TESTING 1.0330 User manual

TESTING Bluhm & Feuerherdt GmbH

Production and distribution of

construction-material testing devices

Motzener Str. 26b

DE - 12277 Berlin

Tel. +49(0)30/710 96 45-0

Fax +49(0)30/710 96 45-98

www.testing.de

1

Operating Manual

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

In accordance with EN 196

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

2

CAUTION: Do not place this device into operation until you have made yourself fully ac-

quainted with its connection, with its function, and with the position of all its control ele-

ments and functions.

Contents Page:

1. Basic instructions ..................................................................................................3

1.1 Designation.................................................................................................................3

1.2 Purpose for which this system was designed..............................................................3

1.3 Conditions under which this system may NOT be used...............................................4

1.4 Guarantee...................................................................................................................5

1.5 Safety instructions.......................................................................................................5

1.6 Acceptance of delivery and transport..........................................................................6

1.7 Setting up the Cabinet.................................................................................................7

2. Placing the Cabinet into operation .......................................................................7

2.1 General information ....................................................................................................7

2.2 Humidifier....................................................................................................................8

2.3 Connection to the power supply..................................................................................8

2.4 Switching on the Cabinet ............................................................................................9

3. Characteristics of the system .............................................................................10

3.1 General description of the system.............................................................................10

3.2 Technical data ..........................................................................................................10

3.3 Open- and closed-loop control equipment.................................................................12

3.3.1 Messages and warnings on the display.................................................................14

3.3.2 Calibration of the display value..............................................................................14

3.4 The humidification system.........................................................................................15

4. Maintenance, care, and cleaning of the system ................................................16

4.1 General instructions..................................................................................................16

4.2 Care of the indicator instruments ..............................................................................17

4.3 Care of the humidifier................................................................................................17

5. Troubleshooting...................................................................................................18

5.1 Status and error messages on the controller.............................................................18

5.2 General troubleshooting............................................................................................18

6. Placing the system out of operation...................................................................19

7. Scrapping the system..........................................................................................19

8. After-sales service ...............................................................................................20

8.1 Date of this version of the Operating Manual ............................................................20

8.2 Copyright ..................................................................................................................20

8.3 Spare parts and technical help..................................................................................20

Attachments:

Declaration of conformity

Record of measurement and testing at the manufacturer’s plant

Record of temperature and moisture testing

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

3

1. Basic instructions

1.1 Designation

Designation of the device: Please see the name plate on the cabinet, which shows

the complete characteristic data and the electric prop-

erties of the system.

1.2 Purpose for which this system was designed

This Operating Manual contains the information required for operation of the products

described here, for the purpose for which they have been designed. This Operating Man-

ual is intended to be used only by technically qualified staff.

“Technically qualified staff” is defined as those persons who – as a result of their training;

their experience; the instructions which they have received; as well as their knowledge of

the relevant standards, regulations, accident-prevention regulations, and conditions of

product operation in the company –have been authorized by the person responsible for

the safety of the company equipment to carry out the activities and actions required for

operation of the equipment described below, and who can recognize and prevent any

possible dangers arising from such operation (this definition of technically qualified staff

has been provided in IEC 364).

The User must by all means observe the requirements and limit values, as well as all

safety instructions, given in this Operating Manual. Any use of this device not in conform-

ity with these stipulations shall be considered to be in violation of the use for which this

system was intended. If this device must be operated under special conditions, or with

special modes of operation, then this shall be authorized only after consultation with the

manufacturer, and after obtaining his prior and express approval.

This Cabinet is intended for storage of test specimens in accordance with EN 196, in triple

Moulds. These standards stipulate a temperature of 20 1°C and a relative humidity

> 90% for storage of such Moulds. The Cabinet has been set at the manufacturer’s plant

to conform with these conditions.

Caution

The instructions contained in this Operating Manual are intended only for

the correct use of the Cabinet for Moist Storage of Mortar Prisms in Triple

Moulds. In order toperform the necessarytesting correctly, the User must

observe the specific standards for such testing.

This Operating Manual is intended to be read and followed by the freight carrier,

the fitters and installers, the Operators and Users, the service and repair staff, and

the persons who must dispose of (scrap) the system.

It is absolutely necessary to read and understand all the instructions in this Oper-

ating Manual in order to operate this properly and safely.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

4

This Operating Manual must be considered as a constituent component of the

product. It may be used only together with the system with which it has been de-

livered.

This Operating Manual must be kept closely at hand and in good condition through-

out the entire service life of the machine. It must be immediately available when-

ever it is needed.

If this is sold, the Operating Manual must be passed on to the new owner.

The Manufacturer may not be held liable for any damages that arise as a result of

improper use or handling of the Cabinet.

The Manufacturer reserves the right to modify this technical manual, as well as the

machines that it refers to, without prior notice.

The Caution and Danger alerts have the following meaning:

Caution

“CAUTION” means that the procedures that are being referred to can

seriously damage the machine if they are not carried out with caution.

Danger

“DANGER” means that the procedure can be dangerous for the oper-

ating person, if the procedure is not carried out with caution.

1.3 Conditions under which this system may NOT be used

This Cabinet was not intended for use under the following conditions. It may therefore

NOT be used under such conditions or for the following purposes:

This Cabinet is not suitable for storing and cooling medicines or laboratory prepa-

rations and may not be used to store explosive or chemical substances.

Do not disassemble this system. Do not try to repair it or to modify it.

Operate this product only with an electrical system which satisfies the ratings for

voltage and current as given in this Operating Manual.

Do not cover this Cabinet. There must be sufficient open space above the Cabinet

so that the heat from the system can properly dissipate into the surroundings.

Do not operate the Cabinet in locations which are subject to the following condi-

tions or substances: Ice formation, Heat radiation, Formation of condensation wa-

ter, Dust, Corrosive gases, Vibrations, Severe physical impact (jolts), High relative

humidity, Temperature fluctuations

Any misuse of the appliance may result in damage to or spoilage of stored goods.

Furthermore, the appliance is not suitable for operation in potially explosive at-

mospheres.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

5

1.4 Guarantee

Our General Terms of Sales and Delivery apply in all cases.

The Manufacturer guarantees that this Operating Manual has been prepared in conform-

ity with the technical and functional parameters of the Cabinet as delivered. The Manu-

facturer reserves the right to add supplementary information to this Operating Manual as

required.

The guarantee provided by the Manufacturer is the legal guarantee. This guarantee does

not cover wear-and-tear parts.

The Manufacturer guarantees trouble-free operation onlyif the User observes the instruc-

tions in this Operating Manual, and only if the User employs the Cabinet for the purpose

for which it is intended.

The Manufacturer shall not be liable for damages that may occur if the Cabinet is used

for purposes for which it is not intended, or if the User does not observe the instructions

and rules for operation as set forth in this Operating Manual.

No claims for damages may be lodged against the Manufacturer if theCabinet is modified

in its structural or constructional characteristics without the prior written consent of the

Manufacturer, or if its functional characteristics are modified without such consent.

1.5 Safety instructions

Only those persons may independently operate the Cabinet who have received sufficient

training in the operation of this system.

This Cabinet has been designed and built in accordance with the state of the engineering

art and the recognized rules of good engineering practice. At the same time, however,

dangers can arise during its operation, and damage to the electrical components can

occur.

Before putting this system into operation, check to make sure that the ratings of your

mains power voltage and current are the same as the electrical data specified on the

rating plate (nameplate). Connect this Cabinet only to alternating current (AC).

Use this Cabinet only for the purpose that has been described in this Operating Manual.

If this system is improperly used, or used for purposes for which it was not intended, the

guarantee will not be valid.

If the Cabinet or its power cable are damaged, immediately pull out the power plug. If

shortcomings or damages to the Cabinet occur that impair its operational safety, the sys-

tem must immediately be taken out of operation. It may be put back into operation only

after all sources of danger have been eliminated. The Cabinet has been provided with

two internal automatic circuit breakers (automatic cutouts) to prevent electrical problems.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

6

1.6 Acceptance of delivery and transport

Acceptance of delivery

When accepting delivery of the Cabinet, first inspect it for its outer, visible condition. If

this inspection is satisfactory, the machine may be accepted from the freight forwarder

(railways, parcel service, or other haulage company).

If there are no shortcomings, and if there are no transport damages, then use the bill of

delivery to make sure that the consignment is complete, and that all parts have been

delivered.

If you assume or suspect transport damage, or if transport damage becomes apparent

only after you have accepted the delivery, immediately make an exact report of the con-

ditions and any damage as they exist. Send us this report immediately by fax or e-mail.

Important: Absolutely do not make any changes to the delivered goods.

After we have studied your report, we can make a decision whether we can:

•Deliver spare parts to you, or

•Send a specialized fitter/installer to your plant, or

•Ask that you return the system to us for repair.

Transport

The Cabinet is delivered on a wooden frame.

You can move the Cabinet to its place of installation by leaving it on the wooden frame

and by moving it with a fork-lift truck or other suitable transport equipment. It is necessary

for this equipment to reach under the wooden frame to move the Cabinet to its intended

location.

Do not use cables or ropes wrapped around the equipment, or any similar lifting appa-

ratus, to lift the system –unless you can assure that lateral forces will not act on the

packing from the side or on any parts of the system while it is being lifted.

The weight of the equipment is approx. 90 kg.

After you have unpacked the Cabinet, make sure that the system has not been damaged

during transport. If you are not sure whether the machine has been damaged or not, get

in touch with the person who sold you the system.

Caution

Before you dispose of the packing material, be sure not to leave any

of the following items in the packing: accessory parts, printed instruc-

tions, documents, or spare parts.

Be careful not to knock or bump against the Cabinet. Be sure that it

cannot fall over.

When the transporting or perating the appliance at an altitude of more

than 1500 m above sea level, the glass pane in the door can break

fragments are sharp-edged and can cause seriousinjury.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

7

1.7 Setting up the Cabinet

Set up the Cabinet on a surface that is level, that is not subject to vibrations, and that can

sufficiently support the weight of the cabinet. Now level the cabinet. Compensate for un-

even floors with the adjustable feet.

The ambient conditions that must be observed are as follows:

Permissible temperature conditions:

+ 15 … 35°C

Permissible relative humidity:

30 ... 75%

Maximum elevation:

1,000 metres above sea level

provide the required humidity in the Cabi-

net

Use of internal tank with distilled water

Electrical ratings:

230 V and 50 Hz, with fusegear (circuit

breaker) rated at 16 A.

The climate rating indicates the room temperature at which the appliance may be oper-

ated in order to achieve full refrigeration performance. The climate rating is indicated on

the type plate.

The main working position of the Operator will be in front of the Cabinet. The Cabinet

must be set up in such a way that it is open to easy access from the front and on both

sides. This will allow maintenance work to be conducted without difficulty. At the rear, the

Cabinet must have approx. 100 mm clearance from the wall. The Cabinet should also be

installed as far as possible away from any sources of heat or cold. Make sure that air can

freely circulate around the lower supporting structure of the Cabinet: this means not

placing any objects near the Cabinet, to the front and back, or to the sides.

Place the appliance in its final positon at the place of installation.Extend the adjustable

foot at the bottom hinge bracket until it rests on the floor and then make a further 90 °

turn.

2. Placing the Cabinet into operation

2.1 General information

To place the Cabinet into operation, you need the following:

Distilled water to provide the required humidity

Electric power connection with 230 V and 50 Hz, and with fusegear (circuit

breaker) rated at 16 A

Note:

Before being put into operation, the Cabinet must remain unused for

at least one (1) day at the place where it will operate. This time is

necessary for it to adapt to the local ambient conditions.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

8

Danger:

When you are loading the shelves of the Cabinet, make sure that you

do not pull out the shelf. If all the shelves are full, and if you pull out

all the shelves, there is a danger that the Cabinet will fall over to-

ward the front.

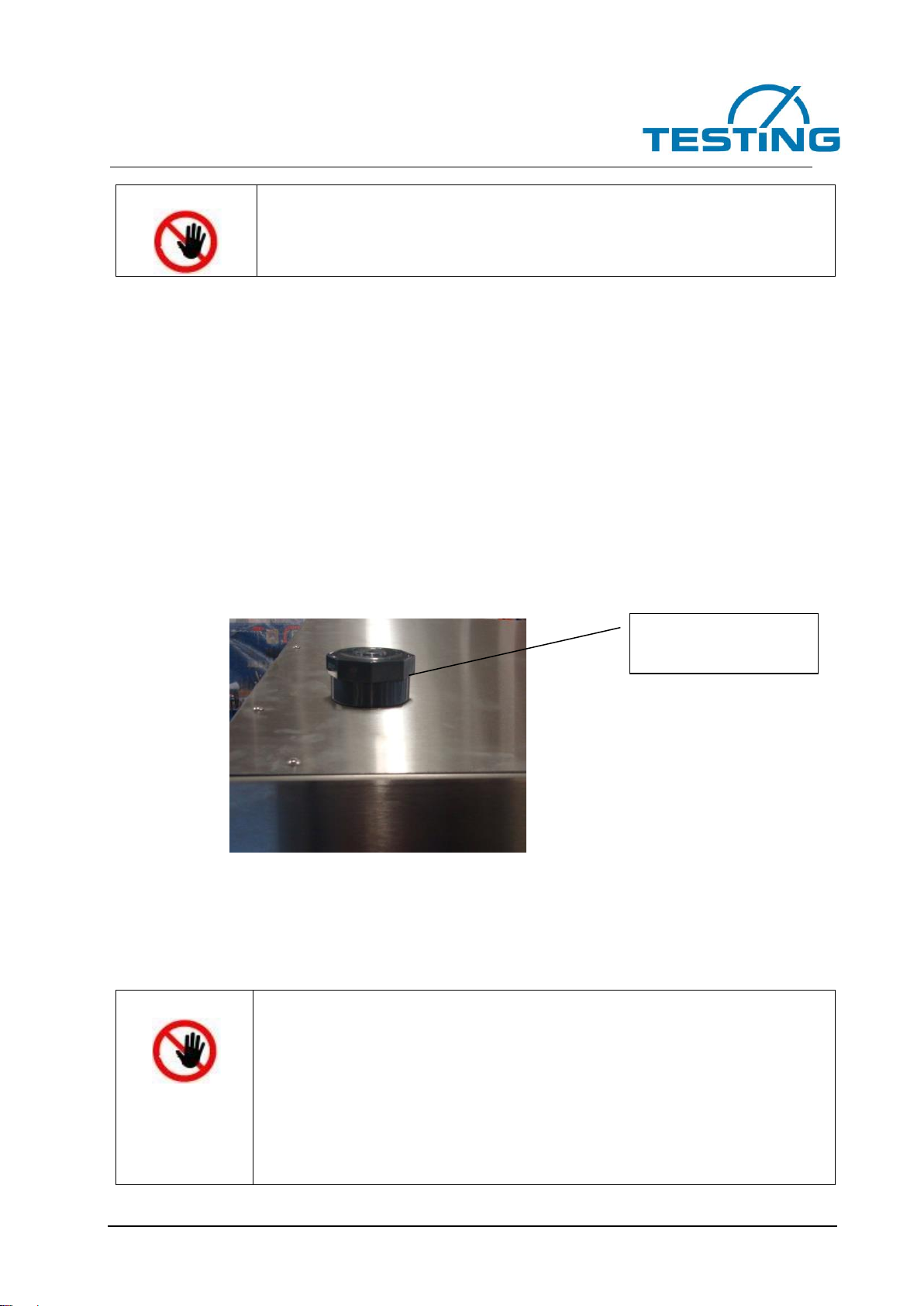

2.2 Humidifier

The system in the Cabinet that produces the required moisture for the air must be filled

with de-mineralized water. Normal water may not be used, since it would leave deposits

inside the humidifier that would reduce the service life of the Cabinet.

An internal water tank filled with distilled water is used to feed the Cabinet. The water

tank (3 litres) is installed inside the Cabinet. This tank is filled through a filling opening

with a stopper, which is located on the top side of the Cabinet. You must regularly check

the filling level of the Cabinet to ensure that enough distilled water is in it. An inspection

window on the front side of the Cabinet shows how much water is left in the tank. Do not

allow the level of the water to fall below the lowest section of this window.

2.3 Connection to the power supply

The Cabinet has a 3-core power cable that is 2.0 metres long. The ratings for the power

supply of the Cabinet must be 230 V and 50 Hz.

Danger

The Cabinet must be connected to the building power system by

a qualified electrician.

In accordance with the pertinent standards, the yellow-green con-

nection terminal must be attached to the earthing system before

additional electrical connections are made.

Before making the electrical connections, please study the en-

closed wiring diagram. Also check the machine rating plate to

make sure that the ratings of the building power supply conform

Cap for water tank

only distilled water !

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

9

to the requirements for voltage, wattage, amperage, and fre-

quency of the Cabinet.

The electrical socket must have a safety device that will protect

the system against over-current. This safety device must satisfy

the stipulations of the relevant standards,and must match thema-

chine voltage. The technical characteristics of this safety device

must also satisfy the standards that apply in the country in which

the machine is installed.

Do not connect the appliance using an extrension cable or exten-

sion socket.

Do not use stand –alone inverters (conversion of direct current to

alternating current/threephase current)or energy-saving

plugs.Risk of damage to the electronic control system!

Caution

The manufacturer of this Cabinet cannot be held liable for any dam-

ages that result because the information here is not observed.

2.4 Switching on the Cabinet

Note:

First, the temperature in the Cabinet must be regulated to the required

level. Then the relative humidity in the Cabinet will reach the level as

set by you. When you switch the Cabinet on, the default settings from

the factory are as follows: the top controller is active, and the lower

controller is deactivated.

Steps for switching on the Cabinet:

1. Switch on the main switch. This will automatically regulate the temperature inside

the Cabinet to 20°C.

2. When the temperature has reached the set level, then press the standby button

on the lower controller. This will activate the control function for the humidification

of the air.

3. If the humidity does not begin to rise, then there is no water supply. The following

reasons can mean that there is no water supply:

–There is no distilled water in the tank, or there is not enough water.

–There is a kink (i.e., a twist or curl) in the water-supply hose. Please

straighten out the hose so that the water can flow freely.

–The water hose has a leak. Repair the leak.

After following the steps above, use an external, officially calibrated testing system to

measure the exact temperature and humidity inside the Cabinet. If the officially calibrated

testing system measures values that are different from the display on the controller, you

must use a correction factor in the controller to change the display reading to match the

actually measured values.

The Cabinet is now ready for operation.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

10

3. Characteristics of the system

3.1 General description of the system

The purpose of the Cabinet is to store test samples of mortar prisms in triple moulds, in

accordance with EN 196, for use in laboratory and research work. Standard EN 196 stip-

ulates a temperature of 20°C 1°C and a humidity > 90%.

The Cabinet has a double wall, with heat insulation between the walls. It is primarily con-

structed of stainless-steel plate. It has an upper and a lower part. The lower part serves

as a climate-controlled storage chamber, and the upper part contains the technical equip-

ment for operating the Cabinet. The Cabinet is designed for use in enclosed areas. Do

not operate the appliance outdoors or areas where it is exposed to splash water or damp

conditions.

The Cabinet maintains the conditions at the required temperature and humidity by sys-

tems that heat or cool, and that humidify the air inside the Cabinet.

The LED light strip illuminates the interior of the appliance. It is not suitable for lighting a

room.

3.2 Technical data

Power ratings:

230 V AC, 50 Hz, 0.2 kW

Hysteresis:

As required, by setting the switch-on or

switch-off points

Precision of temperature control:

0.1°C

Precision of relative-humidity control:

1%

Degree of enclosure protection:

IP 54, in accordance with DIN 40050 and

ICE 144 (the front is protected by mem-

brane keypad)

Enclosure protection class:

Class 2, in accordance with VDE 0100

Storage capacity:

10 moulds: i.e., a maximum of 2 ea. triple

moulds per compartment

Maximum load capacity per shelf:

30 kg

Controlled temperature:

20°C 1°C

Controlled relative humidity:

> 90%

Dimensions:

660 mm wide x 700 mm deep x 1,900 mm

high

Weight (mass) of the Cabinet:

Approx. 90 kg

Maximum water consumption:

1 litre per day (it is not possible to provide

an exact value here, since the water con-

sumption will depend, for example, on the

type of sample material in the Cabinet and

on the laboratory-room temperature)

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

11

The Cabinet operates with the refrigerant R606a, which does not contain chlorofluorocar-

bons (CFC's).

The Cabinet belongs to those types of work equipment whose noise emissions generally

do not reach a rating level of 85 db(A) as stipulated in DIN 45 635. The level of noise

produced by the particular Cabinet will depend on various factors: e.g., on the product,

the place where it is in operation, and other equipment installed near the Cabinet.

The manufacturer will test and calibrate the Cabinet before it is delivered. The measuring

equipment used for this testing and calibration is checked for accuracy at regular intervals

by state institutes.

Note:

Currently valid standards stipulate that the Cabinet must be tested for

proper calibration every time the Cabinet is moved to another place of

operation.

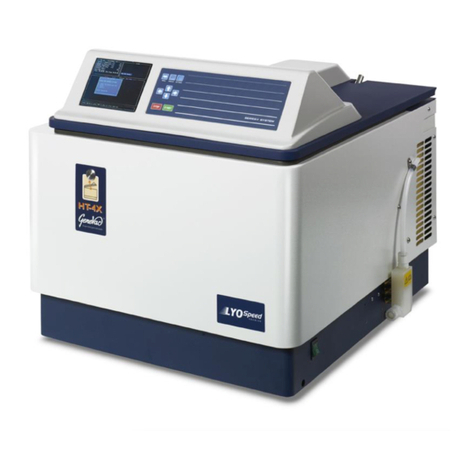

main

Indicator

Water tank

Cap for water tank

only distilled water !

Sensor for

temp. and

humidity

door

contact

Controller

Temperature

Humidity

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

12

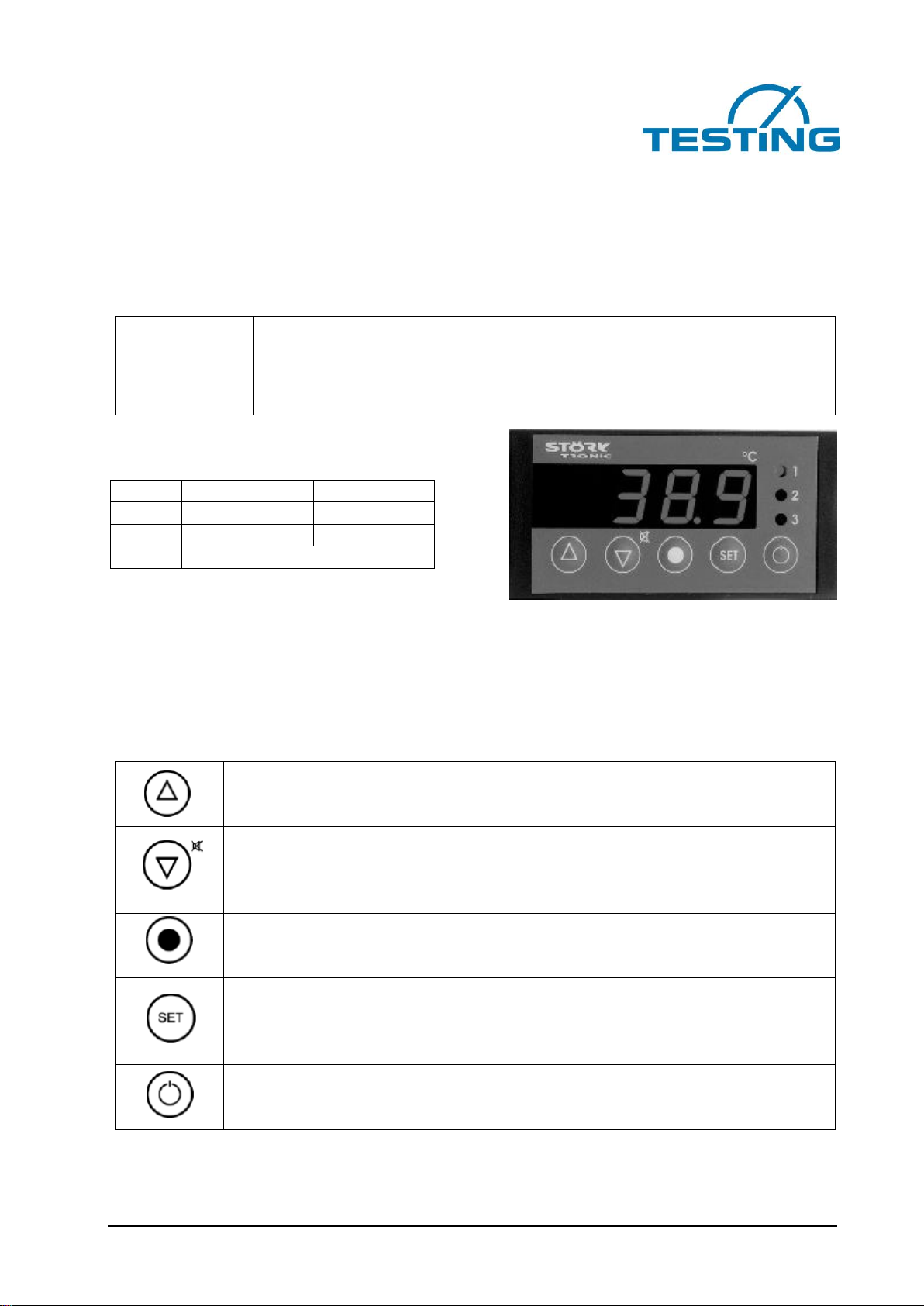

3.3 Open- and closed-loop control equipment

The Cabinet automatically controls the temperature and humidity to the values set by the

User. It is not necessary for the user to make manual changes to the temperature and

humidity.

Note:

When the Cabinet is installed for the first time, and whenever it is put

back into operation after not being used for a long time, the Cabinet

will require at least one (1) day before the temperature and humidity

settle down to the desired settings.

Es bedeuten

Temperature

Humidity

1

heating

moisten

2

cooling

dehumidify

3

without function

The open- and closed-loop control equipment installed in the Cabinet was developed for

control systems in which several outputs are required. A membrane keyboard with 5 keys

is used to input the settings for the required values (setpoints), the standby values, and

all other parameters for the controllers.

Settings that can be made on the Cabinet:

Button: UP

By pushing this button, you increase the parameter or the

parameter value.

Button:

DOWN

By pushing this button, you decrease the parameter or the

parameter value. In case of an alarm, you can also shut

off the acoustic alert (buzzer) by pressing this button.

Not active

Button: SET

When you press this button, it will display the desired set-

ting (setpoint value). This button is also used to set the

parameters.

Standby

Standby circuitry

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

13

The controller has three (3) operation levels:

Operator level no. 1:

Parameterization of the setpoint value:

You can directly select the setpoint value for heating by pressing the SET button (regard-

less of the standby mode). If you release the SET and then press the UP and DOWN

buttons, you can increase or decrease the setpoint values. The newly set values will then

apply for the control functions.

Operator level no. 2 (P parameters):

If you press both the UP and DOWN buttons at the same time and hold them both down

for at least 4 seconds, you will go into a parameter list for the control parameters (these

parameters begin with P1). You can then use the UP button to move the list upward, and

the DOWN button to scroll downward in this list. When you press the SET button, this will

display the value of a single parameter. If you then press the UP or the DOWN button,

while still holding down the SET button, then you can increase or decrease the value of

the respective parameter. When you release all the buttons, the new value will be saved.

If you then take no action and press no buttons for more than 60 seconds, the system will

jump back to the basic state.

The following is a brief description of some of the parameters:

Parameter

Description of the function

Setting range

P0

Actual value

—

P1

Desired value (setpoint) for cooling

–99.9 ... +99.9 K

P2

Hysteresis control-contact 1

0.1 ... 99.0 K

P3

Hysteresis control-contact 2

0.1 ... 99.0 K

P4

Lower limit for setpoint value

–99°C ... P5

P5

Upper limit for setpoint value

P4 ... 999°C

P6

Correction of actual value

–20.0 ... +20.0 K

P19

Locking the keyboard buttons

0 = unlocked; 1 = locked

P30

Lower limit value for alarm

–99 ... 999°C/K

P31

Upper limit value for alarm

–99 ... 999°C/K

P32

Hysteresis alarm, one-sided

0.1 ... 99.9 K

Operator level no. 3:

To move into the third operator level, first go into the second operator level as described

above (Operator level no. 2). Then scroll the parameter list up to the highest parameter.

Then press the UP button and hold it pressed for at least 10 seconds. The display will

show “PA”. Then press the UP and DOWN buttons at the same time, and hold them both

down for at least 4 seconds. This will take you to the parameter list on the third operator

level. The parameters there begin with “A1”. You can then use the UP button to move the

list upward, and the DOWN button to scroll downward in this list. When you press the

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

14

SET button, this will display the value of a single parameter. If you then press the UP or

the DOWN button, then you can increase or decrease the value of the respective param-

eter. When you release all the buttons, the new value will be automatrically saved. If you

then take no action and press no buttons for more than 60 seconds, the system will jump

back to the first display.

Changing the parameters beginning with the letter “A…” can modify the characteristics of

the system. Therefore be very careful when modifying these values.

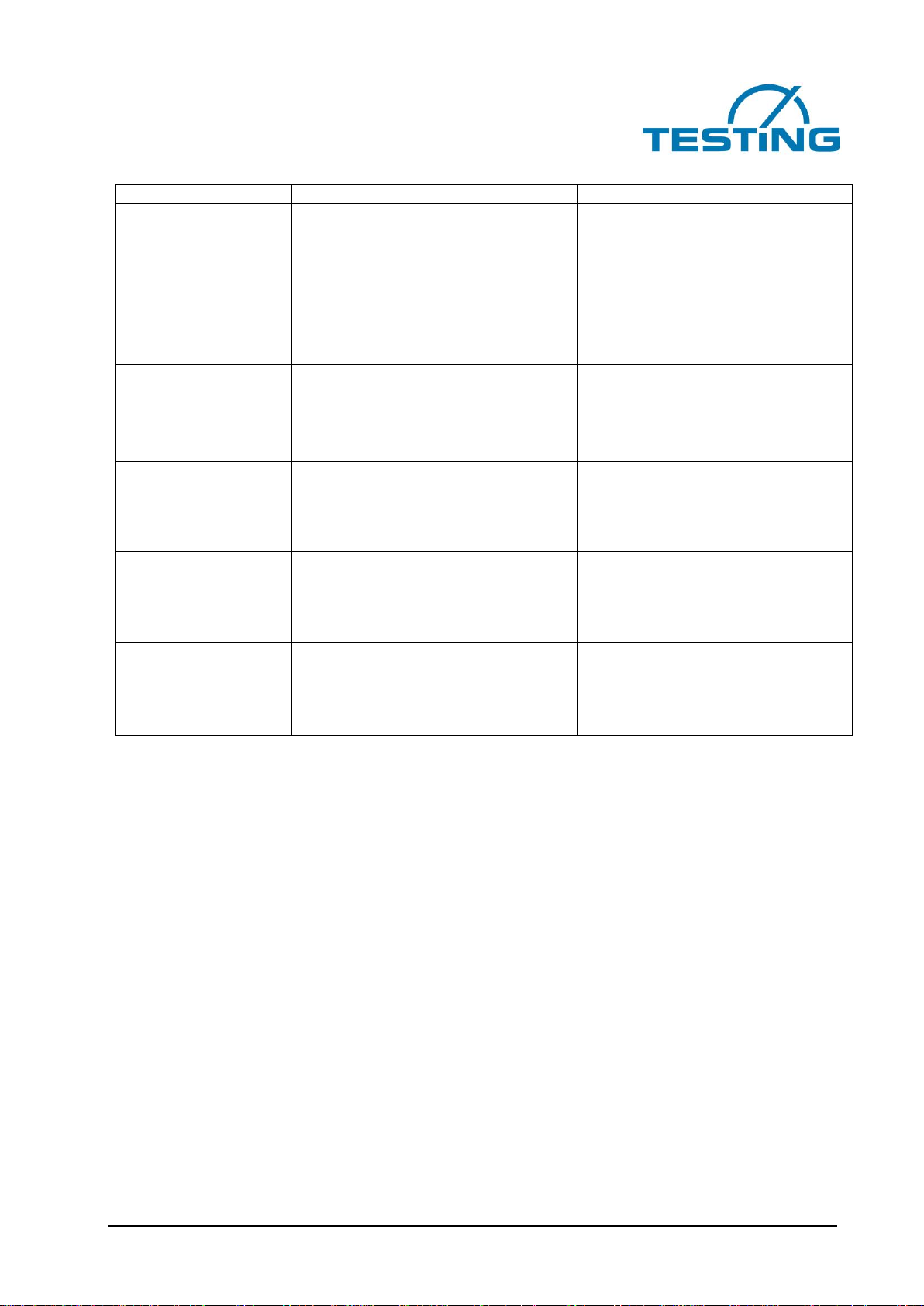

3.3.1 Messages and warnings on the display

Message

Description

Action to be taken

OFF

Standby mode. There are no con-

trol functions.

Switch on by pressing the

standby-button

F1L

Sensor fault or short circuit.

Check the sensors and the sensor

connection terminals.

F1H

Sensor fault or breakage in the

sensor.

Check the sensors and the sensor

connection terminals.

The keyboard locking function is

active.

See Parameter P19 or A19.

The display is

flashing

Temperature alarm (see A31)

The acoustic

alarm sounds

(buzzer)

Temperature alarm (see A31)

Shut off the acoustic alarm

(buzzer) by pressing the DOWN

button.

EP

Data loss in parameter memory

(control-contacts no. 1 and 2 are

without current)

Switch the mains power OFF, then

ON again. If this does not solve

the problem, the controller must

be repaired.

Sensor error messages are saved and will continue to be shown, even if the cause of the

problem has been corrected. If you acknowledge these error messages by pushing the

DOWN button, this will delete the error message.

3.3.2 Calibration of the display value

After the Cabinet has been set up, it is necessary to use an officially calibrated reference

testing system to measure the exact temperature and humidity that actually occurs inside

the Cabinet. This is necessary to compare the actual temperature and the humidity of the

interior of the Cabinet with the values being displayed by the system. If the values being

displayed are not the same as the actual values inside the Cabinet as measured by the

reference testing system, then proceed as follows:

Go to the second operator level, under P6, to make the correction.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

15

Then change the value shown here so that it is the same as the value actually measured

by the officially calibrated reference sensor.

3.4 The humidification system

The enclosure of the humidification unit contains ultrasonic atomization modules, the so-

lenoid valve, and the float switch.

A compact-designed atomization module is installed on the bottom of the water tank. It

contains an oscillatory circuit, an amplifier, and an oscillator. The ultrasonic oscillations

produced by this module are directed to the surface of the water in the tank. This effect

reduces the water to fine particles (atomization).

To achieve optimal atomization of the water, it is necessary to keep the water level in the

tank as constant as possible. To provide these conditions, an automatic water-level con-

trol system with a solenoid valve and a float switch have been installed. When the water

level in the tank falls below the normal level, the float switch goes ON, and the solenoid

value will open. This will allow water to flow into the tank. When the water in the tank has

reached the proper level, the float switch will go OFF and will close the solenoid valve.

The Cabinet also contains an automatic feed-water monitoring system with a solenoid

valve and a float switch, to protect the Cabinet from drying out.

If the water level in the tank falls below a pre-selected level, a float switch and a relay will

automatically shut off the power to the Cabinet. A thermostat switches the power off when

the temperature in the humidifier unit rises above a pre-selected point. Fuses and voltage-

dependent resistors (varistors) are installed to protect the electronic system.

A fan blows the fog produced in the water tank through the fog emission pipes and into

the Cabinet.

Range of permissible conditions and possible ambient conditions

Water quality

< 5 µS/cm, briefly to 20 µS/cm

Power voltage for the humidifier unit

48 V AC + 10%

Permissible water pressure

0.5 … 6 bar upstream (in front of) the hu-

midifier

Temperature of input water to be used for

the Cabinet

8 … 30°C

Relative humidity (ambient)

< 90%

Air temperature (ambient)

5 … 35°C

The User must provide a drain pipe connected to the building piping system to drain away

the safety overflow from the humidifier, and to drain away the condensed water that col-

lects in the system.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

16

4. Maintenance, care, and cleaning of the system

4.1 General instructions

It may be necessary to conduct special maintenance work on the Cabinet: for example,

repairs, exchange of parts, and any other work that is not described in this Operating

Manual. If such work becomes necessary, then you must get into direct contact with the

manufacturer.

After the Cabinet has been used for a longer period of time, we recommend that you give

it a thorough cleaning on the outside and inside. The frequency and thoroughness of

cleaning will depend on how often you use the Cabinet, and on the ambient conditions.

All maintenance work on the components of the Cabinet, and on its electrical system,

must be conducted by specialists.

After a certain period of time, spots can form on the stainless-steel surfaces of the Cabi-

net, and the surfaces can become unsightly. In such cases, please use a normal, com-

mercially available cleaning agent especially designed for stainless steel or with lukewarm

soapy water. After cleaning, wipe off the cleaned parts with clear, warm water so that

there is no soap remaining on the parts. Finally, carefully dry off all parts that you have

cleaned.

Caution

Never use a direct stream of water or a high-pressure cleaning system

to spray water onto the Cabinet. Such action would damage the sys-

tem and would represent a safety hazard.

Do NOT in any case use normal-steel wool or steel brushes or similar

tools made of normal steel to clean the parts of the Cabinet. The use

of such tools could cause particles containing iron to remain on the

stainless steel surfaces of the Cabinet. This would cause rust spots

by means of oxidation. If necessary in extreme cases, you may use

stainless-steel wool to clean stubborn spots on the Cabinet. In this

case, however, press the stainless-steel wool only in the direction of

the satin finish of the Cabinet.

The User is responsible to ensure that all maintenance, inspection, and assembly work

is performed only by authorized and qualified specialist persons who have carefully stud-

ied all instructions in this Operating Manual.

If a water storage tank is used to provide the water for the Cabinet, it is necessary to

check the level of the water in the tank every day.

From time to time, we recommend that you remove any particles of building materials that

may have fallen to the bottom. To perform this cleaning, first remove the shelves and the

bottom metal closure panel.

We recommend that you replac the filter once a year.Filters can be obtained from your

dealer.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

17

Changing the filter: Take the filter by the handle.Turn it 90 °to the left or right and re-

move.

Inserting the filter: Insert with the handle in a vertical position. Turn it 90 °to the left or

right until it clicks into place.

Saving energy:

Do not cover ventilation opeins or grille.

Alwaya keep fan louvers clear.

The energy consumption depends on the installation conditions, e.g. the ambient

temperature.

Keep the time the appliance is open to a minimum.

Accumumulated dust increases the energy consumption:

Once a year, dust the refrigerating unit together with the metal grille of the heat

exchanger at the back of the appliance.

4.2 Care of the indicator instruments

To clean the plasticfilm on the front, use normally available cleaning agents: for example,

household washing-up liquid. Do NOT use organic solvents such as petroleum ether,

turpentine, kerosene, methylated alcohol, or the like. Also do not use high-pressure clean-

ing equipment.

4.3 Care of the humidifier

Never perform any maintenance or repair work on the Cabinet before shutting down the

system. Before performing any repair or maintenance work, first switch off the power sup-

ply to the system. After shutting off the power, first use a meter to ensure that the system

is in fact completely without electric power. IMPORTANT: It is in such cases absolutely

necessary to follow the instructions given in this Operating Manual for shutting down the

Cabinet.

The User must provide a drain pipe connected to the building piping system to drain away

the safety overflow from the humidifier, and to drain off the condensed water that collects

in the system.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

18

5. Troubleshooting

Important:

Any work done on the electrical components or systems must be

performed by qualified specialist personnel.

5.1 Status and error messages on the controller

Message

Description

Action to be taken

OFF

Standby mode. There are no con-

trol functions.

Switch on the standby button

Keyboard lock is active

See parameter P19.

F1L

Sensor fault or short circuit.

Check the sensors and the sensor

connection terminals.

F1H

Sensor fault or breakage in the

sensor.

Check the sensors and the sensor

connection terminals.

F2

Sensor fault, 3-wire connections

Equalizing conductor at Pt100-3L

was not correctly connected.

The display is

flashing

Temperature alarm (see A31)

The acoustic

alarm sounds

(buzzer)

Temperature alarm (see A31)

Shut off the acoustic alarm

(buzzer) by pressing the DOWN

button.

EP

Data loss in parameter memory

(control-contacts no. 1 and 2 are

without current)

Switch the mains power OFF, then

ON again. If this does not solve

the problem, the controller must

be repaired.

Sensor error messages are saved and will continue to be shown, even if the cause of the

problem has been corrected. If you acknowledge these error messages by pushing the

DOWN button, this will delete the error message.

5.2 General troubleshooting

TROUBLE

CAUSE

SOLUTION

The interior of the Cabi-

net is too wet.

Controller setting is not correct.

The sensor is defective.

There is too much condensate, and too

much water in the catch pan at the bot-

tom.

The drain of the condensate catch pan

is stopped up.

Get in touch with the manufacturer.

Get in touch with the manufacturer.

Wipe out the condensate catch pan at

the bottom. Make sure that the drain

system is functioning properly.

Clean out the drain system and make

sure it is working properly.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

19

TROUBLE

CAUSE

SOLUTION

The humidifier is producing too much

moisture.

The humidifying pipes are not in their

correct positions.

There is no air circulation. The internal

fans are defective.

The controller settings are not correct.

Get in touch with the manufacturer.

Get in touch with the manufacturer.

Replace the circulation fans.

The interior of the Cabi-

net is too dry.

The water supply is not functioning

properly.

The humidifier is not switched on, or it

switched itself off.

If using a water tank: refill with dis-

tilled water.

Check to make sure the water supply

is properly functioning. Get in touch

with the manufacturer.

The interior of the Cabi-

net is too warm.

The cooling system is defective. The

controller or the sensors are defective.

The controller settings are not correct.

The fans are defective. There is no

proper air circulation.

Get in touch with the manufacturer.

The interior of the Cabi-

net is too cold.

The heating system is defective. The

controller or the sensors are defective.

The controller settings are not correct.

The fans are defective. There is no

proper air circulation.

Get in touch with the manufacturer.

The controllers do not

show a measured

value, although the

main switch is ON.

Excessive voltage. Short circuit.

The miniature circuit breakers have

been turned OFF.

Take off the front panel of the Cabinet

and turn ON the miniature circuit

breakers in the electrical box. Find out

why the circuit breakers tripped. Get

in touch with the manufacturer.

6. Placing the system out of operation

If the Cabinet should be placed out of operation for a lengthy period of time, it must be

disconnected from the mains power supply. Then, during this time, conduct all mainte-

nance on the system that is required. Drain or remove the water from all storage tanks.

Cover the Cabinet to protect it from dust. Keep the door open in order to prevent unpleas-

ant smells.

If the humidifier is not used over longer periods of time, the water must be drained.

7. Scrapping the system

If the Cabinet cannot be further used, we recommend scrapping it as follows:

Disconnect the equipment from the mains power

Drain all the water out of the system

Dispose of the refrigerant in accordance with currently valid laws.

Take the system apart and scrap it in accordance with currently valid laws.

Cabinet for Moist Storage

of Mortar Prisms in Triple Moulds

1.0330

20

8. After-sales service

Great care was taken to assure that this Operating Manual was properly prepared. We

cannot, however, guarantee that it has no mistakes, or that all data are complete and

correct in the event of technical modifications.

8.1 Date of this version of the Operating Manual

Version no. 11

Oct. 2017

8.2 Copyright

The copyright to this Operating Manual is held by:

TESTING Bluhm & Feuerherdt GmbH

This Operating Manual is intended for use only by the User and his/her staff. It contains

instructions and data that may NOT be:

Reproduced,

Distributed, or

Provided to any third party.

Any person acting in violation of the above stipulations may be prosecuted before a court

of law.

8.3 Spare parts and technical help

If you have any questions of technical nature, or if you need spare parts, please get in

touch with the following address:

TESTING Bluhm & Feuerherdt GmbH

Motzener Str. 26b

DE –12277 Berlin

Germany

Tel. [+ 49 30] 710 96 45-0

Fax [+ 49 30] 710 96 45 98

www.testing.de

Table of contents

Other TESTING Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Heidelberg Engineering

Heidelberg Engineering MLA 150 user manual

Hettich

Hettich ROTANTA 460 S operating instructions

Hygiena

Hygiena RiboPrinter reference guide

Showa Denko

Showa Denko Shodex PROTEIN LS-G 4J Operation manual

Oxford Instruments

Oxford Instruments Andor Marana-X quick start guide

Tektronix

Tektronix 1741C Declassification and security instructions