OPA 161RKTY (c/w EC motor & UC7 Controller)

Packaged Reverse Cycle R410A

Air Cooled Air Conditioner Installation &

Maintenance

shown returns the fan control voltage

down to the minimum value for 'High'

fan speed (3.0V).

v. When the desired setting for high

fan speed is selected then wait for

30 seconds. The controller will save

the selected value in its memory and

return to normal operation.

vi. To adjust the indoor fan 'Low' speed

repeat the above procedure but wait

until the display shows the letter 'L'

before releasing the push button. The

factory default value for low speed is

5.5V.

If the air returning to the indoor unit is

regularly expected to be above 50%RH,

then the coil face velocity should be limited

to be 2.5 m/s or less (refer Air Handling

graph in Technical Data pamphlet).

High humidity levels can occur in tropical or

subtropical conditions, and/or when heavily

moisture laden fresh air is introduced. Select

a fan speed that avoids water carry-over

problems.

CHECK TESTS

1. Leave the remote switch in the off

position and close the mains isolating

switch.

A four hour delay period is required to

allow the crankcase heater to drive any

liquid refrigerant out of the compressor

oil.

2. Check that all fan motors are free

running.

3. Check that the thermostat is correctly

wired to the unit and is set at the desired

temperature.

4. Checkthattheairlters,ifany,have

been correctly installed.

5. Check any supply air diffuser dampers

are open.

START UP PROCEDURE

Use the supplied Commissioning Sheet to

help you complete the following procedure:

1. Switch on the unit after the four hour

delay period for the crankcase heater

has expired.

2. Check for correct rotation of the

compressor. If rotation is incorrect the

compressor will not pump, be noisy, and

will draw minimal current. To correct

motor rotation, change the phasing at

the main power terminal.

3. Check the supply voltage.

4. Measure the current draw on the

compressor motor and on each fan

motor. Check all readings against the

speciedvalues-particularlytheindoor

fan amps if the unit is installed in a free

blow application.

Compressor

The compressor is directional scroll

type. The compressor lubricant is polyol

ester oil (POE). Note, this oil absorbs

moisture quickly if exposed to open air. On

commissioning, the compressor must be

checked for correct rotation (refer Start Up

Procedure).

ELECTRICAL REQUIREMENTS

Electricalworkmustbedonebyaqualied

electrician. The outdoor unit must be wired

directly from a distribution board by means

of a circuit breaker and a mains isolator

provided - preferably close to the unit.

Standard units are suitable for use with

thermostats with either manual Heat/Cool

selection or automatic changeover subject

to the contact ratings of the thermostats.

To connect alternative thermostats (non-

communicating contact switching types),

refergure2forwiringdiagram.

A 24 hour power supply to the crankcase

heaters is required, otherwise the warranty

is void.

INDOOR FAN SPEED

The Indoor fan can be switched ON through

the thermostat by selecting High, Medium

or Low fan speed, or via BMS. This can be

done without starting the compressor.

1. Check the operation of the indoor fan for

noise and vibration.

2. CheckiftheHighspeedairowisto

specication.

3. CheckiftheLowspeedissufciently

low yet without risk of frost on the indoor

coil.

4. Refer wiring diagram for the factory

default setting of the maximum fan

speed and the fan speed range High –

Low.

5. If either High speed or Low speed need

adjusting, use the UC7 Controller board

to adjust the indoor fan speed:-

i. Ensure the compressor is off and the

thermostat or BMS does not request

for the compressor to start.

ii. Press and hold down the SW3 push

button on the UC7 circuit board until

the display shows the letter 'H', then

release the push button.

iii. The indoor fan will start and run at the

'High' speed setting (factory default

setting is 7.5V). The display will show

the value ('7.5') and the indoor fan will

run at the selected speed.

iv. Each following press on the SW3

push button increases the indoor fan

control voltage in steps of 0.5V, up

to a maximum of 10.0V. Pressing the

push button again when value 10.0 is

GENERAL

This OPA 161 unit must be installed in

accordance with all national and local safety

codes.

OPTION (Field Fitted)

TZT-100 Room Temperature Controller

INSTALLATION

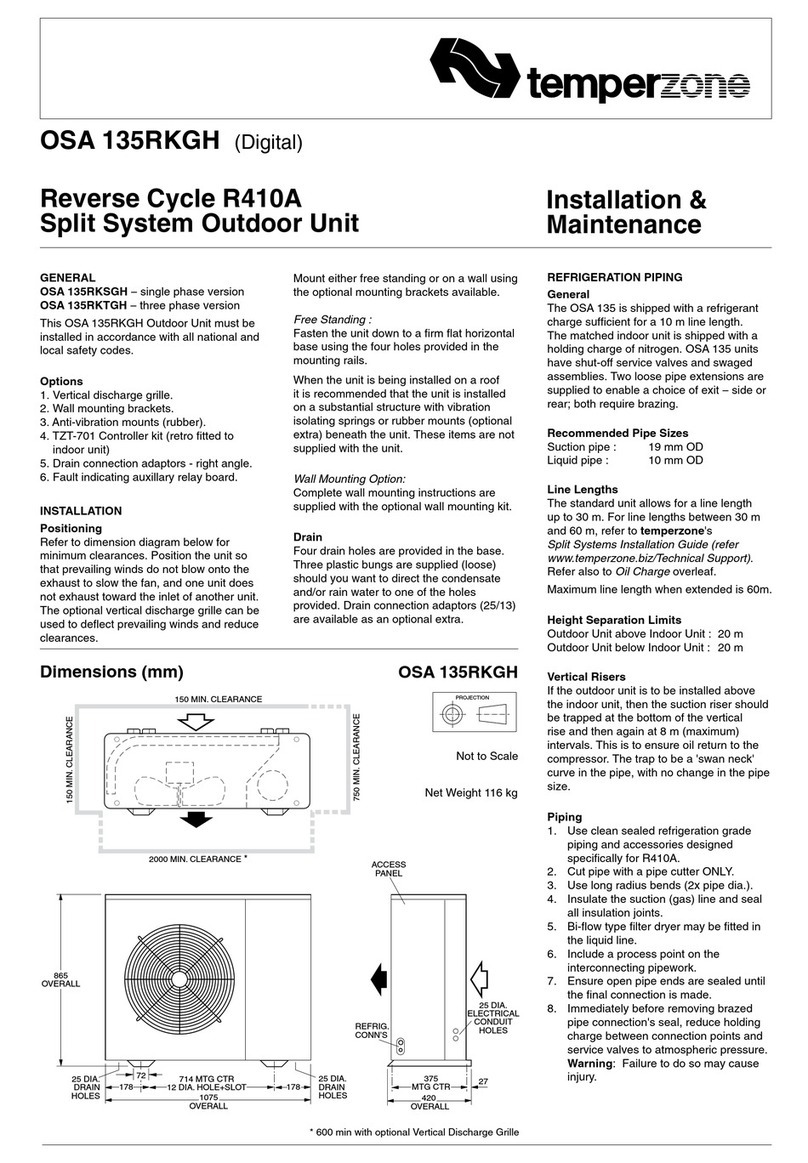

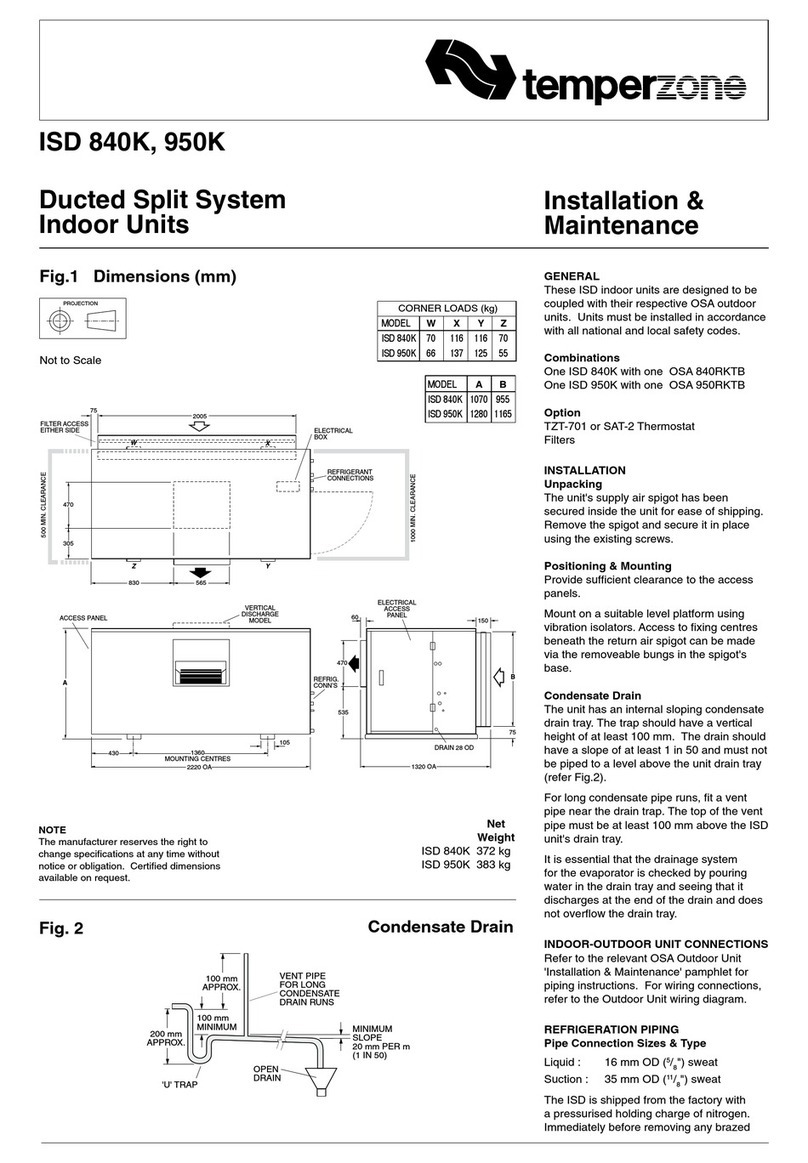

Positioning

Refer to dimension diagram for minimum

clearances. If multiple units are to be placed

side-by-side then allow at least 2 m between

coil faces.

Mounting

Fastentheunitdowntoarmathorizontal

base using the four holes provided in the

mounting rails.

When the unit is being installed on a roof

it is recommended that the unit is installed

on a substantial structure with with anti-

vibration mounts or pads beneath the unit.

Flexible duct connections are recommended

between the supply and return ducts and

the unit.

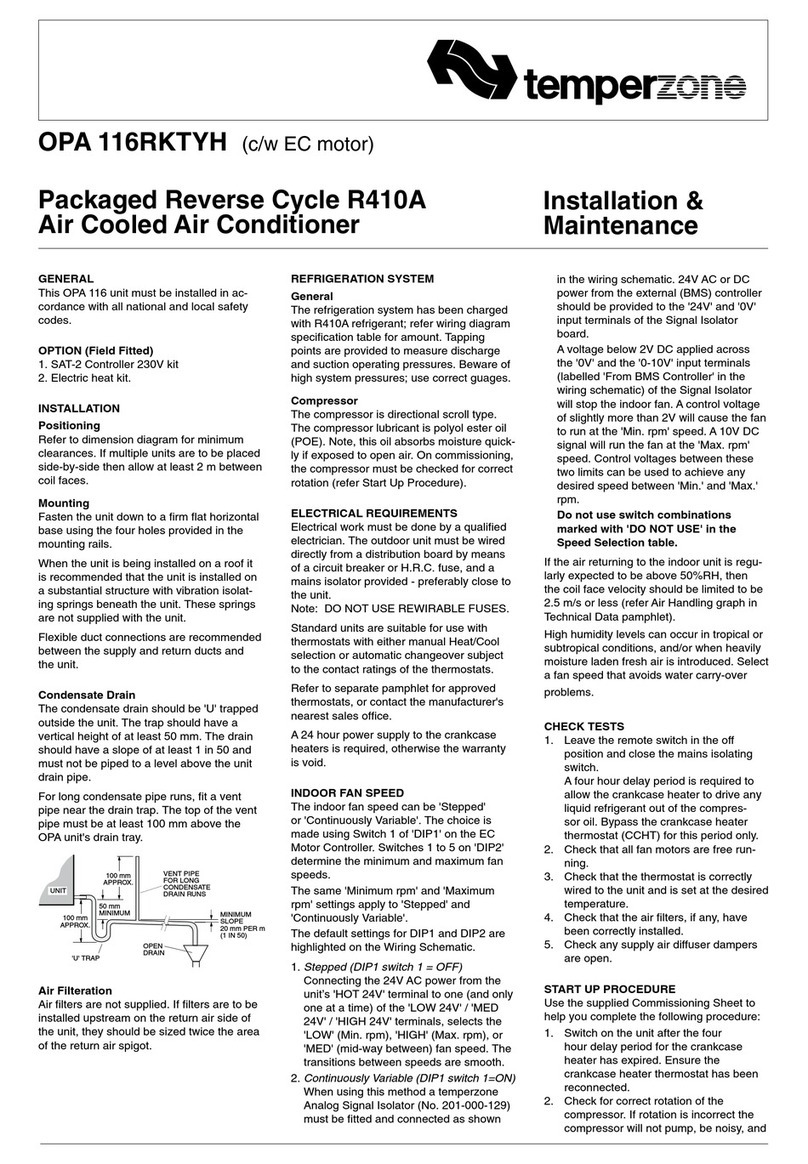

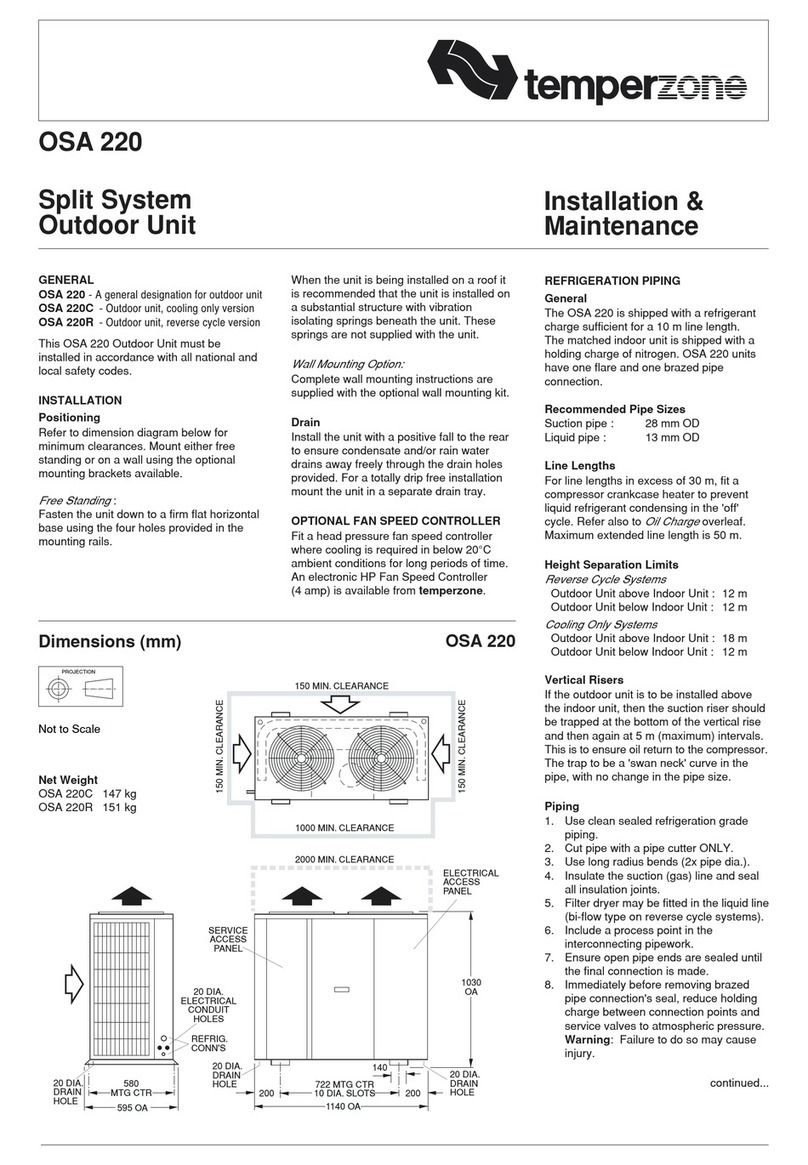

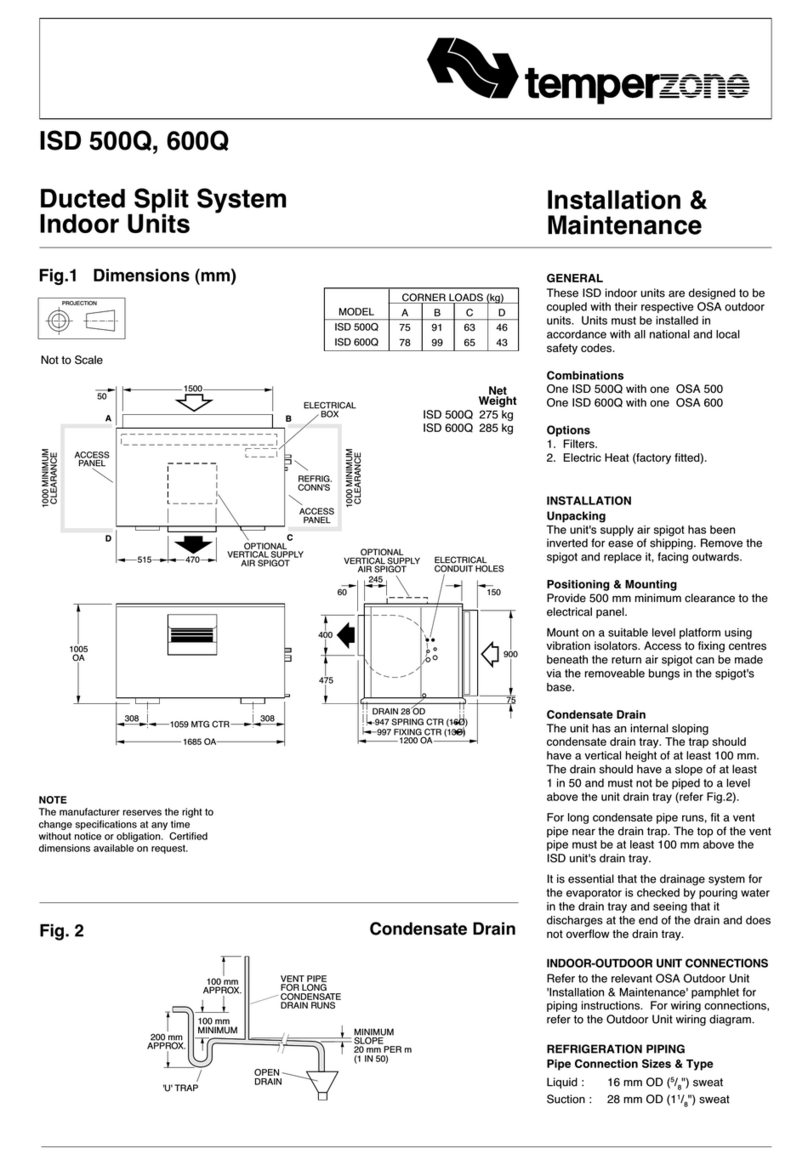

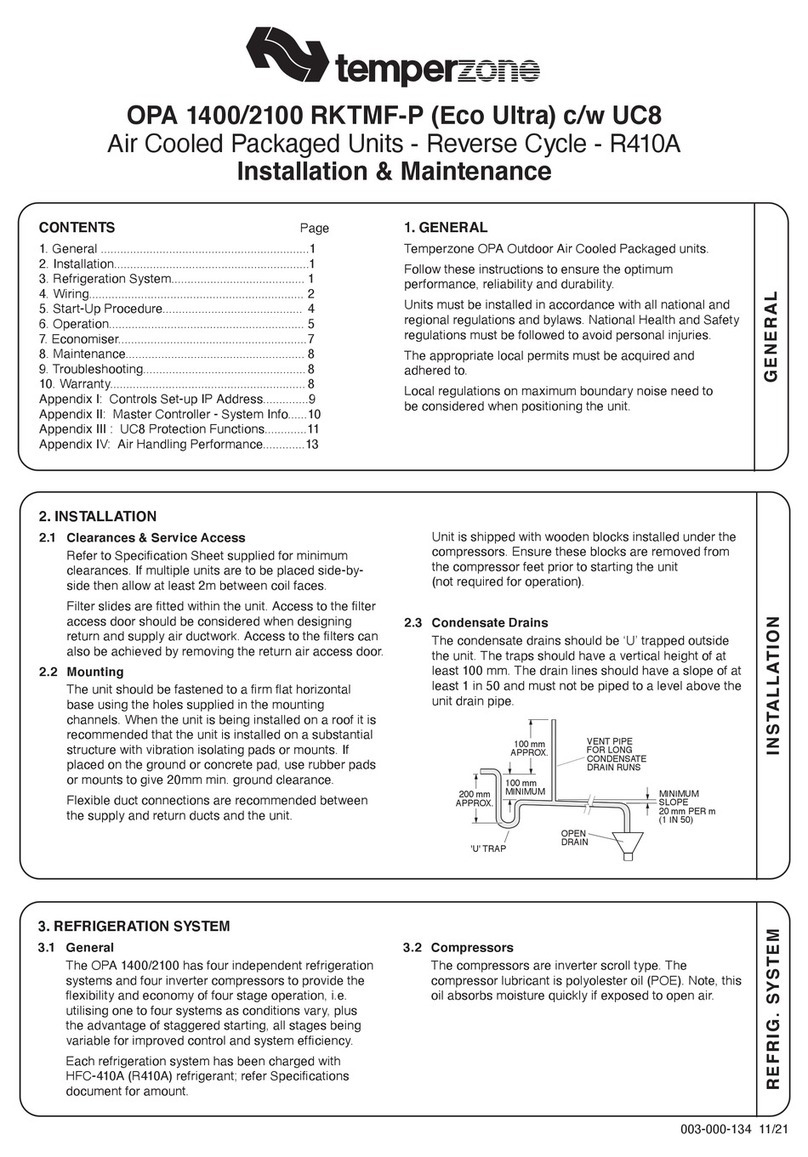

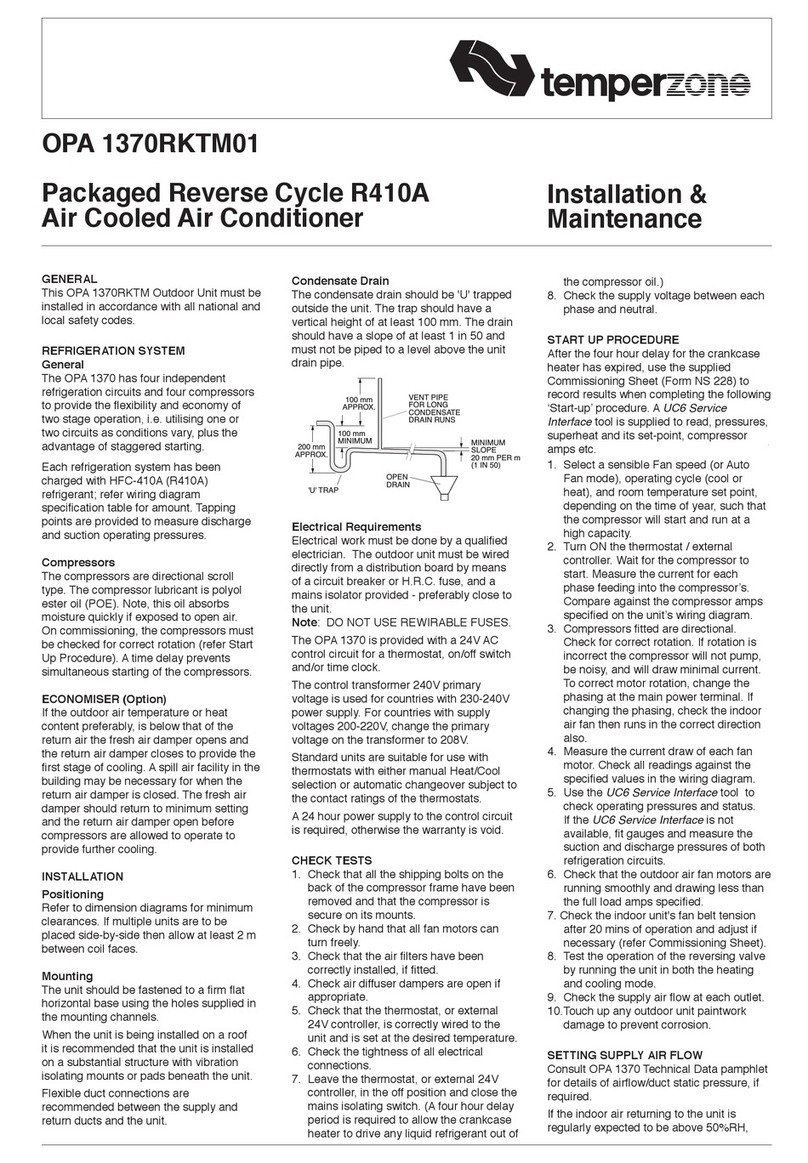

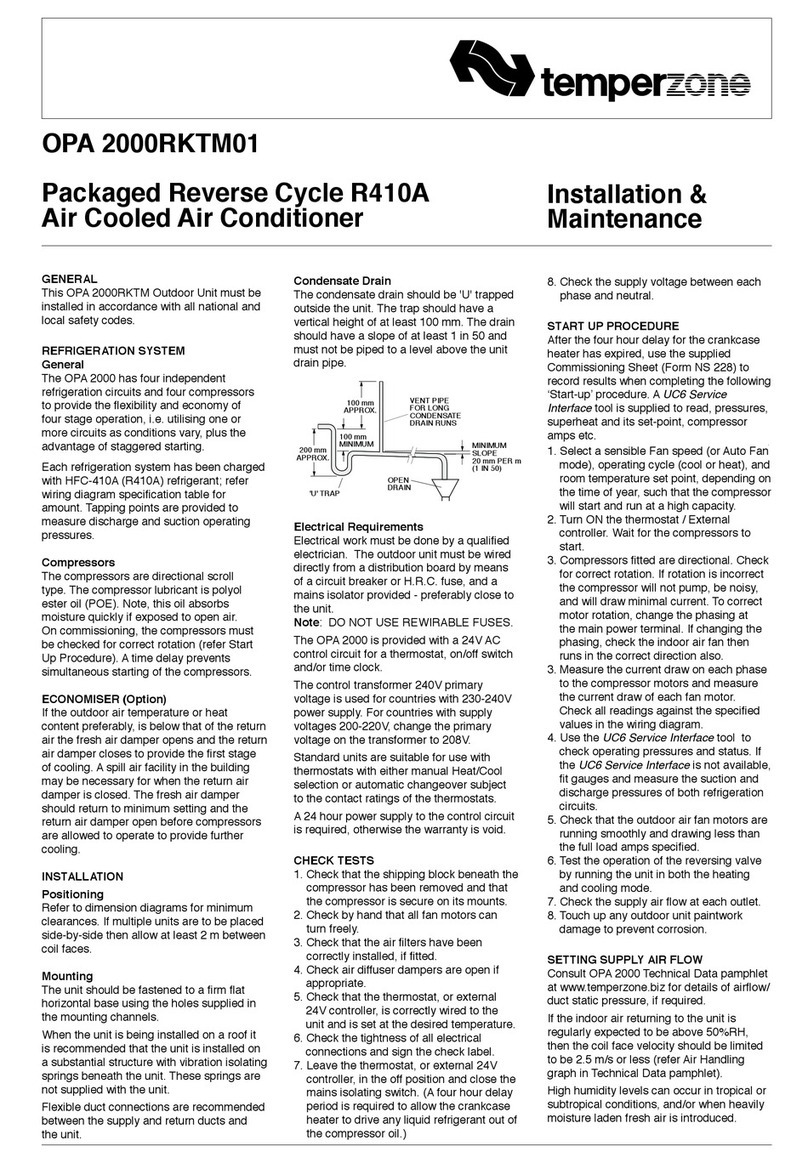

Condensate Drain

The condensate drain should be 'U' trapped

outside the unit. The trap should have a

vertical height of at least 50 mm. The drain

should have a slope of at least 1 in 50 and

must not be piped to a level above the unit

drain pipe.

Forlongcondensatepiperuns,tavent

pipe near the drain trap. The top of the vent

pipe must be at least 100 mm above the

OPA unit's drain tray.

REFRIGERATION SYSTEM

General

The refrigeration system has been charged

with R410A refrigerant; refer wiring

specicationtableforamount.Tapping

points are provided to measure discharge

and suction operating pressures. Beware of

high system pressures; use correct guages.

OPEN

DRAIN

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

50 mm

MINIMUM

100 mm

APPROX.

'U' TRAP

100 mm

APPROX.

VENT PIPE

FOR LONG

CONDENSATE

DRAIN RUNS

UNIT