www.element14.com

www.farnell.com

www.newark.com

www.cpc.co.uk

Page <5> V1.023/08/18

Characteristics

• MCU computer offers PID advanced algorithms industrial control with thermo-control and thermo-stability, which makes

more exactly control temperature

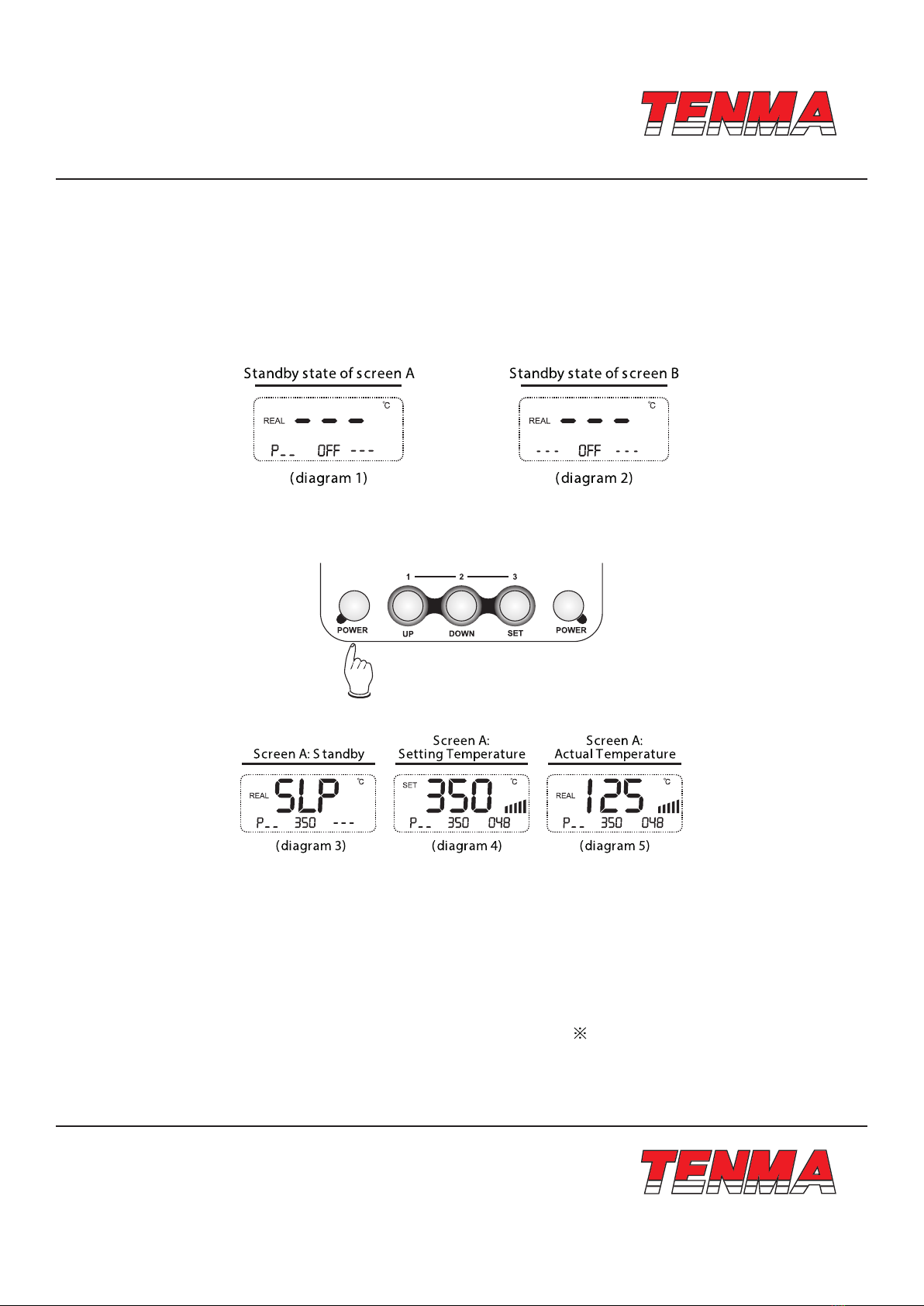

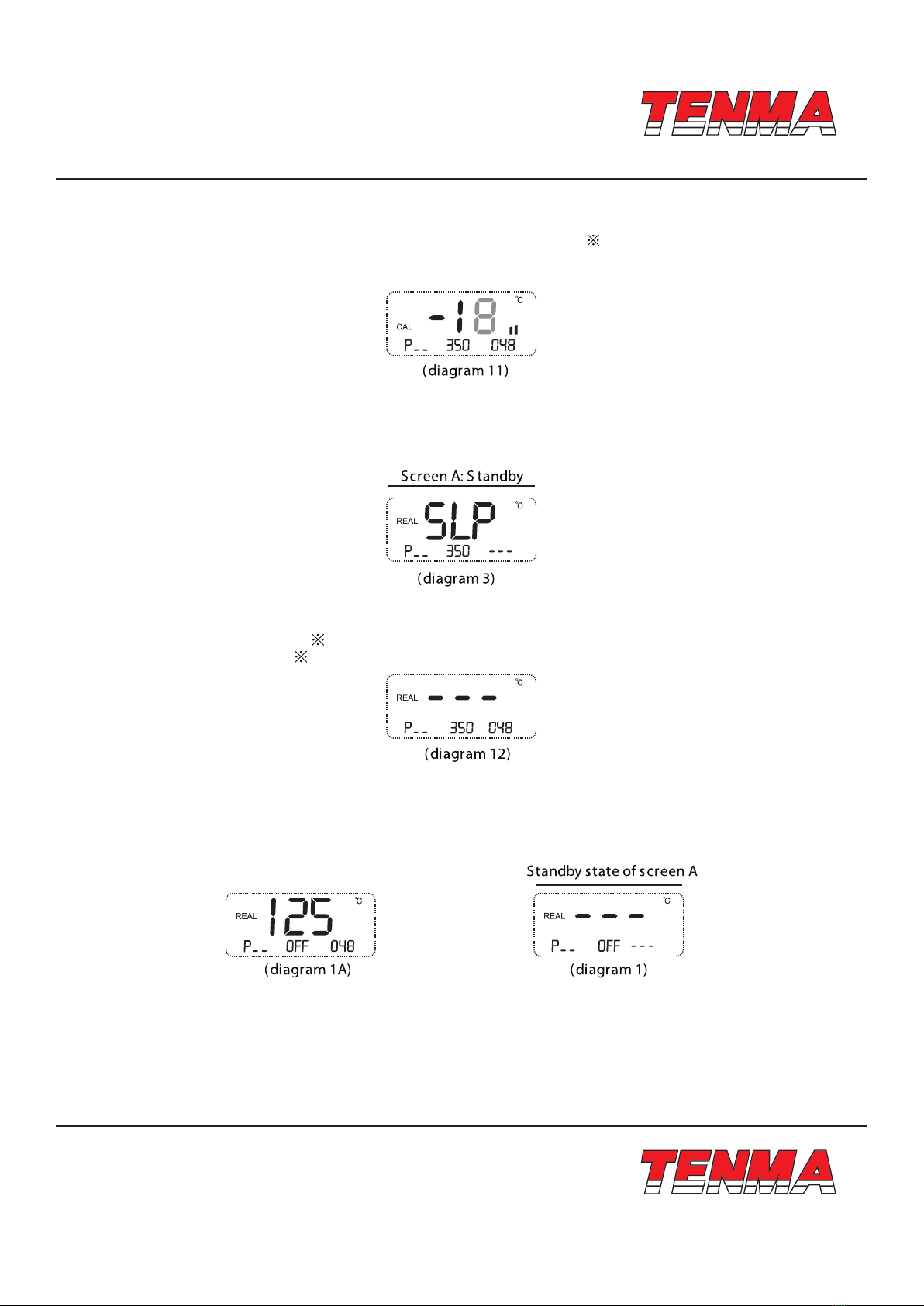

• Dual LCD screen respectively and separately display the working state and parameter, which is very directly. So customer

can understand the output state at a glance

• Temperature rapidly rises with large output power

• High ow diaphragm pump suitable for varies of nozzles to de-solder SMD components

• Dormancy, automatic shutdown and other power-saving features

• Shortcut keys on the handle make it more convenient for the user to adjust temperature and air volume

• Three groups of storage functions can bring very fast mode of switching different groups of temperature and hot-air volume

to the customers

• All units are equipped with temperature compensation, which ensure stable state of operation

• Indicator for malfunction alert.

Warning

• This tool be placed on its stand when not in use. The instructions for heat guns and hand-held paint strippers shall include

the substance of following:

• A re may result if the appliance is not used with care, therefore be careful when using the appliance in places where there

are combustible materials:

• Do not apply to the same place for a long time

• Do not use in presence of an explosive atmosphere

• Be aware that heat may be conducted to combustible materials that are out of sight

• Place the appliance on its stand after use and allow it to cool down before storage

• Do not leave the appliance unattended when it is switched on

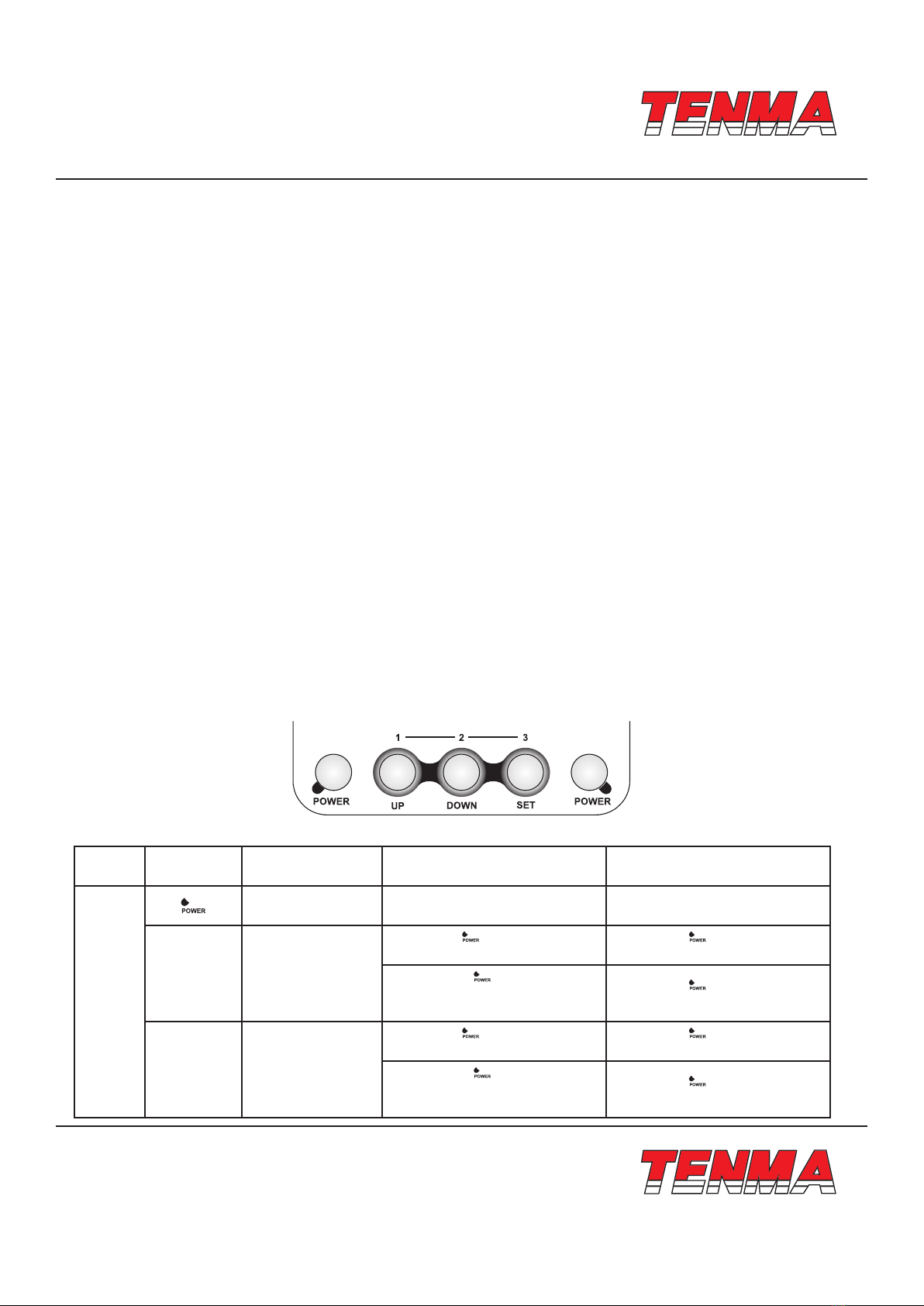

Button instructions

Position Knob/Button First function Second function

(short press < 5s)

Second function

(long press > 5s)

Front

Panel

Buttons

Work and shutdown

of the rework station Group Group

UP Value increasing

Press with knob and then se-

lect hot-air quick key 1 to set.

Press with knob and deposit

the setting of hot-air quick knob 1

Press with knob and then

select soldering station quick key

1 to set.

Press with knob and deposit

the setting of iron quick knob 1

DOWN Value decreasing

Press with knob and then se-

lect hot-air quick key 2 to set.

Press with knob and deposit

the setting of hot-air quick knob 2

Press with knob and then

select soldering station quick key

2 to set.

Press with knob and deposit

the setting of iron quick knob 2