www.terrateck.com 21

INTRODUCTION

PRESENTATION

Thank you for purchasing the Terrateck RJP 80M harvester. We hope that this machine will bring you complete satisfaction thanks to its

user-friendly features and manoeuvrability.

The Terrateck RJP 80M babyleaf harvester is designed for occasionally harvesting babyleaf crops, i.e. the various multicut salads (mesclun,

purslane, spinach).

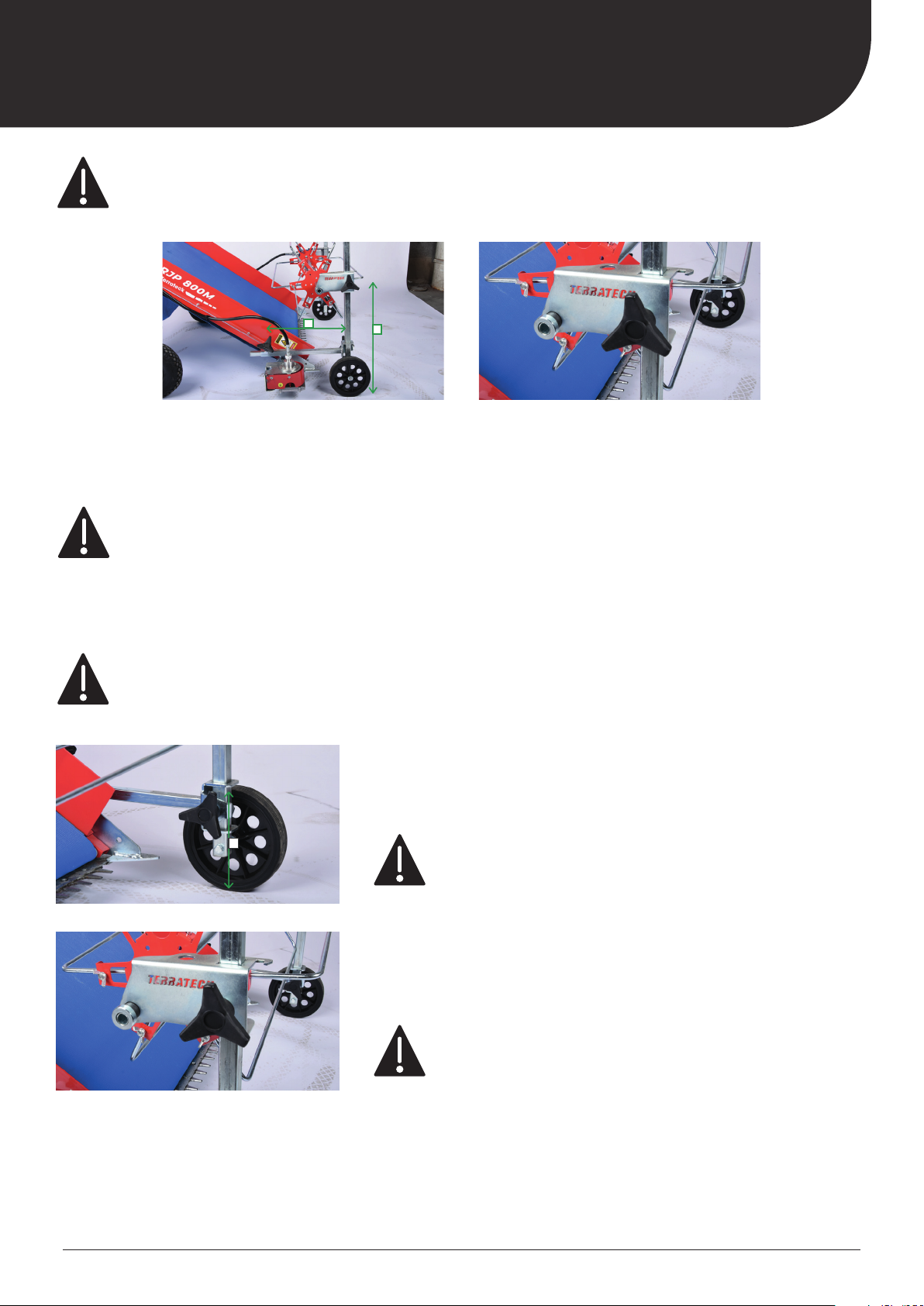

Equipped with an 80cm wide cutter bar, this babyleaf harvester cuts the plants cleanly and precisely. The cutter bar and pick-up reel

height are adjustable according to the height of the vegetation in order to comply with the different harvesting standards.

Designed and assembled in our workshop, the babyleaf harvester is a lightweight manoeuvrable tool.

The Terrateck RJP 80M babyleaf harvester meets the requirements of producers in terms of speed and consistent cutting quality. By

mechanising the harvesting process, our RJP 80M babyleaf harvester can cover 30 metres in 120 seconds.

Thanks to its electric motor, the Terrateck RJP 80M babyleaf harvester complies with environmental standards by eliminating the harmful

exhaust gases that would be discharged from a combustion engine in a conned environment (production greenhouses).

This user manual provides the information you need to use and maintain your harvester safely and correctly.

This manual contains the following information:

• Safety instructions for using this machine safely,

• Operating instructions for ensuring the best possible occupational standards for the best possible yield,

• Technical information for prolonging the life and improving the performance of the harvester.

COMMENTS:

• Keep this user manual in a place where it will not get damaged and that is easily accessible for future reference as needed.

• If this manual should become unusable or get lost, please purchase a new one from your Terrateck dealer-repairer.

• When hiring out the machine, please be sure to give this manual to the hirer.

• Should the machine be transferred or sold, be sure to give this manual to the new owner.

IDENTIFICATION OF YOUR MACHINE

SAFETY INSTRUCTIONS

Before you start using the machine for the rst time, carefully read the entire user manual to familiarise yourself with how the machine

operates and carry out your work properly and safely.

Keep the manual in a convenient place so that you can consult it when necessary. We recommend that you to read it again from time to

time to refresh your memory.

Terrateck has carried out a pre-shipment inspection of your new machine.

When you receive your harvester and before rst use, review the safety instructions, operating instructions and technical information

contained in this manual.

Do not use the machine for any other purpose not covered in this manual. Furthermore, Terrateck shall not be held liable for any such use.

All the information, illustrations and features contained in this manual are based on the latest information available at the time of

publication. We reserve the right to make changes at any time without notice.

The words and symbols below, which you will nd in the user manual and on the decals, are given as a reminder to read the instructions

because they concern your safety.

TERRATECK SAS

600 rue Adam Grunewald 62136 LESTREM - FRANCE

ANNÉE DE FABRICATION :

TYPE :

N° DE SÉRIE :

POIDS À VIDE :

MASSE EN CHARGE ADMISSIBLE : Kg

Kg

VÉHICULE NON HOMOLOGUÉ

To ensure a fast and efcient service, order parts or request a repair from your Terrateck

agent, make a note of the information engraved on the identication plate of your

machine.

Sprout picker

Year of manufacture

Type

Serial no.

Push bar

Reel

Cutter bar Front wheel

Rear wheel

Harvesting bag