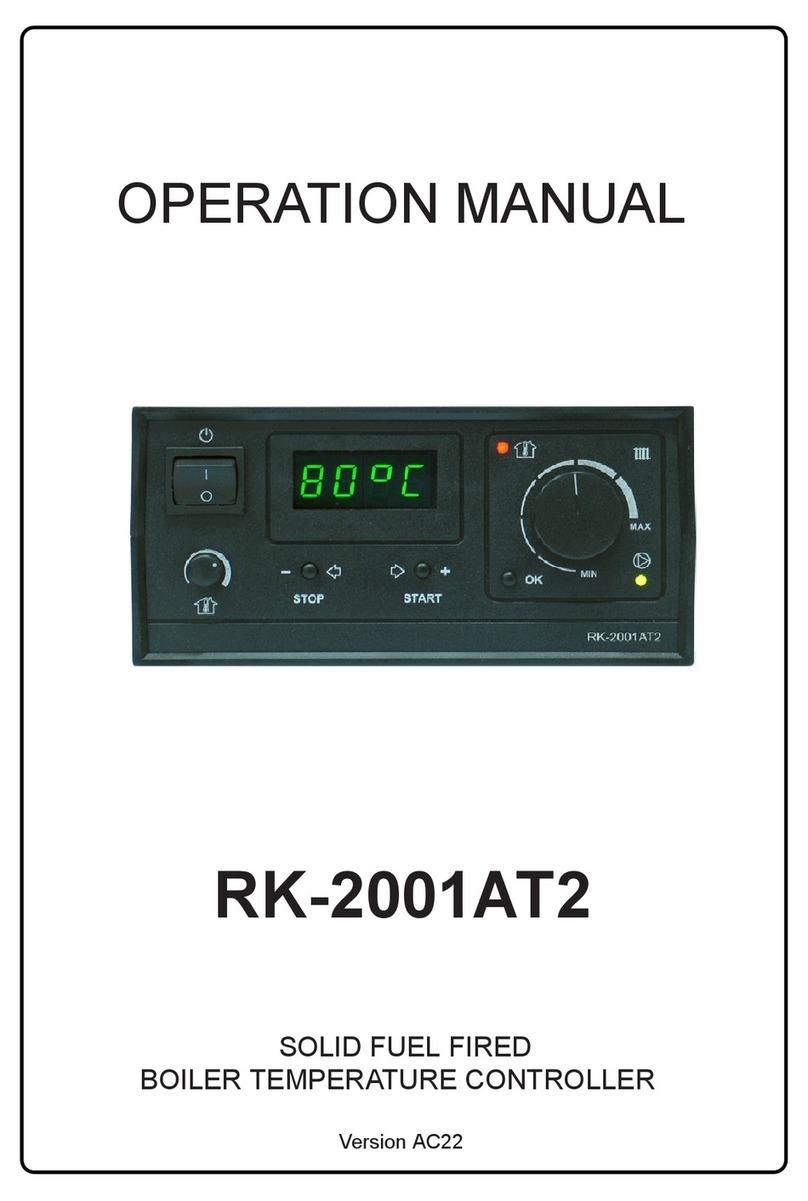

TEC-9200 Fuzzy Logic plus PID microprocessor-based controller incorporates a bright, easy to read, 4-digit LED display which indicates

the process value. Fuzzy Logic technology enables a process to reach a predetermined set point in the shortest time, with the minimum

of overshoot during power-up or external load disturbance. The units are housed in a 1/16 DIN case, measuring 48mm x 48mm with

75mm behind-panel depth. The units feature three touch keys to select the various control and input parameters. Using a unique function,

you can determine which parameters are accessible by the user. You can also put up to five parameters at the front of the user menu by

using SEL1 to SEL5 found in the setup menu. These are particularly useful to OEM's as it is easy to limit access and configure the menu

to suit the specific application.

TEC-9200 is powered by 20–32 or 90–264VAC supply, incorporating a 3 amp control relay output and dual 3 amp alarm relay outputs as

standard with a second alarm that can be configured in the second output for cooling purposes or as a dwell timer. Alternative output options

include SSR drive, triac, 4–20mA and 0–10 volts. TEC-9200 is fully programmable for PT100, thermocouple types J, K, T, E, B, R, S, N,

0–20mA, 4–20mA, and voltage signal input, with no need to modify the unit.

Digital communications format RS-485 or 4–20mA retransmission are available as an additional option. These options allow the TEC-

9200 to be integrated with supervisory control systems and software, or alternatively to drive remote displays, chart recorders, or data

loggers.

For nearly a hundred years, PID control has been used and has proven to be an efficient controlling method by many industries, yet

PID has difficulty dealing with some sophisticated systems such as second and higher order systems, long time-lag systems, during set

point changes and/or load disturbances, etc. The PID principle is based on a mathematical model which is obtained by tuning the

process. Unfortunately, many systems are too complex to describe precisely in numerical terms. In addition, these systems may vary

from time to time. In order to overcome the imperfections of PID control, Fuzzy Technology was introduced. What is Fuzzy Control? It

works like a good driver. Under different speeds and circumstances, he can control a car well based on previous experience, and does

not require knowledge of the kinetic theory of motion. Fuzzy Logic is a linguistic control which is different from numerical PID control. It

controls the system by experience and does not need to simulate the system precisely as a PID controller would.

The function of Fuzzy Logic is to adjust PID parameters internally in order to make manipulation of output value MV more flexible and

adaptive to various processes.

The Fuzzy Rule may work like this:

If the temperature difference is large, and the temperature rate is large, then ∆MV is large.

If the temperature difference is large, and the temperature rate is small, then ∆MV is small.

PID+Fuzzy Control has been proven to be an efficient method to improve control stability as shown by the comparison curves below:

3

PROCESS

PID

FUZZY

MV PV

_

+

SV

+

+

Fuzzy Rule

Fuzzy Inference

Engine DefuzzifierFuzzifier

Digital

information

Language

information

Digital

information

Figure 1.1

Fuzzy PID System Block

Figure 1.1

Fuzzy PID System Block

PID + FUZZY CONTROL

Warm Up Load Disturbance

PID control with properly tuned

PID + Fuzzy control

Set point

Temperature

Time

Figure 1.2 Fuzzy PID

Enhances Control

Stability

Figure 1.2 Fuzzy PID

Enhances Control

Stability

2. Numbering System

TEC-9200-_ _ _ _ _ _ _ _

1 2 3 4 5 6 7 8

(1) Power Input

4 . . . . . . . . 90–264VAC

5 . . . . . . . . 20–32VAC/VDC

9 . . . . . . . . Other

(2) Signal Input (can be programmed in the field)

5 . . . . . . . . TC-Configurable: J, K, T, E, B, R, S, N

6 . . . . . . . . RTD-Configurable: DIN or JIS

7 . . . . . . . . Linear-mV or mA: 4–20, 0–20mA; 0–1, 0–5, 1–5, 0–10VDC

9 . . . . . . . . Other

(3) Range Code

1 . . . . . . . . Field configurable

9 . . . . . . . . Other

(4) Control Mode

3 . . . . . . . . Field configurable

9 . . . . . . . . Other

(5) Output 1

0 . . . . . . . . None

1 . . . . . . . . Relay-3A/240VAC

2 . . . . . . . . Pulse DC for SSR drive-24VDC (20mA max)

3 . . . . . . . . 4–20mA, linear (max. load 500 ohms)

4 . . . . . . . . 0–20mA, linear (max. load 500 ohms)

5 . . . . . . . . 0–10VDC, linear (min. impedance 500K ohms)

6 . . . . . . . . Triac-SSR output 1A/240VAC

9 . . . . . . . . Other

(6) Output 2

0 . . . . . . . . None

(7) Alarm

0 . . . . . . . . None

2 . . . . . . . . Dual relays-2A/240VAC, field configurable (Alarm 2 can be used for output 2/cooling)

9 . . . . . . . . Other

(8) Data Communications

0 . . . . . . . . None

1 . . . . . . . . RS-485

2 . . . . . . . . 4–20mA retransmission

3 . . . . . . . . 0–20mA retransmission

9 . . . . . . . . Other

4

3. Specifications

Input

*Accuracy = Linearity Error + Cold Junction Compensating Error + Lead Compensating Error + Offset Drift Error

Linear voltage input impedance: 100K ohms

Cold junction compensation: 0.1°F/°F ambient typical

Sensor break protection: Configurable by operator

External resistance: 100 ohms max.

Normal mode rejection: 60dB

Common mode rejection: 120dB

Sample rate: 5x/second

Control

Proportion band: 0–360°F (0–200°C)

Reset (Integral): 0–3600 seconds

Rate (Derivative): 0–1000 seconds

Ramp rate: 0–99.99°F (0–55.55°C)/minute

Dwell: 0–9999 minutes

On-off: Adjustable hysteresis 0.1–19.9°F (0–11.0°C)

Cycle time: 0–99 seconds

Control action: Direct (for cooling) and reverse (for heating)

Power

Rating: 90–264VAC, 50/60Hz

Consumption: Less than 5VA

Environmental and Physical

Safety: UL 873, CSA 22.2/142-87, IEC 1010-1

Protection: NEMA 4X, IP65

EMC emission: EN50081-1, EN55011

EMC immunity: IEC801-2, IEC801-3, IEC801-4

Sensor Input Type Range (°F) *Accuracy (°F) Range (°C) *Accuracy (°C)

J Iron/Constantan -58 to 1832°F ±3.6°F -50 to 1000°C ±2°C

K Chromel/Alumel -58 to 2500°F ±3.6°F -50 to 1370°C ±2°C

T Copper/Constantan -454 to 752°F ±3.6°F -270 to 400°C ±2°C

E Chromel/Constantan -58 to 1382°F ±3.6°F -50 to 750°C ±2°C

B Pt30%RH/Pt6%RH 32 to 3272°F ±5.4°F 0 to 1800°C ±3°C

R Pt13%RH/Pt 32 to 3182°F ±3.6°F 0 to 1750°C ±2°C

S Pt10%RH/Pt 32 to 3182°F ±3.6°F 0 to 1750°C ±2°C

N Nicrosil/Nisil -58 to 2372°F ±3.6°F -50 to 1300°C ±2°C

RTD PT 100 ohms (DIN) -328 to 752°F ±0.72°F -200 to 400°C ±0.4°C

RTD PT 100 ohms (JIS) -328 to 752°F ±0.72°F -200 to 400°C ±0.4°C

Linear 4–20mA -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

Linear 0–20mA -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

Linear 0–1VDC -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

Linear 0–5VDC -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

Linear 1–5VDC -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

Linear 0–10VDC -1999 to 9999 ±0.05% -1999 to 9999 ±0.05%

5

Operating temperature: 14 to 122°F (-10 to 50°C)

Humidity: 0 to 90% RH (non-condensing)

Insulation: 20M ohms min. (500VDC)

Breakdown: 2000V (AC), 50/60Hz, 1 minute

Vibration: 10–55 Hz, amplitude 1mm

Shock: 200m/s² (20g)

Moldings: Flame retardant polycarbonate

Dimensions: H: 1.875” (48mm) x W: 1.875” (48mm) x D: 3.375” (86mm)

Depth behind panel: 2.875” (73mm)

Weight: 4 oz. (110g)

4. Installation

Dangerous voltage capable of causing death can be present in this instrument. Before installation or beginning any

troubleshooting procedures, the power to all equipment must be switched off and isolated. Units suspected of being

faulty must be disconnected and removed to a properly equipped workshop for testing and repair. Component

replacement and internal adjustments must be made by a qualified maintenance person only.

To minimize the possibility of fire or shock hazards, do not expose this instrument to rain or excessive moisture.

Do not use this instrument in areas under hazardous conditions such as excessive shock, vibration, dirt, moisture,

corrosive gases, or oil. The ambient temperature of the areas should not exceed the maximum rating specified.

4–1 Unpacking

Upon receipt of the shipment, remove the unit from the carton and inspect the unit for shipping damage. If there is any

damage due to transit, report the damage and file a claim with the carrier.

Write down the model number, serial number, and date code for future reference when corresponding with our service

center. The serial number (S/N) and date code (D/C) are labeled on the box and the housing of the controller.

4–2 Mounting

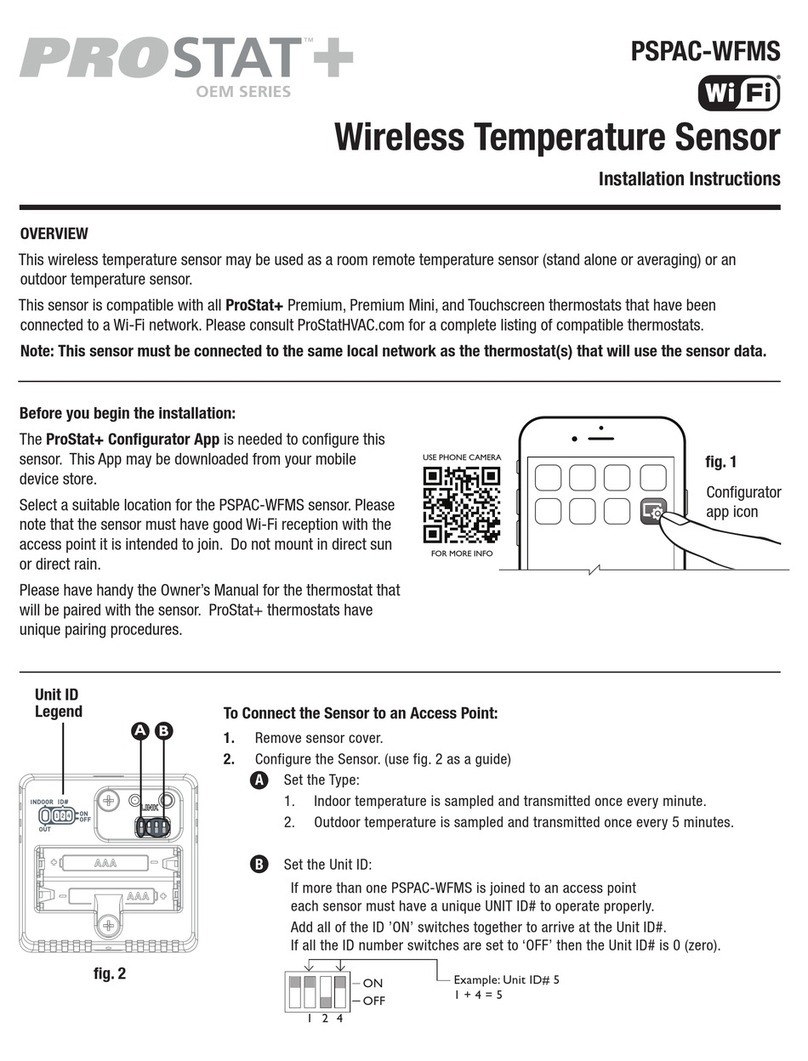

Make the panel cutout to fit the dimensions shown in figure 4.1.

Remove both mounting clamps and insert the controller into the panel cutout. Reinstall the mounting clamps. Gently

tighten the screws in the clamp until the controller front panel fits snugly in the cutout.

6

Figure .1 Mounting Dimensions

Figure 4.1 Mounting Dimensions

1.81"

(46mm)

1.81"

(46mm)

Panel

2.95"

(75.0 mm)

0.5"

(13.5mm)

0.4"

(11.0mm)

SCREW

MOUNTING

CLAMP

Panel cutout

4–3 Wiring Precautions

• Before wiring, check the label to verify the correct model number and options. Switch off the power while checking.

• Care must be taken to ensure that the maximum voltage ratings specified in section 3 are not exceeded.

• It is recommended that the power source for these units be protected by fuses or circuit breakers rated at the minimum

value possible.

• All units should be installed inside a suitably grounded metal enclosure to prevent live parts from being accessible to

human hands and metal tools.

• All wiring must conform to the appropriate standards of good practice and local codes and regulations. Wiring must be

suitable for the voltage, current, and temperature ratings of the system.

• The "stripped" leads as specified in figure 4.2 below are used for power and sensor connections.

• Beware not to over-tighten the terminal screws.

• Unused control terminals should not be used as jumper points as they may be internally connected, causing damage to

the unit.

• Verify that the ratings of the output devices and the inputs are not exceeded.

• Electrical power in industrial environments contains a certain amount of noise in the form of transient voltage and

spikes. This electrical noise can adversely affect the operation of microprocessor-based controls. For this reason we

strongly recommend the use of shielded thermocouple extension wire which connects the sensor to the controller. This

wire is a twisted-pair construction with foil wrap and drain wire. The drain wire is to be attached to ground at one end

only.

4–4 Connection and Wiring

The following connections for outputs and inputs are found on the back of the controller housing.

7

4.5 7.0 mm

0.18" 0.27"

~

~

2.0mm

0.08" max.

Figure .2 Lead Termination

Figure 4.2 Lead Termination

- +

- +

mV

-

B

BT/C +

A

RTD 0-20mA

4-20mA

- +

OUT1

ALARM 1

- +

1615

TC+

COM+ mA- V-

OUT2

ALM2

13

PTA

11 12

TC-

mV-

14

34 6578

N L

109

AO+

TX1 AO-

TX2

1 2

90-264VAC

50-60Hz

0-10V

V

Figure 4.3 RearTerminal Connections

Power Wiring

The controller is supplied to operate on 24V (20–32VAC/VDC) or 90–264VAC. Verify that the voltage of the power

supply corresponds to that indicated on the product label before connecting power to the controller.

This equipment is designed for installation in an enclosure which provides adequate protection against electrical

shock. The enclosure must be connected to earth ground.

Local requirements regarding electrical installation should be rigidly observed. Consideration should be given to prevent

unauthorized personnel from gaining access to the power terminals.

Input Wiring

Connect the appropriate sensor to terminals 12, 13, 14, 15, or 16 as indicated in figure 4.3. Make sure that the correct

sensor type is selected on the controller, and that the correct polarity is observed at both ends of the cable.

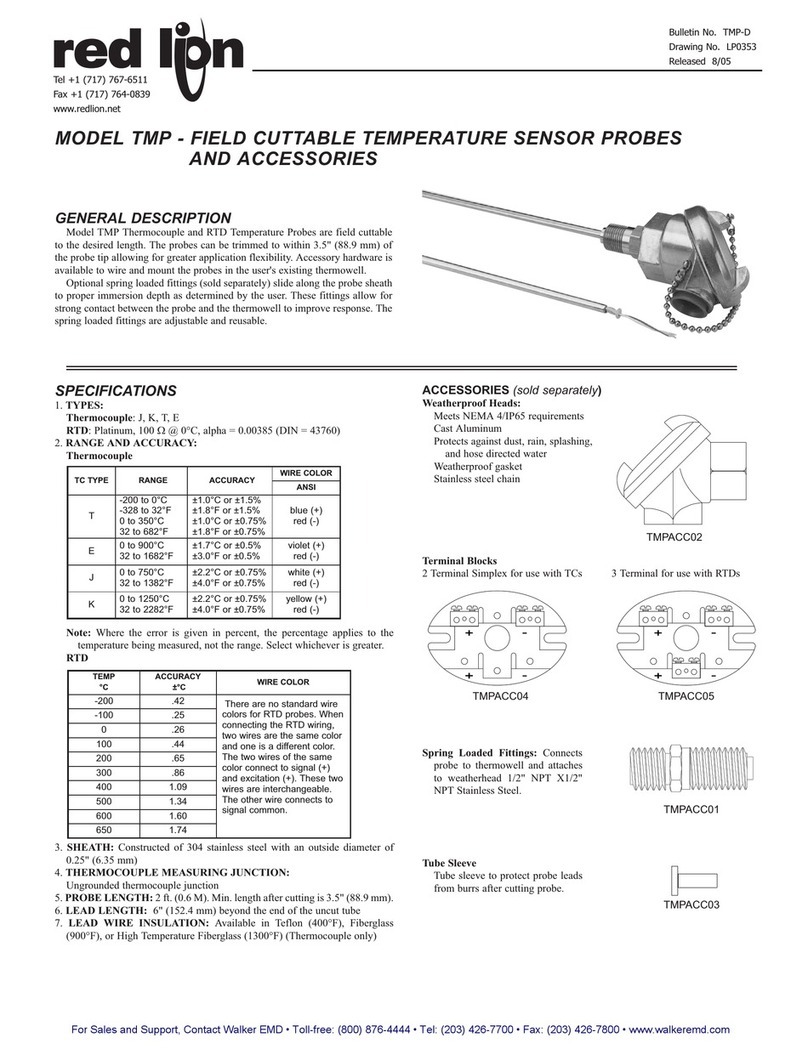

For thermocouple wiring, the correct type of extension wire must be used for the entire distance between the controller

and the thermocouple. The extension wires must be the same alloy and polarity as the thermocouple, and joints in the

cable should be avoided, if possible. The color codes used on the thermocouple extension wires are shown in table 4.1.

For wiring three-wire RTD, the two common wires should be connected to terminals 13 and 14, compensating lead

connected to terminal 13. When using a two-wire RTD, install a jumper between terminals 13 and 14. A three-wire RTD

offers the capability of lead resistance compensation, provided that all three leads are the same gauge and material, and

of equal length.

Table 4.1 International Thermocouple Cable Color Codes

* Color of overall sheath

Output Wiring

There are several types of output modules (see section 2) that can be selected for output 1 when ordering the TEC-

9200, depending on the control application. Make sure the output device you selected is appropriate for your application

requirements. The external connections will depend on the type of output installed. If pulsed voltage is selected, note

that pulsed voltage output is non-isolated.

Sensor Placement

Proper sensor installation can eliminate many problems in a control system. The probe should be placed so that it can

detect any temperature change with minimal thermal lag. In a process that requires fairly constant heat output, the probe

should be placed close to the heater. In a process where the heat demand is variable, the probe should be close to the

work area. Some experiments with probe location are often required to find the optimum position.

In a liquid process, the addition of a stirrer will help eliminate thermal lag. Since a thermocouple is basically a point

measuring device, placing more than one thermocouple in parallel can provide an average temperature readout and

produce better results in most air-heated processes.

Thermocouple

Type

Cable

Material

American

ANSI

British

BS

German

DIN

French

NFE

J Iron/Constantan

+ white

- red

* black

+ yellow

- blue

* black

+ red

- blue

* blue

+ yellow

- black

* black

K Chromel/Alumel

+ yellow

- red

* yellow

+ brown

- black

* red

+ red

- green

* green

+ yellow

- purple

* yellow

TCopper/

Constantan

+ blue

- red

* blue

+ white

- blue

* blue

+ red

- brown

* brown

+ yellow

- black

* black

R

SPlatinum/Rhodium

+ black

- red

* green

+ white

- blue

* green

+ red

- white

* white

+ yellow

- green

* green

B Platinum/Rhodium

+ grey

- red

* grey

+ red

- grey

* grey

8

The proper sensor type is also a very important factor in obtaining precise measurements. The sensor must have the

correct temperature range to meet the process requirements. In special processes, the sensor might have additional

requirements such as leak-proof, anti-vibration, antiseptic, etc.

Standard sensor limits of error are ±4°F (±2°C) or 0.75% of sensed temperature (half that for special) plus drift caused

by improper protection or an over-temperature occurrence. This error is far greater than controller error and cannot be

corrected on the sensor except by proper selection and replacement.

5. Operation

5–1 Front Panel Description

5–2 Keypad Operation

*It takes 12 seconds with power on to memorize the new value of a parameter once it has been changed.

9

Alarm Outputs

Process Value

3 Silicone Rubber Buttons

for ease of control setup

and set point adjustment.

Set Point Value

Control Output

A1 A2 PV 'C'F

SV

OUT

TEC-9200

Press and release quickly to select which digit of a numerical parameter to change.

Press and hold to increase the value of the selected digit or to change the selection

for an index parameter.

Selects the parameter in a direct sequence. Also used to select the tool program

parameters.

Selects the parameters in higher security level, and actuates the selected tool

program whenever the display is showing a tool program.

Disables keypad operation to protect all the parameters from being tampered with.

Selects the tool programs in sequence.

Unlocks keypad operation and resets the front panel display to normal display mode,

exits tool program, or stops the autotuning function.

Starts the autotune program.

Press

for at least 3.2 seconds

Press

Press

Press

Press

for at least 3.2 seconds

Up Key

Down Key

(Direct) Scroll Key

Long Scroll/Enter Key

Reverse Scroll/Callibration

Verification Key

Lock Key

Tool Program Key

Reset/Exit Key

Autotune Key

TOUCHKEYS FUNCTION DESCRIPTION

Selects the parameters in a reverse direction during parameter scrolling, or verifies

the display accuracy for various input types during callibration.

Press

for at least 3.2 seconds

Press and release quickly to select which digit of a numerical parameter to change.

Press and hold to decrease the value of the selected digit or to change the selection

for an index parameter.

5–3 Menu Overview and Descriptions of Parameters

10

Security

Level 0

ASP1

RAMP

OFST

ASP2

Scrolls through parameters

step by step in reverse order

Hold until display stops

flashing (3.2 seconds)

Short scroll advances forward

through parameters step by step

Exits parameters and

returns to PV/SV

PROCESS VALUE

SET POINT VALUE

SHIF

PB

TI

TD

AhY1

AhY2

hYST

ADDR

LO.SC

hI.SC

PL.1

PL.2

INPT

UNIT

RESO

CON.A

A1.MD

A1.SF

A2.MD

A2.SF

CYC

CCYC

C.PB

D-B

Security

Level 1

Security

Level 2

Short scroll advances forward

through parameters step by step

Short scroll advances forward

through parameters step by step

Hold until display stops

flashing (3.2 seconds)

Short scroll

returns to PV/SV

Short scroll

returns to PV/SV

Short scroll

returns to PV/SV

NOTE: The display will return to PV/SV

in 25 seconds if no entry is made.

Parameter descriptions:

11

Default

Security

Level

Display

Code Description Adjustment Range Default

Setting

0

SV Set point value of control Low scale to high scale value 212°F

ASP1 Alarm 1 set point value or Dwell

time

Trip point within high/low scale or

0–9999 minutes (for dwell time) 18°F (10°C)

RAMP Ramp rate 0–99.99°F/minute (0–55.55°C/minute) 0.00

OFST Offset value for manual reset 0–100% Only functional if integral (TI) is set to 0. 0.0

ASP2 Alarm 2 set point value Trip point within high/low scale 18°F (10°C)

1

SHIF Display shift -199–199°F (-111–111°C) 0

PB Proportional band of Output 1 0–360°F (0–200°C) 0: for ON-OFF control 18°F (10°C)

TI Integral (reset) time of Output 1 0–3600 seconds 120

TD Derivative (rate) time of Output 1 0–1000 seconds 40

AhY1 Hysteresis of Alarm 1 0–19°F (0–11°C) 0

AhY2 Hysteresis of Alarm 2 0–19°F (0–11°C) 0

hYST Hysteresis of ON-OFF control 0–19°F (0–11°C) 0

ADDR Interface address 0–40 0

2

LO.SC Low scale of range.

Adjust for your process Minimum value for the selected input to high scale 0°F

hI.SC High scale of range.

Adjust for your process Low scale to maximum value for the selected input 999°F

PL.1 Power limit of Output 1 0–100% 100%

PL.2 Power limit of Output 2 0–100% 100%

INPT Input type selection J,K,T,E,B,R,S,or N-TC=J, K, T, E, B, R, S, or N type

T/C

PT100 DIN (PTDN), PT100 JIS (PTJS), 4–20mA, 0–20mA,

|

J-TC

UNIT Display units QC =°C QF =°F PU =process units (Engineering °F

RESO Resolution NODP=No decimal point 1DP =1 decimal place

2DP =2 decimal places (only when UNIT = PU)NODP

CON.A Control action of Output 1 DIRT =Direct (cool) action REVR =Reverse (heat) action REVR

A1.MD Alarm 1 mode

DVhI=Deviation high DVLO=Deviation low

DBhI=Deviation band high DBLO=Deviation low

FShI=Full scale high FSLO=Full scale low DVhI

A1.SF Alarm 1 special function

NONE=No special function LTCh=Latching alarm

hOLD=Holding alarm LThO=Latching/holding alarm

TOON=Timer on as time out TOOF=Timer off as time out NONE

A2.MD Alarm 2 mode Same as Alarm 1 mode DVhI

A2.SF Alarm 2 special function NONE=No special function LThO=Latch/hold alarm

hOLD=Hold alarm LTCh=Latch alarm..COOL=Out. 2 NONE

CYC Proportional cycle time of Output

10–99 seconds, 0 for linear current/voltage output 20 for

relay output

CCYC Cooling cycle time 0–99 seconds, 0 for linear current/voltage output 20 for

relay output

C.PB Cooling P band 0–360°F (0–200°C) 18°F (10°C)

D-B Deadband for PB and CPB -199–199°F (-111–111°C) 0

5–4 Flow Chart of Tool Programs

12

HAND

CONT

Configure Security Levels

Parameters can be

moved from one

security level to

another.

Indicates percentage power

of output 1 (heating)

Exits Tool Programs

h___

C___ Indicates percentage power

of output 2 (cooling)

Long

Long

Adjust the percentage of on-time for output 1

using the up and down keys. Range: 0-100%

(Not functional with TEC-9200)

READ

PEAK

Manual Mode

(hand control)

Used if sensor fails.

Peak Process Value

Stored minimum and

maximum values. hI.PV

LO.PV

Indicates maximum (peak) process value Resets the maximum process value

Indicates minimum (peak) process value

Long

Long

Resets the minimum process value

CALI

A-D

Calibrate

A-D converter T___

A___

D___

Adjusts Cold Junction compensation

code (range -19.9-42.7)

or

or

or

Adjusts Drift compensation code

(range -6.6-6.6)

Long

Long

Long

Calibrate the A-D converter and enter

the Cold Junction compensation code

Calibrate the 0-20mA and enter it

Enter the Drift compensation code

FAIL

SAFE

Fail Safe

Defines the status of

the outputs if the

sensor fails. OUT.1

ALM.1

ALM.2

or

or

or

OUT.2

or

Select the status for Output 1: ON or OFF

Select the status for Alarm 1: ON or OFF

Select the status for Alarm 2: ON or OFF

Select the status for Output 2: ON or OFF

Long

Long

Long

Long

Enters the selection

Enters the selection

Enters the selection

Enters the selection

LOCK

PARA

Lock Parameters

Parameter levels can

be locked out to

prevent tampering. LEV.0

LEV.1

LEV.2

or

or

or

Select LOCK or FREE for all Level 0 parameters

Select LOCK or FREE for all Level 2 parameters

Select LOCK or FREE for all Level 1 parameters

Long

Long

Long

Enters the selection

Enters the selection

Enters the selection

ASP.1

D-B

or

or

CONF

LEVL Change the security level of the selected parameter

Change the security level of the selected parameter

Long

Long

Enters the selection

Enters the selection

Displays the rest of the parameters

according to the standard sequence.

LEVL

=0: Puts parameter in

Level 0

=1: Puts parameter in

Level 1

=2: Puts parameter in

Level 2

The Tool Programs menu can be entered at any time by pressing

5–5 Setting-Up Procedures

When power is applied, the model number and software version number of the controller will be displayed for 3.2

seconds, then all of the display segments and LED indicators will light up for 3.2 seconds. After this initial cycle, the

controller will enter normal display mode, showing the process value in the upper display, and the set point value in the

lower display. The upper display will flash continuously in the following cases:

1. while executing autotune program

2. while executing manual mode program

3. to warn that the next parameter is a higher level parameter (as the scroll key is pressed). The warning will remain for

3.2 seconds. If the scroll key is released after this duration elapses, the upper display will show the code of the next

parameter, and the lower display will show its value. Otherwise, it will return to normal display mode.

The upper display will blink for a moment when a new value of a parameter is being written into the non-volatile memory.

The upper display is also used to display error messages if an abnormal condition occurs.

Parameter Definitions

SV—Set Point Value

This parameter is the desired target of the process. It can be adjusted within the range defined by the low scale value

(Lo.SC) and high scale value (hi.SC). The default value is 212°F (100°C).

ASP1—Alarm 1 Set Point Value or Dwell Time

This sets the levels at which alarm 1 will function if A1.SF (alarm 1 special function) is set for an alarm function. If A1.SF

is selected for dwell timer (to.on or to.of), then ASP1 is the timer setting in minutes. The dwell timer starts counting when

the process value reaches the set point value. See sections 5–10 and 5–13 for more details.

RAMP—Ramp Rate

This controls the heating (or cooling) rate of the process. The setting is in degrees per minute. Set this parameter to

zero if no ramp is needed.

OFST—Offset Value for Manual Reset

This parameter will only function if the integral time (TI) is set to zero. OFST is then used to compensate for any

deviation between the process temperature and the set point temperature. If the process temperature stabilizes below

the set point, set a positive value for OFST; if the process temperature stabilizes above the set point, set a negative

value for OFST. Wait for the system to stabilize, then make additional adjustments as needed.

ASP2—Alarm 2 Set Point Value

This sets the levels at which alarm 2 will function if A2.SF is set for an alarm function. If A2.SF is set for cooling, alarm 2

will preform as a cooling output which is governed by CCyC, C.pb, and d-b. ASP2 will then have no effect.

SHIF—Shift Process Value

This value will be added to or subtracted from the process value. This can be used to compensate if the sensor reads a

different temperature than the item being sensed.

PB, TI, and TD—PID Values

Proportional band, Integral (reset) and Derivative (rate) time constants. These must be set as close as possible to the

process application requirements. See section 5–7 for more details.

AHY1, AHY2—Hysteresis Values of Alarm 1 and Alarm 2

These values define the deadbands for the alarms. The alarms will not change state until the temperature is outside the

deadband.

HYST—Hysteresis Value of On-Off Control

This parameter defines the deadband when on-off control is being used and PID control has been disabled.

13

ADDR—Interface Address

This parameter provides an identity code for the RS-485 interface. Note that no two controllers communicating with the

same computer can have the same identity code. Ignore this parameter if the controller does not use the RS-485

interface.

LO.SC, HI.SC—Low/High Scale Range

If thermocouple or PT100 is selected as the input type (INPT), these parameters are used to define the range of the set

point adjustment. If linear process input is selected, these parameters are used to define the range of the process value

and set point adjustment. See section 5–14 for more details.

PL.1, PL.2—Power Limit for Heating and Cooling Outputs

These parameters limit the maximum output percentage of power for heating or cooling during warm up and in

proportional band. If the control has relay or pulsed voltage outputs, the percentage of “on” time will be decreased. If the

control has linear current or linear voltage outputs, the actual output levels will be decreased. These are only used for

processes where heating or cooling at full speed would be dangerous or would produce unsatisfactory results. For

normal applications, these parameters are set at 100%.

INPT—Input Type

This is used to program the control for the type of input sensor used.

UNIT—Process Units

This parameter is used to select the units displayed. For linear process input, Pu (process unit) can be selected in

addition to °F or °C.

RESO—Resolution (Set Decimal Point Placement)

This parameter defines the position of the decimal point in the process and set point values. no.dP=no decimal point;

1.dP=one decimal point; 2.dP=two decimal points. Note that 2.dP can only be used for linear process input when Pu is

selected for UNIT.

CON.A—Control Action of Output 1

This selects reverse (heating) action or direct (cooling) action for output 1.

A1.MD, A2.MD—Alarm Mode Selection for Alarm 1 and Alarm 2

This sets the type of alarm required: deviation alarm, band alarm, or process alarm. See section 5–10 for more details.

A1.SF—Alarm 1 Special Function

Use this parameter to select any special functions required for use with alarm 1. Latching or holding alarms can be

selected (see section 5–10), or to.on or to.of can be selected if dwell timer function is required (see section 5–13).

A2.SF—Alarm 2 Special Function

Select hold function or latch function for alarm 2, or select COOL to reconfigure alarm 2 as a cooling output.

CYC, CCYC—Proportional Cycle Time of Output 1 and Cooling Output

Select a proper value for the process in accordance with the output devices used. Note that CCYC is only used if A2.SF

has been set for cooling. See the following section on initial setup for further discussion.

C.PB, D-B—Cooling Proportional Band, Cooling Deadband

Only used if A2.SF has been set for cooling. Otherwise, they may be ignored. See section 5–9 for more details.

Initial Setup

Use the keypad to view the value of each parameter. Use the up and down keys to set the correct value for each

parameter. Note that the new value of each parameter is automatically entered into nonvolatile memory.

The adjustment of proportional cycle time (CYC and CCYC) is related to the speed of the process response and the

output device fitted. For a faster process, it is recommended to use SSR (select SSR drive output) or SCR (select linear

current or voltage output) to drive the load. The relay output is used to drive a magnetic contactor in a slow process. If a

14

long cycle time is selected for a fast process, the process may become unstable as a result. Theoretically, the smaller

the cycle time selected, the better the control that can be achieved. However, for a relay output, the cycle time should be

as large as possible (while maintaining satisfactory control) in order to maximize the life of the relay.

The following table provides cycle time recommendations for avoiding premature relay failure:

Note: In an on-off control (when PB is set to zero) the cycle time parameter may be ignored.

FAIL-SAFE Configuration

FAIL-SAFE is a tool program used to define as on or off the status of output 1 (OUT1), output 2 (OUT2), alarm 1 output

(ALM1), and alarm 2 output (ALM2) in the event of a failure. Press and release and repeatedly until FAIL-SAFE

appears in the display windows. Press the scroll key until the desired output is shown in the upper display. Now press

and hold the up or down key to change the status as shown in the lower display. Note that if the desired setting is

different from the original one, a long scroll (pressing the scroll key for 3.2 seconds) will be required to enter the new

value before proceeding to the next tool parameter. If the FAIL-SAFE status is not critical for a process if the controller

should fail, then this section can be ignored.

LOCK Parameter

The flow chart in section 5–4 shows how to reach LOCK PARA and from there reach LEVEL (LEV.0–LEV.2), which is

shown in the upper display, and the lock status of that level (LOCK or FREE), which is shown in the lower display. For

example, if you select LOCK for LEV.2 and press the scroll key for 3.2 seconds to enter the selection, the all parameters

in level 2 can no longer be changed. A LOCK message will appear in the upper display if someone attempts to change a

locked parameter.

Configuring Security Levels of Parameters

One of the features of this controller is the ability to assign the security level for each parameter individually. One of four

levels (level 0, level 1, level 2, or level 3) can be assigned to any parameter. The parameters with lower security levels

will be displayed before parameters with higher security levels as one cycles through the parameters using the scroll

key. Furthermore, level 3 parameters are not displayed on the front panel, so any unused parameters can be assigned

security level 3 and removed from the viewing rotation completely.

As shown in section 5.4, to configure a new level for a parameter, press and to reach CONF LEVL, then press

to display the desired parameter. The lower display will indicate the level of the selected parameter. You can now

change the level for that parameter using the up and down keys. Finally, press and hold for 3.2 seconds or longer to

enter the new value. For example, if ASP1 and RAMP are set as level 0, PB, TI, and TD are set as level 1, ASP2 is set

at level 2, and all other parameters are set as level 3, the scrolling sequence of parameters will be as follows:

Output Device

(OUT1 or Cooling Output)

Cycle Time

(CYC or CCYC) Load (resistive)

Relay

20 sec. or more

recommended

10 sec. minimum

2A/250VAC

or contactor

5 sec. minimum 1A/250VAC

Solid State Relay Drive 1–3 sec. SSR

Linear Current/Voltage 0.1 sec. Phase control module

15

ASP1 RAMP TI TDSV PB ASP2

5–6 Auto-Tune

The auto-tuning process is performed at the set point. The process will oscillate around the set point during the

auto-tuning process. Set the set point to a lower value if overshooting beyond the normal process value would be likely

to cause damage.

The auto-tune program should be applied:

• During initial set-up

• When the set point is changed substantially from the previous auto-tune

• When the control results are unsatisfactory

When preparing to run the auto-tune program:

• Make sure that all parameters are configured correctly.

• Make sure that PB is not set to zero, because the auto-tune program cannot be run in on-off control mode.

• Set the set point at the normal operating process value (or at a lower value if overshoot is likely to cause damage) and

use normal load conditions.

• Press and hold the up and down keys for 3.2 seconds then release together. The upper display will flash while the

auto-tune program is running.

Auto-tune “teaches” the controller the main characteristics of the process. It “learns” by cycling the output on and off.

The results are measured and used to calculate the optimum PID values for the process which are then automatically

entered into the nonvolatile memory.

During the second period of the auto-tune program, the controller performs PID control to verify the results, and an

OFST value is obtained and entered in the memory.

To stop the auto-tune program, press the up and down keys and release them together. The upper display will stop

flashing, indicating that the auto-tune program has been aborted. Once the controller has entered the verifying period,

auto-tuning cannot be stopped.

5–7 Tuning the Controller Manually

• Make sure that all parameters are configured correctly.

• Set PB to zero. Set HYST to minimum (0.1°F or 0°C).

• Set the set point at the normal operating process value (or at a lower value if overshoot is likely to cause damage) and

use normal load conditions.

• Switch on the power supply to the heater. Under these conditions, the process value will oscillate about the set point

and the following parameters should be noted:

1. The peak to peak variation (P) of the first cycle in °F or °C (i.e., the difference between the highest value of the first

overshoot and the lowest value of the first undershoot).

2. The cycle time (T) of the oscillation in seconds (see figure below).

The control setting should then be adjusted as follows:

PB=P (°F or °C)

TI=T (seconds)

TD=T/4 (seconds)

16

SV

T

PV

Time

P

The PID parameters determined by the above procedures are rough values. If the control results using the above values

are unsatisfactory, the following rules may be used to further adjust the PID parameters:

Effects of PID adjustments on process response:

17

Adjustment Sequence Symptom Solution

Proportional Band (P)

PB

Slow response Decrease PB

High overshoot or oscillations Increase PB

Integral Time (I)

TI

Slow response Decrease TI

Instability or oscillations Increase TI

Derivative Time (D)

TD

Slow response or oscillations Decrease TD

High overshoot Increase TD

PV

Time

P action

Perfect

PB too high

PB too low

Set point

PV

Time

I action

Perfect

TI too low

TI too high

Set point

PV

Time

D action

Perfect

TD too high

TD too low

Set point

5–8 On-Off Control

If the alarm output is configured as an alarm function, it basically performs as an on-off control. If you adjust the P band

to PB=0, you can get an additional channel of on-off control with variable hysteresis. Hysteresis, also called differential

or deadband, is measured in degrees. See the figure below for a description of on-off control.

On-off control may create excessive process variation from the set point, even if the hysteresis is set at the minimum

possible value. When using on-off control, the parameters TI, TD, and CYC will have no effect on the system, and both

manual mode and the auto-tune program will be disabled.

5–9 Cooling Control

Cooling control options:

Output

Configurations Heating Output Cooling Output Adjusted Parameters

On-Off Cooling

(no heating) None OUT1

CONA=DIRT

HYST

SV

Proportional Cooling

(no heating) None OUT1 CONA=DIRT

PB, TI, TD, CYC, SV

Heating +

On-Off Cooling OUT1 ALM2

CONA=REVR

A2SF=NONE

A2MD=DVHI (or FSHI)

AHY2, SV (or ASP2)

Heating +

Proportional Cooling OUT1 ALM2

CONA=REVR

A2SF=COOL

CPB, DB, CCYC, SV

18

SP+HYST/2

SP–HYST/2

SP

Reverse 100%

OUTPUT

PV

Time

Time

Direct 100%

Action

(CONA=REVR) 0%

0%

Action

(CONA=DIRT)

P action

Functions of CPB and DB: the cooling P band CPB and the deadband DB are measured in degrees.

5–10 Alarm

There are at most two independent alarms that can be made available by adjusting the alarm special function

parameters A1SF and A2SF. While the descriptions in this section are based on alarm 1, they can also be applied to

alarm 2.

• Latch Alarm: A1SF=LTCH

When selected, the alarm output and indicator latch as the alarm occurs. The alarm output and indicator will be

energized even if the alarm condition has been cleared, unless the power is shut off.

• Hold Alarm: A1SF=HOLD

When selected in any alarm mode, prevents an alarm on power up. The alarm is enabled when the process value

reaches the set point value.

• Latch and Hold Alarm: A1SF=LT.HO

When selected in any alarm mode, prevents an alarm on power up. The alarm is enabled when the process value

reaches the set point value. Thereafter, the alarm acts as a latch alarm as described above.

• Hysteresis (AHY1) adjustment

Example: no special function used with deviation high alarm, SV=100°C, ASP1=10°C, AHY1=4°C

19

PV (∞F or ∞C)

Cooling

Output

100%

CPB

0%

SV+DB

SV

DB Negative

DB Positive

•

•

No special function: A1SF=

: Alarm on

A1MD

Deviation

high alarm

ON

SV

SV+ASP1

A1MD

Deviation

low alarm

ON

SV

SV+ASP1

(ASP1 negative)

A1MD

Deviation band

high alarm

ON

ON

SV

SV+ASP1

SV-ASP1

A1MD

Deviation band

low alarm

ON

ON

SV

SV+ASP1

SV-ASP1

A1MD

Full scale

high alarm

ON ASP1

A1MD

Full scale

low alarm

ON ASP1

112 112112 112 112

108 108108 108 108

100 100100 100 100

ON

OFF

Process proceeds

Below 108∞C

alarm off

Below 108∞C

alarm off Below 108∞C

alarm off

Above 112∞C

alarm on

Above 108∞C

alarm stays on

5–11 Viewing the Output Percentage Power

Scroll through the tool programs until you come to HAND CONTROL , then press the scroll key. The

upper display will now show the process value and the lower display will show the percentage power of output 1 (for

example, ). To view the cooling output, press scroll again. If alarm 2 is configured as a cooling output

(A2SF=COOL), the lower display will now show the percentage power of alarm 2 (for example, ). If alarm 2 is

configured as an alarm, this percentage power reading is invalid and should be ignored.

The range of percentage power is from 0–100%. If the unit is configured for on-off control, only 0 or 100 will be

displayed. For a proportional control, the output percentage power represents the percentage of the duty cycle the

output spends in the ON-state. (e.g., if cycle time CYC=10 seconds, and the output spends 4 seconds on and 6 seconds

off during each duty cycle, the lower display would read )

5–12 Manual Control

Follow the procedures from section 5–11, then press and hold the scroll key for 3.2 seconds and release. The controller

will now enter manual control mode. The upper display will begin to flash and the output percentage can now be

adjusted using the up and down keys. Note that manual control mode is not available if the control is configured for on-

off control (PB=0). If it is attempted, an error message (OPER) will appear in the upper display.

Manual control mode should be used:

• When teaching the process

• If the controller fails

Manual control mode is an open loop control. The process may rise to a dangerous temperature. Special attention

must be paid to the process in order to prevent damage to the system.

5–13 Ramp and Dwell

The controller can be configured to act either as a fixed set point controller or as a single ramp controller on power up.

This function enables the user to set a predetermined ramp rate (RAMP) to allow the process to reach the set point

temperature gradually, producing a “soft start” effect.

A dwell timer is incorporated in the controller. Alarm 1 can be configured to provide either a dwell function or a soak

function when used in conjunction with the ramp function.

Ramp Function

If the ramp function is selected, the process will increase or decrease at a predetermined rate during initial power up, or

with set point changes or process variations.

The ramp rate is determined by the “RAMP” parameter, which can be adjusted through a range from 0–99.99°F/minute

(0–55.55°C/minute). If the “RAMP” parameter is set to zero, the ramp function is disabled.

In the example below, RAMP is set at 5.00°F/minute, the ambient temperature is 50°F, and power is applied at zero

time. The process value climbs to the initial set point of 150°F over a period of 20 minutes. The process temperature is

held until the set point value is changed to 175°F at 40 minutes. The process value then climbs to the new set point over

a period of 5 minutes and the new set point is held. At 70 minutes, the set point value is decreased to 100°F and the

process value falls to the new set point over a period of 15 minutes.

20

20 40 45 Time (minutes)

∞F

0

175

150 PV

50

100

70 85

Table of contents

Other Tempco Temperature Controllers manuals