RXW Multi-Depth Soil Moisture Sensor (RXW-GPx-xxx) Manual

6

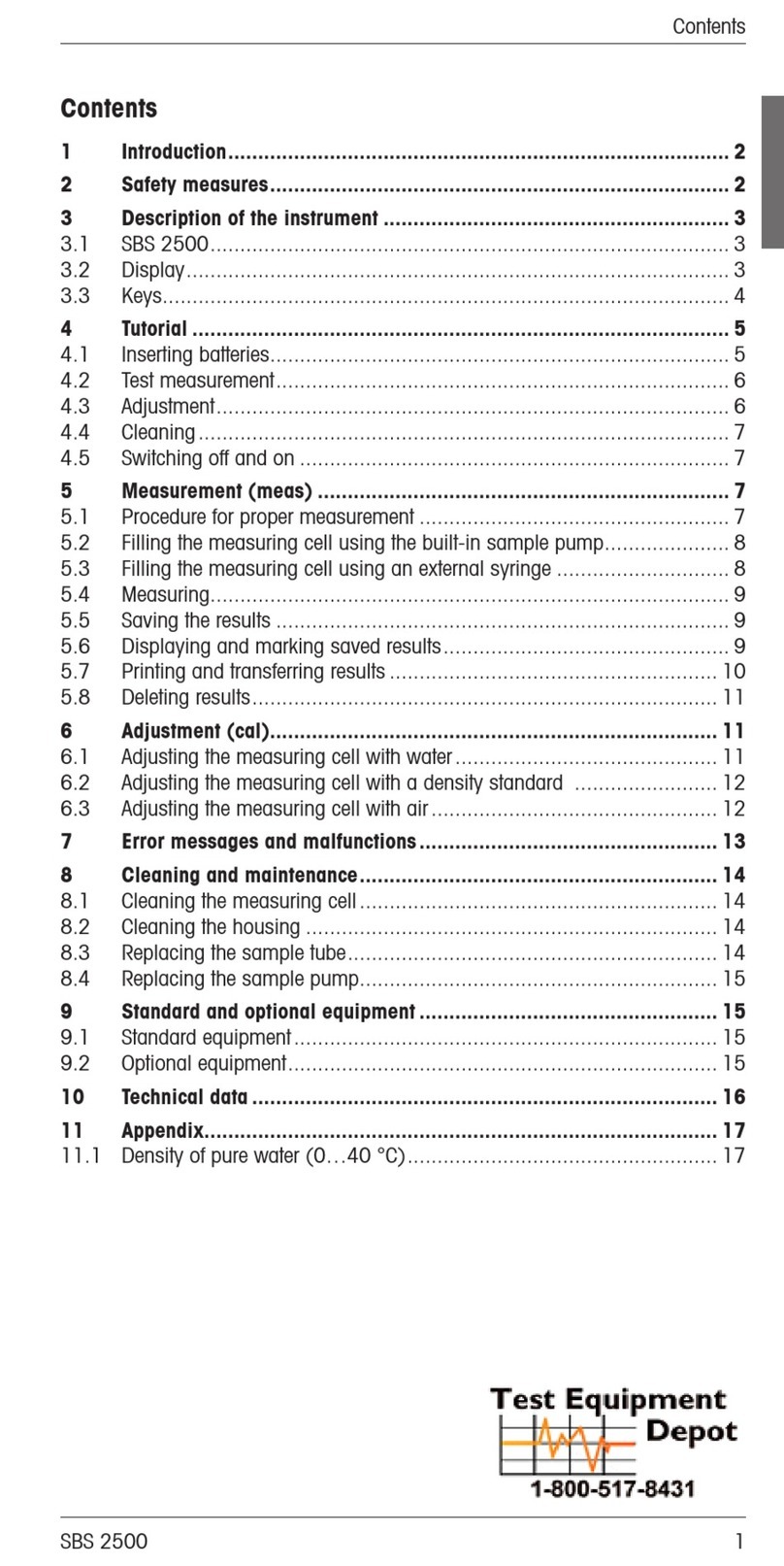

Part

Number

Minimum Logging

Interval Using Solar

Power with

Rechargeable Batteries*

Minimum Logging

Interval Using

Non-Rechargeable

Lithium Batteries

RXW-GP3-

xxx

5 minutes year round 10 minutes with a 1-year

battery life

RXW-GP4-

xxx

5 minutes summer,

10 minutes winter

15 minutes with a 1-year

battery life

RXW-GP6-

xxx

5 minutes summer,

15 minutes winter

15 minutes with a

7-month battery life

*Requires the solar panel is positioned directly toward the sun and

without shade (see Mounting and Positioning the Mote)

Note that this logging interval will be applied to all wireless

sensors in the HOBOnet® wireless network. For solar powered

RXW-GPx motes, logging intervals faster than the

recommended minimum can result in missing data because

there will be insufficient charge for the batteries. For RXW-GPx

motes with non-rechargeable lithium batteries, faster intervals

will require more frequent battery replacement.

Use HOBOlink to monitor mote status and health. If a mote is

temporarily offline, any logged data is saved until it is back

online. In addition, if a mote is offline for 30 minutes, the

station will automatically connect to HOBOlink and report the

mote as missing. Once the mote is back online, any logged data

will be uploaded the next time the station connects to

HOBOlink.

See the HOBOlink Help for details on how to change the logging

and connection intervals, view data, check mote status, add the

mote to a map, and more.

Installing the Sensor

To install the sensor, it is recommended that you use a slide

hammer (Onset part number SLIDE-HAMMER) and pilot rod to

form a hole to insert the sensor probe (use Onset part number

PILOT-ROD4 with RXW-GP3 and RXW-GP4 models or use PILOT-

ROD6 with the RXW-GP6 model). These tools will create a pilot

hole that is the exact size and shape of the sensor without air

gaps to ensure good soil contact with the sensor and accurate

measurements. You may also need tape, two adjustable

wrenches, and water. There are also two alternate installation

methods described later in this section if a slide hammer and

pilot rod are not available.

WARNING: Follow these important safety guidelines when

working with a slide hammer and pilot rod:

●Be careful when carrying and using the slide hammer as the

bottom part of the slide may drop down, potentially causing

injury. Steel-toed work shoes are recommended to prevent

possible injury to toes and feet.

●Eye and ear protection are recommended at all times when

using the slide hammer. When in use, the slide hammer

generates harmful levels of acoustic energy. Hearing

protection with a Noise Reduction Rating of 20 decibels

should always be worn.

●Wear work gloves and keep both hands on the slide hammer

when driving the pilot rod. Be careful to avoid getting fingers

caught in the slide mechanism.

Sensor Installation Guidelines

Before installing the sensor, follow these guidelines.

•Install the probe when the soil is dry to minimize the air

gaps that can form around the probe as wet soil dries out.

Also avoid excessively rocky soil whenever possible as

cavities may form when rocks are pushed out of the way

when creating the pilot hole.

•The sensor probe must be installed vertically. Hold the

slide hammer and pilot rod perfectly vertical to avoid

making the hole larger than the size of the sensor.

•Always maintain control of the slide hammer with a firm

grip to avoid wobbling or moving the hammer side-to-side.

This is especially important while the first half of the pilot

rod is being hammered in place.

•Check that the pilot rod is tightly screwed to the slide

hammer during the insertion process as the threads may

loosen during repeated impacts. Failure to check the

connection may place excessive force on the threads and

damage them.

•Drive the pilot rod only as far as needed for the length of

probe being used. A hole that is too short may cause

damage to the probe during insertion. A hole that is too

long may allow water to collect in the void below the

probe and cause inaccurate readings.

•When extracting the pilot rod, make sure it remains

vertical so the hole does not become enlarged, which may

result in air gaps forming between the probe and soil and

potentially incorrect soil moisture readings.

•Once the pilot rod is removed, insert the probe as soon as

possible. Any delay may allow moisture to swell the sides

of the hole or water to enter the hole.

•If the pilot hole is larger at the top than the bottom due to

side-to-side movement of the slide hammer during

installation, it may take a few days to a week for the soil to

settle back and seal against the probe. You can also create

a soil slurry at the surface to fill the hole. See Maintenance

for more details on using a slurry.

•To reduce air gaps from forming over time as soil expands

and contracts, limit the variation of moisture content of

the soil if possible, such as by periodic irrigation.

•Secure the sensor cable to the mounting pole or tripod

with cable ties.

•Use conduit to protect the cable against damage from

animals, lawn mowers, exposure to chemicals, etc.

Slide Hammer and Pilot Rod Installation Method

1. For assembled pilot rods, skip to step 2. For disassembled

pilot rods, select the appropriate number of middle rod

segments based on the length of your probe: two segments

for RXW-GP3 and RXW-GP4 models, or three for the RXW-

GP6 model. Assemble the pilot rod by screwing one

segment into the other, connecting each rod segment

together to form the body of the pilot rod, making sure all

edges are aligned. Screw in the pilot rod tip to one end of

the pilot rod body and the top cap to the other end.

2. Lay the pilot rod down next to the sensor probe, with both

tips aligned. Wrap a piece of tape around the pilot rod at