TESTING DT-202 User manual

DT-202_007

Operation Manual

for Drop Tester

Model DT-202

SHINYEI TESTING MACHINERY CO.,LTD.

i

Cautions on safety

Please understand the following items and then, read this instruction manual (text) carefully for preventing the

danger to workers and surrounding persons and using this tester safely. Keep this instruction manual near the

tester for reading it whenever necessary.

Indications of tester

Negligence of this display during work may cause personnel death or serious injuries.

Observe the instruction contents.

Negligence of this display during work may cause a fire, an electric shock accident, or

other accidents that may result in workers’ injuries. Never disassemble the equipment

when power is being applied to the equipment. Observe the instruction contents.

Negligence of this display during work may cause an electric shock accident. Observe

the instruction contents.

Warning

Never

Disassemble

Electric Shock

ii

Warnings and cautions

1. The specimen supporting base freely drops. Never enter the tester base, otherwise an accident may result.

2. A specimen may tilt down in an unexpected direction due to drop collision. Particularly be careful since certain

specimens may be broken to scatter.

3. Make sure at all times that none of other workers, packaged cargoes, and other material exists around the base.

4. If the other tester exists nearby, don’t disturb mutual work with due care by calling out to each other.

5. Set each specimen at the specified position on the specimen fixing base without fail and use the equipment

within the rated weight range.

6. Don’t process any noxious chemicals around the tester, otherwise a color change of paint or a trouble may occur.

7. Turn off the power switch if smoke goes up, an offensive smell gives out, or other abnormal symptom occurred,

or if water or the like was introduced into the tester or control unit. Don’t use the equipment as it is, otherwise

a fire or an electric shock accident may occur.

8. Don’t remove any parts of the main unit or disconnect the control unit from the case during test, otherwise it

may cause ingress of foreign substances to result in a trouble. It is possible that parts are replaced and checked

due to unavoidable circumstances during repair of a trouble.

In such a case, never perform any work other than specified by our instruction contents. If a foreign

substance should have introduced into the tester, turn off the power switch and contact us. Don’t continue

the work as it is, otherwise a trouble or an electric shock accident may occur.

9. Never modify the equipment, otherwise a fire, an electric accident, or a trouble may occur.

10. Don’t put any heavy package on the power cord of the control unit nor pull, forcibly bend, or scratch it,

otherwise a fire or an electric shock accident may result.

11. For relocating the equipment, contact us and observe our instructions.

If the hoisting position or work procedures for moving the equipment are wrong, the tester and control unit

may be damaged. Don’t ride on the tester or control unit nor put any heavy package on them, otherwise the

package may drop or break to cause injuries.

If the tester or control unit should have been damaged, please contact us.

12. It is recommended to execute “periodical maintenance check (check and repair)″once every year. Contact

us.

iii

Cautions on operation

1. Check if screws of each part are securely fastened or the tester is free of abnormal symptoms before starting a

test.

2. Check if the tester base is kept free of obstacles.

3. Don’t test any specimen exceeding the specified range (maximum dimensions and maximum weight).

4. Never apply any external force to the pneumatic cylinders which fix the specimen, otherwise the pneumatic

cylinders may become defective.

5. A specimen is released by drop operation to drop freely. Don’t approach to the tester base interior.

6. A specimen may tilt down in an unexpected direction due to drop collision. Particularly be careful since certain

specimens may be broken to scatter.

7. If the cover is removed from the control unit, etc. due to unavoidable circumstances, turn off the power source

to prevent an electric shock accident.

8. Turn off the power source before checking the tester.

9. The power supply is 220VAC, single-phase (with a grounding terminal). Connect the equipment to the ground

without fail.

10. If it is necessary to stop running the equipment urgently due to unavoidable circumstances, turn off the

[POWER] switch.

11. If the equipment is not used for a long time, disconnect the power cord plug from the plug socket.

iv

User support

Periodical calibration

You are recommended to calibrate the instrument for confirming the performance once every year.

Please contact us.

Reference or Contact

SHINYEI TESTING MACHINERY CO., LTD.

(HEAD OFFICE)

B47-11,Katoridai,Tsukuba,Ibaraki,300-2657,Japan

Tel: +81-29-848-3571(Sales) FAX: +81-29-848-3572

E-mail: sales@stm.shinyei.co.jp

(KOBE OFFICE)

SHINYEI BLDG.5F,77-1,KYOMACHI,CHUO-KU,KOBE,Hyogo, 650-0034,JAPAN

Tel: +81-78-392-6963 FAX:+81-78-332-1619

(NAGOYA OFFICE)

Nishiki emuai BLDG. 5F, 1-7-39, Nishiki,Nakaku, Nagoya,Aichi, 460-0003, Japan

Tel: +81-52-218-5472 Fax: +81-52-218-6112

For inquiries through telephone

Monday to Friday (Excluding national holidays and festivals)

09:00 hours to 17:30 hours (Japan time)

Home Pages

For the guidance and latest information on this product and commodities being manufactured and sold by our

company, please refer to our home page.

URL:http://www.shinyei-tm.com/

Other

Please ask us if you have any question about the measurement and analysis of shocks and vibrations, related

standards (JIS, ISO, etc.) on shock testing methods as well as this product.

v

Contents

§1 Summary of equipment.................................................................................................................. 1

1-1 Specimen supporting base···································································································1

1-2 Fixing and drop operation of specimen ···················································································1

1-3 Drop height setting············································································································1

1-4 Safety measures of operation·······························································································1

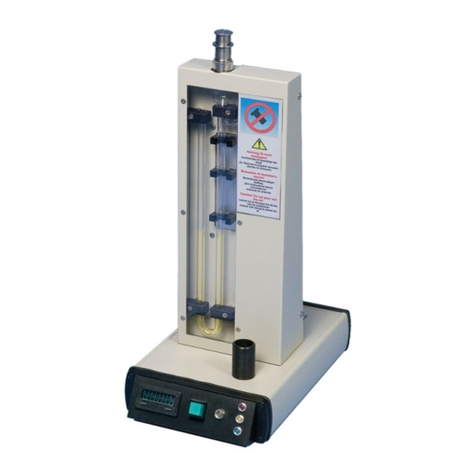

§2 Outer View ...................................................................................................................................... 2

§3 Preparation ..................................................................................................................................... 3

3-1 Preparation to be executed first after installation ·······································································3

3-2 Preparation for test············································································································4

§4 Structure of components................................................................................................................ 5

4-1 Base ······························································································································5

4-2 Main column····················································································································5

4-3 Drop releasing device·········································································································5

4-4 Specimen supporting base···································································································5

4-5 Height setting pointer·········································································································5

4-6 Pneumatic pen cylinders (for fixing and releasing a specimen) ······················································5

4-7 Contacts ·························································································································5

4-8 Pneumatic regulator···········································································································6

§5 Operation method .......................................................................................................................... 7

5-1 Control unit ·····················································································································7

§6 Troubleshooting............................................................................................................................ 10

6-1 [POWER] indicator lamp does not light ················································································· 10

6-2 [POWER] indicator lamp lights, but the specimen does not drop·················································· 10

6-3 Pneumatic pen cylinders don’t operate·················································································· 10

§7 Daily check.................................................................................................................................... 11

§8 Performance and specifications ................................................................................................... 12

§9 Diagram ........................................................................................................................................ 14

9-1 Wiring diagram··············································································································· 14

9-2 Parts list in wiring diagram································································································· 15

Parts list in wiring diagram...........................................................................................................................15

9-3 Pneumatic piping diagram ································································································· 16

§1 Summary of equipment

1

§1 Summary of equipment

This tester is used to test the shock resistance of a small and lightweight product (portable telephones, etc.)

by freely dropping it from the height of 250~ 2200mm

1

while holding it under an optional position.

1-1 Specimen supporting base

This specimen supporting base is used to support a specimen and freely drop it from an optional

height. It is provided with pneumatic pen cylinders to be able to release the specimen momentarily

at a specified position.

1-2 Fixing and drop operation of specimen

A specimen is set by [SET] and [RESET] push-button switches of the control unit. The specimen is

dropped by [DROP] push-button switch.

1-3 Drop height setting

The drop height can be set by setting the height setting bracket to an optional scale position of the

scale.

1-4 Safety measures of operation

The control system is designed by taking a serious view of safety.

1) When the pneumatic cylinders are set to the pull side, the drop operation is not done even if [DROP]

push-button switch is pressed.

2) Drop operation is done by [DROP] push-button switch. An alarm buzzer sounds when pressing this

switch and s specimen drops when releasing the switch.

3) If a trouble was detected when the buzzer is sounding by pressing [DROP] push-button switch, turn

off [POWER] switch without releasing [DROP] push-button switch, and the drop operation is not

done.

4) The electromagnetic holder for dropping a specimen is operated by feeding its power supply so that

no specimen drops when power was interrupted to ensure safe operation. The pneumatic cylinders

(solenoid valves) for releasing the specimen are also operated by feeding power, so that no

specimen drops when power was interrupted to ensure safe operation so long as the pneumatic

pressure is supplied normally.

1

250-500mm: In this range specimen can be just released from the setting height while chuck itself would be stay at

setting height.

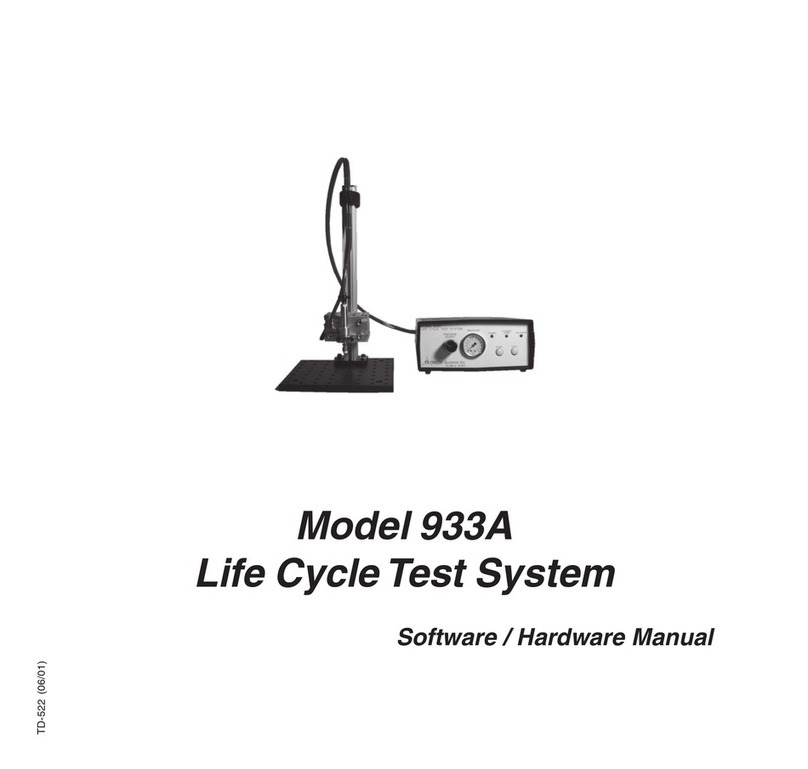

§2 Outer View

2

§2 Outer View

DROP

POWER TOTA L

CONTRO LLER DT-202

YOSHID A SEIKI

RESETSET

123456

2200max.

500min.

250min.

Drop height

Chuck

Guide rail

Column Scale

Shockabsober

Base

Pen cylinder

Control unit

Sensor

600

500

440

50 3

153

3054030

221 379

104

setting pointer

2382

16

Fig. 1

§3 Preparation

3

§3 Preparation

3-1 Preparation to be executed first after installation

When this tester is used for the first time after mounting (or relocating) it, perform the following

preliminary operation and confirm its operation according to the following procedure.

1) Power supply

A single-phase 220VAC power supply is necessary as the control power supply for this tester. An

earth plug is mounted at the tip of the power cord of the control unit Connect the earth to the

ground without fails.

2) Pneumatic pressure source

Pneumatic pen cylinders are used for fixing a specimen. Feed the air pressure from the

compressor

2

(option) or indoor piping (higher than 0.49MPa) in a building.

The air pressure supplied to the tester body is regulated by a filter regulator. The regulated air

pressure operates the pneumatic pen cylinders through the solenoid valves. Since the air pressure

system is operated by feeding power supply, the pneumatic pen cylinders are controlled to fix a

specimen so long as the air pressure is supplied when turning off the power supply.

2

If the compressor (option) is provided with a start/stop (ON/OFF) switch, turn on the switch before starting the test.

§3 Preparation

4

3-2 Preparation for test

1) Shape and size of specimens

The maximum weight and the maximum size in case of face drop of a specimen should be within the

rated ranges. (See §8. Performance and specifications)

2) Check of each section

Check each section (the pneumatic pen cylinders for fixing a specimen, in particular) for normal

condition before starting the test. (See Fig.2)

3) Drop height setting

Set the height setting pointer to an optional position of the scale, and fix it by fastening the knob.

The drop height scale shows the distance from the upper face of the base to the pneumatic pen

cylinder center. Set the drop height by adding the distance from the pneumatic pen cylinders to the

lower face of specimen to the drop height.

Fig. 2

Scale

Drop height setting pointer

§4 Structure of components

5

§4 Structure of components

4-1 Base

The base is made of flat steel to enable a specimen to touch the base horizontally. Its main column

is mounted on the upper face and its lifter and control unit are mounted. The base is perforated at

its corners so that it can be fixed to the floor by grip anchoring (or anchor bolts).

4-2 Main column

The main column is fixed to the base vertically and a height setting scale is mounted at the front

center.

4-3 Drop releasing device

The drop releasing device is equipped with the electromagnetic holder for coupling the specimen

supporting base, height setting pointer, and the fixing knob for position holding. Power is supplied

to the electromagnetic holder to drop the specimen according to a signal from the control unit.

4-4 Specimen supporting base

The specimen supporting base is provided with two pneumatic pen cylinders for fixing and releasing

a specimen. The drop height is set to the center axis of these pneumatic pen cylinders.

4-5 Height setting pointer

The height setting pointer is mounted on the drop releasing device side.

4-6 Pneumatic pen cylinders (for fixing and releasing a specimen)

The pneumatic pen cylinders for fixing and releasing a specimen are operated by an air pressure as

the drive source.

If the power supply is turned off while fixing a specimen, the pneumatic cylinders hold their position

so that the specimen does not drop to ensure safe operation.

4-7 Contacts

Two kinds of contacts shown below are attached as accessories.

Even if a specimen is light, it cannot always be held depending upon its profile and its gravity center

position. If you desire the other contacts satisfying your profile requirement, we will manufacture

them within a possible range. Please contact us in such a case.

Fig. 3

M5 screw

Point pressing contact

Face pt

M5 screw

§4 Structure of components

6

4-8 Pneumatic regulator

1) Filter regulator for pneumatic pen cylinders

This filter regulator is mounted on the lower side of the control unit to regulate the operating

pressure of the pneumatic cylinders for fixing and releasing a specimen. Please set it over 0.49MPa

at least.

Fig. 4

2) SET adjusting speed controller

This speed controller is mounted on the pneumatic pen cylinders.

This airflow regulator for pneumatic pen cylinders can adjust the airflow to an optional speed.

The airflow becomes slow when turning this controller clockwise and it becomes fast when turning

this controller counterclockwise.

Fig. 5

Speed controller

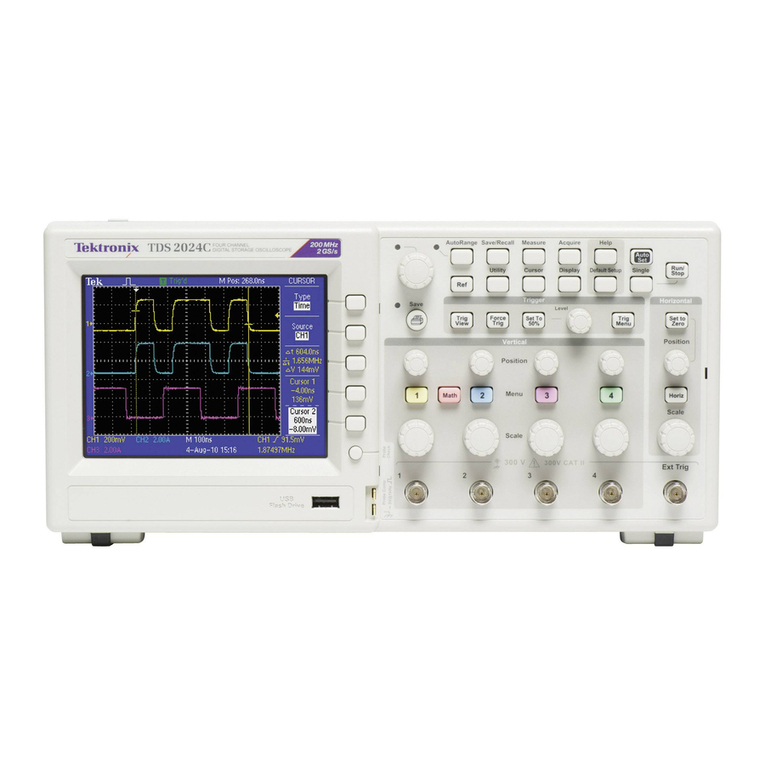

§5 Operation method

7

§5 Operation method

5-1 Control unit

The control unit panel is provided with [POWER], [DROP], [SET], [RESET] push-button switches,

[500mm] selector switch, and [TOTAL] (total counter). A sequence control is mounted inside. The

drop operation of the tester is controlled by these component parts.

The push-button switches on the operation panel function as follows.

1) [POWER] push-button switch

By pressing this illuminated push-button switch, its indicator lamp lights and all operations are set to

be standing by.

For turning off the power supply, push this switch again. This switch is also used if an operation

trouble occurred or if the operation is stopped urgently.

The pneumatic pen cylinders are controlled to fix the specimen when the power supply has been

turned off.

2) [DROP] push-button switch

This push-button switch is used for dropping a specimen.

A specimen must be set to the specimen supporting base as a requirement for drop operation.

By pressing this switch, a buzzer sounds to call attention to surrounding persons. When releasing

this switch, the electromagnetic holder operates to drop the specimen supporting base.

3) [SET] push-button switch

By pressing this push-button switch, the pneumatic pen cylinders mounted to the specimen

supporting base are protruded to fix a specimen. The rod can be adjusted to an optional speed by

the speed controller.

4) [RESET] push-button switch

By pressing this push-button switch, the preset pneumatic pen cylinders are reset. This switch is

used for removing a specimen or changing its set position.

§5 Operation method

8

DROP

POWER

DROP TESTER DT-202

RESETSET

188

1

2

DH 500mm

DH 500mm

4 3

TRG

140 240

1 2 3 4 5 6 7

TOTAL

COUNT

1234

SHINYEI TESTING MACHINERY CO.,LTD.

Fig. 6 Control unit

§5 Operation method

9

5) [500mm] selector switch

By selecting this switch, two dropping (specimen releasing) methods are selectable.

a) [DH>500mm]

A specimen drops together with the specimen supporting base and the pneumatic pen cylinders

operate at the specified position to release the specimen.

b) [DH<500mm]

The specimen supporting base keeps stopping at the position and the pneumatic pen cylinders

operate to release the specimen.

Memo

If the drop height is lower than 500mm, the releasing operation does not function even if the

switch is set to [DH>500mm]. Set the switch to [DH<500mm] without fail.

Memo

An automatic drop height detecting function is not provided.

6) [TOTAL] (total counter)

This counter indicates the total number of tests after starting the use of this tester. It cannot be

reset to 0 halfway.

7) [TRG] (Trigger terminal for high-speed camera photography)

This trigger output terminal is provided for using a high-speed camera. When the switch for

detecting the releasing of a specimen functions, a trigger signal (contact output) is issued.

§6 Troubleshooting

10

§6 Troubleshooting

6-1 [POWER] indicator lamp does not light

1) Check the primary power supply.

2) Check if the metal connector Co1 on the rear panel of the control unit is connected. (See 9-1 Wiring

diagram)

3) Check the power plug socket and power cord for their connection and breakage

4) Check if the fuse mounted on the rear panel of the control unit is not blown out. (The circular hole

of the fuse is displayed white if the fuse is blown out.)

6-2 [POWER] indicator lamp lights, but the specimen does not drop

1) Press [SET] switch and make sure that the specimen is set.

2) Check if the metal connector Co.2 on the rear panel of the control unit is connected. (See 9-1 Wiring

diagram)

6-3 Pneumatic pen cylinders don’t operate

1) Check if the metal connector Co.1 on the rear panel of the control unit is connected. (See 9-1 Wiring

diagram)

2) Make sure that air is fed from the pneumatic pressure source.

3) If the set value of the regulator of the tester is lower than 0.2MPa, the air pressure may leak from

the solenoid valve mounted on the specimen supporting base to cause the pneumatic pen cylinders

to be not operated. (This does not mean any trouble.)

In such a case, increase the setting pressure.

4) If the selector switch is selected to [DH>500mm], the proximity switch for detecting the specimen

supporting base during drop may be defective. Please contact us.

§7 Daily check

11

§7 Daily check

7-1 Lubricate the guide rail with a lubricant (recommendable product,oiltype:ISO VG10) may cause dust

to be attached easily more or less. Wipe off the guide rail by a clean cloth without fail after use.

7-2 The operation may change due to dust, etc. after a long time use.

Check the conditions of each component (pneumatic pen cylinder operation, in particular) once

every 500 times drop test.

§8 Performance and specifications

12

§8 Performance and specifications

8-1 Type Drop tester

8-2 Model DT-202

8-3 Specified performance

1) Maximum specimen size 150mm in width

3

2) Maximum weight of specimen 2kg

3) Drop height range 250 ~ 2200mm

4

4) Drop height setting Setting by scale and setting pointer

5) Fixing of specimen By pneumatic cylinders

6) Floor area for installation 600mm in width ×500mm in depth

7) Tester dimensions 600mm in width×500mm in depth×2382mm in height

8) Tester weight approx. 110kg

9) Painting color 《Body》Munsell code 10B5/10

(Japan Painting Industrial Association B69-50T)

《Control unit》Munsell code N9.5

(Japan Painting Industrial Association BN-95)

10) Feed power supply 100VAC, Single-phase, 5A

(Correspond from 100VAC to 240VAC)

11) Air source 0.49MPa or higher

12) Ambient temperature range 5~35℃

(JIS standard: Temperature condition at test places Class 4)

3

For the maximum specimen size, see Fig.7.

4

250-500mm: In this range specimen can be just released from the setting height while chuck itself would

stay at setting height..

Table of contents

Other TESTING Test Equipment manuals