Warning. Static Electricity

Static sparks can cause explosion resulting in

severe injury or death.

Ground the pump and the pump connections like

hoses and containers into which or from the fluid is

being transferred. Connect the grounding wire to

any bolt on the pump.

Check continuity of electrical path to ground at

regular intervals.

Consult local building and electrical codes for

grounding requirements where needed.

Use hoses containing a grounding wire.

Warning: Pump Exhaust

In case of a diaphragm failure, fluid being pumped

may spray out from the exhaust of the pump. This

may cause severe injury depending on the fluid

being pumped.

If the fluid is hazardous, pipe away the exhaust to a

safe remote location using a generous diameter ¾”

pipe preferably with a grounding arrangement, and

refit the muffler at the end of this arrangement.

Always wear safety glasses while in the vicinity of

an operating pump.

Warning: Overpressure/Hazardous

Pressure

Do not exceed the max supply air pressure of 125

PSI.

Make sure all connected hoses and pipelines are

rated to operate safely with the pressures generated

by pump of 125 PSI.

Do not open or handle pump or hoses while

pressurized.

Disconnect air supply line and relieve pressure from

the system by carefully opening discharge and

supply lines.

Warning: Hazardous Materials

Do not move a pump that contains hazardous fluids

trapped inside it. Please observe prescribed

handling and safety codes. Drain the pump safely,

by turning it upside down and collecting the fluid

safely, before moving the pump.

Warning: Explosion

Please check compatibility of fluids intended to be

handled with the materials of construction of the

pump. Severe reactions and explosions may occur

if materials are incompatible.

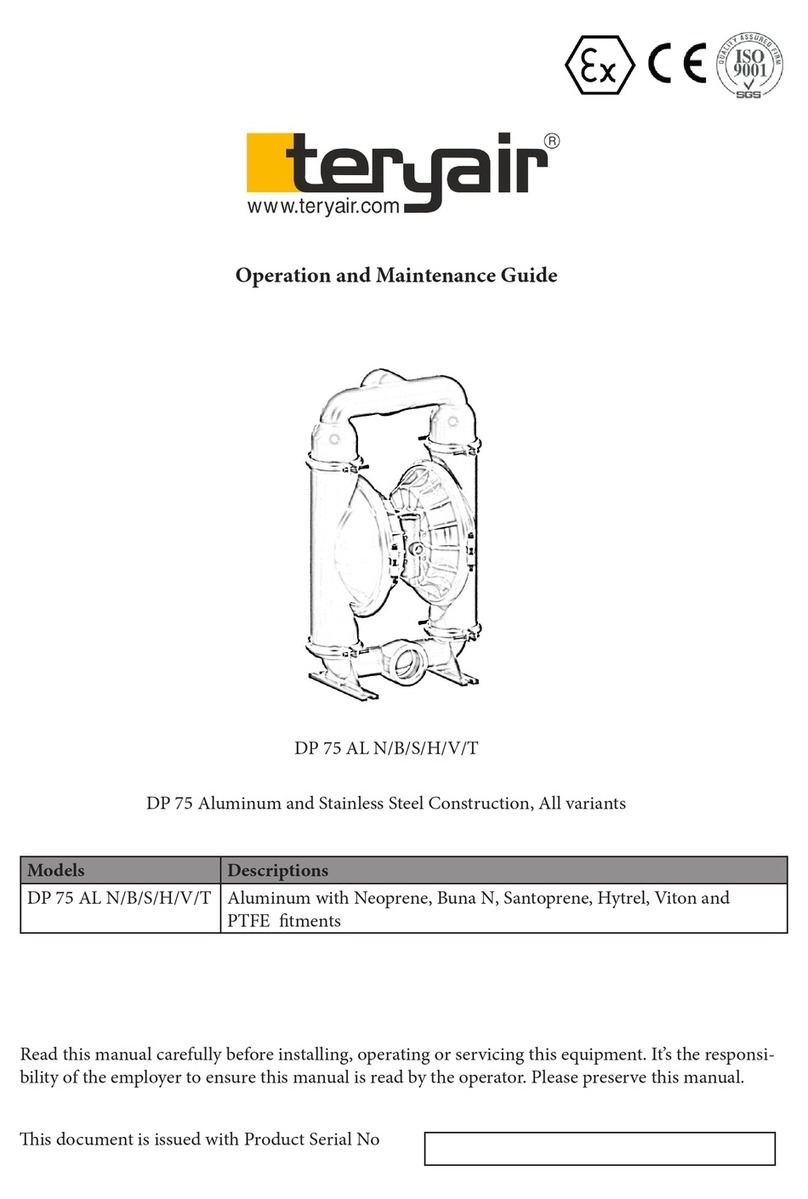

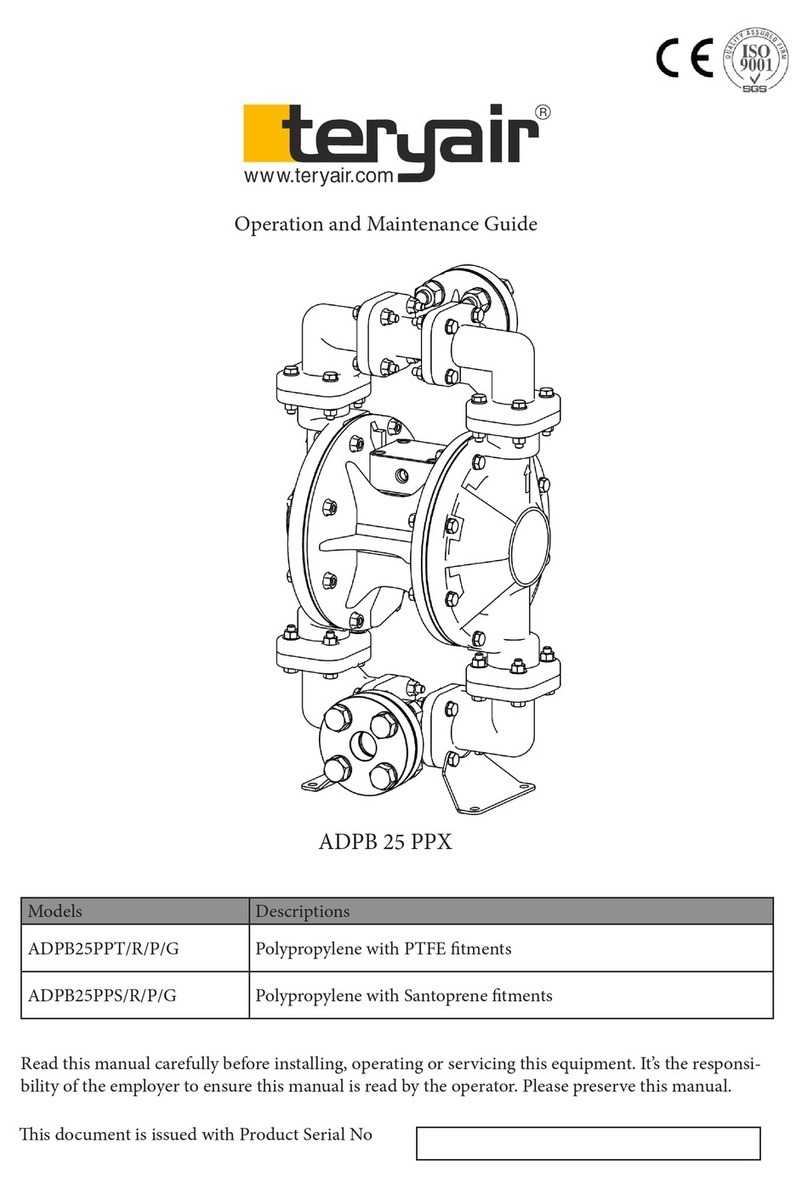

Caution: Chemical Compatibility

Please check that the fluid being pumped is

compatible with the wetted parts of the pump. Refer

Cole Parmer compatibility

(http://www.coleparmer.in/Chemical-Resistance)

guide for details. Note that chemical compatibility

may change with temperature; take this into account

while selecting pump material.

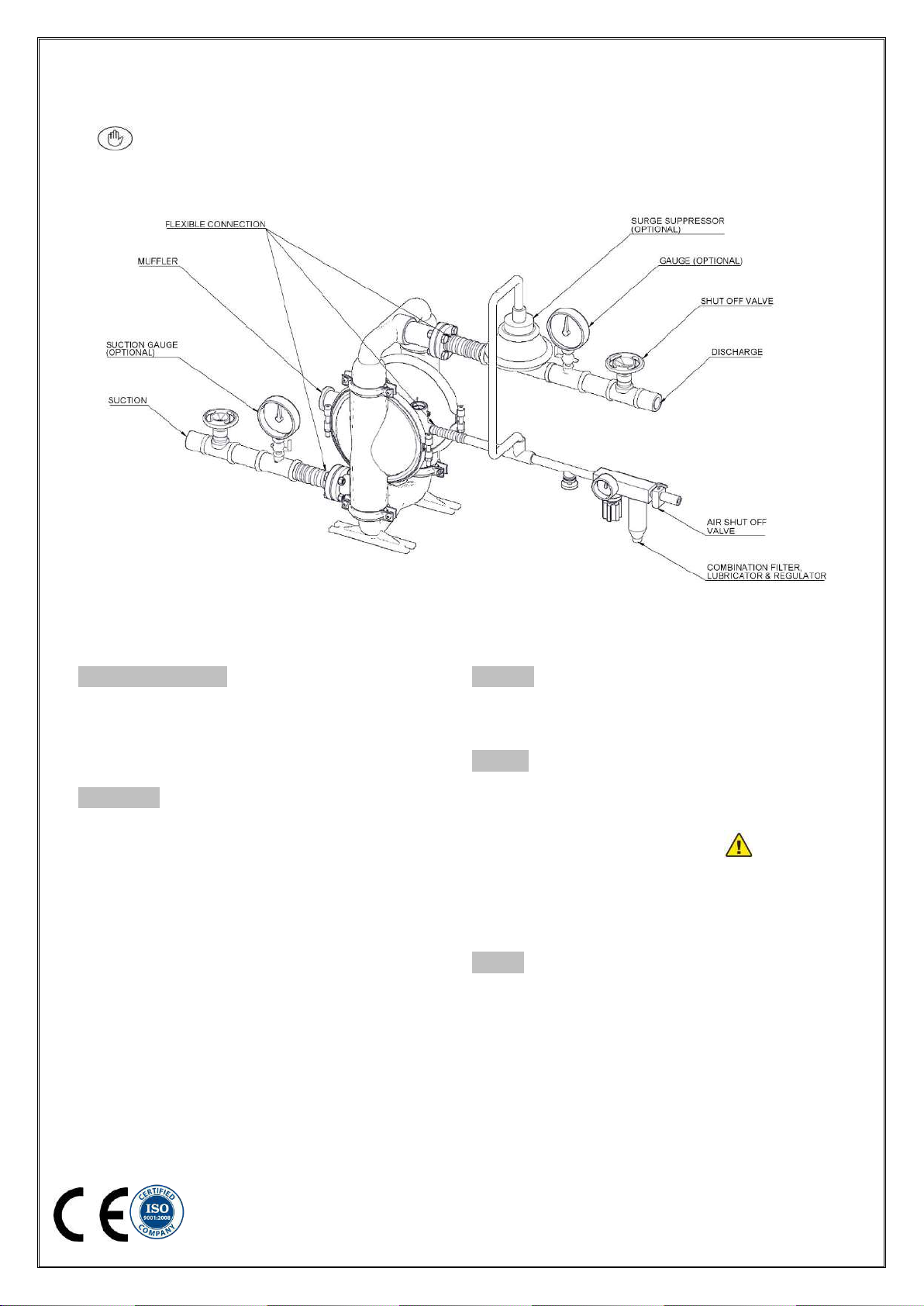

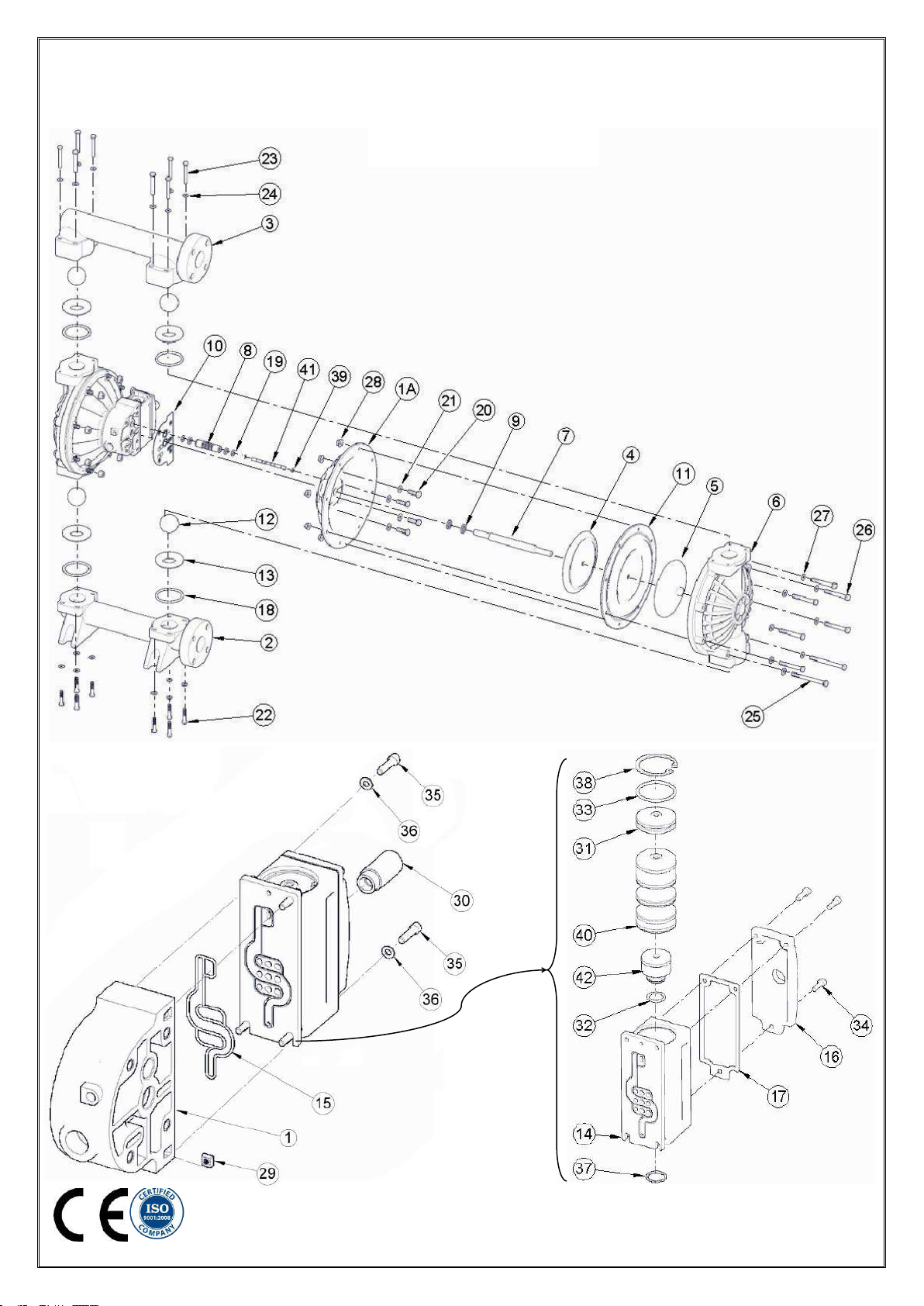

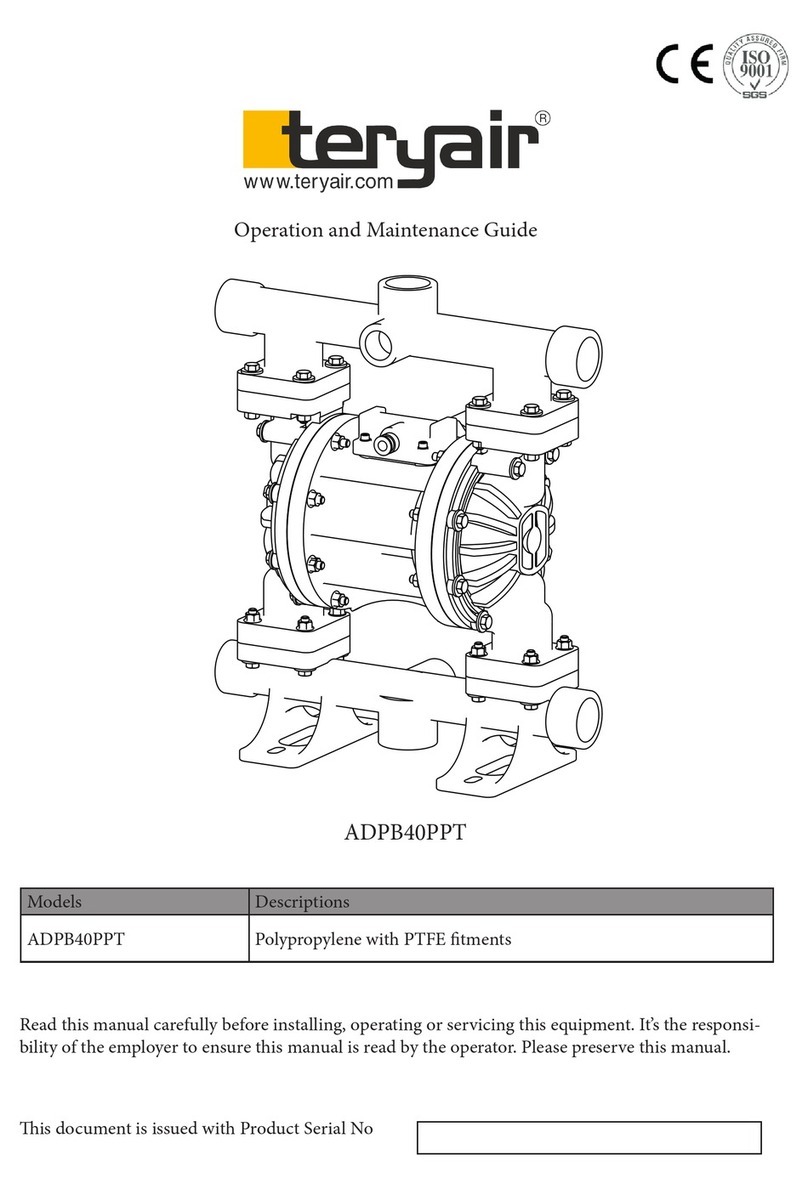

Caution: Structural Support

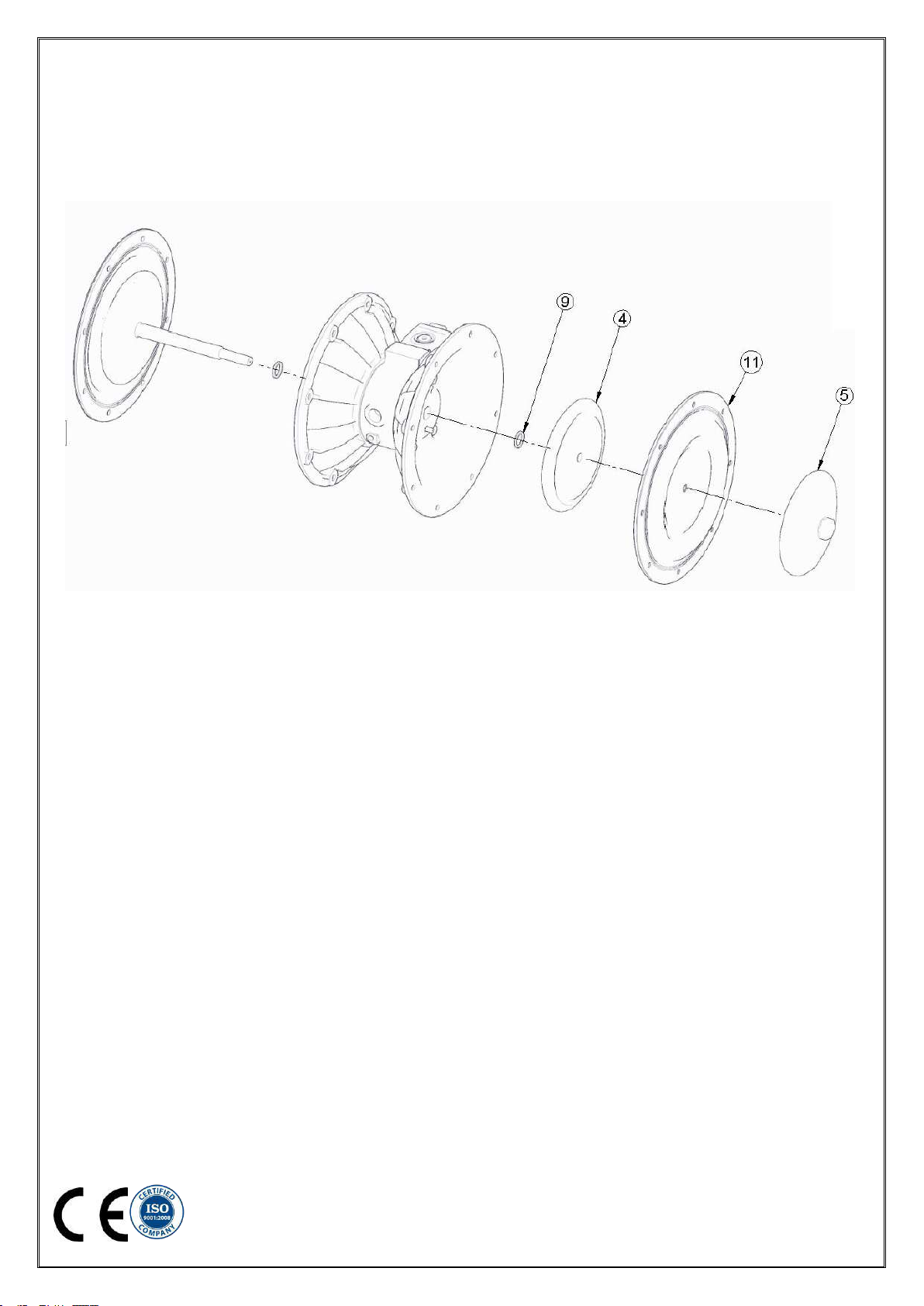

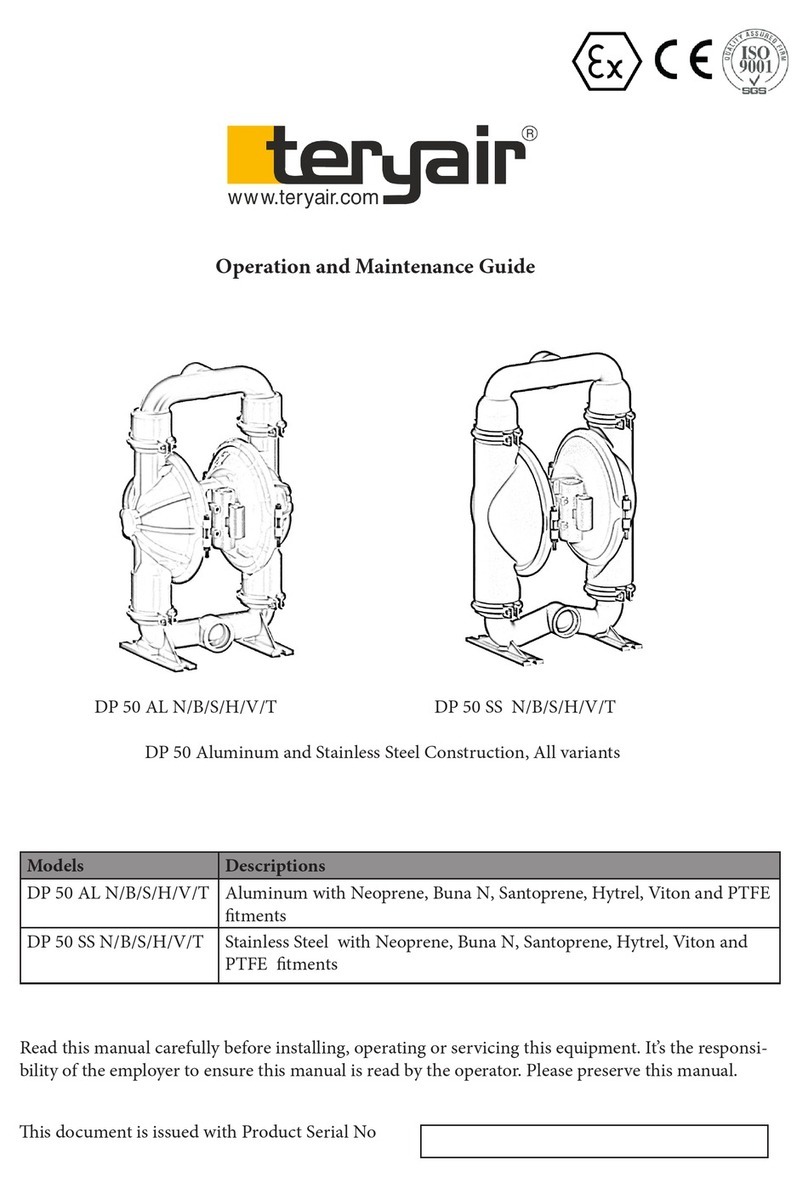

Please refer figure 1 and ensure that the piping

system is independently supported and does not

load the pump. The pump is not designed to take

the continuous and often pulsating load of a piping

system. Important to use a flexible connection

between rigid piping and pump casings.

Caution: Running dry, disconnection of

hoses when not in use for long periods.

Although these pumps can be run dry for long

periods, it is advisable to avoid this as it causes

unnecessary wear of wearing parts.

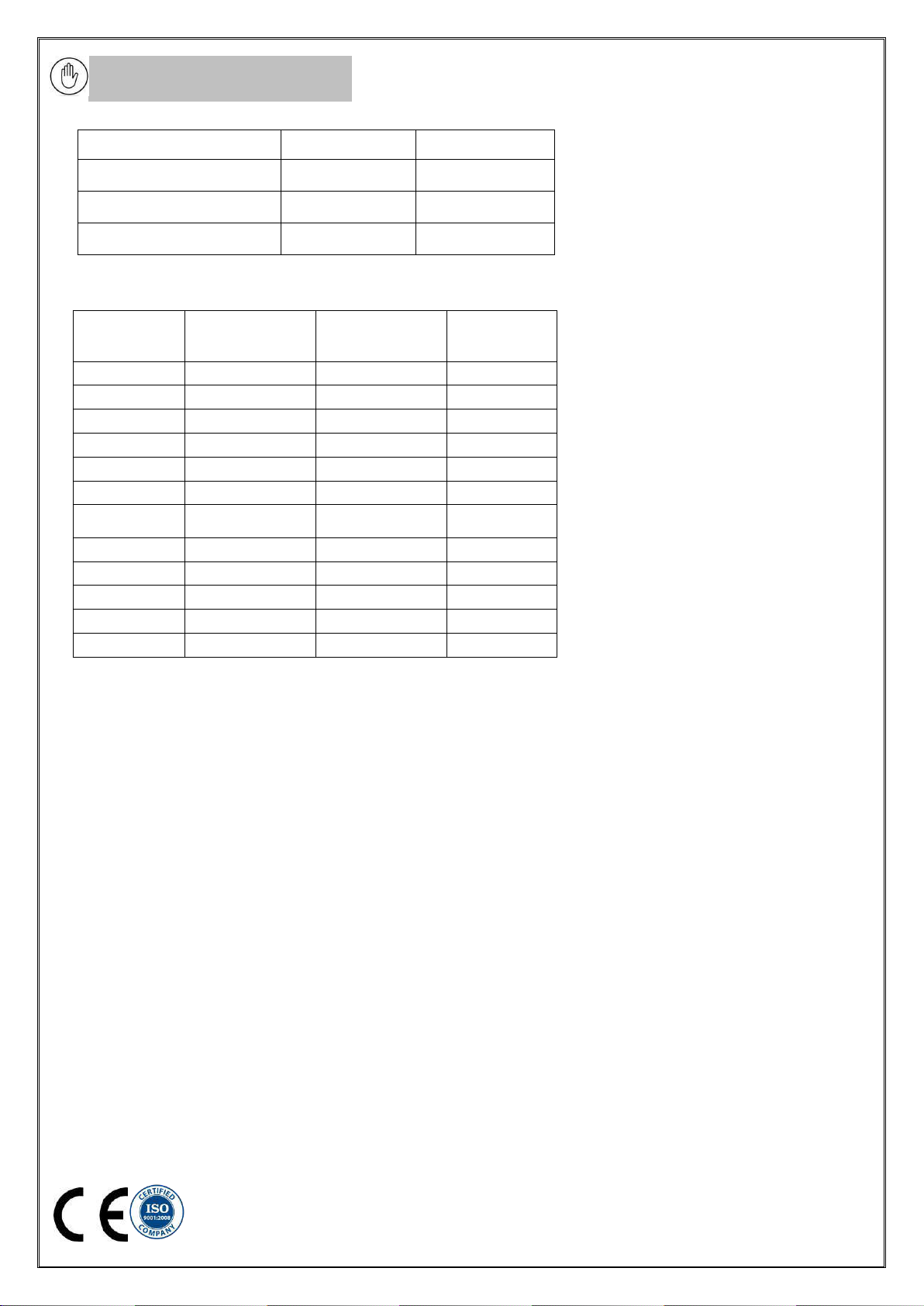

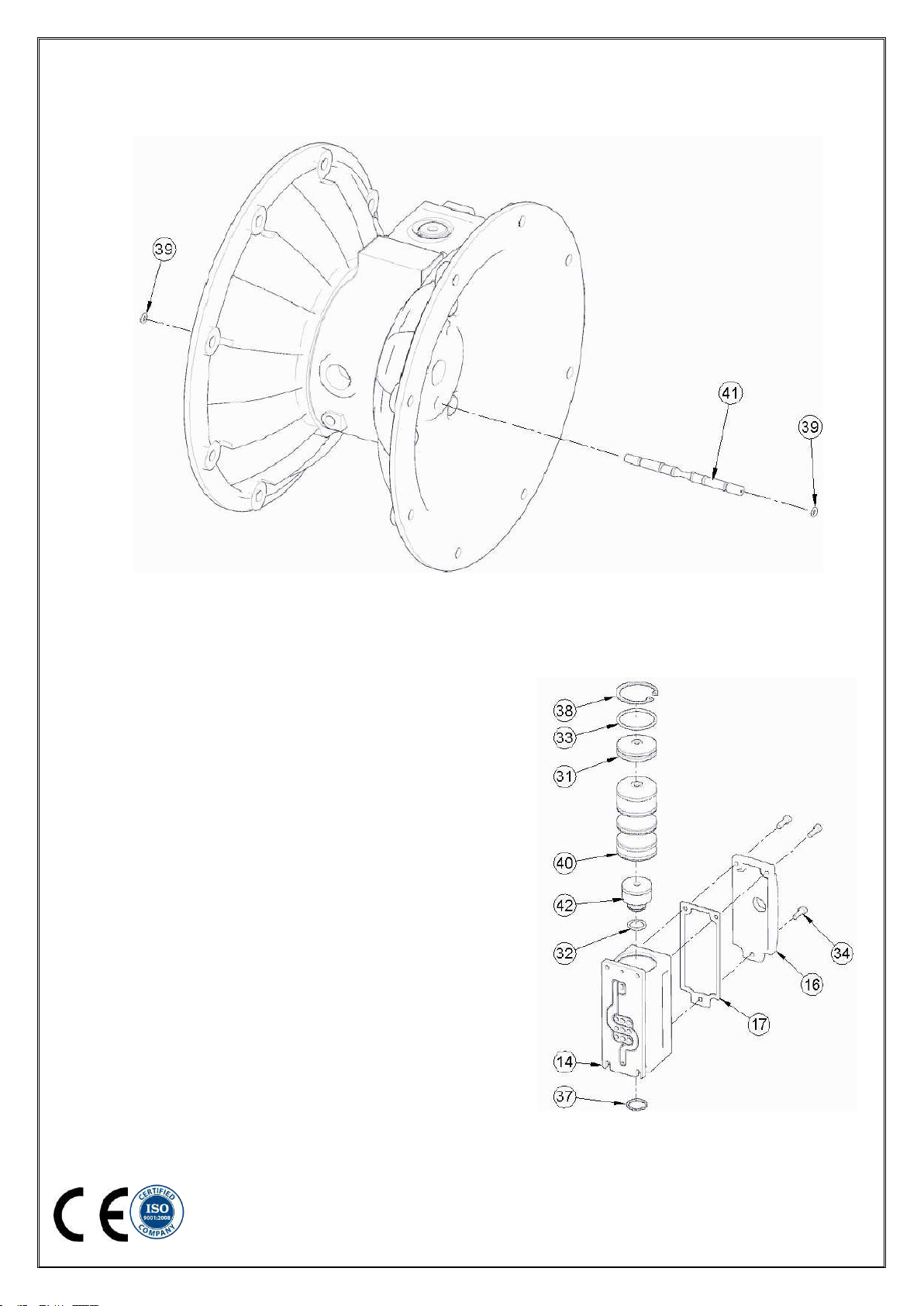

Caution: Tightening Torques and timely

re checking

Outer flange to Shaft 88Nm

Bolt for Outer Chamber and air disc 41Nm

Bolt for Inlet and Outlet 41Nm

Air Valve Body to Housing 3.5Nm

Caution: Operator Understanding

Please ensure that all operators have read this

manual and have the required understanding of

safe working practices and are equipped with safety

equipment when working on/around the pump.

Caution: Using genuine Teryair parts

and fitting as instructed

Use genuine Teryair parts to ensure correct pump

operation and maximize life.