Terrier TPH User manual

1

GEBRUIKERSHANDLEIDING

Terrier buishaken

OWNER’S MANUAL

Terrier pipe hooks

GEBRAUCHSANLEITUNG

Terrier Rohrhaken

MODE D’EMPLOI

Crochets le tube Terrier

Productcode

TPH/TPH-HD

Distributed By: Super Slings Inc 866-787-7544

2

Lees deze gebruiksaanwijzing aandachtig door, nog voordat u de buishaken gebruikt.

Bij twijfel raadpleeg uw leverancier!

Deze gebruikershandleiding is bedoeld als referentiebron

gedurende de levenscyclus van uw product.

Commentaar en op- of aanmerkingen met betrekking tot de inhoud

van deze handleiding wordt op prijs gesteld.

In verband met voortdurende onderzoeks- en ontwikkelingsactiviteiten,

kunnen technische specificaties en/of uiterlijke kenmerken van de hijsklemmen

zonder voorafgaande kennisgeving gewijzigd worden.

Please carefully read the safety instructions of this owner’s manual

before using the safety pipe hooks.

In case of any doubts, please refer to your dealer!

Our manuals are intended to be a reference source

throughout the lifetime of your product. We appreciate any

suggestions, and/or comments regarding this manual.

Due to continuing research and development activities,

product specifications are subject to change without notice.

Lesen Sie die Gebrauchsanleitung vor Benutzung des Produkts sorgfältig durch.

Bei Fragen wenden Sie sich bitte an Ihren Zulieferer.

Die Gebrauchsanleitung dient während der gesamten Lebensdauer des

Produkts als ständige Informationsquelle.

Für Hinweise oder Anmerkungen zur Verbesserung des Inhalts dieser

Gebrauchsanleitung sind wir dankbar.

Aufgrund kontinuierlicher Forschungs- und Entwicklungsprozesse behalten

wir uns technische Änderungen und/oder Änderungen äußerlicher

Merkmale der Lastaufnahmemittel vor.

Lisez attentivement ce mode d’emploi avant d’utiliser le crochet le tube.

En cas de doute: demandez conseil à votre fournisseur.

Nos modes d’emploi ont pour but de servir de source de référence durant

la durée de fonctionnement de votre produit.

Nous apprécions les suggestions et/ou les remarques concernant ce mode d’emploi.

Dû aux activités continues de recherche et de développement, les spécifications

techniques et l’apparence des pinces peuvent être changés sans avis préalable.

NederlandsEnglishDeutschFrançais

9

English

CONTENTS

1 General 9

2 Authorised applications 9

3 Operating instructions 9

4 Safety regulations 9

5 Lifting 11

6 Maintenance 11

7 Removal/Installation 12

8 Revision 12

9 Destruction 12

10 Checklist for malfunctions and problems 13

11 5-year warranty 13/14

1 GENERAL

Read these operating instructions carefully before using the TPH(-HD).

If in doubt, contact your supplier.

Thank you for choosing one of our high-quality products.The quality systems of manage-

ment and services of Terrier Lifting Clamps B.V. fully comply with ISO 9001 standards. The

many years of vast experience are a guarantee of optimum quality and safety. Terrier Lifting

Clamps are manufactured from high quality alloy steels and comply fully with all standards

and product requirements including: European standard: NEN 13155, Australian standard:

4991, US standard: ASME B30.20-2010 and machinery directive 2006/42/EG.

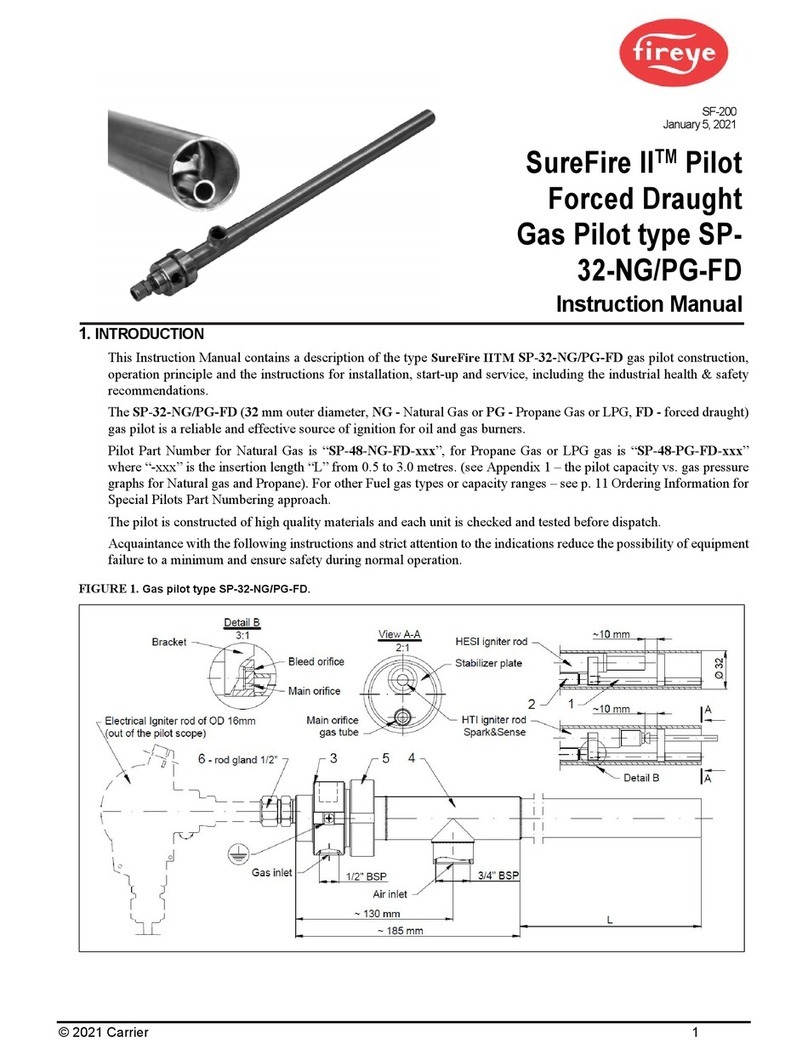

2 AUTHORISED APPLICATIONS

Terrier TPH(-HD) pipe hooks have a high-performance bearing surface finished with a plas-

tic coating, which is easy to replace. Terrier TPH(-HD) pipe hooks are used exclusively for

horizontal lifting and transporting of pipes. The hooks can only be used in pairs using a

two-leg sling or spreader beam. Compact and lightweight in design, Terrier TPH(-HD) pipe

hooks have a high lifting capacity.

3 OPERATING INSTRUCTIONS

Determine whether the WLL of the TPH(-HD) is sufficient for the object to be lifted.

Determine the allowable lifting angle from the “diagram determining allowable lifting

angle” provided below, the thickness of the material to be lifted and the maximum jaw

opening of the hooks in question.

Always use a two-leg sling or spreader beam to lift pipes. Do not use two cranes to do so.

Place the Terrier TPH(-HD) pipe hooks attached at each end of the pipes completely inside

the pipe, until they sit firmly in the back end of the jaws. Lift the load slowly and transfer

it to the destination point, then lower slowly until it is resting on solid ground. The TPH(-

HD) pipe hooks can now be easily removed. They are ready to be used again or put away.

4 SAFETY REGULATIONS

Pay attention to your own safety and to that of direct bystanders!

Read the following safety regulations before using your new TPH(-HD) pipe hooks!

10

For your own safety and the safety of the product, the lifting hook must be inspected and

tested at least once (1x) annually, and revised by Terrier Lifting Clamps B.V. or another au-

thorised revision company, if necessary.

See also Section 8 - Revision. No structural alterations (welding, grinding, etc.) may be made

to the hooks.

Please contact Terrier Lifting Clamps B.V. for more information.

TEMPERATURE

The operating temperature of Terrier TPH pipe hooks is between -40 °C (+40 °F) and + 50 °C

(122 °F). For Terrier TPH-HD pipe hooks, this is between -30°C (-22°F) and +80°C (176°F).

For other ambient temperatures, contact your dealer.

LOADS

Our Terrier TPH(-HD) pipe hooks are used exclusively for horizontal lifting and

transporting of pipes. Do not exceed the WLL specified on the hooks.

AVOID LIFE-THREATENING SITUATIONS

Avoid life-threatening situations by complying with the following guidelines:

- Do not work with pipe hooks that have not been approved.

- Keep a safe distance during lifting operations and never walk or stand under the load.

- Donotusetheliftinghookifdamaged;havethehookrepairedbyTerrier Lifting Clamps B.V.

or another authorised revision company. If in doubt, contact your supplier.

- Check the material to be lifted for defects and cracks.

- Check lifting hook and jaws for defects, cracks and deformations.

- Do not lift loads that are heavier than the safe working load (WLL) that is clearly

indicated on the hook and the certificate.

- Do not lift loads that are thicker or thinner than the jaw opening, as specified on

the lifting hook and the certificate.

- Terrier TPH(-HD) pipe hooks can only be used in pairs with a two-leg sling or spreader

beam.

- Clean the area on the object where the hook is to be attached, removing any grease, oil,

dirt, corrosion and contamination.

- The pipe hooks are suitable for use in normal atmospheric conditions.

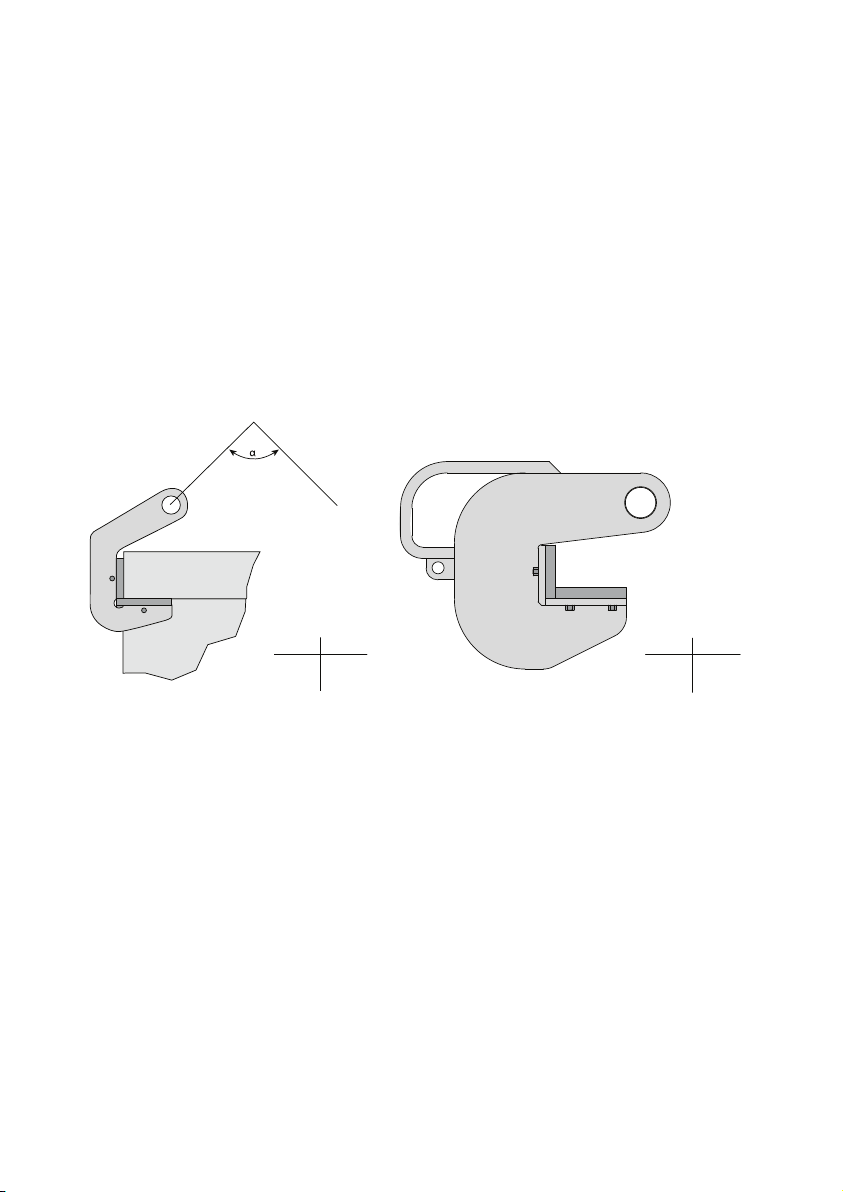

R ɲ

< Max 10 - 90°

= Max 10 - 120°

TPH-HD

R ɲ

< Max 10 - 60°

= Max 10 - 90°

TPH

Diagram determining allowable lifting angle

11

English

WARNING

- A free fall or uncontrolled swinging on the two-leg sling or spreader beam whereby

there is contact with objects can damage the lifting hook. Should this occur, the hook

must first be thoroughly inspected before use.

- TPH(-HD) pipe hooks are not suitable as a form of permanent link.

- The hook must undergo preventive maintenance every month, see Section 6 - Mainte-

nance.

- Do not make any structural alterations to the lifting hook (welding, grinding, etc.). Such

alterations may compromise the performance and safety of the hook. If any such altera-

tions are made, all forms of warranty and product liability become invalid.

- The warranty and liability conditions also only apply when original Terrier components

are used.

- Improper use of the hook and/or failure to comply with the instructions and warnings

in the operating instructions regarding the use of this product can adversely affect the

health of the user and/or bystanders.

5 LIFTING

- Check that the safe working load (WLL) and jaws (clamping the hook) correspond to the

load to be lifted.

- Attach the pipe hooks to lifting equipment, either:

- by means of a belt or chain, in combination with a chain shackle or D shackle,

if necessary.

- Make sure all attachment devices are approved and are of the correct tonnage. All the

attachment links and securing devices must be sufficiently large, so that the hook can

move freely.

- Check that the hook has no visible damage.

- Inspect the plastic coating for wear and defects (the plastic coating must be free of con-

tamination, dry and undamaged).

- Check the frame and jaw for damage, cracks or deformation (which is indicative of over-

load).

- Remove grease and dirt from the area on the pipe where the lifting hook is to be at-

tached.

- Place the hook completely in the pipe until it sits firmly in the back end of the jaws and

make sure that the hook is positioned in such a way as to balance the load when it is

being lifted.

- Lift steadily to allow effective gripping by the hooks on taking up the load.

- Make sure the load is stably positioned before the hooks are removed.

6 MAINTENANCE

For maximum safety, inspect the lifting hook at least once a month.

Do not use the hook if:

- it is cracked or deformed,

- the plastic coating is damaged or contaminated.

If any of the above defects are found, see Sections 7 and 8.

12

7 REMOVAL/INSTALLATION

- With a pin driver, tap the tension pins from one side of the lifting hook completely

through the housing (for TPH models; 1.5 to 8 tonnes).

- With a pin driver, tap the tension pins from both sides of the hook so far into the plastic

that the tension pin is seated just beyond the side plate of the hook (for TPH models;

10 to 20 tonnes).

- Loosen all nuts and remove the bolts (for TPH-HD models; 5 to 60 tonnes).

- The plastic blocks can now be removed from the hook.

- Install all new components.

- Make sure that the vertical and horizontal covers are installed correctly. The vertical

cover is T-shaped (in the TPH model).

- First place the vertical and then the horizontal cover.

- Always use new original tension pins; insert them with a hammer and tongue-and-

groove pliers (in the TPH model).

- Always use new original bolts and locknuts (in the TPH-HD model).

- For replacement, use original Terrier parts only.

8 REVISION

At least once (1x) per year, or if the lifting hook becomes damaged, TPH(-HD) pipe hooks

must be inspected, tested and revised by Terrier Lifting Clamps B.V. or another authorised

revision company, if necessary.

9 DESTRUCTION

At the end of its working life, the TPH(-HD) pipe hooks can be treated as scrap iron, as long

as it is rendered unusable first.

VERTICAL COVER

HORIZONTAL COVER

Clamp type: TPH Clamp type: TPH-HD

13

English

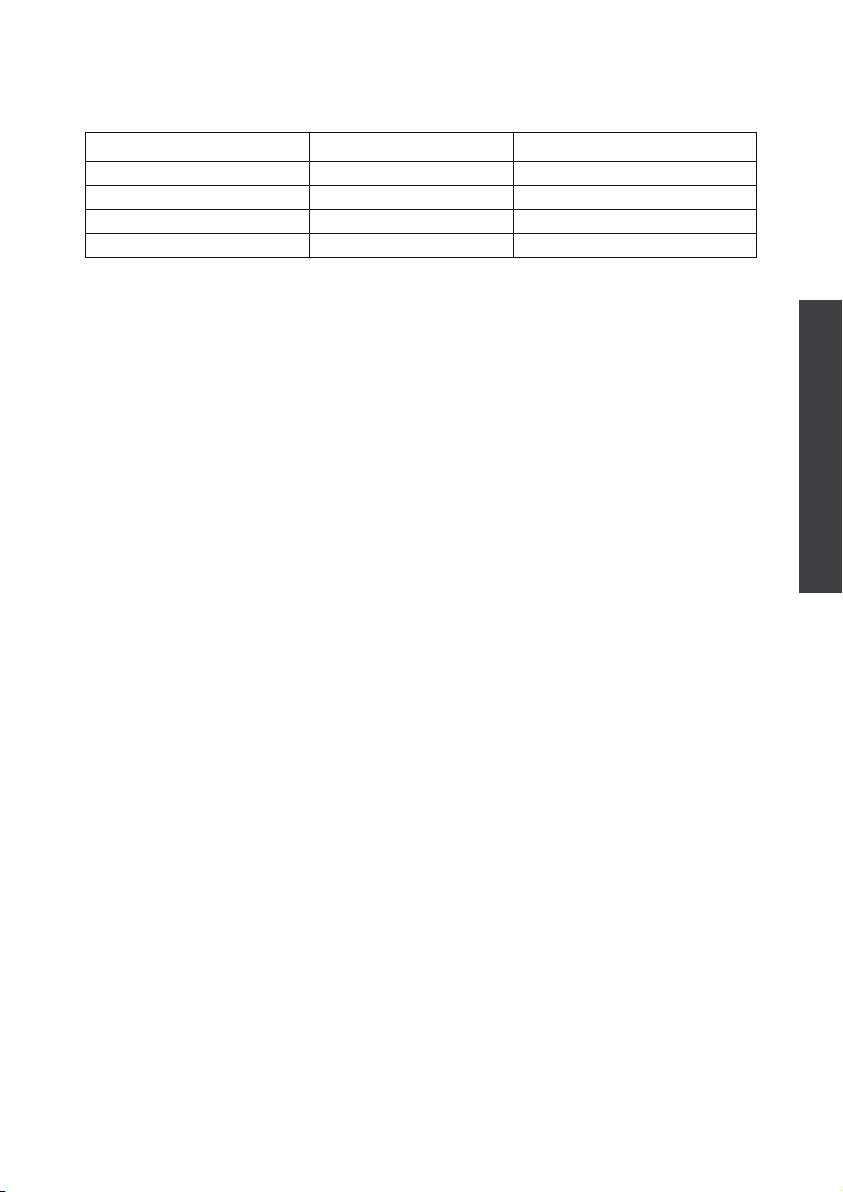

10 CHECKLIST FOR MALFUNCTIONS AND PROBLEMS

11 5-YEAR WARRANTY

Terrier Lifting Clamps B.V. offers end users a 5-year warranty on the lifting equipment.

This warranty is limited to the original end user of the lifting equipment and is subject to

the equipment being inspected, controlled and maintained according to the producer and

dealer instructions throughout the warranty period. The warranty period is 5 years from

the purchase date and is subject to the conditions and measures given here.

11a TERMS AND CONDITIONS

The warranty only covers defects in the lifting equipment resulting from manufacturing

errors. The warranty does not cover wear to components. If a defect occurs within this war-

ranty period, the lifting equipment will be replaced or repaired as the producer thinks fit.

No warranty is given for lifting equipment in which defects occur due to:

- Regular wear and tear.

- Overloading.

- Incorrect and/or rough use.

- Damage.

- Non-compliance with procedures and measures.

- Lifting materials other than those shown on the lifting equipment or in the user manual.

- Modification/alteration of the Terrier lifting hook.

- Improper use of the hook and non-compliance with any instructions given in the user

manual in question.

- Maintenance and/or revision work not carried out by an authorised Terrier dealer.

The producer is not responsible for incidental damage or damage due to wrong use of the

lifting tools as well as from violation of this manual.

Malfunction/problem Possible cause Action

Housing deformed Lifting hook overloaded Reject hook

Spindle bent Lifting hook overloaded Reject hook

Tension pins missing Incorrect installation Fit new tension pins

Plastic covers damaged Covers worn Fit new cover set

14

11b PROCEDURE FOR SAFETY INSPECTION

All inspection and repair work must be noted in the inspection schedule.

This applies not only to your own inspection work but also to inspection work carried out

by your authorised Terrier dealer. When the equipment is submitted for maintenance and

inspection, the maintenance report must always be provided.

Defective pipe hooks

On discovering any form of wear or damage, the following measures must be taken.

1 Decommission the lifting hook (Note down the date of decommissioning of the lifting

hook).

2 Try to find the cause of the defect, for example (see full list under point a):

These types of damage are not covered by the warranty! Please follow this procedure in

order to guarantee your safety and that of your colleagues/personnel.

3 Hand in your lifting hook with maintenance history to your authorised Terrier repair

shop.

4 Once the hook has been revised/repaired by your repair shop, it can be used again.

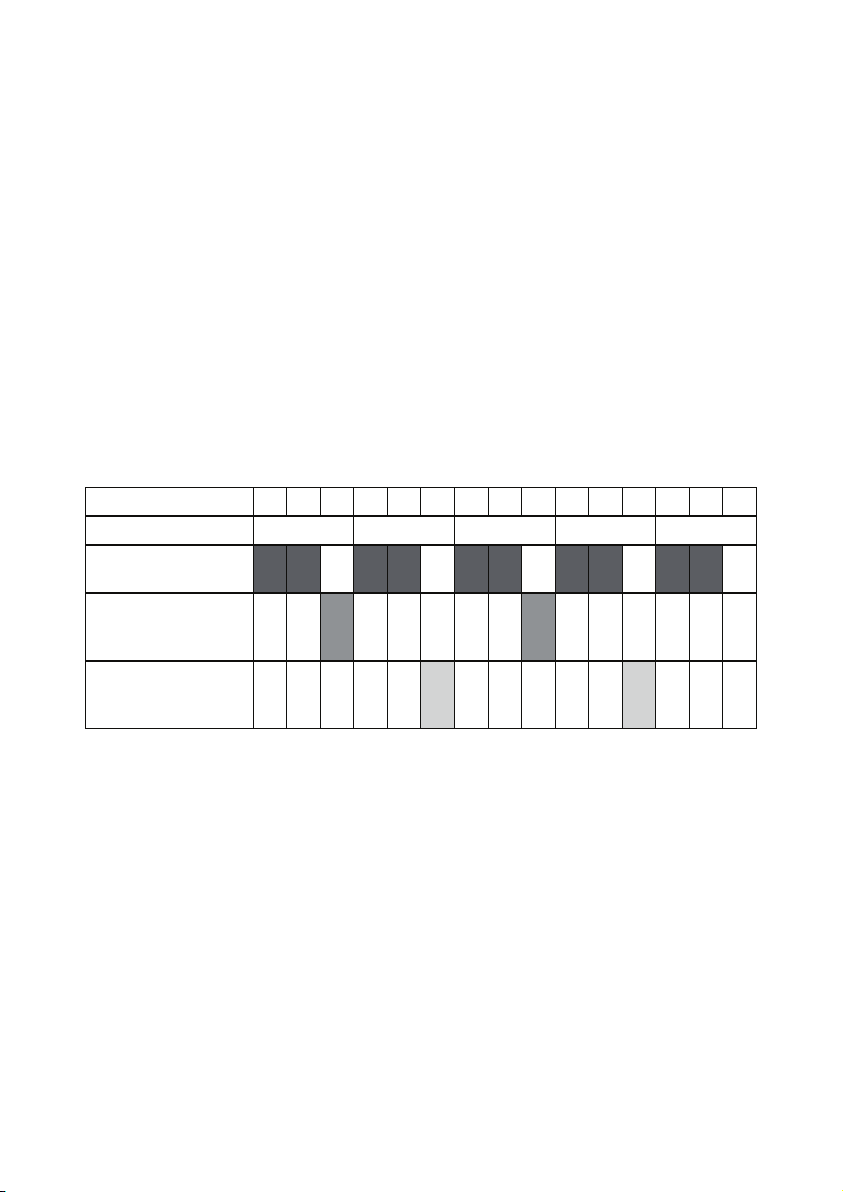

11c INSPECTION TABLE

Months 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60

Years 12345

Safety inspections by

your own inspector

Maintenance by an

authorised Terrier

repairshop

Revision by an

authorised

Terrier

repairshop

27

Français

28

WWW.TERRIERCLAMPS.COM

Terrier Lifting Clamps B.V.

Ohmweg 11

4338 PV Middelburg

P.O. box 8119

4330 EC Middelburg

Nederland

Tel : +31 118 - 65 17 17

Fax : +31 118 - 65 17 18

Email: [email protected]

Find us on

youtube/terrier lifting clamps

Other manuals for TPH

1

This manual suits for next models

1

Table of contents

Other Terrier Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Kalamazoo

Kalamazoo K10HS instruction manual

Nidec

Nidec LEROY-SOMER LSA 49.1 IC6 Installation and Maintenance

Dorner

Dorner 2200 series Safety, Setup, Operation & Maintenance Manual

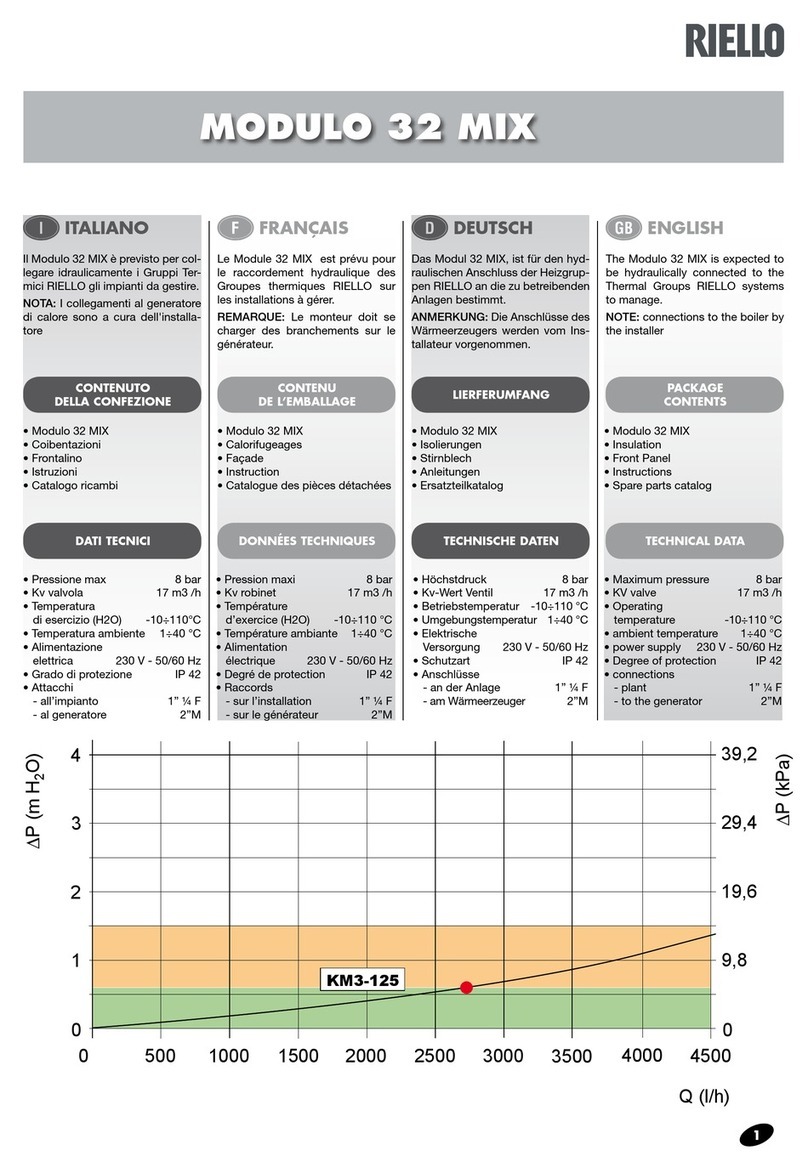

Riello

Riello MODULO 32 MIX instruction manual

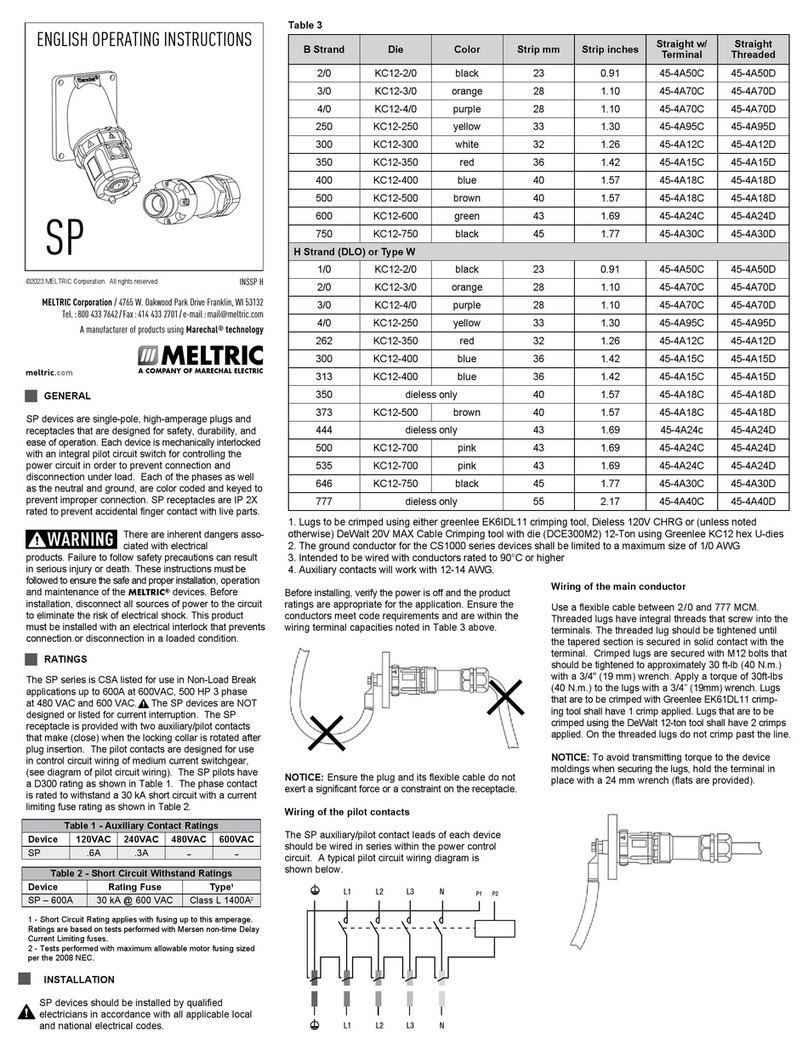

Meltric

Meltric SP Series operating instructions

Conductix-Wampfler

Conductix-Wampfler Enduro+ Series manual