TESTING 1.0204.LV User manual

Laboratory mortar mixers

Model 1.0204.LV

1

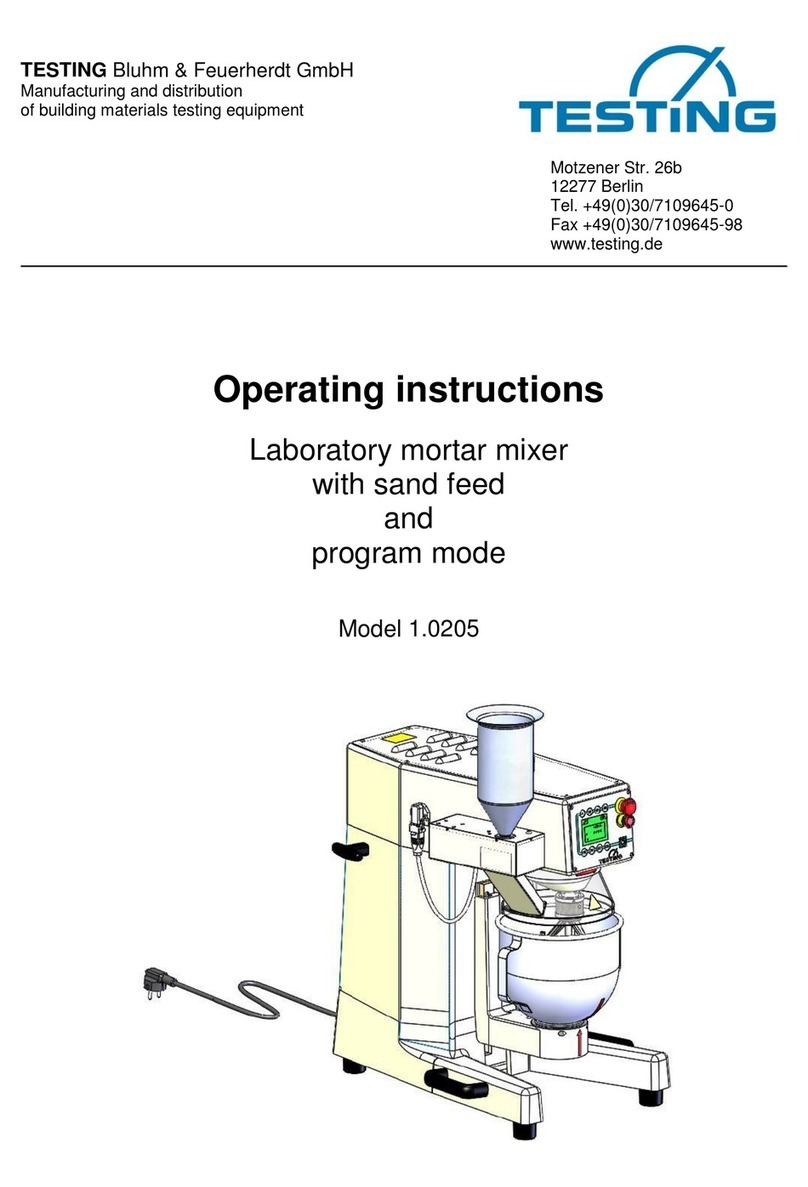

Operating instructions

Laboratory mortar mixer

Model 1.0204.LV

Laboratory mortar mixers

Model 1.0204.LV

2

Significance of the operating instructions

Before operating the laboratory mortar mixer, the operating instructions must be read

and understood.

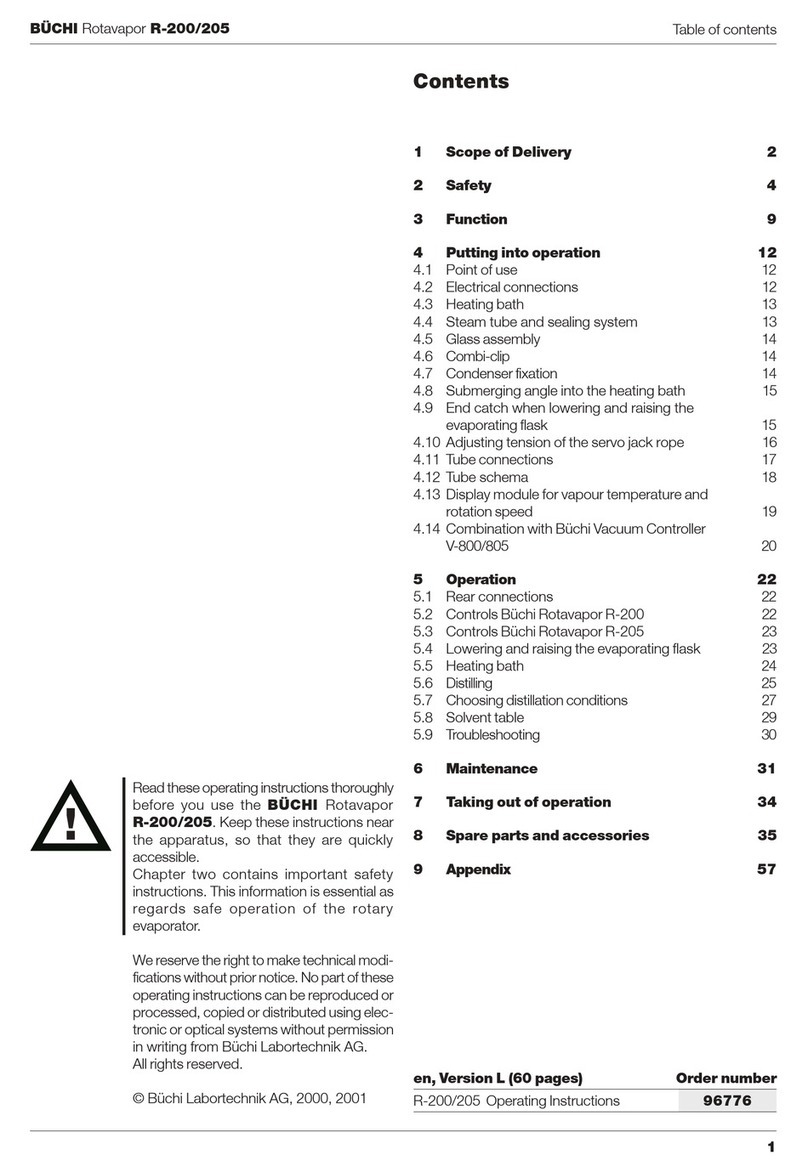

Table of contents Pages

1. Receipt, transport...................................................................................................6

1.1 Receipt..............................................................................................................6

1.2 Transport...........................................................................................................6

1.3 Removing the transport packaging....................................................................6

1.4 Transport by hand.............................................................................................7

2. Scope of delivery....................................................................................................7

3. Basic safety instructions.......................................................................................8

3.1 Obligations of the operator................................................................................8

3.2 Requirements for the operating personnel ........................................................8

3.3 Obligations of the operating personnel..............................................................8

3.4 Workplace.........................................................................................................8

3.5 Dangers when handling the mortar mixer..........................................................9

4. Basic information...................................................................................................9

4.1 Intended use .....................................................................................................9

4.2 Improper usage...............................................................................................10

4.3 Information about the CE marking...................................................................11

4.4 Requirements imposed on the operator..........................................................11

4.5 General safety instructions..............................................................................12

4.6 Protective clothing...........................................................................................14

4.7 Regular checks................................................................................................14

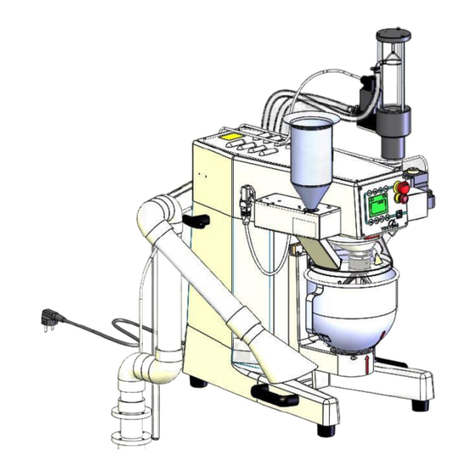

5. Description of the mortar mixer..........................................................................14

5.1 Mechanical structure.......................................................................................14

5.2 Safety devices.................................................................................................15

6. Preparations for start-up .....................................................................................15

6.1 Installation site/environmental conditions........................................................15

6.2 Electrical connection .......................................................................................15

7. Prior to first operation..........................................................................................16

7.1 Loosen and remove the stirrer ........................................................................16

7.2 Removing the mixing bowl ..............................................................................16

7.3 Inserting the mixing bowl.................................................................................17

7.4 Insert the stirrer and clamp securely ...............................................................17

7.5 Checking the distance between mixing bowl and stirrer..................................18

7.6 Correct distance..............................................................................................19

8Optional splash guard ring..................................................................................20

8.1 Installing the splash guard ring........................................................................20

9. Operation ..............................................................................................................21

9.1 Switching the mortar mixer on and off.............................................................21

9.2 Explanation of the control unit.........................................................................21

10. Setting speeds ..................................................................................................22

Laboratory mortar mixers

Model 1.0204.LV

3

11. Warranty............................................................................................................23

12. Connection plan................................................................................................24

13. Cleaning and maintenance ..............................................................................26

13.1 Cleaning the mortar mixer...............................................................................26

13.2 Maintenance of the mortar mixer.....................................................................26

13.3 Checking and adjustment................................................................................26

13.4 Taking the mortar mixer out of operation.........................................................27

14. Disposal.............................................................................................................27

14. Issue date of the operating instructions.........................................................28

15. Copyright...........................................................................................................28

16. Address of the manufacturer...........................................................................28

Laboratory mortar mixers

Model 1.0204.LV

4

Table of figures

Figure 1 Loosen and remove the stirrer.........................................................................16

Figure 2 Lower the mixing bowl and remove the stirrer................................................16

Figure 3 Inserting and locking the mixing bowl..............................................................17

Figure 4 Inserting and tightening the stirrer...................................................................17

Figure 5 Removing contact protection...........................................................................18

Figure 6 Height adjustment............................................................................................19

Figure 7 Mixer with splash guard ring............................................................................20

Figure 8 Installing splash guard ring..............................................................................20

Figure 9 Power switch/Power connection/Fuses...........................................................21

Figure 10 Control panel.................................................................................................21

Figure 11 Boards...........................................................................................................22

Figure 12 Connection plan.............................................................................................24

Laboratory mortar mixers

Model 1.0204.LV

5

The notes have the following meaning:

Warning

This warning applies to all procedures that need to be performed

with care to avoid damage to the device.

Danger

This warning applies to all procedures that represent a risk for the

operator if the process cannot be performed with care.

Note

provides practical information about handling the machine

Annex documents:

Test report

Test and measurement report

Laboratory mortar mixers

Model 1.0204.LV

6

1. Receipt, transport

1.1 Receipt

Check the visible external condition of the delivered shipment. If it is in good condition,

the shipment can be accepted by the carrier (parcel service or freight forwarder).

If there is no objection or any transport damages detected, the completeness of the ship-

ment must be checked against the delivery note.

If any transport damages occur after a successful acceptance, a production log with an

exact report and a photo about the extent of the damage must be immediately prepared.

Please send us the production log immediately by fax. Absolutely no changes may be

made to the delivered shipment.

On the basis of this production log, we should be able to assess whether the damage can

be remedied

- by delivery of spare parts or

- by sending a specialist technician or only

- by returning the device.

1.2 Transport

The mortar mixer is supplied in suitable cardboard packaging, standing on a pallet.

The weight of the mortar mixer is approx. 22 kg.

Dimensions of the mortar mixer are H=568, W=235, D= 396

The mortar mixer can be moved to its intended location in the delivery packaging, by

means of a pallet truck or other suitable floor-level conveyors that must be able to reach

under the pallet.

Wrapping with ropes or similar lifting gear is only permissible if it is ensured that no lateral

forces are exerted on the packaging and therefore also possibly on parts of the mortar

mixer.

1.3 Removing the transport packaging

To remove the transport packaging, proceed as follows:

Open the lid of the transport packaging

Remove the cardboard or styrofoam transport protection (inserts)

Side panels should be cut open at the vertical edges

Cut side panels at the horizontal bottom edges

Laboratory mortar mixers

Model 1.0204.LV

7

Danger

The packaging materials (plastics, polystyrene, screws, nails, wood

etc.) must be kept away from children.

They must be disposed of correctly.

Warning

Before disposal of the packaging, please check to see whether there

are any further components, instructions, documents or replacement

parts in the packaging.

After unpacking the device, make sure that the mortar mixer has not been damaged in

any obvious way during transport. If in doubt, do not plug in the device and contact your

seller.

1.4 Transport by hand

The mortar mixer can be transported to its intended destination by hand.

Its weight is about 22 kg.

2. Scope of delivery

Item

Amount

Description

Serial number

1.

1

Mortar mixer (including operating instruc-

tions)

1.0204.LV

2.

1

Stainless steel stirrer

3.

1

Stainless steel bowl

4.

1

Power cable

5.

1

Operating Instructions

Laboratory mortar mixers

Model 1.0204.LV

8

3. Basic safety instructions

3.1 Obligations of the operator

The operating instructions must be easily accessible and kept in the immediate vicinity of

the mortar mixer. Only suitably qualified operating personnel may work with the mortar

mixer. The operating personnel must be trained before using the mortar mixer. Check

that the operating personnel have read and understood the operating instructions. Estab-

lish exact responsibilities for the operating personnel. Personal protective equipment

must be provided to all operating personnel.

The person operating the equipment must ensure that they do not put themselves or

anyone else at risk.

If the operational safety is compromised due to defects or damage to the mortar mixer,

the mortar mixer must be taken out of operation immediately and must only be used again

after all potential hazards have been eliminated.

3.2 Requirements for the operating personnel

The mortar mixer may only be operated by suitably qualified specialist personnel who

have been assigned and trained by the operator. The minimum age for the operator is

18 years. Under 18 years of age, the mortar mixer may only be operated under the su-

pervision of a qualified specialist. The operator is responsible for the work area of third

parties.

3.3 Obligations of the operating personnel

The operating personnel must read the operating instructions carefully before handling

the mortar mixer. Please observe the safety regulations. When handling the mortar

mixer, personal protective equipment must be worn.

3.4 Workplace

The workplace is located at the control panel in front of the mortar mixer. The workplace

is determined by the customer-connected peripherals. It must therefore be designed by

the operator in order to be safe. The workplace’s design is also based on the applicable

requirements from the German Health and Safety at Work Regulations (Betriebs-Sicher-

heits-Verordnung, BetrSichV) and the analysis of workplace hazards.

Laboratory mortar mixers

Model 1.0204.LV

9

3.5 Dangers when handling the mortar mixer

The mortar mixer is constructed in accordance with the latest technology and accepted

technical rules. Nevertheless, danger to the user's life or that of third parties or damage

to machine parts or other property may occur during its use.

The mortar mixer must only be used

for the intended purpose

and in a technically faultless safe condition.

Faults that could impair safety must be eliminated immediately.

4. Basic information

4.1 Intended use

This description contains the required information for the intended use of the products

they describe. It is intended for technically qualified personnel. The operator must define

his staff’s area of responsibility precisely.

Qualified personnel are persons who, based on their education, experience, and instruc-

tion as well as their knowledge of relevant standards, provisions, accident prevention

regulations and operating conditions have been authorized by those responsible for the

safety of the machine to execute their respectively required activities and who can recog-

nize and prevent any possible dangers while doing so

(definition for specialist personnel according to IEC 364).

The requirements and limit values specified in these operating instructions and the safety

instructions provided must be observed. Any other use is considered to be improper. If

special work practices or conditions are required, the manufacturer's consultation and

approval should be acquired.

The manufacturer accepts no liability for damages caused as a result of a failure to ob-

serve these "safety and operating instructions".

The mortar mixer is used exclusively for the mechanical mixing of mortars and cement

paste for the production of test specimens according to different standards.

Intended use includes the following applications:

The requirements and limit values, as well as the safety instructions provided in these

operating instructions, must be complied with in all cases.

Note

The mortar mixer is designed for operation in dry spaces.

Laboratory mortar mixers

Model 1.0204.LV

10

Any other use is considered to be improper. If special work practices or conditions are

required, the manufacturer's consultation and approval should be acquired.

Note

The operating instructions indicated in these instructions only apply

to the correct use of the mortar mixer. In order to perform the opera-

tion correctly, the user must observe the specific standards for the

test.

These operating instructions are intended for the forwarding agent, the installer,

the operator, the maintenance technician and the disposal company.

Please read these instructions carefully, because they describe how the mortar

mixer is safe to operate.

These operating instructions shall be considered to be part of the product and only

apply to the mortar mixer that they are supplied with.

Keep the operating instructions in a suitable condition throughout the entire oper-

ating period, so that they can be consulted if necessary.

If the mortar mixer is to be sold, the operating instructions and the attachments

must be handed over with it.

The manufacturer assumes no liability for any damage caused resulting from an

improper use of the device.

Subject to change without notice: The manufacturer reserves the right to make

alterations to the technical descriptions as well as the parts to which these descrip-

tions refer to, without any prior notice.

4.2 Improper usage

The mortar mixer may only be used in a technically flawless condition.

Only use the mortar mixer for the described use, any improper use shall result in the loss

of the warranty claim.

Manipulations and modifications to the mortar mixer (electrical, mechanical changes, etc.)

that have not been authorized in a written agreement with the manufacturer are consid-

ered to be prohibited and the manufacturer does not accept any claims for damages.

We recommend only using original spare parts and accessories; otherwise the manufac-

turer assumes no liability.

Ensure that no hazardous situations occur during the work. The mortar mixer must be

switched off immediately if it does not work properly and the manufacturer or their author-

ized service personnel must be notified immediately.

Not intended use and therefore not permissible are the following:

Laboratory mortar mixers

Model 1.0204.LV

11

Mixing of substances other than those specified under 4.1

Filling and processing of food

Overfilling the mixing bowl

Setting up and operating the mixer in environmental conditions other than those

named under 6.1

4.3 Information about the CE marking

TESTING Bluhm & Feuerherdt test equipment carries the CE symbol.

The CE marking confirms the conformity of the product with the EC directives relevant to

the product and compliance with the "essential requirements" defined therein, i.e. the

established, generally applicable level of protection. The conformity assessment proce-

dure has been carried out in accordance with the applicable EC directives. Decisive here

is Council Decision 93/465/EEC on the modules to be used in the technical harmonization

directives for the various phases of the conformity-assessment procedure and the regu-

lations for the affixing and use of the CE marking.

4.4 Requirements imposed on the operator

The person operating the equipment must ensure that they do not put themselves or

anyone else at risk. Only persons who have been instructed in the operation are allowed

to operate the device independently.

If the operating safety is compromised by faults or damage to the device, it must be taken

out of operation immediately and must only be used again after the elimination of all haz-

ards.

Check to see whether the specification given on the identification plate corresponds with

your power supply voltage. Connect only to alternating current.

If the device or the connection cable is damaged, pull out the power plug immediately.

Danger

Take the necessary precautionary measures when mixing, in order to

prevent dust from getting into the eyes, mouth and nose.

The use, lifting, installing, waiting and scrapping of the mortar mixer may only be car-

ried out by qualified personnel. Qualified employees are persons who are authorized

to work with the machine on the basis of their experience and knowledge concerning

the operation of the mortar mixer and the directives, regulations and handling. The

Laboratory mortar mixers

Model 1.0204.LV

12

user must be carefully trained, in order to operate the machine and safety equipment

with which the machine is equipped, in order to avoid an incorrect use. Safety equip-

ment must always be installed and checked daily.

Manipulations and modifications to the machine (electrical, mechanical changes, etc.)

that have not been authorized in a written agreement by the manufacturer are consid-

ered to be prohibited and the manufacturer does not accept any claims for damages.

Ensure that no hazardous situations occur during the work. Stop the machine imme-

diately if it does not work properly, and immediately notify the manufacturer or their

authorized service personnel.

Do not place any wires or tools in the existing openings.

4.5 General safety instructions

Warning

All instructions must be read. Failure to comply with the instructions

that are described below could cause electric shocks, fires and/or

serious injuries.

1) The workplace

Keep your working area clean and tidy. Disorder and unlit work areas may result

in accidents.

Do not work with the mortar mixer in hazardous environments where there are

flammable liquids, gases or powders. Electrical tools produce sparks that may ig-

nite the powder or vapors.

Keep children and other persons away from the device during use. You could lose

control over the device if you are distracted.

Laboratory mortar mixers

Model 1.0204.LV

13

2) Electrical safety

The mortar mixer contains an IEC power connector (IEC 60320 C14).

The supplied connecting plug type F (CEE 7/4) of the mortar mixer must fit into the

corresponding socket (CEE 7/3). The plug must not be changed in any way. Do

not use adapter plugs together with protective grounding devices. Unchanged

plugs and suitable sockets reduce the risk of electrical shock.

Avoid bodily contact with grounded surfaces, such as pipes, heaters, stoves and

refrigerators. There is an increased riskof electrical shock if your body is grounded.

Keep the device away from rain or moisture. The penetration of water into an elec-

trical appliance increases the risk of electrical shock.

Do not use the cable to carry the device, to hang it, or to pull the plug out of the

socket. Keep the cable away from heat, oil, sharp edges or moving parts. Dam-

aged or tangled cables increase the risk of an electric shock.

3) The safety of personnel

Be attentive, pay attention to what you do, and work rationally. Do not use the

device if you are tired or under the influence of drugs, alcohol or medication. A

moment of carelessness during use of the device may result in serious injury.

Wearpersonal protective equipment and always wear protective goggles.Wearing

personal protective equipment, such as a dust mask or non-slip safety shoes, re-

duces the risk of injury.

Remove adjusting tools or wrenches before turning the mortar mixer on. A tool or

key that is in a rotating part of the device can cause injury.

Wear suitable clothing. Do not wear loose clothing or jewelry. Keep hair, clothing

and gloves away from moving parts. Loose clothing, jewelry or long hair could be-

come tangled in moving parts.

4) Careful handling and usage of power tools

Remove the power plug from the socket before carrying out any device settings or

changing accessory parts. This precautionary measure prevents an unintentional

turning on of the device.

Keep unused power tools out of reach of children. Do not allow persons to use the

device who are unfamiliar with the device or who have not read the instructions.

Power tools are dangerous when used by inexperienced persons.

Maintain the device with care. Check whether movable parts of the device are

functioning properly and do not jam, whether parts arebroken or damaged, in such

a way that the function of the device is compromised. Have damaged parts of the

device repaired before use. Many accidents are caused by poorly maintained ma-

chines.

Use power tools, accessories, insertion tools, etc. according to these instructions

and as required by this particular type of device. Take into account the working

conditions and the work to be carried out. Using power tools for applications for

which they were not intended can lead to dangerous situations.

Laboratory mortar mixers

Model 1.0204.LV

14

5) Service

Allow your device to be repaired only by qualified specialist personnel and only

with original replacement parts. This will ensure that the device will remain safe.

4.6 Protective clothing

The operator must ensure that all personnel wear the appropriate protective clothing, for

example:

Safety shoes

Suitable outer clothing

Protective gloves

Face protection

Respiratory protection

4.7 Regular checks

The mortar mixer must be checked for industrial safety at regular intervals. There are

national regulations for this, which must be observed.

5. Description of the mortar mixer

5.1 Mechanical structure

The housing of the mortar mixer is made of stable aluminum and stainless steel.

The mixer is made of stainless steel and is coupled with the planetary gear by a snap

closure. It rotates on its own axis and is moved by an electric motor in a planetary motion

around the bowl axis at 2 fixed speeds.

The mixing bowl is made of NIROSTA steel and can be removed from the working posi-

tion after lowering.

This distance can be adjusted by loosening two clamping screws.

Laboratory mortar mixers

Model 1.0204.LV

15

5.2 Safety devices

The mortar mixer is equipped with the following safety devices:

1. EMERGENCY STOP switch

When the EMERGENCY STOP switch is pressed, the drive motor is disconnected

from the 24V supply.

To put the mortar mixer back into operation, the EMERGENCY STOP switch must

be returned to its basic position by turning it in the direction of the arrow.

2. Inductive, electronic proximity switch

The proximity switch above the mixing bowl holder detects the edge of the mixing

bowl.

If the mixing bowl is not inserted into the mounting, the safety module prevents the

mortar mixer from being operated. The motor cannot be powered up.

3. Fixed protective cover

The mixing bowl is covered in the mixing position by a fixed protective cover which

encloses the stirrer on all sides.

6. Preparations for start-up

6.1 Installation site/environmental conditions

Warning

The operation of the mortar mixer is

permitted only in dry rooms!

The following limit values apply:

Ambient temperature DIN EN 60204-1, 4.4.2 +5C to +40C

Humidity DIN EN 60204-1, 4.4.3 30% to 95%

Note

Place the mortar mixer on a stable, level surface.

6.2 Electrical connection

An IEC power connection cable is used to provide the power connection of the mortar

mixer. The mortar mixer contains an IEC power connector (IEC 60320 C14).

Voltage: 85-264V~; Frequency: 47-63Hz

Laboratory mortar mixers

Model 1.0204.LV

16

7. Prior to first operation

Handling bowl and stirrer

7.1 Loosen and remove the stirrer

Move the right hand lever at the right side of the mortar mixer to the back and upwards.

The mixing bowl lowers.

The container holder is in the lowered position.

Use your left hand to hold the mixer and firmly hold the cord ring of the mixer attachment

with your right hand.

Turn the cord ring counterclockwise as far as it will go. Now pull the stirrer downwards.

Figure 1 Loosen and remove the stirrer

7.2 Removing the mixing bowl

Fold out the bolts of the bowl to the outside.

Tilt the bowl slightly and remove it to the front.

Figure 2 Lower the mixing bowl and remove the stirrer

The bowl can now be filled, if desired.

Laboratory mortar mixers

Model 1.0204.LV

17

7.3 Inserting the mixing bowl

The container holder is in the lowered position.

Insert the bowl so that the rear tab of the bowl first engages the rear of the recess in the

mounting.

Then set the bowl on the pins and fold the latches towards the bowl.

Figure 3Inserting and locking the mixing bowl

7.4 Insert the stirrer and clamp securely

Insert stirrer laterally at an angle into the mixing bowl. Turn the cord ring counterclockwise

as far as it will go. Position the stirrer under the holder so that the stud in the knurling

surface and the flat surface on the stirring ring are aligned. Insert the stirrer into the holder

as far as it will go and tighten the cord ring clockwise. Position the mixing bowl (lifting)

.

Figure 4Inserting and tightening the stirrer

Note

The mixer can not be started with the mixing bowl lowered or missing.

Stud

Surface on the

ring

Laboratory mortar mixers

Model 1.0204.LV

18

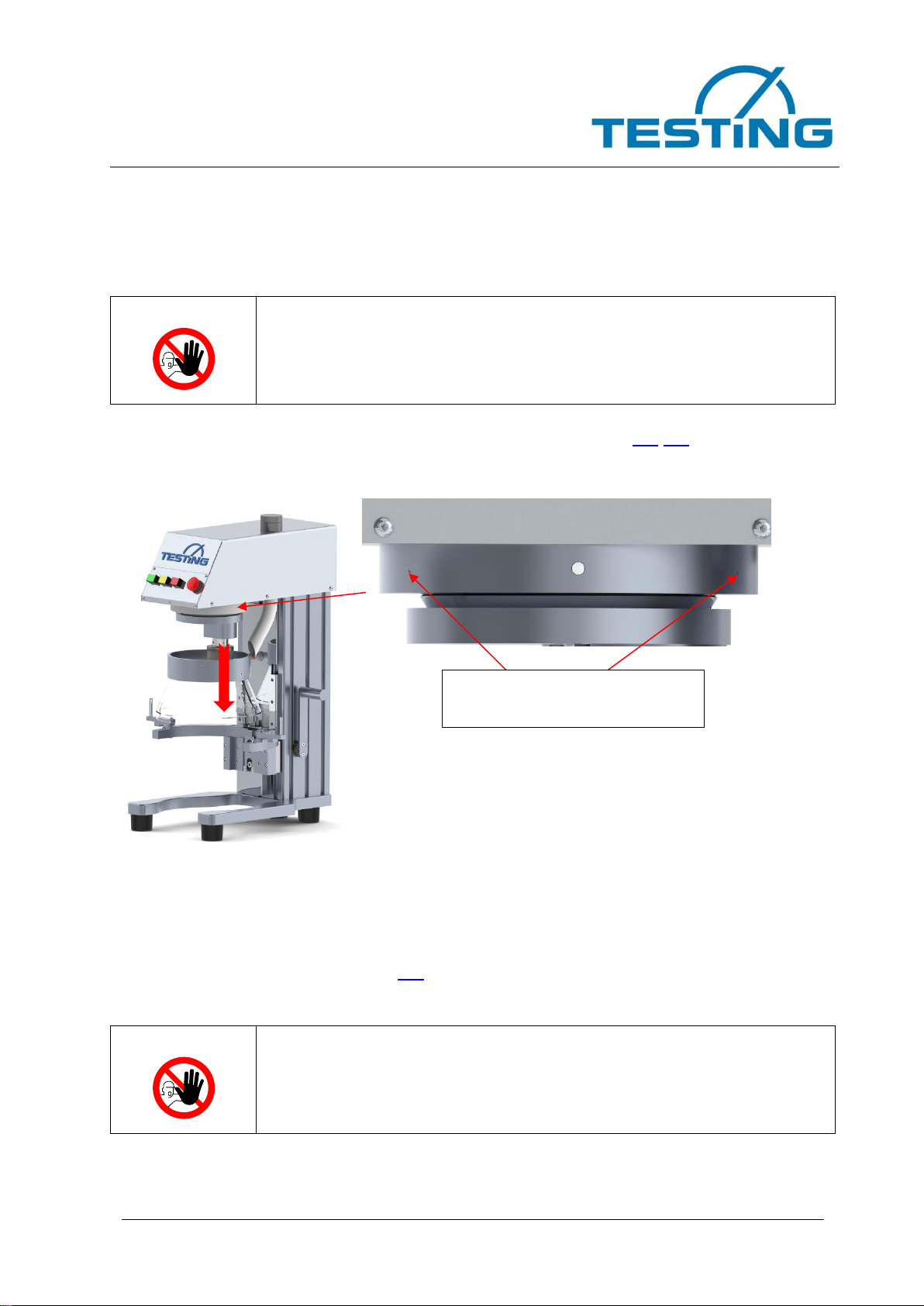

7.5 Checking the distance between mixing bowl and stirrer

If the distance between the mixing bowl and the stirrer is greater or lesser than the ap-

plicable standard allows for, this can be adjusted.

First, the mixing bowl must be lowered and removed (see point 7.1/7.2).

Now remove the contact protection. The contact protection is fixed with 3 spring ball

pressure pieces, it only has to be pressed down.

Figure 5 Removing contact protection

Reinsert the mixing bowl and stirrer.

The stirrer can now be turned by hand.

With the spacing template (TESTING Art.-No.: 1.0203.07), the distance can be checked

and adjusted as described in point 8.2 (see: Height adjustment). If the distance con-

forms to the standards, the contact protection is refitted.

Warning

Disconnect the power plug before starting work!

This could result in serious injuries, as your hands can get caught in

the

rotating stirrer.

Warning

Warning - do not use the mixer without contact protection!

This could result in serious injuries, as your hands can get caught in

the

rotating stirrer.

The contact protection en-

gages at these points.

Laboratory mortar mixers

Model 1.0204.LV

19

7.6 Correct distance

If the distance between stirrer and mixing bowl is not correct,

remove stirrer and mixing bowl.

First, unscrew the cover.

Slightly loosen the two clamping screws.

Now loosen the lock nut of the adjusting screw at the lower end of the mixing bowl

holder, and then set the distance with the help of the adjusting screw from the mixing

bowl mounting and retighten the clamping screws.

Check the distance with the spacing template.

By turning the adjusting screw in a clockwise direction, the distance is reduced.

By turning the adjusting screw in a counterclockwise direction, the distance is in-

creased.

Insert bowl and stirrer and check the distance, repeat the process until the dis-

tance is correct.

If the distance is set correctly, the lock nut, the adjusting screw and both of the

clamping screws on the holder for the mixing bowl must be tightened firmly. The

contact protection must be reassembled, the mixing bowl and the stirrer must

then be inserted.

Figure 6 Height adjustment

Remove these screws

Remove

the cover

Clamping screw

Clamping screw

Lock nut

Adjusting screw

Laboratory mortar mixers

Model 1.0204.LV

20

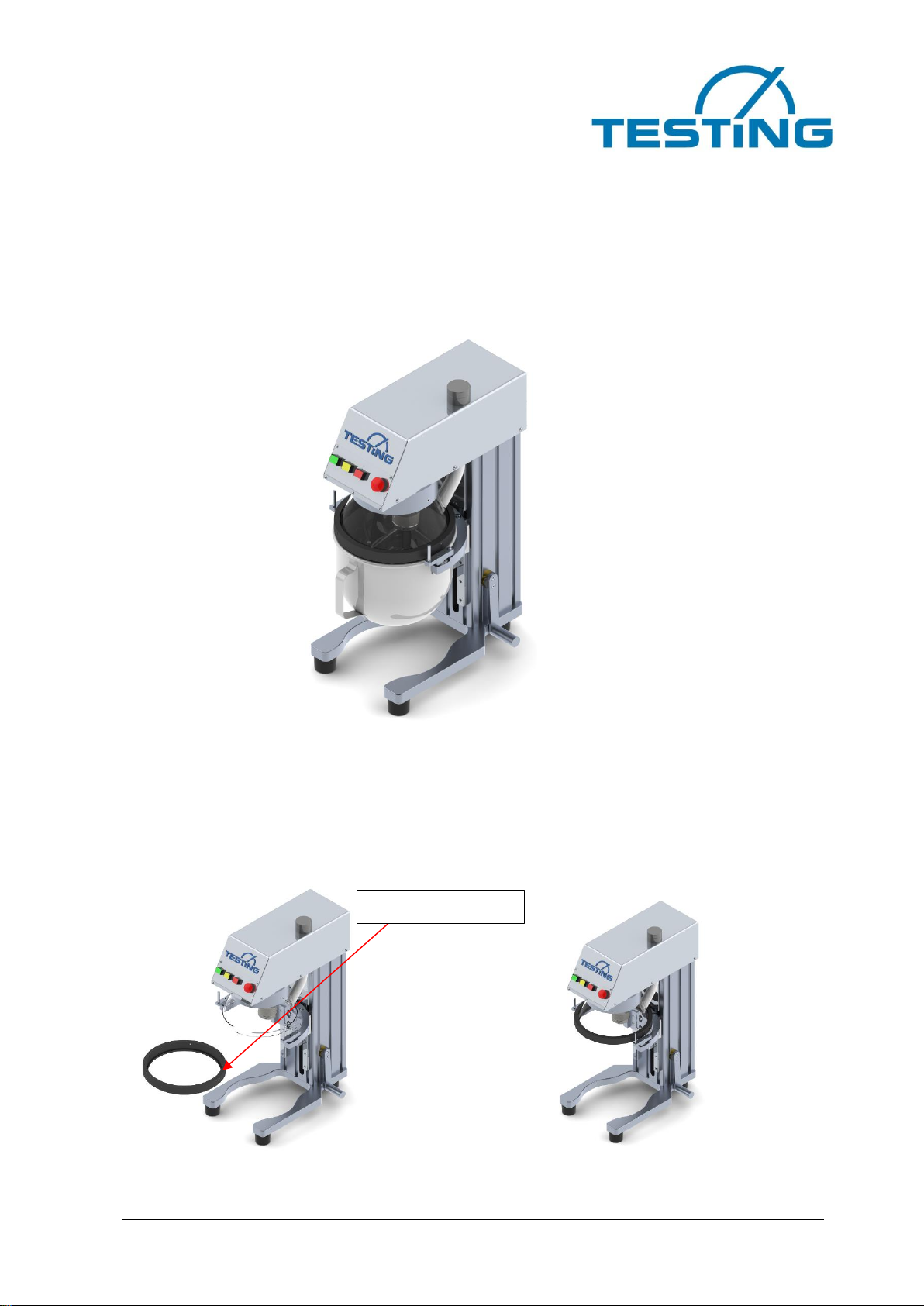

8Optional splash guard ring

In order to avoid splashing out of the material with very thin-bodied sample

material, there is an optional splash guard ring for the mortar mixer.

The optional splash guard ring can be ordered using the catalog number "1.0204.TEN-

07".

Figure 7 Mixer with splash guard ring

8.1 Installing the splash guard ring

To install the splash guard ring, remove the stirrer and the bowl,

push the splash guard ring onto the protective cage until it snaps into place.

Figure 8 Installing splash guard ring

Splash guard

ring

Table of contents

Other TESTING Laboratory Equipment manuals