Tempsens CALsys 1500 L User manual

CALsys 1500 L

CALsys 1500 L

Dry block Temperature Calibrator

USER MANUAL

TEMPSENS INSTRUMENT (I) PVT. LTD UNIT II

1. General Instruction........................................................................1

1.1 Inform tion on oper ting instruction

1.2 Li bility & w rr nty

1.3 Unp cking & initi l inspection

2Before you start.............................................................................2

2.1 S fety inform tion

2.2 W rning

2.3 C ution

3 Technical Data................................................................................3

3.1 Technic l specific tion

3.2 Circuit di gr m

4 O er iew........................................................................................4

4.1 Introduction

4.2 Outline description

5. Operating Instruction.....................................................................5

5.1 Power

5.2 Setting the temper ture

5.3 Oper ting Instruction

6. Operation of Controller...................................................................6

6.1 The Temper ture Controller

6.2 Altering the set point

6.3 Monitoring the Controlling St tus

6.4 Units

7. Maintenance & Trouble shooting.....................................................7

7.1 M inten nce

7.2 Troubleshooting

8. Software Installation......................................................................8

8.1 Inst ll tion

8.2 P r meter in m in screen

1. General nstruction

1.1 Information on operating instruction

Congr tul tions on your purch se of high-qu lity nd efficient CALsys 1500L temper ture

c libr tor.Re d this m nu l c refully to ll instructions on s fety, oper tion nd m inten nce. It

serves s n import nt source of inform tion nd reference for inst ll tion nd oper tion of the

device. The gener l s fety requirements must be strictly dhered to when oper ting the

device. The f ct cont ined especi lly s fety re observed. If you experience ny further

questions, ple se cont ct our technic l support by phone or m il to tech@tempsens.com.

1.2 Liability and warranty

This instrument h s been m nuf ctured to ex cting st nd rds nd is w rr nted for twelve

months g inst electric l bre kdown or mech nic l f ilure c used through defective m teri l or

workm nship, provided the f ilure is not the result of misuse. In the event of f ilure covered

by this w rr nty, the instrument must be returned, c rri ge p id, to the supplier for

ex min tion nd will be repl ced or rep ired t our option.

INTER F ER E N C E WIT H OR F A I L U R E T O P R OP E R L Y M AINT AIN THIS IN S T R U M EN T MAY

INV AL I D T H I S W A R R A N T Y .

1.3 Unpacking & Initial Inspection

Our p cking dep rtment uses custom designed p ck ging to send out your unit, but s

ccidents c n still h ppen in tr nsit, you re dvised, fter unp cking the unit, to inspect it for

ny sign of d m ge, nd confirm th t your delivery is in ccord nce with the p cking note. If

you find ny d m ge or find ny p rt missing during delivery notify us nd the c rrier

immedi tely. If the unit is d m ged you should keep the p cking for possible insur nce

ssessment.

After unp c k in g yo u will find following items.

C lsys 1500 L Insul tion wool RS-232 c ble Softw r e CD

R type sensor

6NOS.He ter s cer mic Block

2. Before you Start

2.1 Safety Information

Use the instrument only s specified in this m nu l. Otherwise, the protection provided by the

instrument m y be imp ired. Refer to the s fety inform tion below nd throughout the m nu l.

The following definitions pply to the terms “W rning” nd “C ution”.

“W rning” identifies conditions nd ctions th t m y pose h z rds to the user.

“C u tio n ” i dentifies conditions nd c ti o ns th t m y d m ge the instrument

being used.

[!] Warning: T h e furnace is only to be used as de scr i b ed in this

manual. It is recommended that you only use accessories pro ided by

the manufacturer.

2.2 Warning

To void possible electric shock or person l injury, follow these guidelines.

This equipment must be correctly e rthed.

A protective e rth is used to ensure the conductive p rts c n not become live in the event of

f ilure of the insul tion.

The protective conductor of the flexible m ins c ble which is colored green/yellow MUST be

connected to suit ble e rth.

W rning: Intern l m ins volt ge h z rd. Do not remove the p nels.

There re no user service ble p rts inside. Cont ct us for rep ir.

Do not use the pp r tus outside its recommended r nge i.e., + 500 to 1500° C.

Ensure infl mm ble m teri ls, re kept w y from hot p rts of the pp r tus, to prevent

fire risk.

Before connecting to the electricity supply, ple se f mili rize yourself with the p rts of the

c libr tor with the help of oper ting m nu l.

BURN HAZARD – Do not touch the t rget surf ce of the unit.

Alw ys repl ce the fuse with one of the s me r ting, volt ge nd type.

Overhe d cle r nce is required. Do not pl ce unit under c binet or other structure.

Do not use this unit for ny pplic tion other th n c libr tion work.

Compl etely u n ttended hi g h te mper ture o per ti o n is not re c o m me n d e d for

s fety re sons.

CALIBRAT ION EQUIPEMENT should only be used by TRAINED PERSONNEL.

We r ppropri te protective clothing.

2.3 Caution

To void possible d m ge to the instrument, follow these guidelines.

Components nd he ter lifetime c n be shortened by continuous high temper ture

oper tion.

Do not c h nge th e v lues o f th e c li b r ti o n const nt s fr om the f ctor y se t

v lues. The co rr e c t setti ng o f these p r m e t e r s is i m po r t nt t o the s fety

n d pr o p er oper tion of the c l ibr tor.

3. Technical Data

3.1 Technical Speci f ic atio n

Volt ge 230 V AC

Power 3.0 KW

Supply Frequency 50/60 Hz

Temper ture r nge 500 to 1500°C

Resolution 0.1 °C

St bility ± 1.0 °C

Controlling sensor R type T/C

Time to re ch m x. Temper ture 2 hours

Oper ting Temper ture 20 to 45 °C

Controller Specific tions Eurotherm

Over temper ture protection Autonics controller with R Type T/C

St biliz tion Time 15 to 20 Min.

Dimensions 640 (H) x 500 (W) x 550 (D) mm

Block 2X6,2x8 mm with 140mm depth

Weight Approx 55 kg

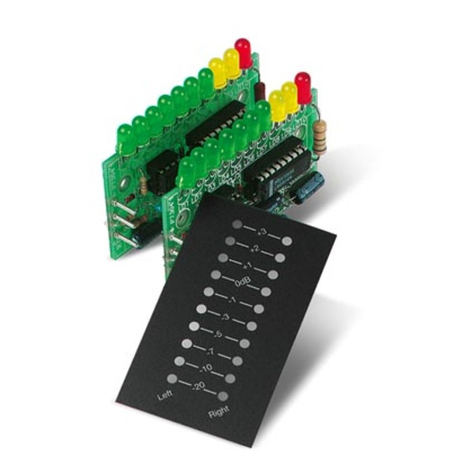

3.2 Circuit Diagram

P: PHASE= RED WIRE N: NEUTRAL = BLACK WIRE E: EARTH =BLUE WIRE

4. Overview

4.1 Introduction:

The ‘CALsys 1500 L’ h s been designed to provide st ble nd ccur te temper ture to en ble

profession ls to c libr te Temper ture Sensing Devices by comp rison method. The

‘CALsys 1500 L’model h s been designed to be rugged nd e sily m int ined. This model

provides n isotherm l enclosure (cer mic block) in which the thermocouple/RTD c n be

c libr ted g inst the temper ture of the c libr tor. For tr ce ble c libr tion m ster

c libr tion sensor should be pl ced into the met l block longside the unit under c libr tion.

The method is widely ccepted bec use the c libr tor provides very st ble temper ture

ne ring to its controlled point, the M ster Thermocouple / RTD, which is c libr ted by

independent L bor tory tr ce ble to N tion l st nd rds, comp res the sensor under

c libr tion.

The ‘CALsys’ models re p rt of wide r nge of L bor tory c libr tors designed nd m de by

us. Ple se cont ct us in c se you required more inform tion bout our other products.

DANGER! Power is present e en if the front panel circuit breaker is in the OFF (0)

position.

4.2 Outline Description:

‘The c libr tor controller uses precision R type thermocouple s controlling sensor nd

controls the well temper ture with 6 silicon c rbide he ter. To obt in nd m int in required

temper ture the controller v ries the power to the he ter vi solid-st te rel y. There is one

electricity driven f n which is situ ted under the he ting ch mber for cooling the he ter. The

CALsys 1500 L dry block c libr tor w s designed for l bor tory, moder te cost nd e se of

oper tion. With proper use the instrument should provide continued ccur te c libr tion of

temper ture sensors nd devices. The user should be f mili r with the s fety guidelines nd

oper ting procedures of the c libr tor s described in the User’s M nu l.

[!]Warning: Do not insert impure materials, metal objects or probes etc. into the

block.

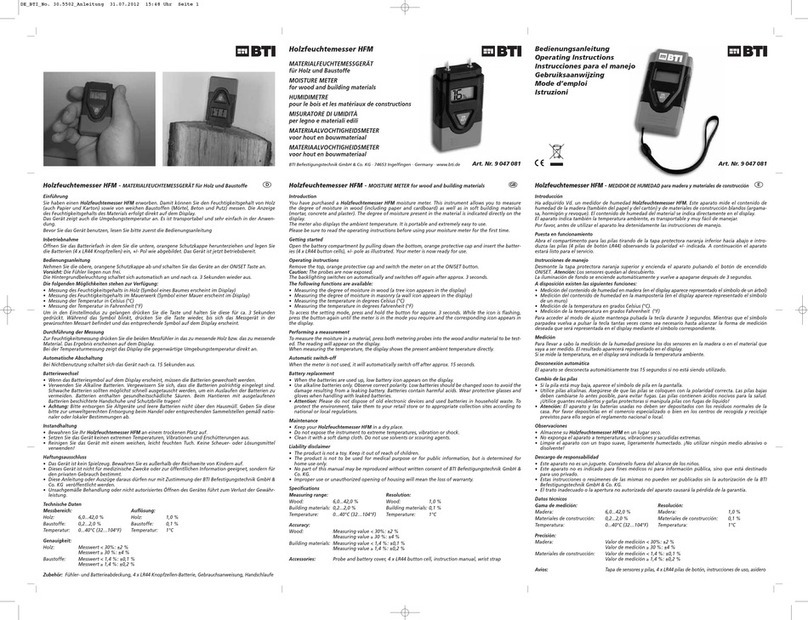

4.3 NSTALLAT ON OF CALSYS 1500L

c lsys 1500L ceremic block Sic he ters

Open the front pl te nd b ck sheet of

CALsys 1500L nd remo e all

packing sheet from inside.

Insert the he ters in to the groves of SS ch mber s

per specified s me sr. no. On he ter holder nd

ch mber.

NOTE: HEATERS INSERT VERY CAREFULLY.

Unpack the furnace carefully and inspect it for any

damage that may ha e occurred during shipment.

If there is shipping damage, notify the carrier

immediately.

After Inserting its tight by screwdri er

connect the Phase and Netural wire as per gi en picture.

Again fix the front and back plate of calsys 1500L

Fix the 6 heater into the chamber and

Connect all the aluminum strip in series.

Heating Element connection.

Fully assembled of CALsys 1500L

5. Operating nstruction

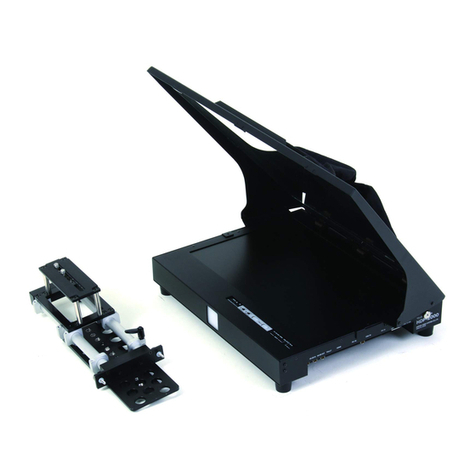

(1) PID Controller

(2) ON/OFF switch of controller

(3) Power c ble RS-232 Power MCB FAN

(4) RS-232 c ble

(5) S fety controller for over he ting temper ture

(6) 1."R" type thermocouple for controlling nd

over temper ture protection.

Inner ch mber of c lsys 1500L

5.1 Power

Pl ce the c libr tor on fl t surf ce with t le st 20 inches of free sp ce round the instrument.

Overhe d cle r nce is required. Do not pl ce under c binet or structure. Insert equilizing block

into the well with help of tong, fter inserting remove the tong from equ lizing block. Plug the

power cord into m ins outlet of the proper volt ge, frequency Typic lly this will be (230 VAC ±10,

50/60 Hz). Turn the “M ins” (He ter) switch loc ted on front p nel. The controller disp ly should

illumin te fter 3-4 sec . After brief self test the controller should begin norm l oper tion. If the

unit f ils to oper te ple se check the power connection.

[!]Warning: Do not connect or disconnect while power is on. Do not disconnect

power when furnace is hot and fans are running.

5.2 Setting the Temperature

Press “UP” or “DOWN” buttons to ch nge the ch nge the temper ture set-point v lue. When the

set-point temper ture is ch nged the controller will switch the CALsys 1500 L ON or OFF to r ise or

lower the temper ture. The displ yed temper ture will gr du lly ch nge until it re ches the setpoint

temper ture. The temper ture b th requires 15 to 20 minutes to re ch the set-point depending on

the sp n. Another 10 to 15 minutes is required to st bilize the temper ture b th within ± 0.5ºC of

the set-point.

5.3 Operating Instruction:-

1. Insert the cer mic block (thermowell) into well of furn ce. Block should be f ce to f ce of inner

ch mber.

2. Connect the ‘CALsys 1500L’ to suit ble power supply & Switch ON the Dry b th source nd set

the desire temper ture v lue in PID by using UP & Down key.

3. Switch ON the MCB,b ck side of furn ce.

4. Insert the reference (M ster) temper ture sensor nd UUC (Unit under c libr tion) into the

thermowell (inconel block).

5. PV (Present v lue) displ y in controller will gr du lly rise until it re ches the set point

temper ture. The controller t kes some times to re ch the set-point depending on the sp n.

Furn ce is st ble when PV is equ l to SV (Set V lue).

Note:

All other controller p r meters re comp ny set nd locked. It is

recommended not to ch nge them.

When the source is oper ted t ny temper ture bove mbient,

the front f ce nd pl te become hot. UP

Key

Down

Key

6. M ster sensor t ke some times to re ch the setpoint temper ture nd st ble t temper ture

ne r bout controller set temper ture.

7. When temper ture of the m ster nd UUC (Unit under c libr tion) re st ble record the

re dings of m ster sensor.

8. Comp re the UUC re ding with the m ster’s re ding & find out the error by comp rison method.

9. Reset the controller nd / or repe t the c libr tion for nother c libr tion point or for nother

sensor.

10. When the c libr tion is complete, reset the controller to 0°C & w it until the unit h s cooled to

below 100°C, before moving the ‘CALsys 1500L to new loc tion.

NOTE: USE INSULATION WOOL FOR HEAT LOSS AT FRONT SIDE OF CERAMIC BLOCK.

6. Operation of Controller

FRONT PANEL LAYOUT

Operator Buttons

6.1 The Temperature Controller

The controller h s du l displ y, the upper displ y indic tes the me sured temper ture, nd

the lower displ y indic tes the desired temper ture or set point.

6.2 Altering the Set point

To ch nge the set point of the controller use the UP nd DOWN keys to r ise nd lower the set

point to the required v lue. The lower displ y ch nges to indic te the new set point.

6.3 Monitoring the Controller Status

A row indic te the controllers st tus s follows

OP1 He t Output

OP2 Cool Output

REM This be con indic tes ctivity on the PC interf ce

ALM this indic tes when PV (Present v lue) is more th n 1500°C.

6.4 Units

Moment ry pressing of the Scroll key will show the controller units °C or °F by using SCROLL

key & UP & DOWN key unit c n be ch nge.

IMPORTANT NOTICE

The controller's function settings re preset nd will not require djustment. Use only up &

down key.

7. Maintenance & Trouble shooting

7.1 Maintenance

The c libr tion instrument h s been designed with the utmost c re. E se of oper tion nd

simplicity of m inten nce h ve been centr l theme in the product development.

Therefore, with proper c re the instrument should require very little m inten nce. Avoid

oper ting the instrument in n oily, wet, dirty, or dusty environment.

If the outside of the instrument becomes soiled, it m y be wiped cle n with d mp cloth

nd mild detergent. Do not use h rsh chemic ls on the surf ce which m y d m ge the

p int.

Avoid knocking or dropping the c libr tor.

If the m ins supply cord becomes d m ged, repl ce it with cord with the ppropri te

g uge wire for the current of the instrument.

Depending on the environment in which it is used, periodic cle ning is recommended.

Cle ning m y be ccomplished by the use of the sm ll pint brush.

7.2 Trouble shooting

1. Unit fails to operate

Check fuse if it is tripped switch is ON. If not power ON of c lsys 1500L consult us.

2. Unit unstable

Controller p r meter h s been interfered, consult us.

3. If the temperature of the calibrator is not rising

( ) The he ting element m y be open.

(b) The thermocouple m y be open.

(c) The SSR m y be d m ged.

(d) The controller m y not be giving output

(e) The mbient temper ture inside the ch mber is r ised nd s fety controller switched

OFF the power

CAUT ONARY NOTE

TEMPSENS PRODUCTS ARE INTENDED FOR USE BY TECHNICALLY TRAINED AND COMPETENT

PERSONNEL FAMILIAR WITH GOOD MEASUREMENT PRACTICES.

IT IS EXPECTED THAT PERSONNEL USING THIS EQUIPMENT WILL BE COMPETENT WITH THE

MANAGEMENT OF APPARATUS WHICH MAY BE POWERED OR UNDER EXTREMES OF

TEMPERATURE, AND ARE ABLE TO APPRECIATE THE HAZARDS WHICH MAY BE ASSOCIATED

WITH, AND THE PRECAUTIONS TO BE TAKEN WITH, SUCH EQUIPMENT.

8. Software Installation

The provided Tempsens softw re offers possibilities toconnect furn ce temper ture b th nd

ch nge set point,m ximum time sp n, view re l time gr ph ndev lu te me suring d t .

1.1 Installation

Inst ll the c libr tion softw re using the inst ll tion guide file on CD ROM. After inst ll tion of

the softw re; Double click the pplic tion. It willopen the screen of softw re.

1.2 Parameter in mainscreen

1.2.1 Communication

Communic tion between the furn ce nd the softw re is implemented vi RS-232 c ble

connected between the furn ce nd the PC seri l port. This en bles the cquisition nd

recording of d t , s well s the tr nsfer of comm nds from the softw re pplic tion to the

tempsens furn ce. Communic tion c n be done by clicking on connect nd select correct COM

port ddress (fig. 1) where furn ce is connected. Also user h s to select type of controller

version3216 (fig. 2). Then click on CONNECT button. Shown com2 connected successfully.

1.2.2 Scale Trend: -in sc le trend you h ve to ch nge the Y-Axis Min v lue 0 nd Y-AxisM x

v lue 1500.M ximumTime Sp n, Minutes h ve to s ve d t the d t logging up to 120

minutes, th n clickon st rt gr ph button. After complete the t sk clickon s ve to file button.

Set Point (°C): - in which you c n set temper ture of furn ce s your requirement.

PVIValue: - Re d the current PVv lue (present v lue of furn ce temper ture)File will be

stored in .xls form tto s ve previous recordopen the file by clicking on menu file open.

Safety instructions:

Do's and don'ts -

1. Keep swich off the power supply fter swich off the furn ce MCB.

2. Don't touch surf ce ch mber during furn ce is ON c uses over he ting injury.

3. Don't remove power plug during furn ce is ON.

4. Keep swich off red button t front of furn ce fter use.

5. Keep down the furn ce temper ture t mbient fter use then switch off the furn ce.

6. After open the furn ce keep pl ce block nd furn ce p rts s fely.

7. Don't open the furn ce ch mber during furn ce is ON.

8. In c se of ny trouble ple se cont ct our cont ct person.

nformation

Packing Instruction

To tr nsport or store the instrument, ple se use the origin l box or box p dded with

sufficient shock bsorbing m teri l. For stor ge in humid re s or shipment overse s, the

device should be pl ced in welded foil ( ide lly long with silicon gel) to protect it from

humidity.

Warranty

TEMPSENS CALsys 1500L instrument h ve w rr nty of one ye r from the invoice d te. This

w rr nty covers m nuf cturing defects. User induced f ults re not covered under this

w rr nty.

Limit of Liability

TEMPSENS not li ble for ny d m ges th t rise from the use of ny ex mples or processes

mentioned in this

Specifications are subject to change without notice

Copyright:@ 2009, TEMPSENS. All right

This document m y cont in propriet ry inform tion nd sh ll be respected s

propriet ry document to TEMPSENS with permission for review nd us ge given only to the

rightful owner of the equipment with which this document is ssoci ted.

TEMPSENS reserves the right to m ke ch nges, without further notice, to ny

product herein to improve reli bility, function, or design . TEMPSENS does not ssume ny

li bility rising out of the pplic tion or use of ny product described herein, neither does it

convey ny license under its p tent right nor the right of others.

Copyright:@2009

TEMPSENS INSTRUMENT (I) PVT. LTD

Table of contents

Other Tempsens Measuring Instrument manuals

Tempsens

Tempsens CALsys 1700 User manual

Tempsens

Tempsens CALsys 1200 User manual

Tempsens

Tempsens CALsys-15/110 Autocal User manual

Tempsens

Tempsens CALsys 1500 BB User manual

Tempsens

Tempsens CALsys -35/200 User manual

Tempsens

Tempsens CALsys 250 User manual

Tempsens

Tempsens CALsys 1500 User manual

Tempsens

Tempsens CALSYS 650 User manual

Popular Measuring Instrument manuals by other brands

Bosch

Bosch DLE 150 Connect operating instructions

Motec

Motec PLM user manual

AEA Technology

AEA Technology Liberator Series Operation manual

MADDALENA

MADDALENA ElecTo SONIC Instructions for installation, use and maintenance

ELTRA

ELTRA ELEMENTRAC CS-i operating manual

KROHNE

KROHNE OPTIWAVE-M 7400 C Short guide