Teryair DP 25 ALS Instruction Manual

This manual suits for next models

11

Table of contents

Other Teryair Water Pump manuals

Teryair

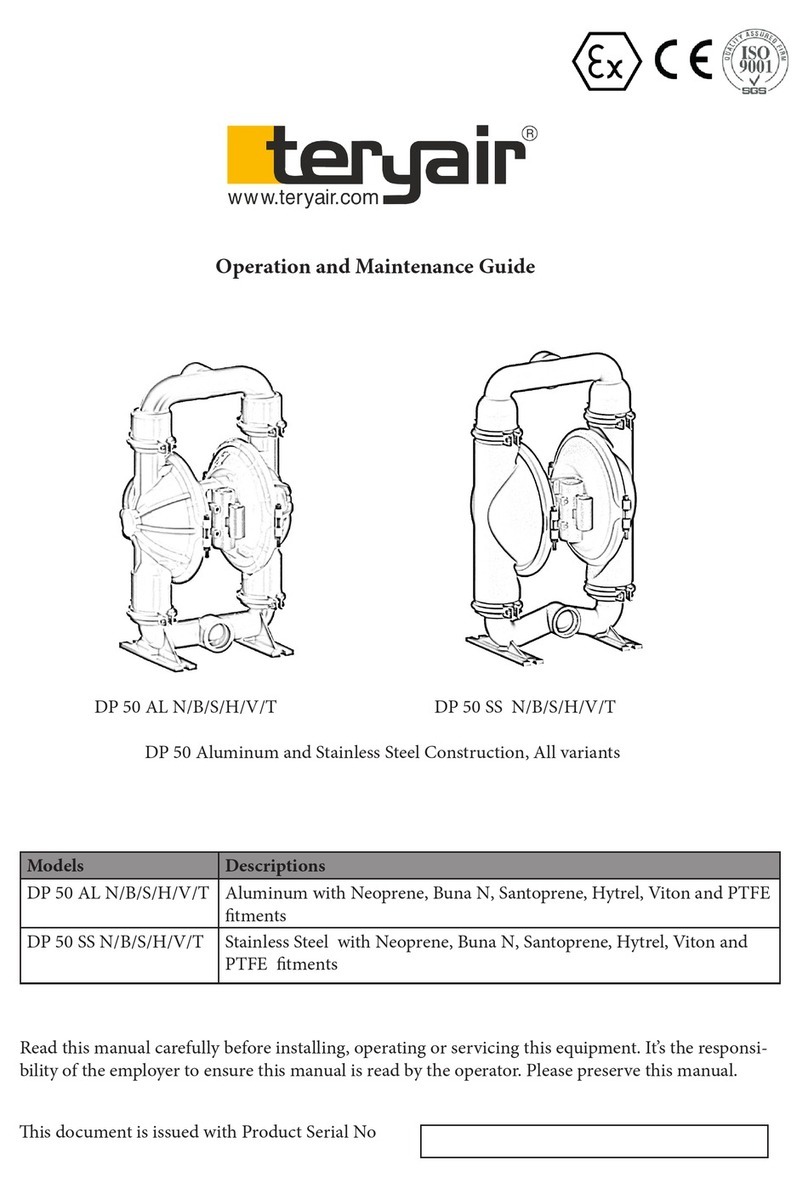

Teryair DP 50 AL N Instruction Manual

Teryair

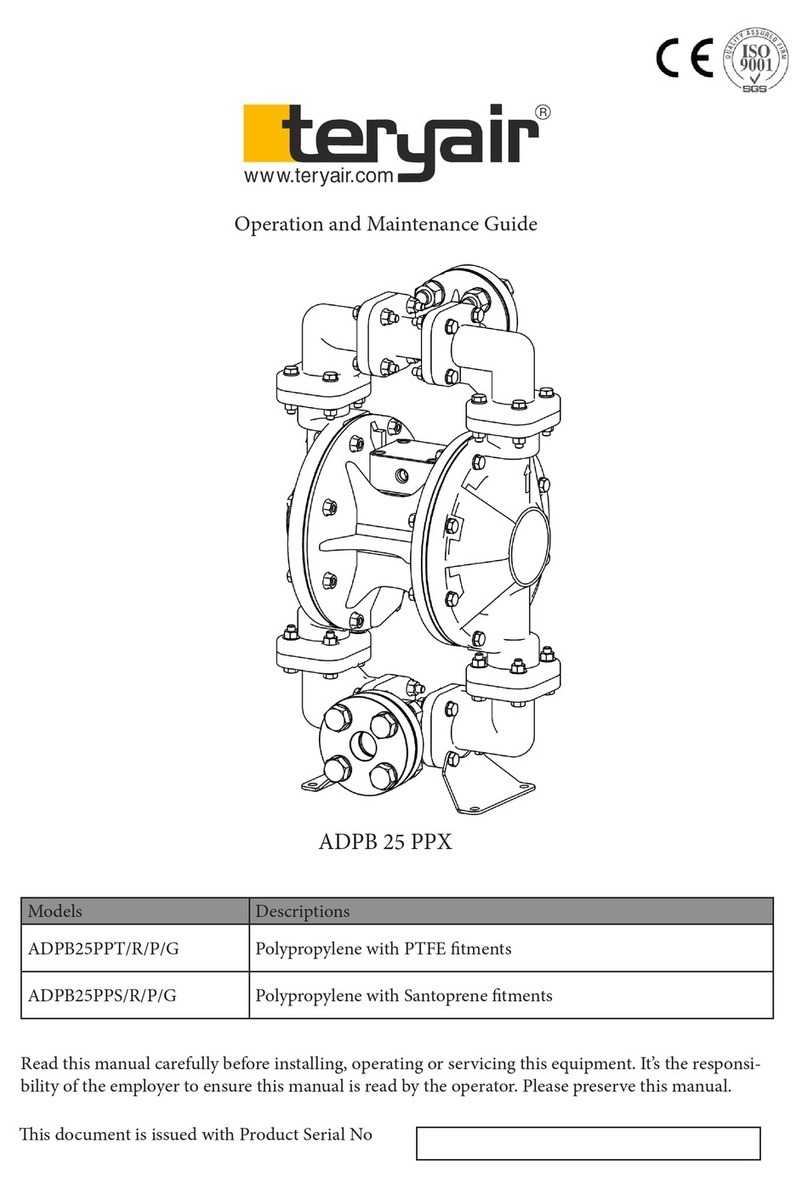

Teryair ADPB 25 PP Series Instruction Manual

Teryair

Teryair SP10 Instruction Manual

Teryair

Teryair ADPB 25 PPX Instruction Manual

Teryair

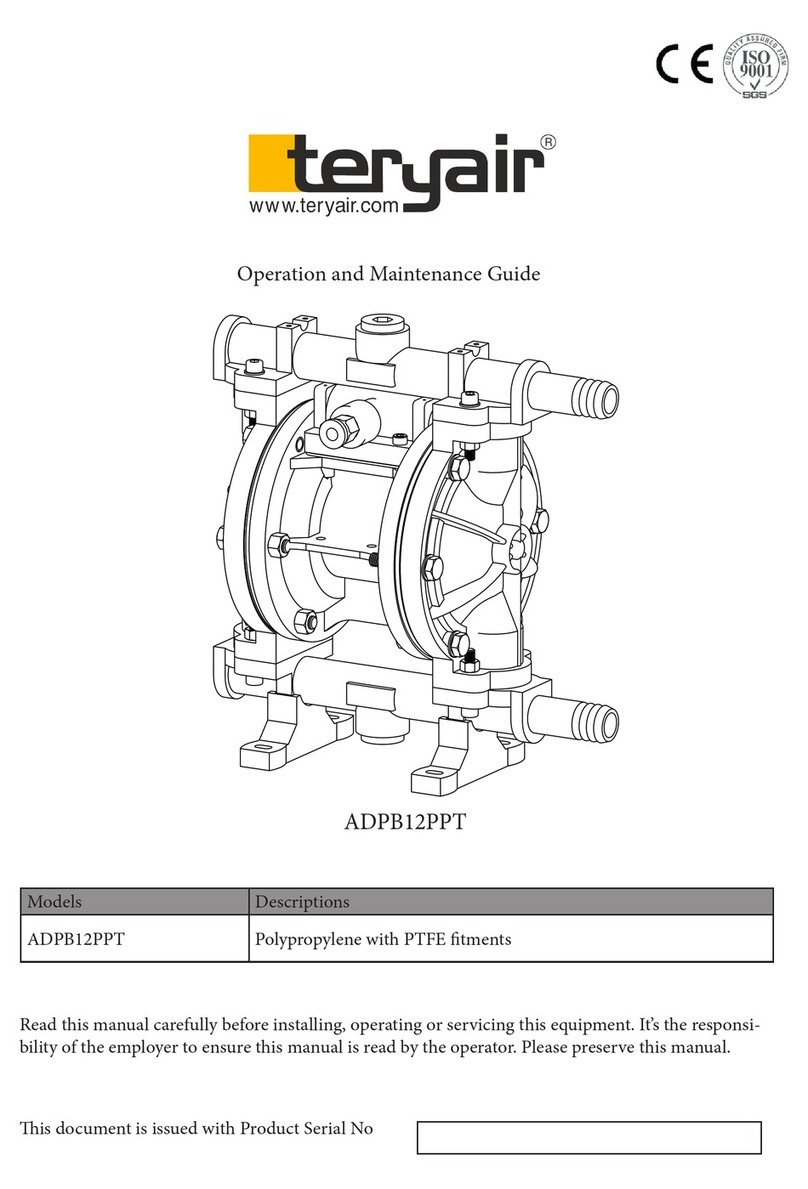

Teryair ADPB12PPT Instruction Manual

Teryair

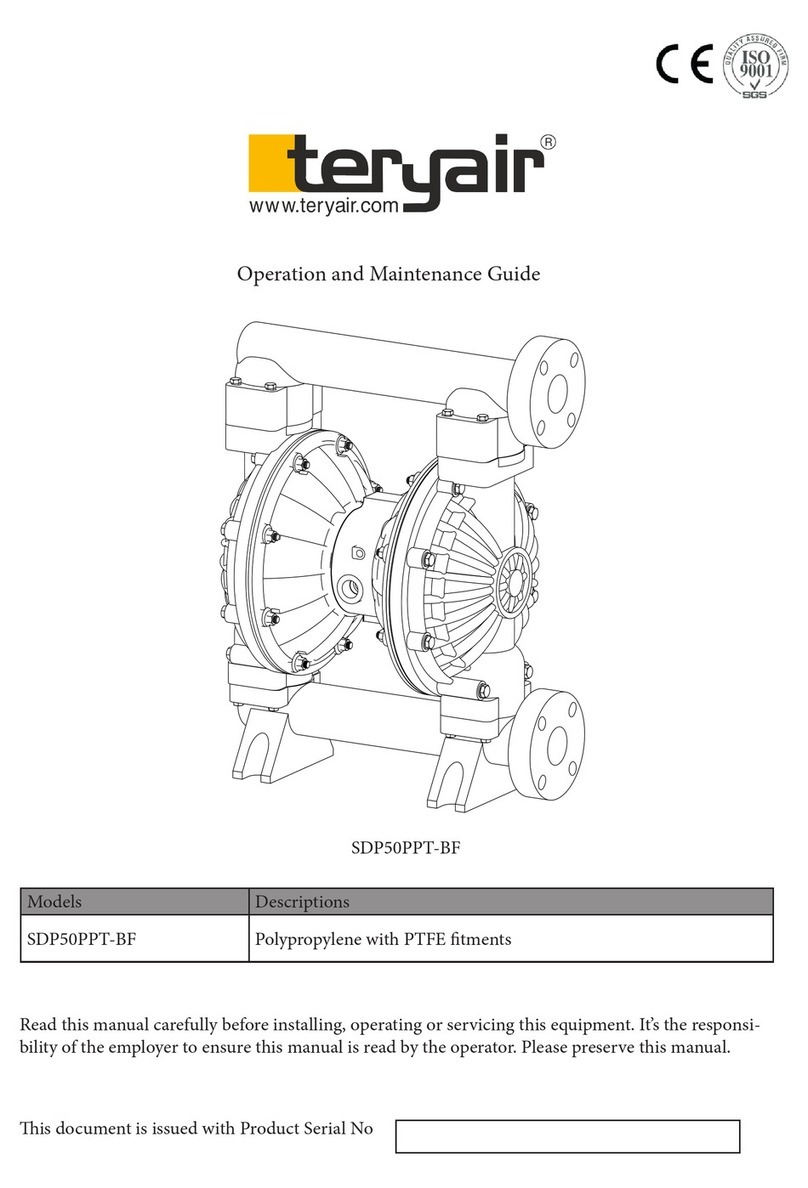

Teryair SDP50PPTB Instruction Manual

Teryair

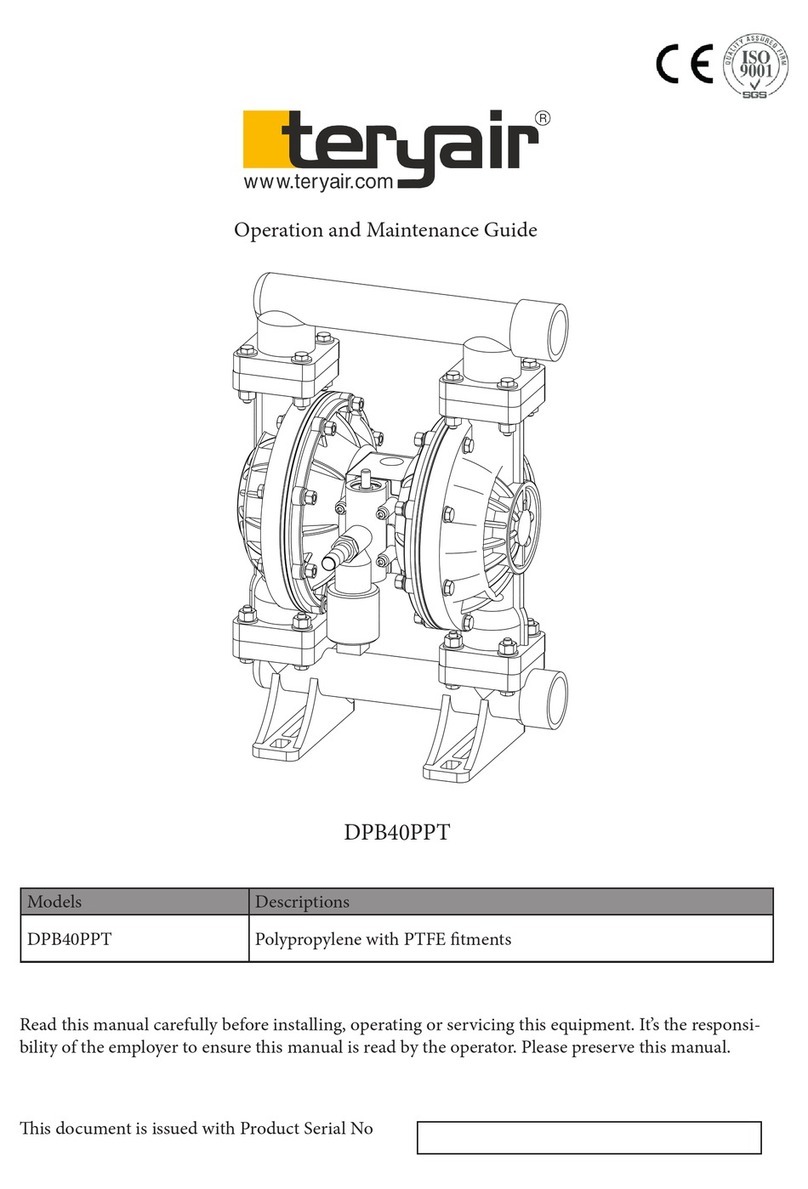

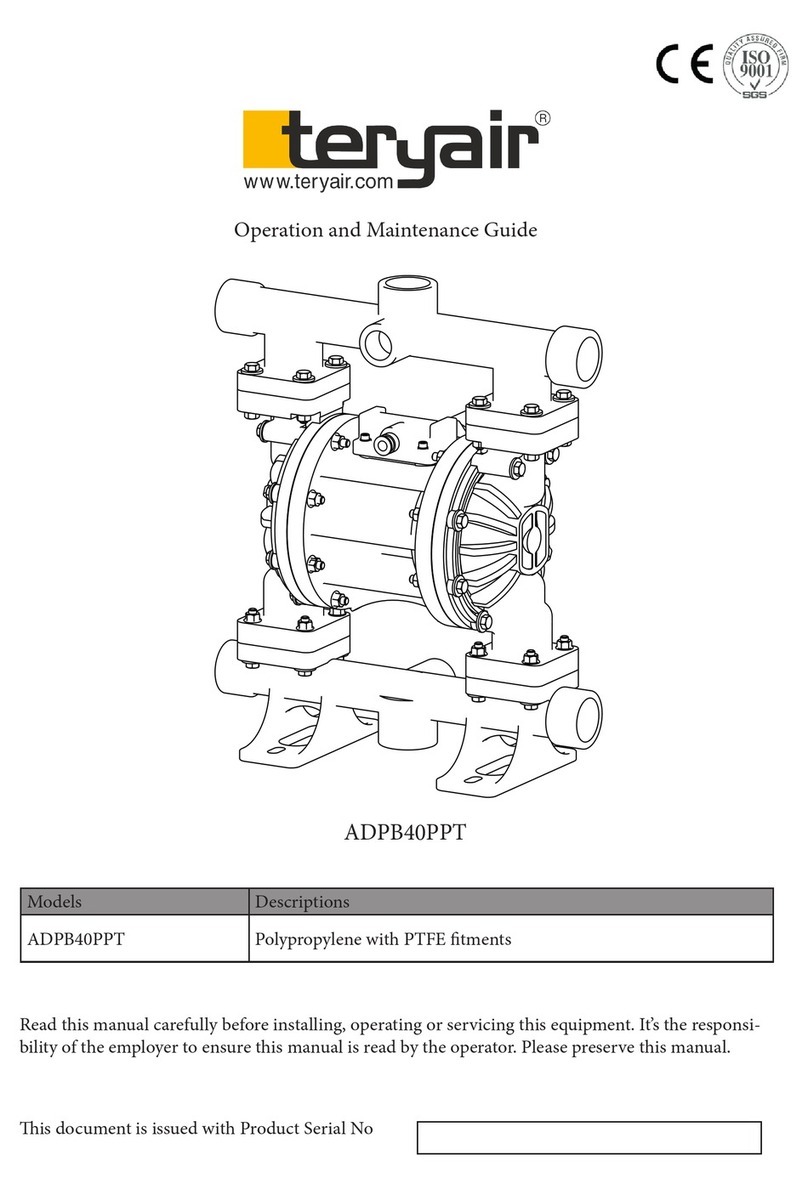

Teryair ADPB40PPT Instruction Manual

Teryair

Teryair BP-10 Instruction Manual

Teryair

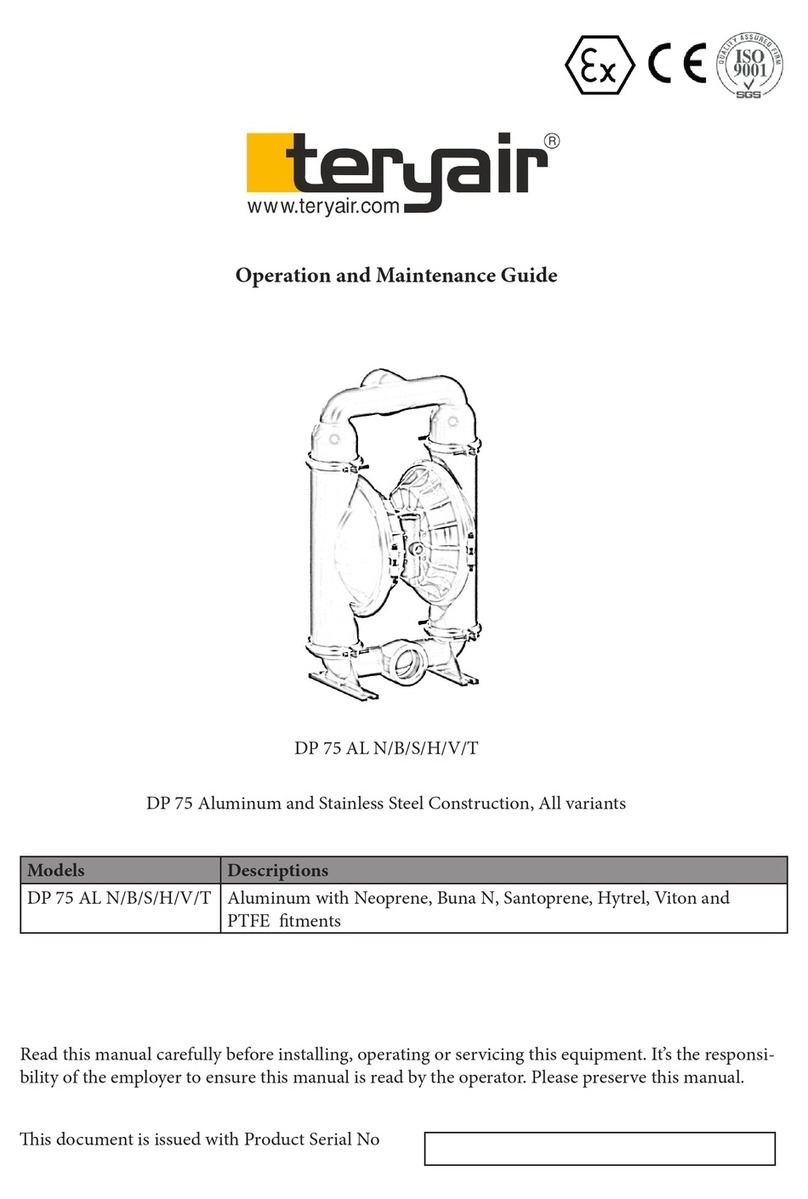

Teryair DP 75 AL N Instruction Manual

Teryair

Teryair DP 40 Metal Series Instruction Manual

Popular Water Pump manuals by other brands

Toku

Toku STRIKER STRIKERMAXX COMPACT quick start guide

GORMAN-RUPP

GORMAN-RUPP GHA SERIES Installation, operation and maintenance manual

Engel

Engel BUBBLER quick start guide

JABSCO

JABSCO 30520-4 Series manual

Power-flo

Power-flo PF15ICU Installation, service & parts manual

Edwards

Edwards iXM Series instruction manual

Lorentz

Lorentz PS600 BADU Top 12 instruction manual

Bestway

Bestway Sidewinder 62139 owner's manual

resideo

resideo CBU142 installation instructions

Ingersoll-Rand

Ingersoll-Rand ARA AF0475L Series Operator's manual

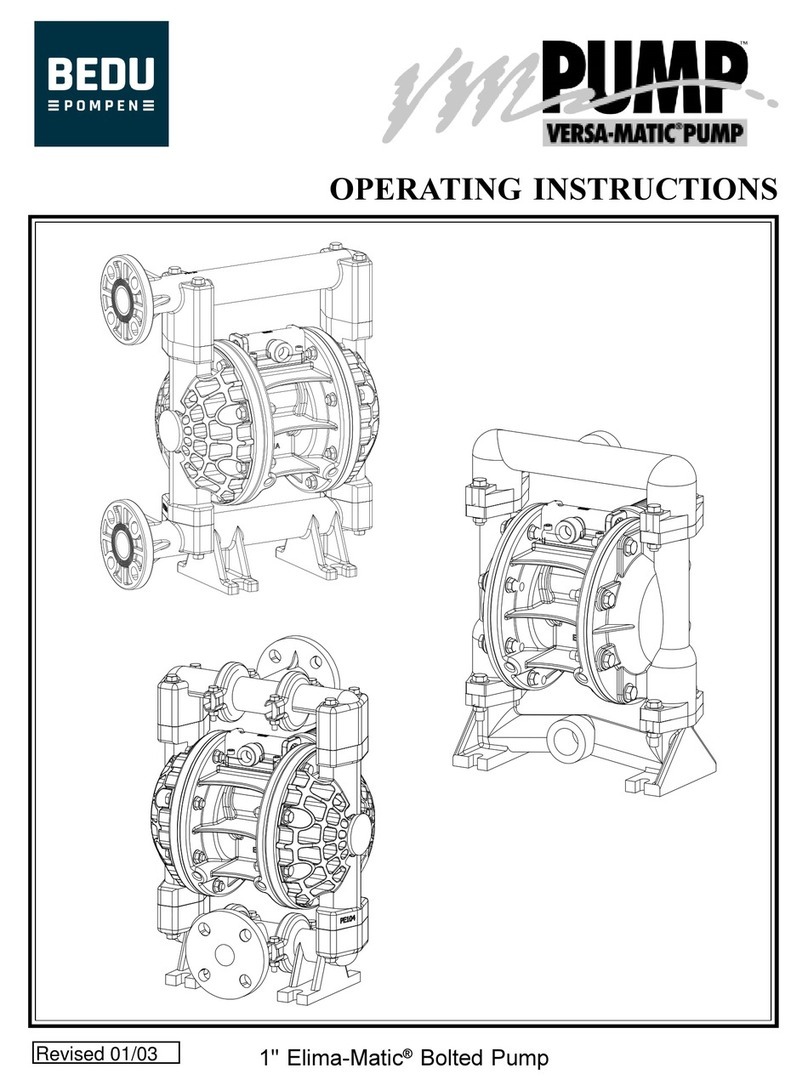

Idex

Idex BEDU POMPEN VERSA-MATIC PUMP Elima-Matic E1PP5 5T... operating instructions

Welch

Welch MXPC 303 Z operating manual

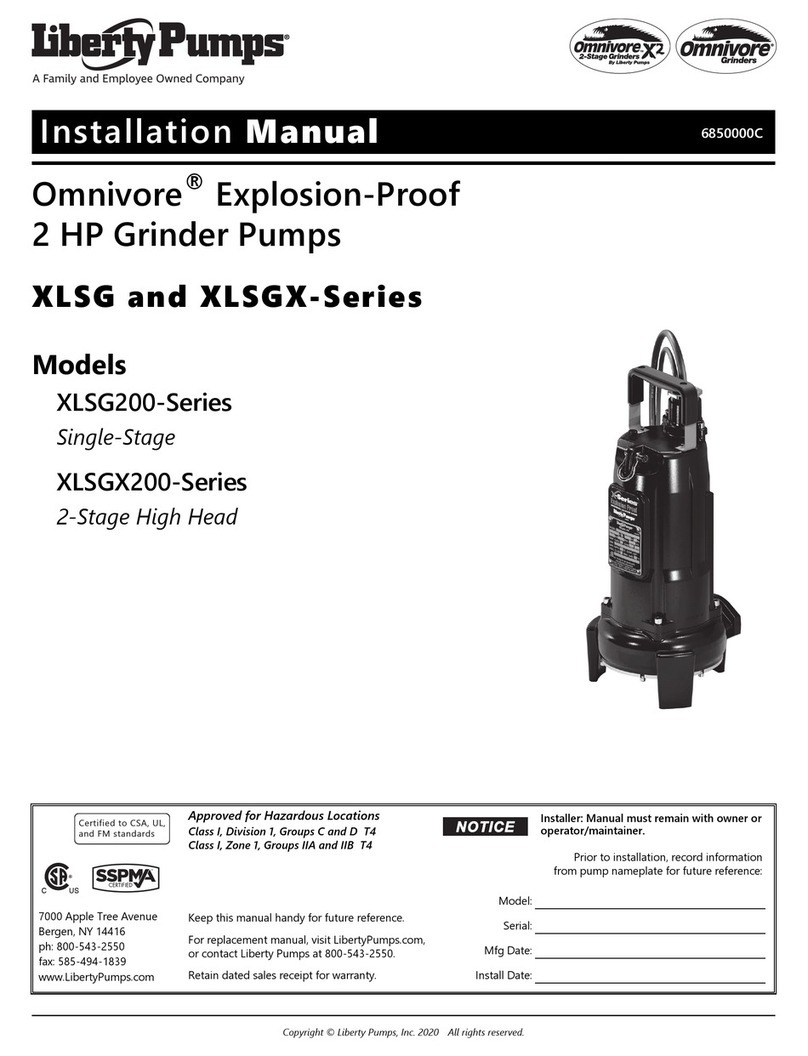

Liberty Pumps

Liberty Pumps Omnivore XLSG Series installation manual

Wilo

Wilo VeroLine-IPL Installation and operating instructions

North Star

North Star M109163D owner's manual

Zoeller

Zoeller Basement Sentry Series Installation

Grundfos

Grundfos DMS 2 Installation and operating instructions

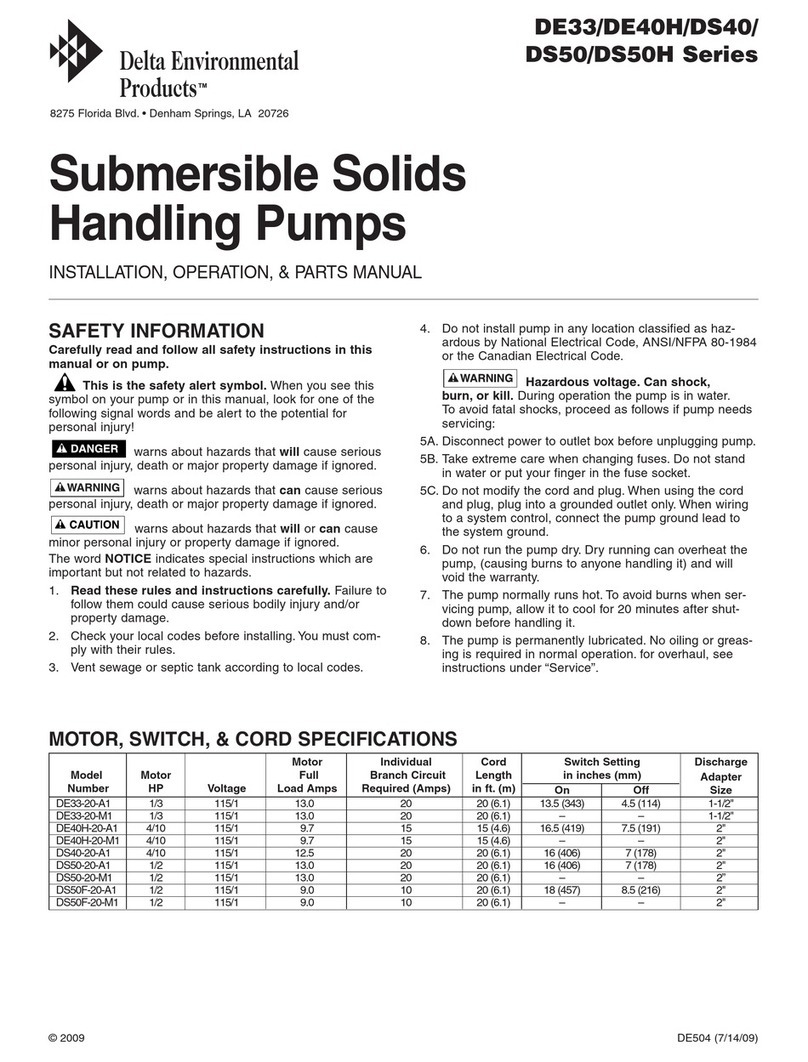

Delta Environmental Products

Delta Environmental Products DE33 Series Installation, Operation & Parts Manual