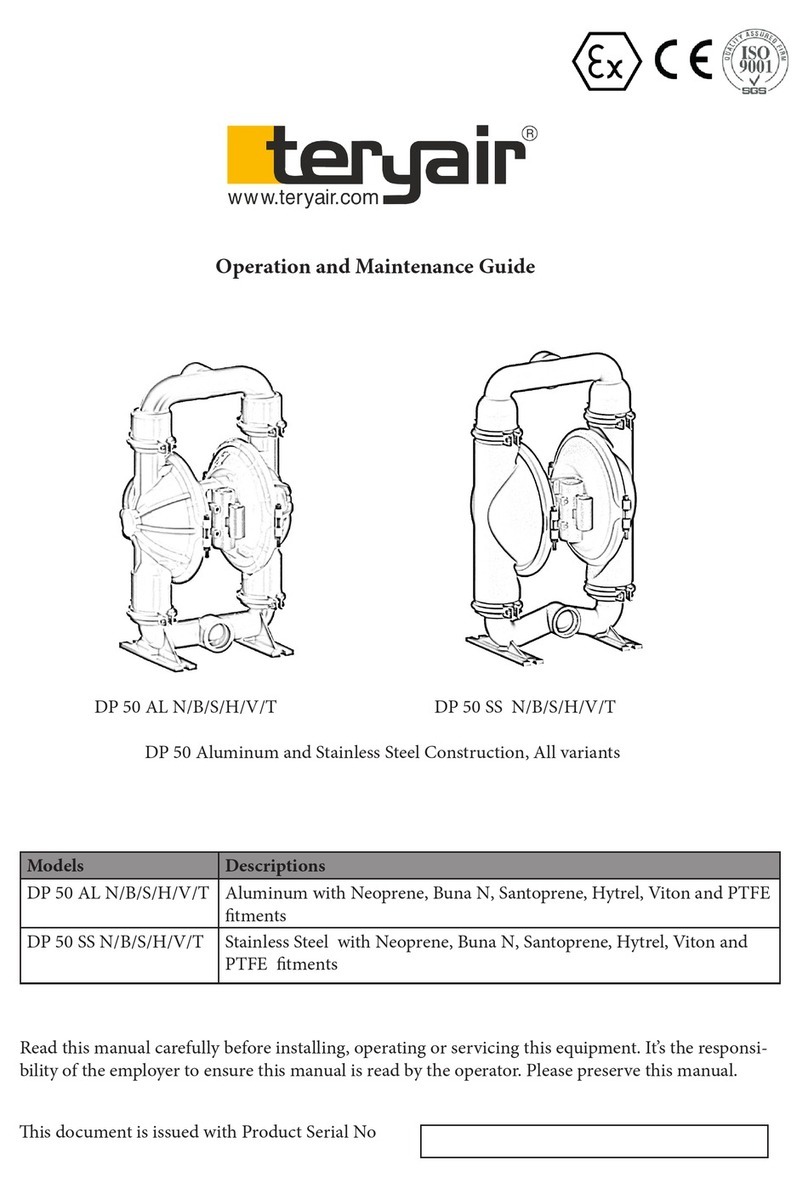

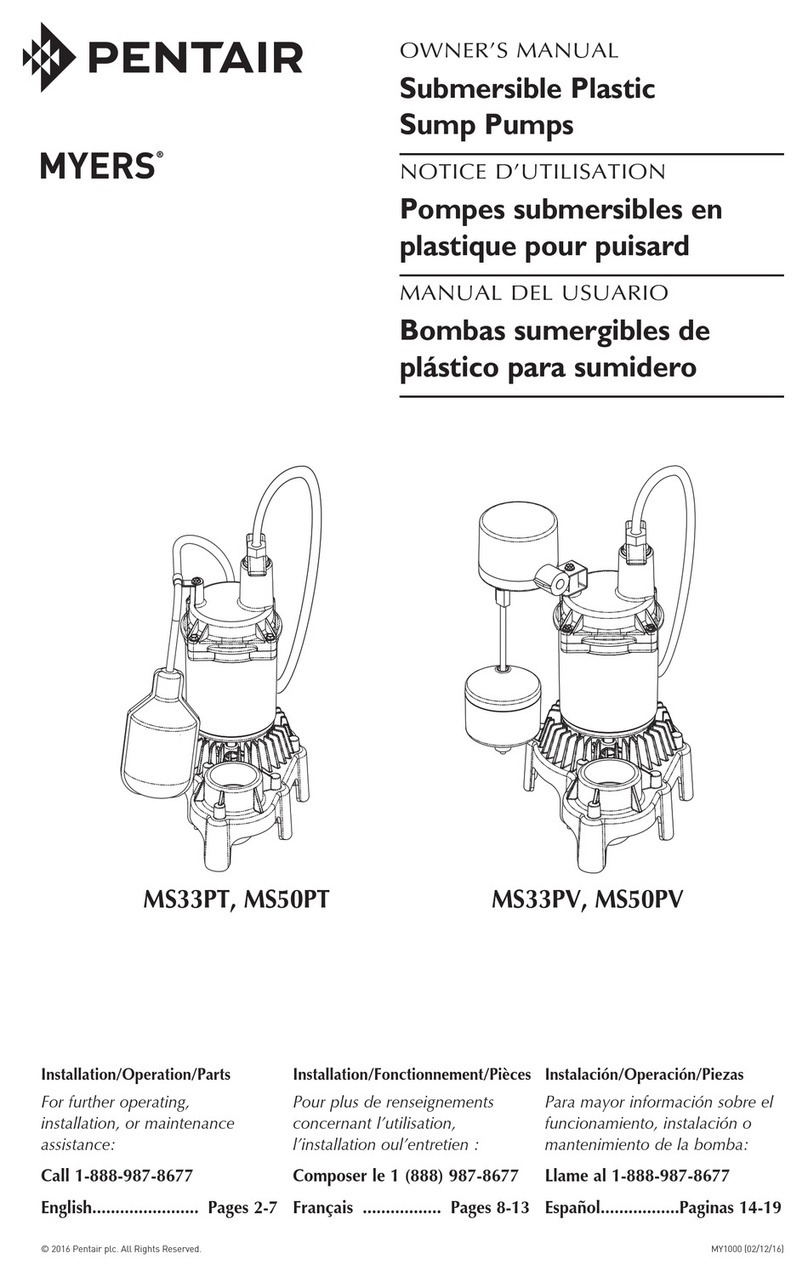

Teryair ADPB40PPT Instruction Manual

Models Descriptions

ADPB40PPT Polypropylene with PTFE tments

ADPB40PPT

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-379-REV - 01

Page 2

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Table of Contents

3 Pump Nomenclature

3 Operating and Safety Instructions

5 Suggested Lubricants

5 Suggested site selection and installation recommendations

7 Troubleshooting

8 Maintenance

8 Bill of Materials for ADPB40PPT Pumps

9 Exploded View for ADPB40PPT Pump

10 Dimensional Data

11 Eu Declaration Of Conformity

12 Warranty Certicate

FF-MM-379-REV - 01

Page 3

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

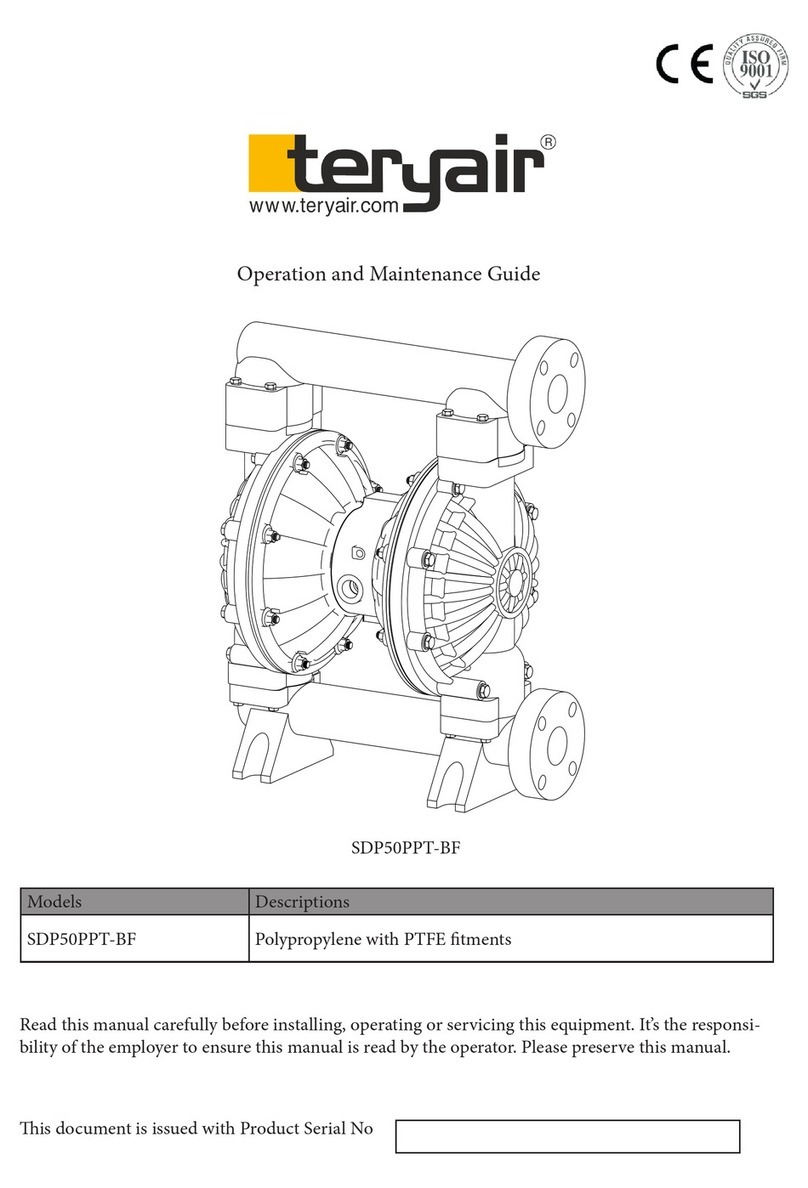

Pump Nomenclature

XX XX XX X X X

Air Valve Type Pump Size Material of Construction Material of

Diaphragm

Bolted or

Clamped

Threading on Inlet

and Outlet

DP - Classic

ADP - Advanced

SDP - MaxFlo

06 - 1/4”

AL - Aluminium

SS - Stainless Steel 316L

PP - Polypropylene

CI - Ductile Iron

B - Nitrile

N - Neoprene

S - Santoprene

T - PTFE

V - Viton

H - Hytrel

B - Bolted

C - Clamped

R- NPT

G - BSPT

P - BSPP

F - Flanged

12 - 1/2”

15 - 1/2”

25 - 1”

40 - 1 - 1/2”

50 - 2 “

75- 3”

100 - 4”

Operating and Safety

Instructions

Warning: Static Electricity

Static sparks can cause explosion resulting in

severe injury or death.

Ground the pump and the pump connections

like hoses and containers into which or from

the uid is being transferred. Connect the

grounding wire to any bolt on the pump.

Check continuity of electrical path to ground

at regular intervals.

Consult local building and electrical codes for

grounding requirements where needed.

Use hoses containing a grounding wire.

Warning: Pump Exhaust

In case of a diaphragm failure, u-

id being pumped may spray out from the

exhaust of the pump. is may cause severe

injury depending on the uid being pumped.

If the uid is hazardous, pipe away the

exhaust to a safe remote location using a

generous diameter pipe preferably with a

grounding arrangement, and ret the muer

at the end of this arrangement.

Always wear safety glasses while in the

vicinity of an operating pump.

Warning: Over pressure /

Hazardous Pressure

Do not exceed the max supply air pressure of

100 PSI.

Make sure all connected hoses and pipelines

are rated to operate safely with the pressures

generated by pump of 100 PSI.

Do not open or handle pump or hoses while

pressurized.

Disconnect air supply line and relieve

pressure from the system by carefully opening

discharge and supply lines.

Warning: Hazardous Materials

Do not move a pump that contains

hazardous uids trapped inside it. Please

observe prescribed handling and safety codes.

Drain the pump safely, by turning it upside

down and collecting the uid safely, before

moving the pump.

Warning :Explosion

Please check compatibility of uids

intended to be handled with the materials of

construction of the pump. Severe reactions

and explosions may occur if materials are

incompatible. Caution: Chemical

compatibility

FF-MM-379-REV - 01

Page 4

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Please check that the uid being pumped is

compatible with the wetted parts of the pump.

Refer Cole Parmer compatibility (http://www.

coleparmer.in/Chemical-Resistance) guide

for details. Note that chemical compatibility

may change with temperature; take this into

account while selecting pump material.

Caution: Structural support

Please refer gure 1 and ensure that the

piping system is independently supported

and does not load the pump. e pumps are

not designed to take the continuous and oen

pulsating load of a piping system. Important

to use a exible connection between rigid

piping and pump casings.

Caution: Running dry,

disconnection of hoses when

not in use

Although these pumps can be run dry for

long periods, it is advisable to avoid this as it

causes unnecessary wear of wearing parts.

Caution: Operator

understanding

Please ensure that all operators have read this

manual and have the required understanding

of safe working practices and are equipped

with safety equipment when working on/

around the pump.

Caution: Using genuine

Use genuine teryair parts to ensure correct

pump operation and maximize life.

e Teryair diaphragm pump generates a alternate stroking of the diaphragms against the

uid in the liquid chambers of the Pump. is reciprocatory action is responsible for the uid

being pumped.

It is possible to control the output of the pump by controlling the supply air pressure.

It is also possible to control the output of the pump by throttling action on the uid owing

in the outlet piping by means of a valve. if such a valve is shut completely the pressure in the

discharge piping increases to a point when the pressure at pump discharge equals it and the

pump comes to a stop. is causes no damage to the pump and the pump consumes no more

energy.

Upon opening of the valve, the pump starts reciprocating once again and resumes uid deliv-

ery.

Operating Instructions

FF-MM-379-REV - 01

Page 5

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Caution: Temperature limitations and diaphragm options

PTFE

Excellent choice when pumping highly aggressive

uids such as aromac or chlorinated hydrocarbons,

acids, causcs, ketones and acetates.

Temperature range +4°C to +104°C (+40°F to +220°F)

Suggested Lubricants

Brand Above 27 Deg C ( From 5 Deg C to 27 Deg C Below 5 Deg C

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- -- -- Arox EP 65 Arox EP 45

Caltex Rando Oil 150 Rando Oil 100 Rando Oil 46

Texaco Regal Oil F Regal Oil PE Regal Oil B

Daltron Silkolene 881 Silkolene 548 Silkolene 773

Burmah Castrol RD Oil 3 RD Oil Light Megna SPX

BP RD 220 HP60C RD150 HP20C RD80 HP10C

Duckham Garnet 7 Garnet 6 Zero Flo 5

Sternol Merlin 87 Merlin 71 Merlin 54

Petrona Purifoc 53 Purifoc 46 Purifoc 32

Chevron Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

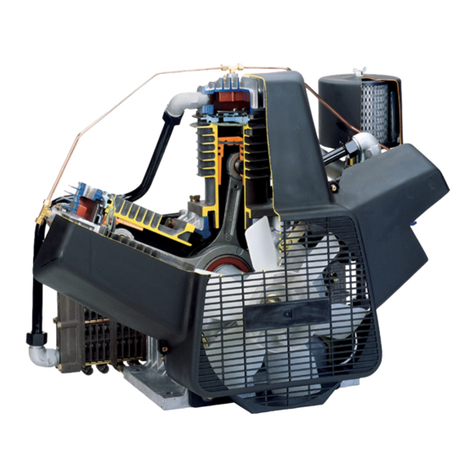

Suggested site selection and installation recommendations

Figure 1

FF-MM-379-REV - 01

Page 6

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Location selection

Pump location must be easily accessible with reasonable

space around for maintenance operations.

Pump dimensional data for each variant is available in

section showing exploded views

Air supply

Compressed air at 90 PSI ( Stroke pumps can take a max

of 100PSI), free from moisture and having an oil mist is

essential. Use of a lter (50 microns), a lubricator and a

regulator is highly recommended and should be installed

as close as possible to the pump inlet.

Ensure correct grade of oil is used in thelubricator bowl.

Too thick oil may slow down the valve shiing mecha-

nism and aect pump performance. See suggested lubri-

cants on page no 5.

Piping

A minimum number of bends and ttings to be used.

A exible connection between suction, delivery and air

supply piping is highly recommended such that piping

stresses and loads do not transfer to pump housing.

Select piping materials such that chemical compatibility is

maintained with the uid being pumped.

Suction

Ensure that the suction head aer installation is well

within the pumps suction capabilities

Use of supplied muer is recommended to bring pump

operation sounds down to comfortable levels, in case of

hazardous uids handling, please read section of safety

regarding piping away of exhaust see

Warning: Pump Exhaust) earlier in this manual.

FF-MM-379-REV - 01

Page 7

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Troubleshooting

Serial No Description Causes Remedial Action

1 Pump stops and

will not start

Insucient Air Pressure Check air pressure is as recommended

at the pump air inlet

Air Filter Blocked Check if debris has clogged the inlet l-

ter on the FRL unit/pump inlet air valve

( some models have air lter on the air

inlet valve ) and ensure clear passage of

air

Internal damage or excessive wear

on components

roceed to dismantle the pump, examine

component for wear, replace any worn

components, re assemble carefully as

instructed in this manual and re start

the pump.

2 Pumps runs slowly,

poor delivery

Cavitation Check if cavitation is occurring in the

suction side, if so reduce suction vacu-

um by slowing down the pump.

Worn Balls and Seats Check proper sealing action of balls

against seals, these components need to

be replaced as a set if they are worn.

Insucient or wrong lubricant in

the air supply.

Ensure that the lubricant is as per the

recommended chart, a thicker lubricant

oen makes the air valve work sluggish-

ly

Internal damage or excessive wear

on components

Proceed to dismantle the pump, exam-

ine component for wear, replace any

worn components, re assemble carefully

as instructed in this manual and re start

the pump.

3 Pump air valve

frerzes

Excessive moisture in supply air

line.

Ensure that the dew point of the

supplied air is low enough. Install a

air dryer or moisture separator on the

supply line

4 Air bubbles in

pump discharge or

product sprays out

of exhaust vent

Broken Diaphragm

Proceed to dismantle the pump,

examine component for wear, replace

any worn components, re assembly care-

fully as instructed in this manual and re

start the pump

mproper seal between inner

pistons, outer pistons and sha.

Air leakage into product from

balls / seats area

Air sucked into suction pipeline

due to insuciently tight joints on

suction pipeline.

FF-MM-379-REV - 01

Page 8

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Maintenance

Regular inspection and maintenance schedules will greatly enhance the life of the pump and

will ensure a trouble free and safe working environment with little chance of breakdowns.

Follow the instructions clearly in “Disassembly and Reassembly” of the pump and in the

troubleshooting section.

Use genuine Teryair spares and if possible mention the serial number of the pump when

ordering spares.

Always replace elastomers as a set, eg diaphragms, balls and seats.

ITEM

NO.

PART NUM-

BER

DESCRIPTION QTY Repair kit-1829711 A.V.Replacement kit-

1829712

1 182 08 01 HOUSING 1

2 182 08 02 INLET 1

3 182 08 03 OUTLET 1

4 182 08 04 LIQUID CHAMBER 2

5 182 08 05 OUTER FLANGE WITH STUD 2

6 182 08 09 COVER FOR SHAFT 2

7 182 10 01 INNER FLANGE 2

8 182 27 01 PRIMARY SHAFT 1

9 182 27 02 SECONDARY SHAFT 1

10 182 40 01 GASKET 1 1 1

11 182 40 06V O'RING 2 2

12 182 90 01S ALLEN BOLT 4

13 182 90 02S PLAIN WASHER 4

14 182 90 03S HEX BOLT 4

15 182 90 04S HEX FLANGE NUT 32

16 182 90 05S PLAIN WASHER 32

17 182 90 06S HEX BOLT 20

18 182 90 07S HEX BOLT 4

19 182 90 08S SELF TAPPING SCREW 4

20 182 90 09S HEX BOLT 4

21 182 08 12 MUFFLER 1

A 182 97 01 AIR VALVE ASSEMBLY KIT 1 1

B 182 97 02 SEAL KIT FOR SECONDARY

SHAFT 1

C 182 97 03 VALVE BALL KIT 1 1

D 182 97 04 DIAPHRAGM SET 1 1

Bill of Materials for ADPB40PPT Pumps

FF-MM-379-REV - 01

Page 9

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Exploded View for ADPB40PPT Pump

FF-MM-379-REV - 01

Page 10

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Dimensional Data

ADPB40PPT

FF-MM-379-REV - 01

Page 11

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description : AIR OPERATED DOUBLE DIAPHRAGM PUMP

Model Number : ADPB 40 Series

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and Har-

monized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16831

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2025

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue : Vasai

Date :

FF-MM-379-REV - 01

Page 12

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

Warranty Certicate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied by the company

be free from defects in material and workmanship for a period of six months from date of Teryair autho-

rized dealer invoice to customer, or one year from date of Teryair invoice to dealer, whichever is earlier.

Failure due to normal wear, misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot guarantee the suitabil-

ity of any product or part for a particular application and Teryair shall not be liable for any consequential

damage or expense arising from the use or misuse of its products on any application. Teryair does not

warranty bought out products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair responsibility is limited solely

to replacement or repair of defective Teryair products or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if: (i) a Product is altered,

changed, modied or tampered with in any way, (ii) a Product is damaged after deposit with the transporter for shipment; (iii) a Product is

not properly preserved, packaged, stored, processed or handled after receipt; (iv) a Product is not used and maintained in accordance with

Teryair’s recommended operating and maintenance manuals, instructions and procedures, if any; (v) a Product is not properly incorporated

or installed in, or not properly combined with, an Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly

or indirectly results from or arises out of, a failure, substandard performance or other issue with another product, material, component or part

not supplied by Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specication or other specic requirement of Dealer/End User; (viii) a Product is used in a manner, with a sub-

stance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise subjected to abnormal

use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x) the issue with a Product is directly or in-

directly attributable to, or directly or indirectly results from or arises out of, normal wear and tear of such Product (including, without limitation,

things such as worn seals, diaphragms, balls, O rings, gaskets, chisels, cutters, hoses and other such wearing components; (xi) the issue with

a Product is directly or indirectly.

Model Number : ADPB 40 Series

Serial Numbar :

Dated :

Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-379-REV - 01

Page 13

Operation and Maintenance Guide ADPB 40 Plastic Pump Series

is page is intentionally

Le blank.

Table of contents

Other Teryair Water Pump manuals

Teryair

Teryair SDP50PPT-BF Instruction Manual

Teryair

Teryair SP10 Instruction Manual

Teryair

Teryair DP 25 ALS Instruction Manual

Teryair

Teryair ADPB12PPT Instruction Manual

Teryair

Teryair DP 40 Metal Series Instruction Manual

Teryair

Teryair DPB40PPT Instruction Manual

Teryair

Teryair DP 75 AL N Instruction Manual

Teryair

Teryair DP 25 ALN Instruction Manual

Teryair

Teryair ADPB 25 PP Series Instruction Manual

Teryair

Teryair ADPB 25 PPX Instruction Manual