FF-MM-373-REV - 03

Operation and Maintenance Guide DP 50 Metal Series Page 9

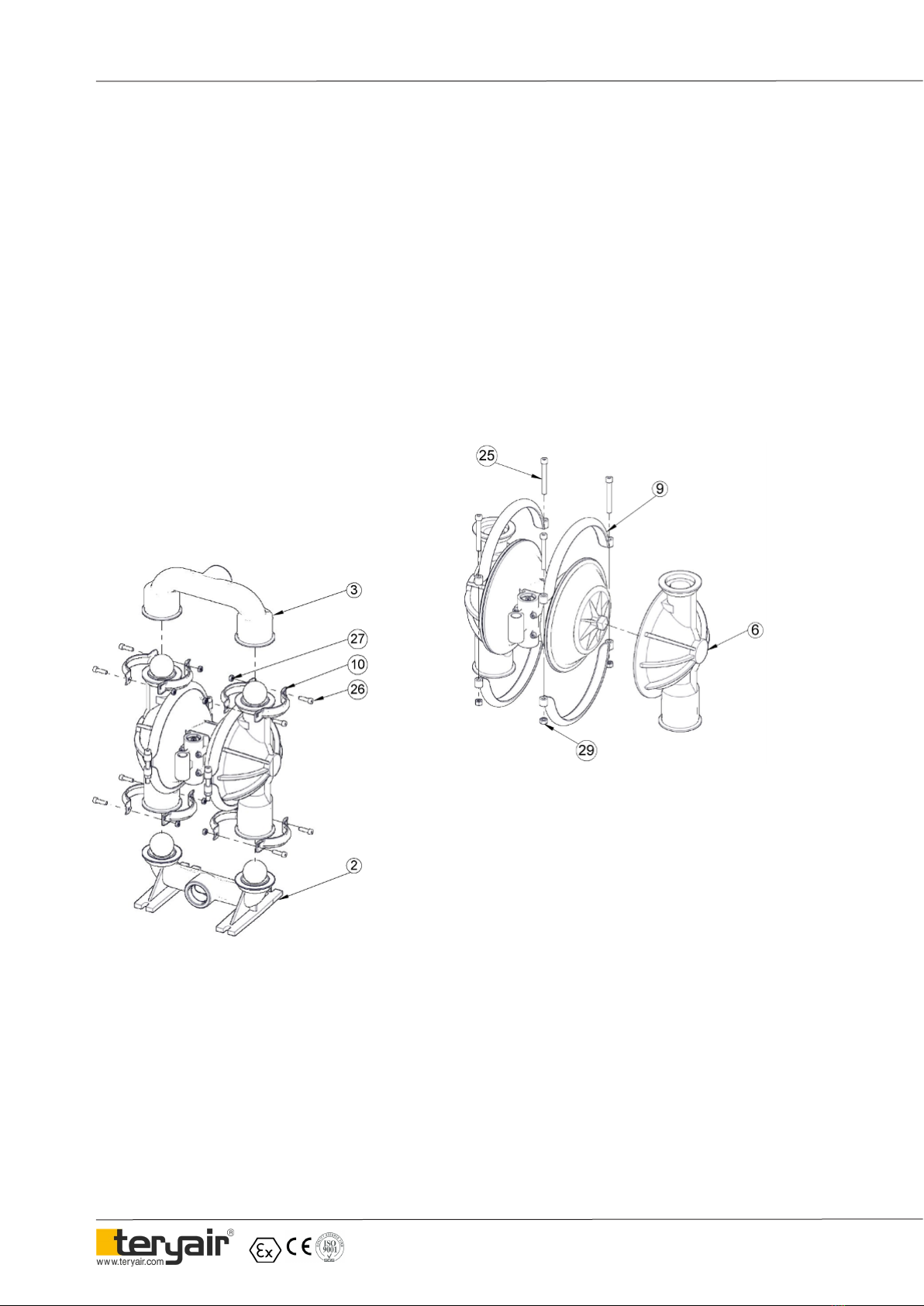

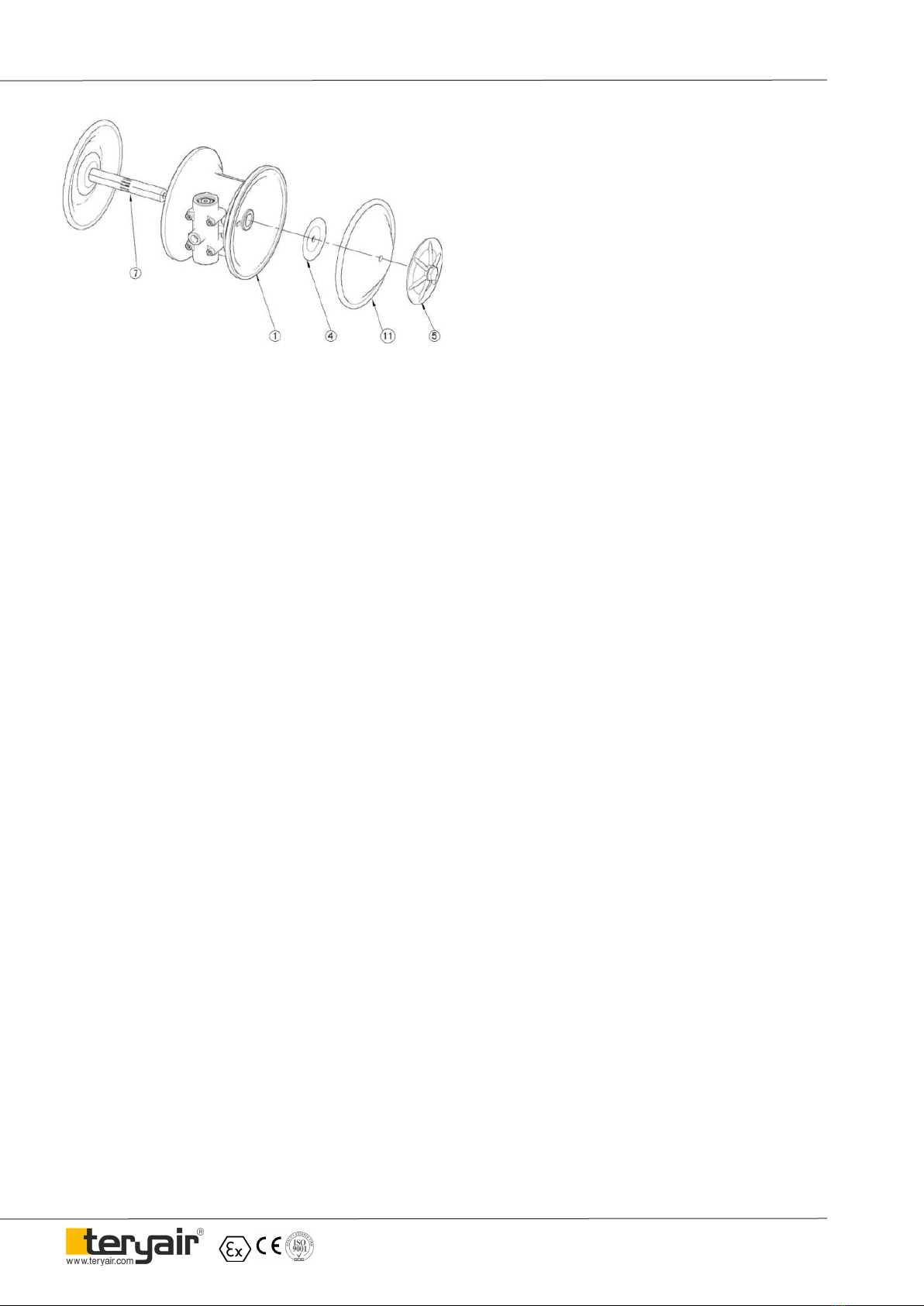

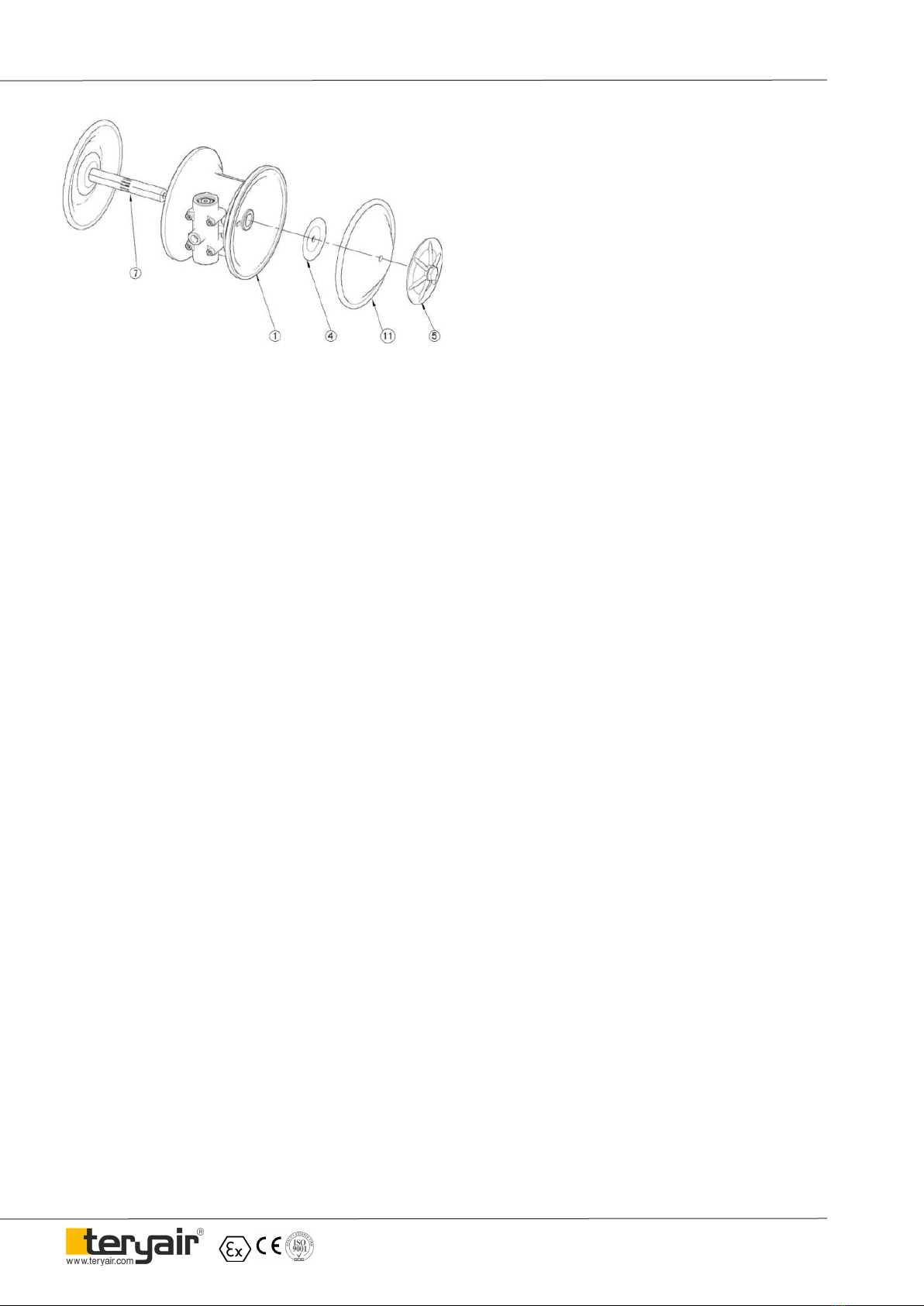

d. Now hold the sha (7) in a vice with proper

packing. Care must be taken not to damage the sha outer

surface. Now remove the outer ange (5) with spanner.

*For ALT/SST series remove the bolt (5A) and remove the

outer ange (5), Backup diaphragm (11), Inner spacer (7A &

PTFE diaphragm (11A).

e. Now replace the diaphragms (11). Ensure that di-

aphragm orientation is correct, i.e. For ALB/ ALN/ALV the

sticker side of the diaphragm (11) to be located in the outer

chamber (6). Now assemble the outer ange (5) in reverse

manner and remove the half sha assembly from vice.

* Refer g. A for ALT & SST model the convex side of outer

ring PTFE diaphragm (11) to be located in outer chamber

(6). For the backup diaphragm (11A) the larger side of outer

ring to be located in sha housing (1) & small in the concave

groove of PTFE diaphragm (11).

* For ALS/ ALH model AIR SIDE marking to be located

toward the sha housing (1).

f. Lubricate the edge of the sha with specied

lubricant. Slowly insert the sha with rotating motion. Care

should be taken not to damage the rubber rings (8).

g. Once the half sha open portion comes out of the

bush, follow the procedure in reverse manner as described in

part (a) & (b) and assemble the pump.

2) Replacement of Shaft O rings

a. For removing the rubber rings from bush, rst

follow the step a, b & c from the diaphragm replacement.

b. Now remove the seals with the help of needle Nose

pliers. Care should be taken not to damage the inner face of

bush.

c. Once all the old seals are have been removed, the

inside of the bushing should be cleaned to ensure no debris

is le that may damage to new seals (Pressurized air is pref-

erable).

d. ese following tools can be used to aid in the

installation of new seals:

• Needle Nose pliers

• Phillips Screwdriver

• Electrical Tape

e. Wrap electrical tape around each leg of the needle

nose pliers (heat shrink may also be used) . is is done to

prevent damaging the inside portion of the new seals.

f. With a new seal in hand, place the two legs of the

nose pliers inside the seal ring. Open the pliers as wide as

the seal diameter will allow, then two ngers pull down on

the top portion of the seal to form kidney bean shape.

g. Lightly clamp the pliers together to hold the seal

into the kidney shape. Be sure to pull the seal into as tight of

a kidney shape as possible, this will allow the seal to travel

down the bushing bore easier.

h. With the seal clamped in the pliers, insert the seal

into the bushing bore and position the bottom of the seal

into the correct groove. Once the bottom of the seal is seated

in the groove, release the clamp pressure on the pliers. is

will allow the seal to partially snap back to its original shape.

i. Aer the pliers are removed, you will notice a slight

bump in the seal shape. Before the seal can be properly

resized, the bump in the seal should be removed as much

as possible. is can be done with either the Phillips screw

driver or your nger, apply light pressure to the peak of the

bump. is pressure will cause the bump to be almost com-

pletely eliminated.

j. Lubricate the edge of the sha with specied lubri-

cant.

k. Slowly insert the sha with rotating motion. is

will complete the resizing of the seals.

l. Perform these steps for the remaining seals.

3) Replacement of Ball seat & Ball

a) Follow the step (a) of diaphragm replacement.

Replace the ball (12) & seat (13) with new one.

* For ALT, SST series change the valve seat

(13) & oring (13A) with new one.

4) Replacement of air valve and oring

of end cap

a) Unscrew commen nut (27) just behind the

washer (28) from the sha housing (1). Remove the air valve

assembly along with the bolt (24). Now remove the circlips

(21) from both ends. Now with the help of bolt (24) pull the

end cap (17) & (19) from both ends. Now slide out the air

valve (16). Change the oring (20) of both end caps.

b) While assembly rst put the end cap with pin (19)

in air valve body (14). Make sure the notch of end cap (19)

matches with the drill hole of body. Push the end cap with

oring (20) gently. Now t the circlip (21). Now slide the air

valve from other side ensuring the drill portion located in

the pin of end cap (19). Now push the end cap (17) with

oring (20) from the other end and t the circlip.

c) You can also change the gasket for air valve body

(15) & blocking pad (22). Now assemble the air valve

assembly in reverse manner. While assembly make sure to

put the spring washer (28) along with the nut (27).