TESTING 1.0306 User manual

TESTING Bluhm & Feuerherdt GmbH

Production and Distribution of

Systems for the Testing of

Construction Materials

Motzener Str. 26b

DE - 12277 Berlin, Germany

Tel. +49 / 30 / 710 96 45-0

Fax +49 / 30 / 710 96 45-97

www.testing.de

1

Operating Manual

Automatic Vicat Needle Apparatus

Automatic

Vicat Needle Apparatus

1.0306

2

Importance of this Operating Manual:

CAUTION: Do not place this machine into operation until you have completely read this

Operating Manual and have fully understood all its contents.

Contents Page

1. Basic instructions ...................................................................................................3

1.1 Designation .........................................................................................................3

1.2 Purpose for which this system was designed......................................................3

1.3 Conditions under which this system may NOT be used ......................................4

1.4 Guarantee ...........................................................................................................5

1.5 Acceptance of delivery, transport, and setting up................................................5

1.5.1 Acceptance of delivery..................................................................................5

1.5.2 Transport ......................................................................................................6

1.5.3 Setting up the system ...................................................................................6

1.6 Scope of delivery.................................................................................................7

1.7 Electrical connections..........................................................................................7

2. Characteristics of the equipment...........................................................................8

3. Operating the Vicat needle apparatus.................................................................10

3.1 Putting the machine into operation....................................................................10

3.2 Description of the control elements ...................................................................12

3.3 The test procedure ............................................................................................13

3.4 Calibration of the needle....................................................................................15

4. Maintenance and cleaning....................................................................................16

5. Troubleshooting....................................................................................................17

6. Shutting down the system for longer periods of time........................................17

7. Scrapping the system...........................................................................................17

8. After-sales service ................................................................................................18

8.1 Date of this version of the Operating Manual ....................................................18

8.2 Copyright...........................................................................................................18

8.3 Spare parts and technical help..........................................................................18

Attachments:

EG Declaration of Conformity

Inspection Record

Record of Measurement and Testing

Automatic

Vicat Needle Apparatus

1.0306

3

1. Basic instructions

1.1 Designation

Designation of the manufacturer:

See page 1 of this Operating Manual

Device serial number

See the rating plate on the unit: it will

show the complete ratings and the electri-

cal specifications.

1.2 Purpose for which this system was designed

This Operating Manual contains the information required for operation of the products de-

scribed here, for the purpose for which they have been designed. This Operating Manual

is intended to be used only by technically qualified staff.

“Technically qualified staff” in the sense of this manual is defined as those persons who –

as a result of their training; their experience; the instructions which they have received; as

well as their knowledge of the relevant standards, regulations, accident-prevention regu-

lations, and conditions under which this system will be used in the company –have been

authorized by the person responsible for the safety of the company facilities to carry out

the activities and actions required for operation of the equipment described below, and

who can recognize and prevent any possible dangers arising from such operation (this

definition of technically qualified staff has been provided in IEC 364).

The User must by all means observe the requirements and limit values, as well as all

safety instructions, given in this Operating Manual. Any use of this device not in conformity

with these stipulations shall be considered tobe in violation of the use for which this system

was intended. If this device must be operated under special conditions, or with special

modes of operation, then this will be authorized only after consultation with the manufac-

turer, and after obtaining his prior and express approval.

This Automatic Vicat Needle Apparatus is intended only for determining the setting time

for cement. The beginning and the end of the setting process is determined by the pene-

tration behaviour of a steel needle into a cement paste sample, under certain specified

conditions.

IMPORTANT

NOTE:

The instructions given in this Operating Manual are valid only under

conditions in which the device is correctly used. In order to properly

perform the test, the User must observe the specific standards that ap-

ply to the test.

Automatic

Vicat Needle Apparatus

1.0306

4

This operating manual contains safety instructions that are to be observed in order to ex-

clude any risk of fatalities, injuries, damage to the equipment or improper operation. Safety

markings are as follows:

Caution!

This warning refers to dangers that could cause material damage.

Danger

This warning refers to dangers that could cause severe injuries or even

fatalities.

Note

Provides practical advice on operation

1.3 Conditions under which this system may NOT be used

This system has been designed and built in accordance with the latest state of the engi-

neering art, and with recognized engineering rules and regulations. However, danger can

arise to the health and safety of the User, and of third parties, and damage can result to

the components of the system, or to other objects of value in the vicinity. For these rea-

sons, the User must observe the following instructions:

Do not take the device apart, and do not try to repair or to modify it.

Operate the device only in the range of voltage supply as given in this Operating Manual.

Do not operate the device in places that are subject to the following conditions:

Formation of ice, Heat radiation, Formation of condensate, Dust, Corrosive gases, Vibra-

tions, Severe impacts, Do not operate the device in places with great relative humidity and

temperature fluctuations.

Caution

The mixing of cement with water causes the release of alkaline sub-

stances. In working with concrete, it is essential to take all necessary

precautions to prevent dry cement from entering the eyes, mouth, or

nose. Use protective clothing to prevent skin contact with wet cement

or concrete. If cement or concrete enters the eyes, immediately and

carefully wash out the eyes with clean water. Seek medicalhelp without

delay. If moist concrete comes into contact with the skin, wash it off

immediately.

Automatic

Vicat Needle Apparatus

1.0306

5

The operating person must take care not to endanger his or her own health and safety, or

the health and safety of other persons. Only those persons may independently operate

this system who have received sufficient training in the operation of this system.

If defects or damages to this system occur that impair its operational safety, the system

must immediately be taken out of operation. It may be put back into operation only after

all sources of danger have been eliminated.

1.4 Guarantee

Our General Terms of Sales and Delivery apply in all cases.

The Manufacturer guarantees that this Operating Manual has been prepared in conformity

with the technical and functional parameters of the product as delivered. The Manufac-

turer reserves the right to add supplementary information to this Operating Manual as re-

quired.

The guarantee provided by the Manufacturer is the legal guarantee. This guarantee does

not cover wear-and-tear parts.

The Manufacturer guarantees trouble-free operation only if the User observes the instruc-

tions in this Operating Manual, and only if the User employs the delivered system for the

purpose for which it is intended.

The Manufacturer shall not be liable for damages that may occur if the product is used for

purposes for which it is not intended, or if the User does not observe the instructions and

rules for operation as set forth in this Operating Manual.

No claims for damages may be lodged against the Manufacturer if the product is modified

in its structural or constructional characteristics without the prior written consent of the

Manufacturer, or if its functional characteristics are modified without such consent.

Any person acting in violation of the above stipulations may be prosecuted before a court

of law.

1.5 Acceptance of delivery, transport, and setting up

1.5.1 Acceptance of delivery

When accepting delivery of the product, first inspect it for its outer, visible condition. If this

inspection is satisfactory, the delivery may be accepted from the freight forwarder (courier

or other haulage company).

Automatic

Vicat Needle Apparatus

1.0306

6

If there are no shortcomings, and if there are no transport damages, then use the bill of

delivery to make sure that the consignment is complete, and that all parts have been de-

livered.

If you assume or suspect transport damage, or if transport damage becomes apparent

only after you have accepted the delivery, immediately make an exact report of the condi-

tions and any damage as they exist. Send us this report immediately by fax or e-mail.

Important: Absolutely do not make any changes to the delivered goods.

After we have studied your report, we can make a decision whether we can correct the

difficulties by one of the following options:

Deliver spare parts to you, or

Send a specialized fitter/installer to your plant, or

Ask that you return the system to us for repair.

1.5.2 Transport

This system can be moved by hand to the place where it should be installed. Its weight

(mass) is approx. 16 kg.

1.5.3 Setting up the system

Set up the system on a level base that is that not subject to vibrations, and that can effec-

tively support the weight of the unit.

The ambient conditions that must be observed are as follows:

Permissible temperature conditions:

From + 5 °C to + 40 °C

Permissible relative humidity:

30 ... 50%

Maximum elevation:

1,000 metres above sea level

Caution

Be sure to take all normal and logical precautionary measures to en-

sure that the equipment is not subject to impact, and that it is not dam-

aged in any other way.

We recommend that the Automatic Vicat Needle Apparatus be placed on a work

desk, so that the drum with the plot of measuring results is located at a conven-

ient level for the operating personnel.

The main working position for the operating personnel is in front of the device.

Automatic

Vicat Needle Apparatus

1.0306

7

1.6 Scope of delivery

In the standard version, the Automatic Vicat Needle Apparatus is delivered with the fol-

lowing accessories:

Container for water storage

Diagram recording paper (500 sheets)

Recording stylus with ball-pen recorder and propelling-pencil leads (leads for me-

chanical pencil)

Drop rod

Ring according to EN: diameter 70 / 80 mm

Needle, with diameter 1.13 mm x 50 mm length

Allen wrench (socket wrench) (size no. 2)

Available as options:

Needle, with diameter 1.13 mm x 30 mm, with special foot

Consistency plunger

Timer switch

1.7 Electrical connections

Danger

In accordance with the pertinent standards, the yellow-green connec-

tion terminal must be connected to the earthing system before addi-

tional electrical connections are made.

Before making the electrical connections. Also check the machine rat-

ing plate to make sure that the ratings of the building power supply

conform to the requirements of the product for voltage, wattage, am-

perage, and frequency.

The technical characteristics of this safety device must also satisfy the

standards that apply in the country in which the machine is installed.

Caution

The manufacturer of this product cannot be held liable for any damages

that result because the information here is not observed.

Actual voltage: 10% of the rated voltage

Frequency: 50 Hertz 1% of the rated frequency, continually; 2% of the rated fre-

quency, on a short-term basis

The manufacturer shall not be liable for damages to persons or property that arise be-

cause the above instructions have not been observed.

We recommend the use of a residual-current-operated circuit-breaker (RCCB) with

30-mA rated residual-current trip.

Automatic

Vicat Needle Apparatus

1.0306

8

2. Characteristics of the equipment

The noise levels given here do not necessarily represent safe levels for persons operating

the equipment. The safety and suitability of the noise levels for operating personnel are

influenced by other factors such as the following: length of time that personnel are ex-

posed to the noise, the surrounding environment, other equipment installed in the vicinity,

etc.

Official data on noise-exposure levels are necessary to evaluate the damage that person-

nel can suffer from being subjected to the noise from this equipment.

Sound pressure level equivalent “A” at the workplace:

23 dB(A)

Standards applying to the above data:

EN ISO 3746

This system belongs to those items of equipment whose acoustic emission in general does

not reach a rating level of 90 db(A) (in accordance with DIN 45 635).

The noise emitted by the system will depend on various factors: e.g., the specific product,

the place of installation, and the like. For this reason, it is not possible to indicate a gener-

ally valid sound pressure level for this system.

Technical data:

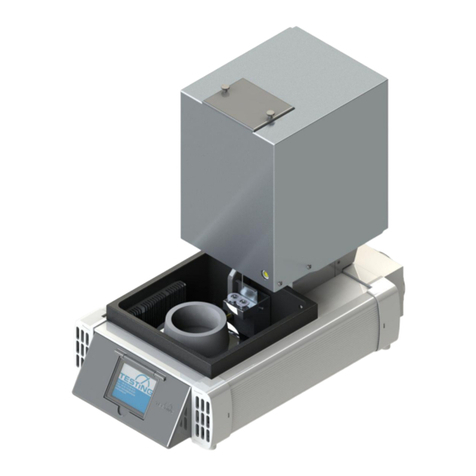

Dimensions:

280 mm wide x 430 mm deep x 460 mm high

Weight (mass):

16 kg

Required electrical ratings:

110-230 VAC; 50-60 Hz

Weight (mass) of drop rod:

300g ± 1

Automatic

Vicat Needle Apparatus

1.0306

9

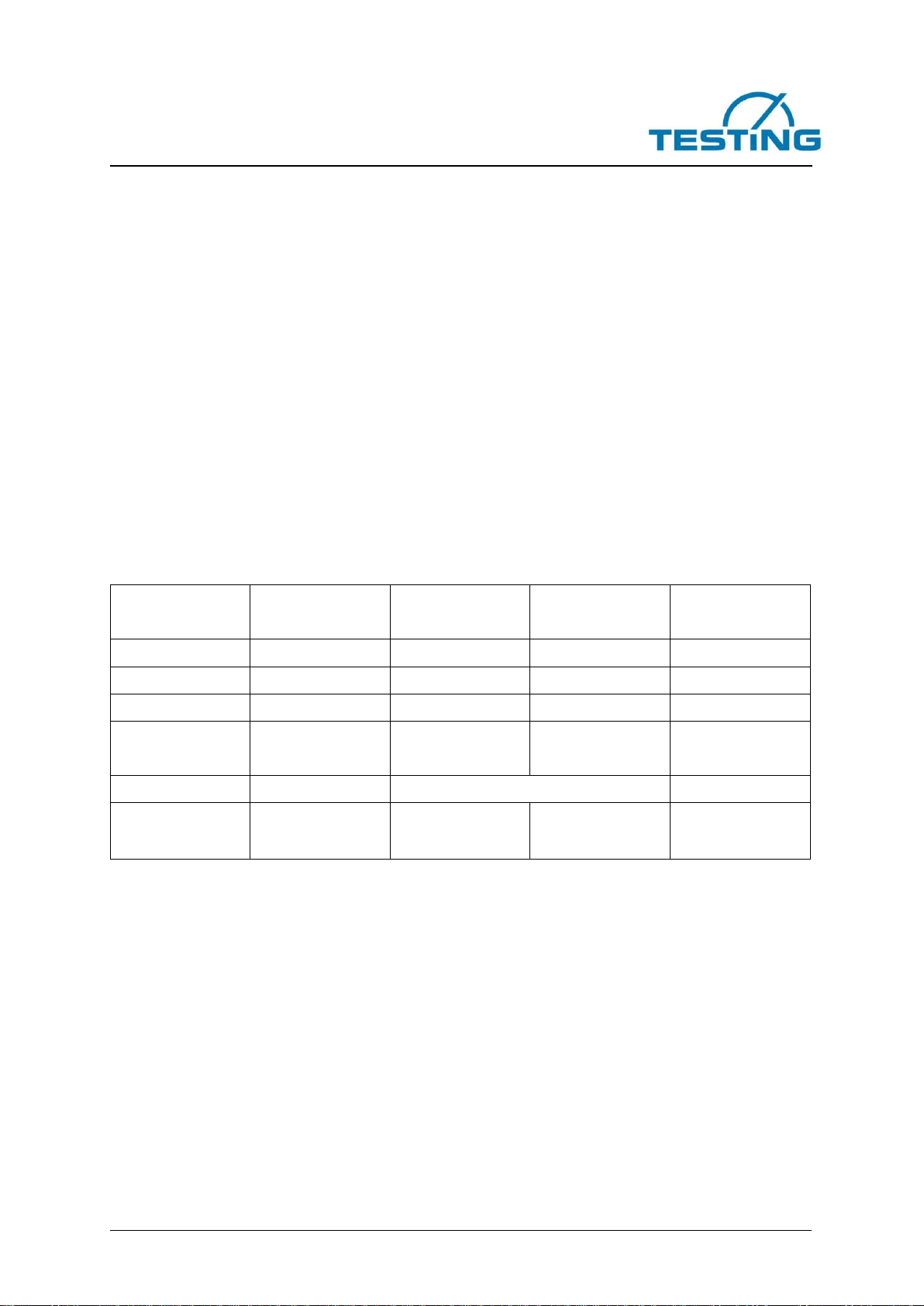

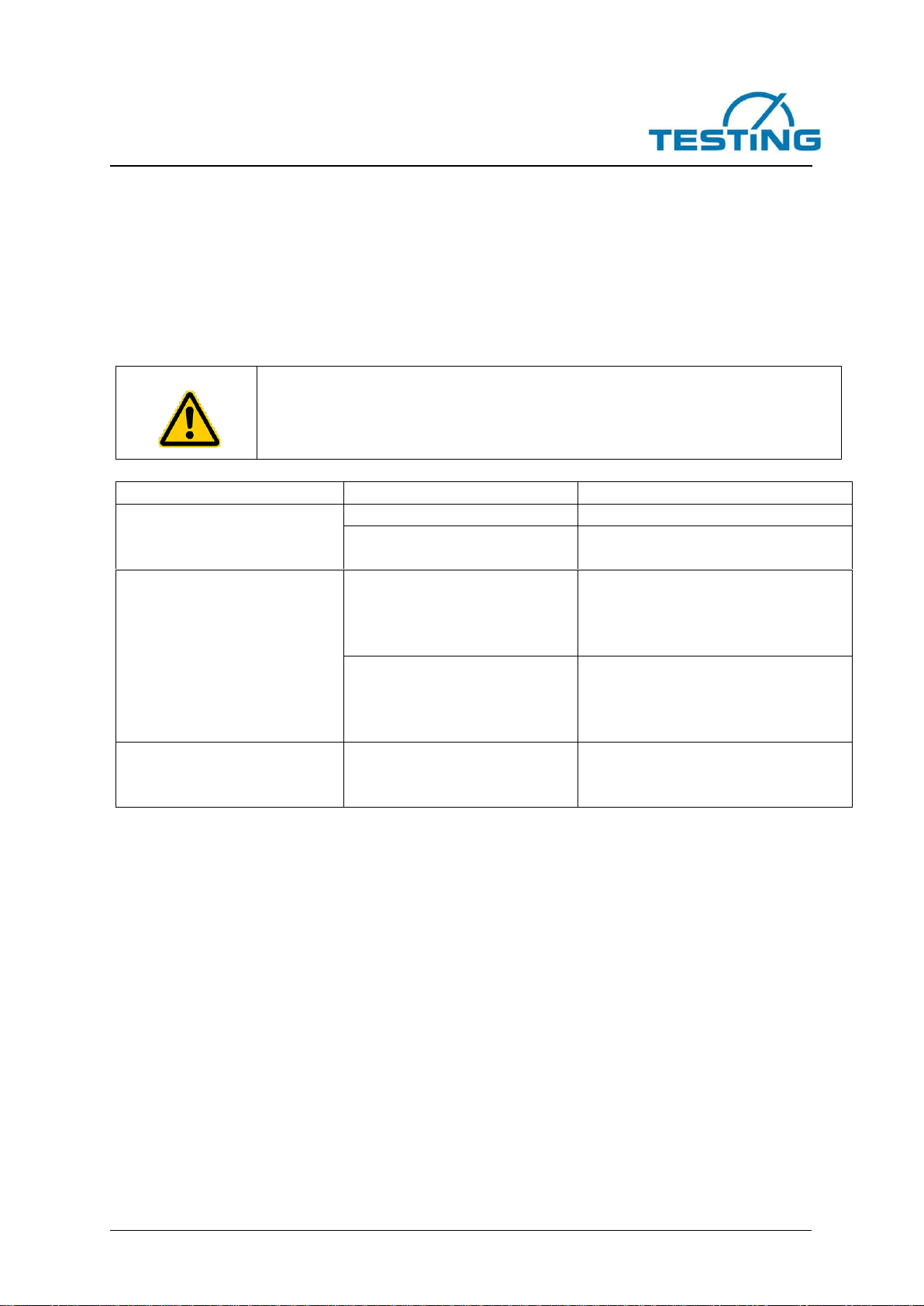

Prog.

A

B

C

D

G

Graphic

represen-

tation

Appl.

Stan-

dard

EN 196

ASTM 191

EN 196

DIN 1168

Needle

cleaning

yes

yes

yes

no

no

Length of

needle

50 mm

50 mm

50 mm

30 mm

50 mm

Diameter of:

Penetrations Mould

Ø 70 mm

Ø 65 mm

Ø 70 mm

Ø 70 mm

Ø 70 mm

26

37

90

22

16

The User can use the following program selections to set and to check the exact height

of the needle:

Test + 30“ Check of needle height: Vicat ring

for needle length = 50 mm

Test + 1’ Check of needle height: Vicat ring

for needle length = 30 mm

Test + 2’ Check for lower end stop

Needle must be slightly above glass plate

After a maximum of 3 minutes, the drop rod is automatically returned to its starting position.

Automatic

Vicat Needle Apparatus

1.0306

10

3. Operating the Vicat needle apparatus

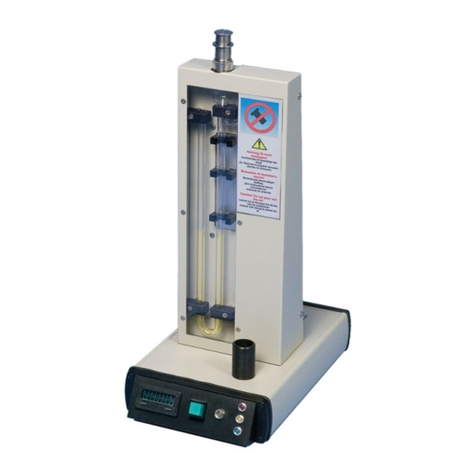

3.1 Putting the machine into operation

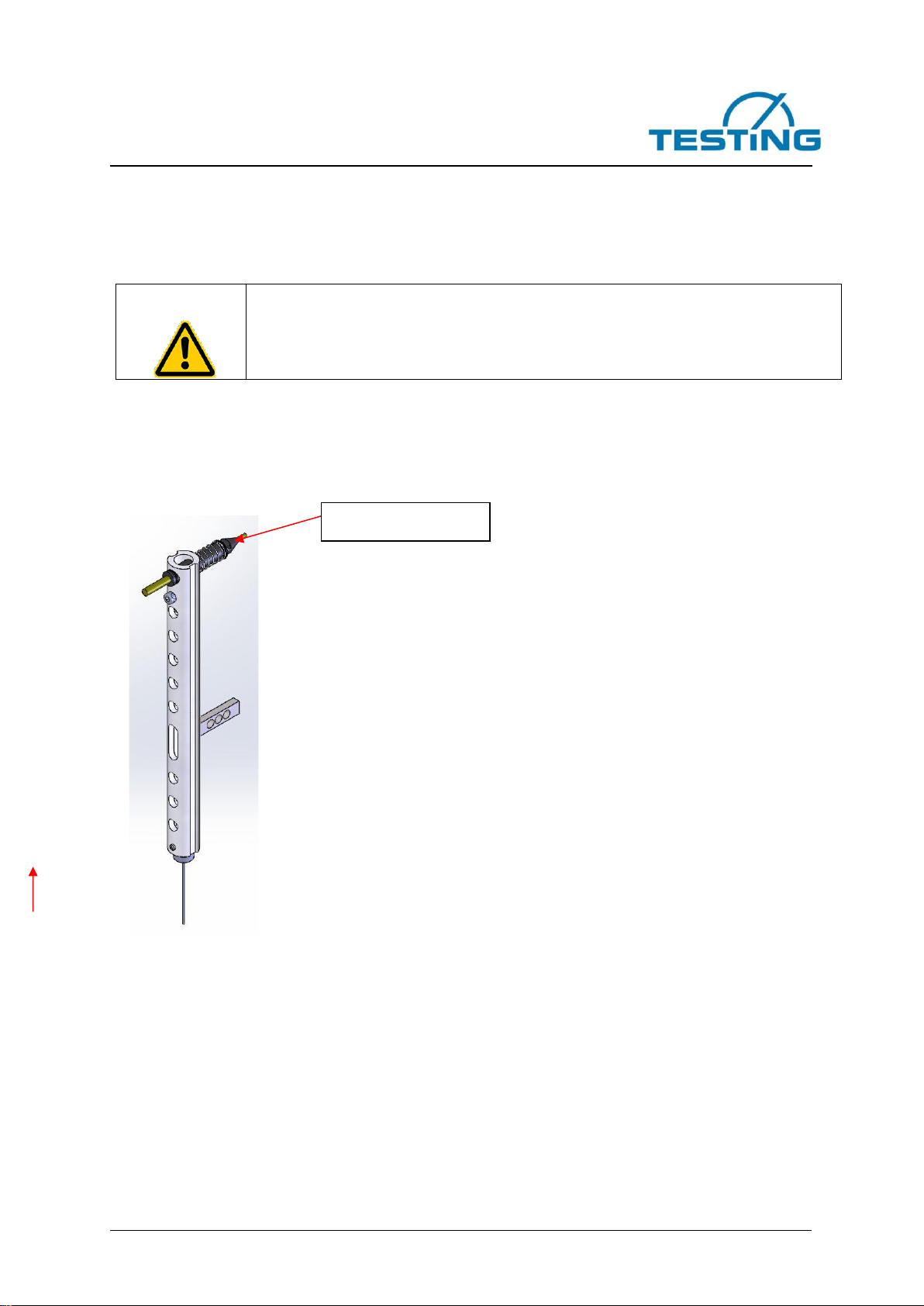

Attention

For reasons of safety, the drop rod must be removed from the machine

before it is transported. Before placing the Vicat needle apparatus into

operation, take the drop rod and insert it into the machine at its proper

place.

The recording stylus for plotting the Vicat results is delivered with a ballpoint-pen refill or

with a propelling-pencil (mechanical-pencil) lead. After you insert the drop rod, you must

use the knurled nut to set the exact distance between the point of the recording stylus and

the recording drum.

Insert the needle into the drop rod as far as it will go. Then lightly

tighten the headless grub screw with the supplied no. 2 Allen

wrench.

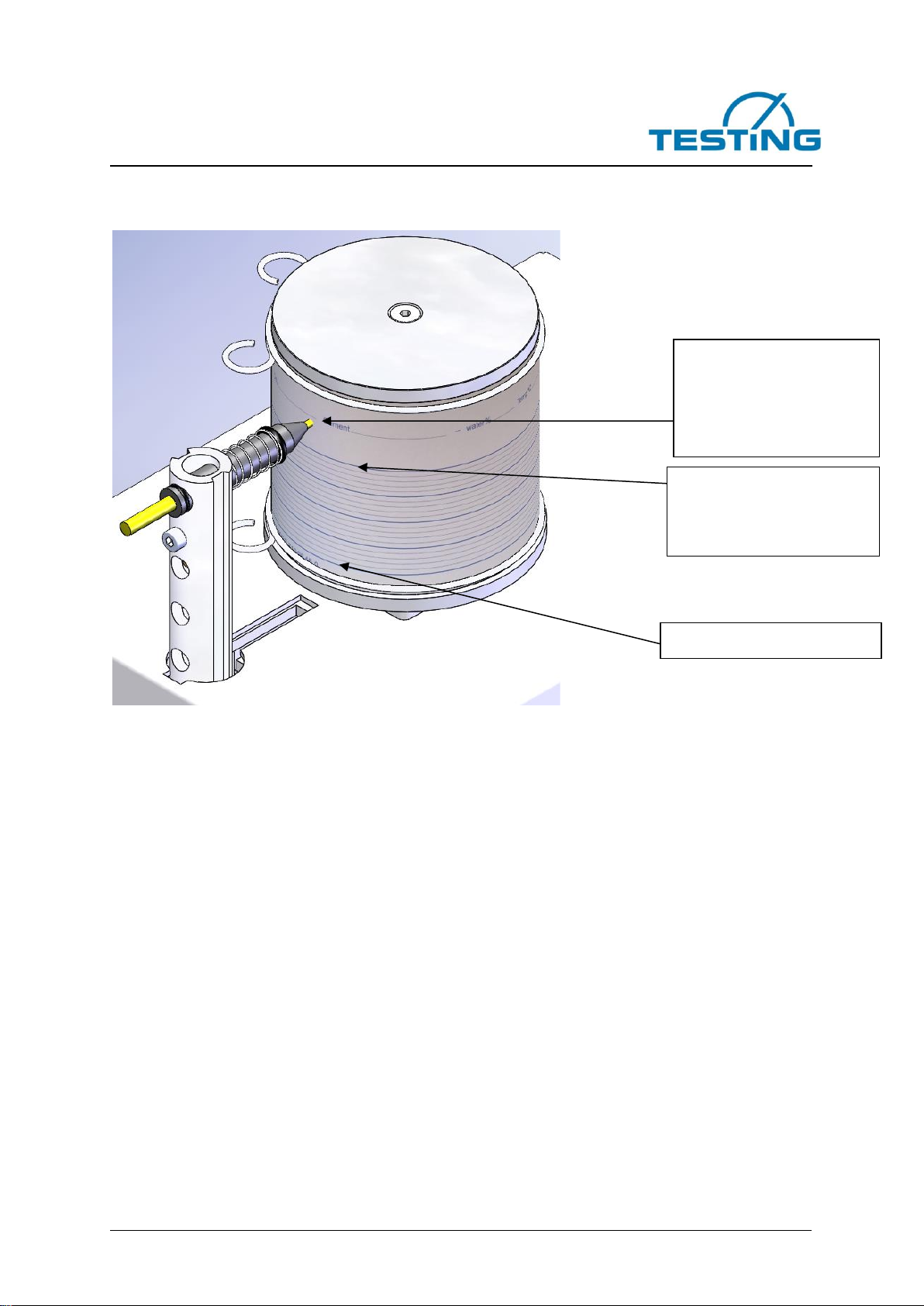

The next step is to wrap the recording paper around the recording drum. Use the paper-

holding springs to hold the paper in place, and shove the paper up to the edge. The lowest

paper-holding spring should be set so as to be positioned just over the edge.

Carefully insert the drop rod, from the top, all the way into the cover of the system housing

lid, until it will go no farther. Push the recording stylus (ballpen refill or pencil lead) back so

that it moves past the retaining spring of the recording drum with the paper.

Switch on the system by using the switch on the rear side.

The system will now perform a self-test. If the system successfully passes the self-test, it

will signal that it is ready for operation by showing the green signal lamp.

grub screw

Automatic

Vicat Needle Apparatus

1.0306

11

Switch on the device on the back side.

The device will start a self-check. When successfully done it will signalize readiness with

a green lamp on.

start position when

drop rod is released

(0mm penetration)

Upper dead-center

position,

the pencil will write a

horizontal line

40mm penetration

Automatic

Vicat Needle Apparatus

1.0306

12

3.2 Description of the control elements

Start

This button starts the test cycle.

Stop

This button stops the test cycle.

Standard

This setting is for selection of the standards that will apply for the test.

Time

This setting is for selection of the time interval between the start of one

penetration and the start of the following penetration.

Delay

The setting is for a start delay

Slow

This button is for selection of the type of needle drop:

OFF Free drop

ON Damped (restrained) drop

Prepara-

tion for

settings

This control element enables moving the drop rod into its lower or upper

position.

This function is used to prepare for the test, or to make settings for the

system.

The functions of the signal lamps:

Green lamp:

is on when the system is switched

on:

This means that the system is ready for opera-

tion.

flashes when the button is

pushed:

The test is running.

Yellow lamp:

This lamp is off:

The rod will drop in free fall.

This lamp is on:

Damped (restrained) drop of the rod.

The button is pressed during the

test:

This will stop the test.

Red lamp:

The red lamp is off:

The system is ready for operation.

The red lamp is flashing:

The system has a defect. See the section

below entitled “Troubleshooting”.

If button is pressed during the

“TEST” program:

The red lamp button will then serve as a

confirmation button.

Automatic

Vicat Needle Apparatus

1.0306

13

If button is pressed while the sys-

tem is performing the normal test:

This will stop the normal test procedure.

3.3 The test procedure

Insert the drop rod from above into the device (in the reverse direction as shown in

the drawing below).

Switch on the system. The drop rod will now move into the upper position.

Make your selection for the following parameters:

oThe standard that will apply to the test

oThe type of fall (free fall or damped fall)

oThe desired time

Place the prepared test specimen on the rotary disk.

Press the START button. The test procedure will then begin.

Programm

Needle length

[mm]

Norm

Vicat-Ring

[Size min.]

Anzahl der

Einstiche

A

50

EN 196

Ø 70/80

26

B

50

ASTM 191

Ø 65/75

37

C

50

EN 196

Ø 70/80

90

D

30

Erstarrungs-

ende

Ø 70/80

22

Test + 5’

50

Normsteife

1

G

50

(Konus)

Gips

DIN 1168

Ø70/80

16

Automatic

Vicat Needle Apparatus

1.0306

14

End of solidification

1st option:

You can read the end of solidification on the drum

2nd option:

Stop the program at the appropriate time

turn the Vicat ring upside dowm

exchange the needle for start of solidification against needle for end of solidification

choose program “D”

The drop rod will now be brought to a lower postion (according to shorter needle) and

released from there (here: zero-line is 20mm lower).

The end of solidification will be determined by the impressions. When there are no circular

impressions to be seen any more, the needle penetrates less than 0,5mm.

This means the end of solidification.

0,5mm

Solidification end

2mm

0mm

Automatic

Vicat Needle Apparatus

1.0306

15

3.4 Calibration of the needle

The Automatic Vicat Needle Apparatus is set at the manufacturer’s plant in accordance

with the heights of the needles as they are delivered. As a result, the User does not need

to make any adjustment settings under normal conditions.

If, however, any deviations are discovered and the User must make adjustments to the

needle calibration, then he should follow the steps below:

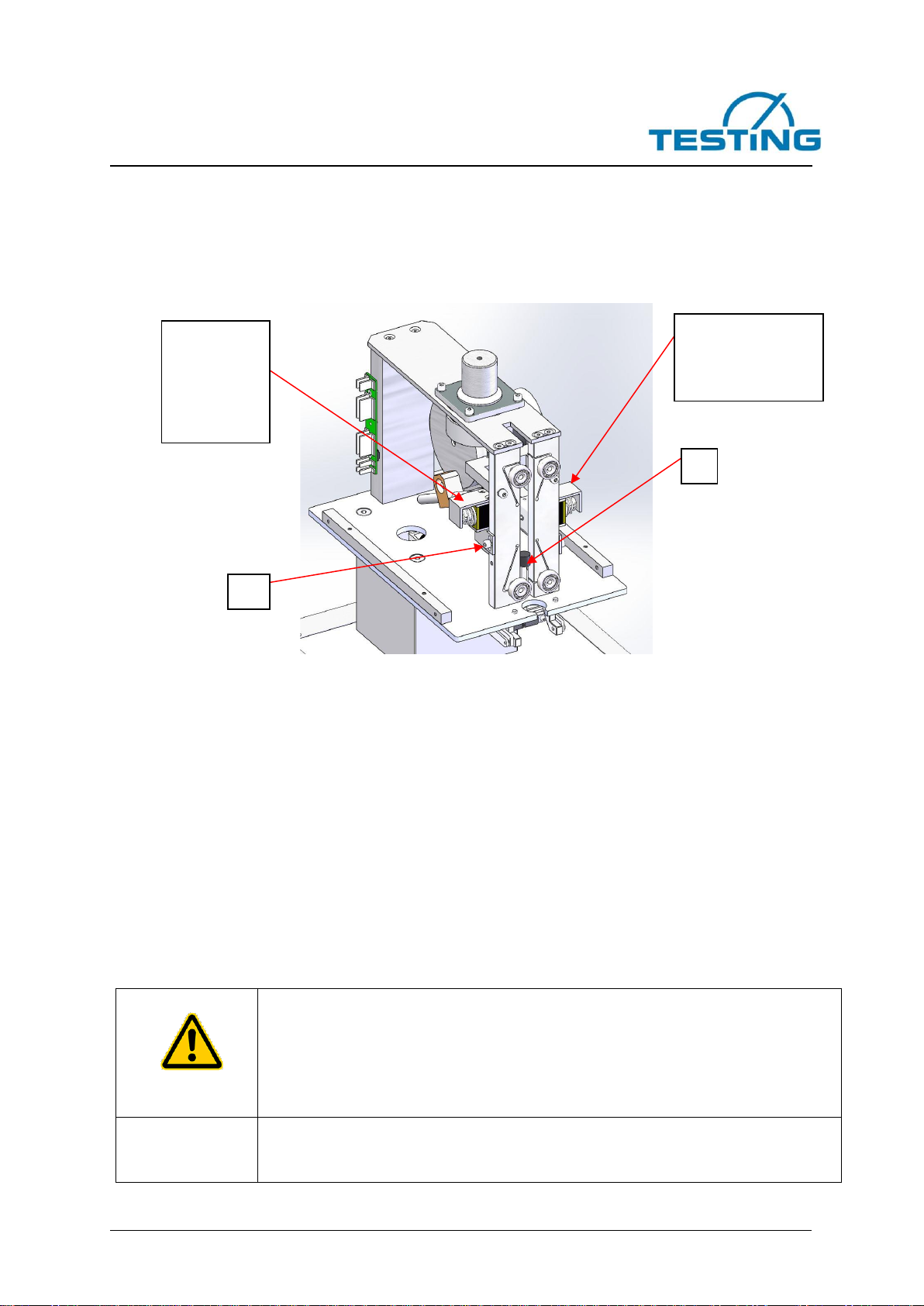

1. Remove the fall rod upward as shown in the drawing below (arrow 1 below).

2. Unscrew the countersunk-head screw on the drum (arrow 2 below).

3. Remove the 4 screws from the side wall of the upper part of the device (arrow 3

below).

2

1

3

Automatic

Vicat Needle Apparatus

1.0306

16

4. Set the distance between the needle and the surface of the Vicat ring by using the

magnets (see arrow 4 in drawing below).

5. Set the lower distance between the needle and the surface of the glass by using

the limit stop (arrow 5 in drawing below).

4. Maintenance and cleaning

Please get directly in contact with the manufacturer in case of any special maintenance

work that may become necessary: for example, repairs, exchange of parts, and all other

tasks that are not described in this Operating Manual.

The Automatic Vicat Needle Apparatus needs practically no maintenance. After several

years of use, we recommend cleaning the system thoroughly and lubricating the moving

parts.

It may become necessary after using the Operating Manual for a long period of time, or

using it in dirty surroundings, to clean the outside the system. Please proceed as follows:

1. Switch off the main power switch of the system.

2. Unplug the system from the power supply.

3. Use a brush or a vacuum cleaner to remove any dust that may lie loosely on the sur-

face of the device. If necessary, you can clean the outside of the unit with a moist

cloth. You can also use normal household cleaning agents if required.

Attention

Do NOT use forced water, rushing water, gushing water, or spray wa-

ter to clean the Automatic Vicat Needle Apparatus. Also do not use

dripping sponges or other unsuitable cleaning agents to clean the sys-

tem. If water enters the controller unit by using such unsuitable clean-

ing methods, this will result in permanent damage to the mechanical,

electronic, and/or electrical components of the system.

All maintenance or repair work involving components of the Automatic

Vicat Needle Apparatus or its electrical system must be performed by

suitably qualified specialists.

Magnet for end

of solidification

5

Magnet

for 50mm

needle

4

Automatic

Vicat Needle Apparatus

1.0306

17

For instructions on how to clean all parts of the system related to the testing procedures

(for example, the needles, weights, and containers), please consult the descriptions in

the applicable standards.

5. Troubleshooting

Attention

All maintenance, testing procedures, inspection, and maintenance

work performed on the system components or the electrical system

must be performed by suitably qualified specialists.

TROUBLE

POSSIBLE CAUSES

ACTION TO TAKE

The system will not start.

There is no power supply.

Check the power cable.

Defective fuse.

Check the fuse on the main

power switch.

The red signal lamp is

flashing.

The drop rod was not in-

serted.

Insert a drop rod.

The photoelectric switches

(light barriers) do not de-

tect the initial position.

Check the photoelectric

switches (light barriers) in the

device. Get in touch with the

manufacturer.

The needle distances are

not correct.

The setting of the needle

height is not correct.

Make the adjustment as de-

scribed above in the section on

Calibration of the Needle.

6. Shutting down the system for longer periods of time

In the event that you intend to shut down the system for a longer period of time, it must be

disconnected from the mains power supply. Then perform all required maintenance tasks.

Finally, cover up the unit to protect it from dust.

7. Scrapping the system

If the system will no longer be used by anyone, we recommend the following procedure:

Unplug the power cable from the mains power supply.

Cover all dangerous parts (for example, sharp or protruding components)

Take the system apart and scrap it according to the valid legal regulations in your

area.

Automatic

Vicat Needle Apparatus

1.0306

18

8. After-sales service

Great care was taken to assure that this Operating Manual was properly prepared. We

cannot, however, guarantee that it has no mistakes, or that all data are complete and

correct in the event of technical modifications.

8.1 Date of this version of the Operating Manual

Version No. 5

March of 2016

8.2 Copyright

The copyright to this Operating Manual is held by:

TESTING Bluhm & Feuerherdt GmbH

This Operating Manual is intended for use only by the User and his/her staff. It contains

instructions and data that may NOT be:

Reproduced,

Distributed, or

Provided to any third party.

Any person acting in violation of the above stipulations may be prosecuted before a court

of law.

8.3 Spare parts and technical help

If you have any questions of technical nature, or if you need spare parts, please get in

touch with the following address:

TESTING Bluhm & Feuerherdt GmbH

Motzener Str. 26b

DE –12277 Berlin

Germany

Tel. [+ 49 30] 710 96 45-0

Fax [+ 49 30] 7510 96 45-98

www.testing.de

Automatic

Vicat Needle Apparatus

1.0306

19

EC Declaration of Conformity in accordance with the Machinery Directive

2006/42/EC Appendix II 1.A

The authorised representative established in the community,

Mr. Feuerherdt

hereby declares that the following product

Manufacturer: TESTING Bluhm & Feuerherdt GmbH

Motzener Str. 26b

12277 Berlin

Product designation: Vicat Needle Apparatus

Serial number: continuous

Serial/Type designation: 1.0306

complies with all of the relevant provisions of the above named guidelines as well as the addi-

tional applied guidelines (following) - including any of the amendments thereto which are in force

at the time of the declaration.

The following additional EU Directives have been applied:

Low Voltage Directive 2014/35/EC

The following harmonised standards have been applied:

DIN EN 60204-1 The Safety of Machines - Electrical Equipment of Machines - Part 1:

General Requirements (corrigendum 2010)

DIN EN ISO 12100 Safety of machinery - General principles for design - Risk assess-

ment and risk reduction (corrigendum 2013)

The name and address of the person who has been authorised to compile the technical docu-

mentation:

Mr. Metge

Location: Berlin

Date: 28/02/2014

_______________________________ _______________________________

(Signature) (Signature)

Managing Director Technician

Table of contents

Other TESTING Test Equipment manuals