TESTING RA 100 Concrete User manual

TESTING Bluhm & Feuerherdt GmbH

Manufacture and sale of equipment

for the testing of construction material

Motzener Str. 26b

DE - 12277 Berlin

Tel. +49(0)30/710 96 45-0

Fax +49(0)30/710 96 45-98

www.testing.de

1

Operating Manual

RA 100 Concrete,

non-destructive, quick determination of compressive strength

and modulus of elasticity on samples

of cement, mortar and concrete

Model 1.0390

RA 100 Concrete

Model 1.0390

2

Importance of this Operating Manual:

We expect and require that the User reads, understands and observes all parts of this Operating

Manual.

Contents: Page no.:

1.!Safety instructions ................................................................................................... 3!

2.!Scope of delivery .................................................................................................... 4!

3.!Start-up ................................................................................................................... 5!

4.!Software .................................................................................................................... 7!

4.1. Tab „Measurement“ ................................................................................................ 7!

4.2. Tab „Archive“ ........................................................................................................ 11!

4.3. Tab „Settings“ ........................................................................................................ 12!

4.4. Tab “Concrete Types” ........................................................................................... 14!

5.!Troubleshooting ..................................................................................................... 15!

RA 100 Concrete

Model 1.0390

3

1. Safety instructions

Application

Product for commercial use only!

Product exclusively for intended use with building material samples!

Safety

Do not interfere or modify our products. Never open the device. Otherwise any warranty /

conformity expires.

Operating temperatures

Microphone: -10 ÆC to +85 ÆC

Tablet: +10 ÆC to +40 ÆC

If you have any questions, please contact us:

RA 100 Concrete

Model 1.0390

4

2. Scope of delivery

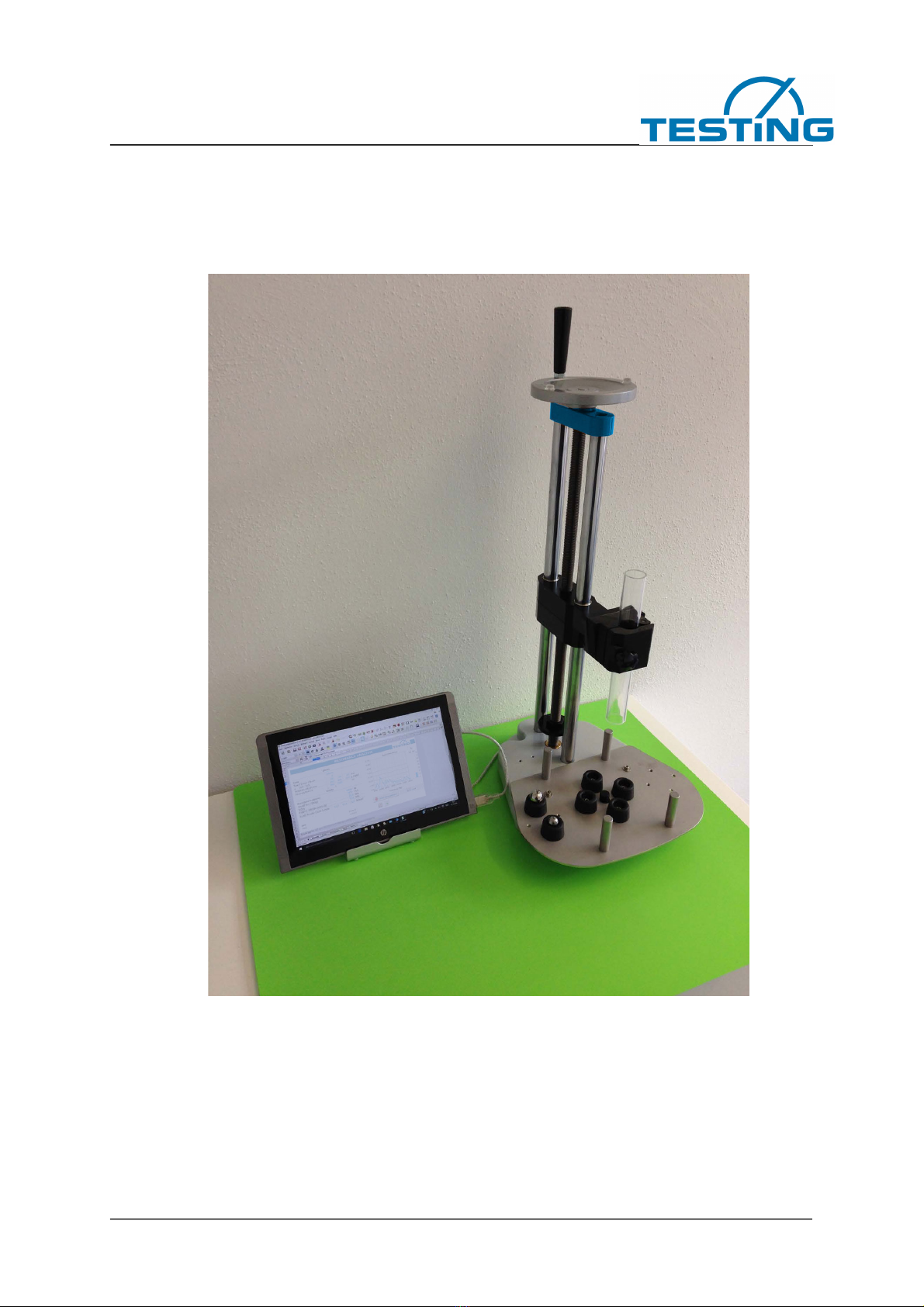

The scope of delivery of the product RA 100 Concrete includes the following parts:

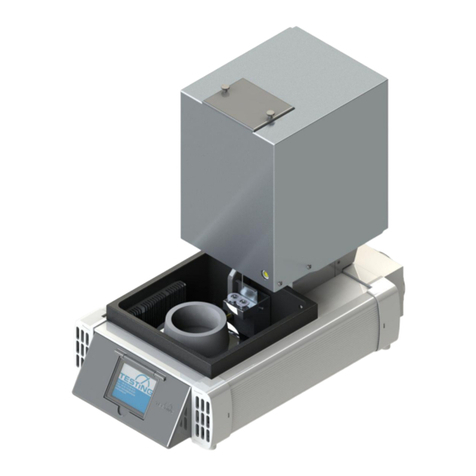

• 1 test stand with integrated USB microphone and 1.8 m USB cable

• 1 tablet, 10", 32 GB, Windows 10

• Pre-installed RA 100 Concrete Software

• 1 stainless steel base plate

• 6 screwable vibration absorbers

• 4 steel balls (2x 20 mm Ø, 2x 14 mm Ø)

• 1 acrylic downpipe

• 1 height-adjustable sample holder

• 1 adjustable tablet holder

• 1 Bluetooth keyboard

• 1 Bluetooth mouse

RA 100 Concrete

Model 1.0390

5

3. Start-up

For easy and uncomplicated starting the following steps are recommended:

1. Place the RA 100 Concrete test stand firmly on a fat surface

2. Assemble base plate

3. Screw in vibration absorbers

4. Set up the test specimen

RA 100 Concrete

Model 1.0390

6

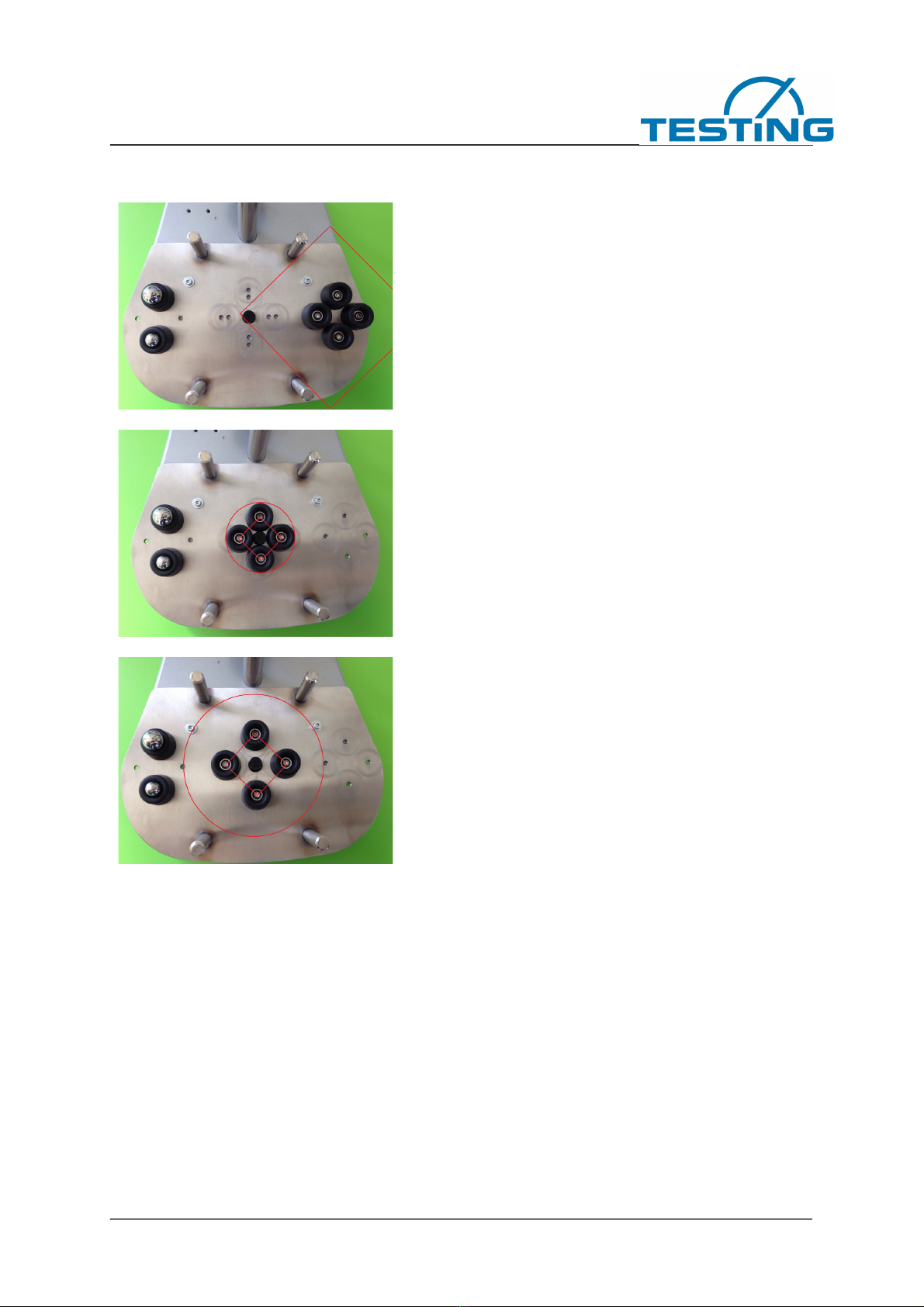

(Position recommendation marked in red)

Recommended sample position of a cube

sample 150mm/150mm/150mm

Recommended frequency range (cube):

3500 Hz - 9500 Hz

Stable sample position for cylinder samples

with small diameter and prism samples with

small width

Recommended frequency range (prism):

10000 Hz - 16000 Hz

Optimum sample position for cylindrical

samples with larger diameters and prism

samples with larger widths

Recommended frequency range (cylinder):

3000 Hz - 9000 Hz

Smaller specimens such as 40 x 40 x 160 mm prisms and smaller drill specimens can be

clamped centrally in the supplied multi-purpose clamp.

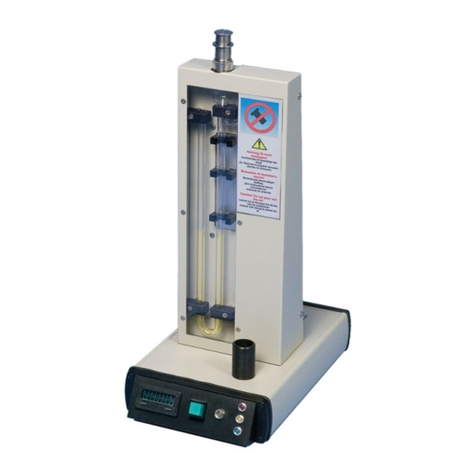

5. Fasten the acrylic downpipe in the holder with the M8 screw

6. Start Tablet and connect the USB adapter to the tablet

7. Start the program Resonance Analysis and make basic settings (see Chapter 4 –

Software)

8. Start Measurement

RA 100 Concrete

Model 1.0390

7

Make sure that USB PnP Sound Device is selected as the default device in the Windows settings

for the recording device.

AGC" must be deactivated under "Properties - User-defined" and a level of 100 must be set

under "Level".

4. Software

The device measures the natural resonances of test specimens by means of a steel ball impact

and microphone. The sound vibrations are digitized and evaluated spectrally. Vibrations are

selected and evaluated which allow analytically simple conclusions to be drawn about the elastic

material values. Based on empirical insights, compressive strength values are also estimated

from the elasticity values for concrete.

4.1. Tab „Measurement“

Entries

In this area the settings are entered in advance of the measurement process.

Description

Name of the measuring process / the sample - free text.

Concrete type, Grain, Fly ash

In the first input cell, the sort description of a concrete can be entered with which properties

stored from the sort table (own spreadsheet of the calculation program) can be called up, of

which - if available - the characteristic cube strength value, the maximum grain size and the fly

ash content are displayed.

RA 100 Concrete

Model 1.0390

8

The fck-cube compressive strength value is used for the target display (first column next to the

diagram) for comparison with the measurement. The maximum grain display is not used directly,

it indirectly influences an otherwise determined calibration correction factor, which is listed in the

last column of the sort list and corrects the determination of compressive strength according to

empirical experience.

x y/d z

Describes the sample shape for calculating the velocity of sound from the resonant frequency

and is used to calculate the sample volume required for density calculation if the sample weight

is entered.

x and y/d describe the base area, z the sample height. If x = 0, x/d input means the diameter of a

cylinder, if x is entered a value, x/d means the second side of a base area rectangle (the sample

then corresponds to a rectangular or square prism, or even a cube).

Example:

300mm standard cylinder

x = blank

y/d = 150

z = 300

160mm standard prism

x = 40

y/d = 40

z = 160

150mm standard cube

x = 150

y/d = 150

z = 150

Weight. De.calc. De.man.

If a weight is entered in the first input cell, the program determines the density with the calculated

volume. If the weight is 0, a density value must be entered manually in the rear input cell or the

value there is taken.

Frequency from to

Here are the frequencies that can be changed at any time (also after the measurement) and

between which a resonance is sought. This area is also used for the adjacent graphic.

Recommendations for common sample shapes:

150mm cube sample: 3500 Hz - 9500 Hz

300mm cylinder sample: 3000 Hz - 9000 Hz

160mm prism sample: 10000 Hz - 16000 Hz

These settings cover the most common varieties.

For very soft or very hard samples the frequency window must be shifted up or down.

RA 100 Concrete

Model 1.0390

9

Start measurement

When this button is pressed, the microphone goes into standby mode and waits for

the pulse that triggers the measurement process

Save

If this button is pressed, the current measurement is stored in the archive

Export as PDF

With this function, the measurement can be exported as a PDF report

Send as e-mail

After completion of the measurement, the measurement data can also be sent as an

e-mail to a stored e-mail address

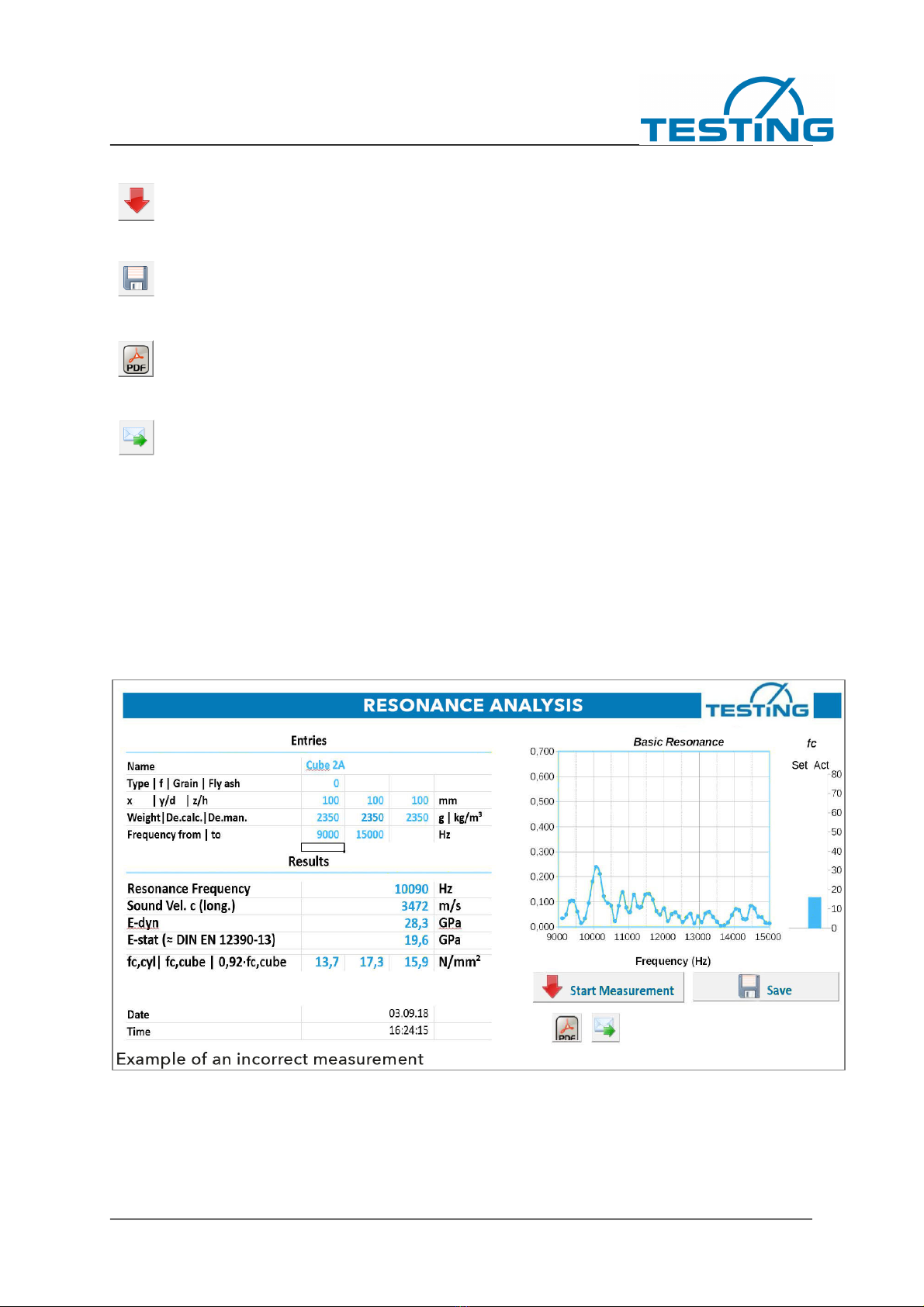

Results

After the measurement process, the result values are displayed in this area. The isolated reso-

nance frequency of the sample and the value of the compressive strength are shown graphically

on the right in a target-actual diagram. The target value of the compressive strength is either

entered manually or taken from the corresponding sort list.

Incorrect measurements due to premature triggering, incorrect sample storage or other

interference can be identified directly on an uneven frequency image.

RA 100 Concrete

Model 1.0390

10

Resonant Frequency

This is the actual and most important measured value.

In the set frequency range, the signal frequency response recorded by the microphone is deter-

mined in the manner of a digital short-term Fourier transformation and also displayed graphically.

A resonance curve expected in the set frequency range is visible and evaluated with regard to its

maximum position in the frequency range and the resonance frequency is used to determine the

corresponding elastic material constants.

Velocity of sound

The pure material constant sound velocity is determined from the resonant frequency and sam-

ple dimensions.

Solids have different types of sound wave propagation, each with its own speed. In an isotropic

solid such as concrete (uniform behaviour in all directions) there are two types of waves in the

unlimited medium, which propagate at different speeds and are described by two independent

elastic constants. These waves are generally detected by ultrasound, since the larger dimen-

sions of the specimens do not play a role in the small wavelengths and the transit time measure-

ments.

In resonance measurements, the interfaces with their abrupt elastic property changes come into

play and complicate sound propagation, according to the sample dimensions. Sound propagation

is simplest measured in long bars where the transverse dimensions are small compared to the

wavelengths. For the velocity of sound determined by longitudinal oscillation resonance the

following applies:

c-shaft = radical (E/den)

and therefore: E = den*c2 (E = Young's modulus and den = density)

In this table result cell, c always means shaft speed. Other measured velocities, including

torsional wave velocities, are converted by means of relationships between elastic constants and

consideration of the specimen shape.

If the transverse contraction coefficient must be used, the mean value 0.2 valid for concrete is

used. The possibility of variation of 0.14...0.26 for concrete has little effect on the result.

Due to the cube specimen shape, which is widely used in the concrete industry, not a longitudi-

nal oscillation shape but the isolated lowest torsional oscillation was selected for reliable detec-

tion, which is converted into a comparable longitudinal speed of sound. The cube basic frequen-

cies are described in:

Harold H. Demarest, Jr. The journal of the Acoustical Society of America Volume 49 Number3

(Part 2) 1971, Cube-Resonance Method to Determine the Elastic Constants of Solids

E-dyn

The dynamic modulus of elasticity is a pure material property, not dependent on specimen geom-

etry and measuring conditions. For concretes, it is largely identical to the modulus of origin of the

stress-strain curve.

RA 100 Concrete

Model 1.0390

11

E-stat DIN EN 12390-13

The static modulus of elasticity is estimated from the dynamic modulus of elasticity according to

theoretical models, similar comparison measurements from literature and own

measurements.

Fc-cyl fc-cube 0,92 fc-cube

The result values correspond to a conversion of the measured sound velocity according to

empirical values obtained in test series with several hundred cube compressive strength values

produced in the ready-mixed concrete product monitoring. For standard concrete, the standard

curve, which can be adjusted with correction factors, corresponds to a dependence of the modu-

lus of elasticity on compressive strength with a power of approx. 0.3, i.e. E proportional fc high

0.3, which is usually preferred in the literature.

The dependence on density implied in E-dyn is not considered in standard concrete, fc is thus

calculated directly from the speed of sound. However, in the case of lightweight concrete, a

smaller power number is used for the compressive strength dependence: The central calibration

curve is designed for the cube strength in the cell fc-cube, the cylinder strength for a

150mm/300mm cylinder is calculated back into the cell fc-cyl. The dry cube storage for the

28-day value with that is taken into account for standard concrete with the factor 0.92 in the cell

0.92 fc-cube.

4.2. Tab „Archive“

On the basis of the measurement processes stored in the archive, it can be precisely traced at

any time under which pre-setting’s, measurement conditions and at which time which character-

istic properties of the test specimens existed.

With the button >Erase archive< the measuring processes are deleted.

In the "Settings" tab, you can define the selection and sequence of the data fields displayed.

RA 100 Concrete

Model 1.0390

12

4.3. Tab „Settings“

The values entered represent the basic software settings.

Recording

Sampling rate:

Sampling rate of the audio recording

Recording time:

Length of the recording

Trigger limit:

Level at which the recording is triggered

Trigger minimum duration:

Time period for which the level must be increased in order to trigger a measurement

Maximum waiting time:

Waiting time for trigger - if the measurement is not triggered, the software returns to the normal

state

RA 100 Concrete

Model 1.0390

13

Changes to these settings can strongly influence the quality of the measurement.

Please contact us if you have any questions:

Audio device

Selecting the recording and playback device. (Not necessary from Windows 8.1)

View

Optionally, the screen can be switched to full screen mode using the

> Switch Screen button <

When changing the setting with the number 1, the program is displayed in full screen mode at

each start.

The desired maximum Y value can be entered for scaling the Y-axis of the "basic resonance"

diagram. If the value is "0", the diagram is automatically scaled.

Archive

Here you can select the cells that are to be stored in the archive after saving.

E-Mail

The addresses of the desired recipients can be entered here (separate multiple entries with com-

mas). In addition, the subject line of the e-mail can be pre-set. The evaluation data to be sent

can be supplemented or reduced in the "E-Mail Text" area by entering the table fields.

Licensing

License number for using the software

RA 100 Concrete

Model 1.0390

14

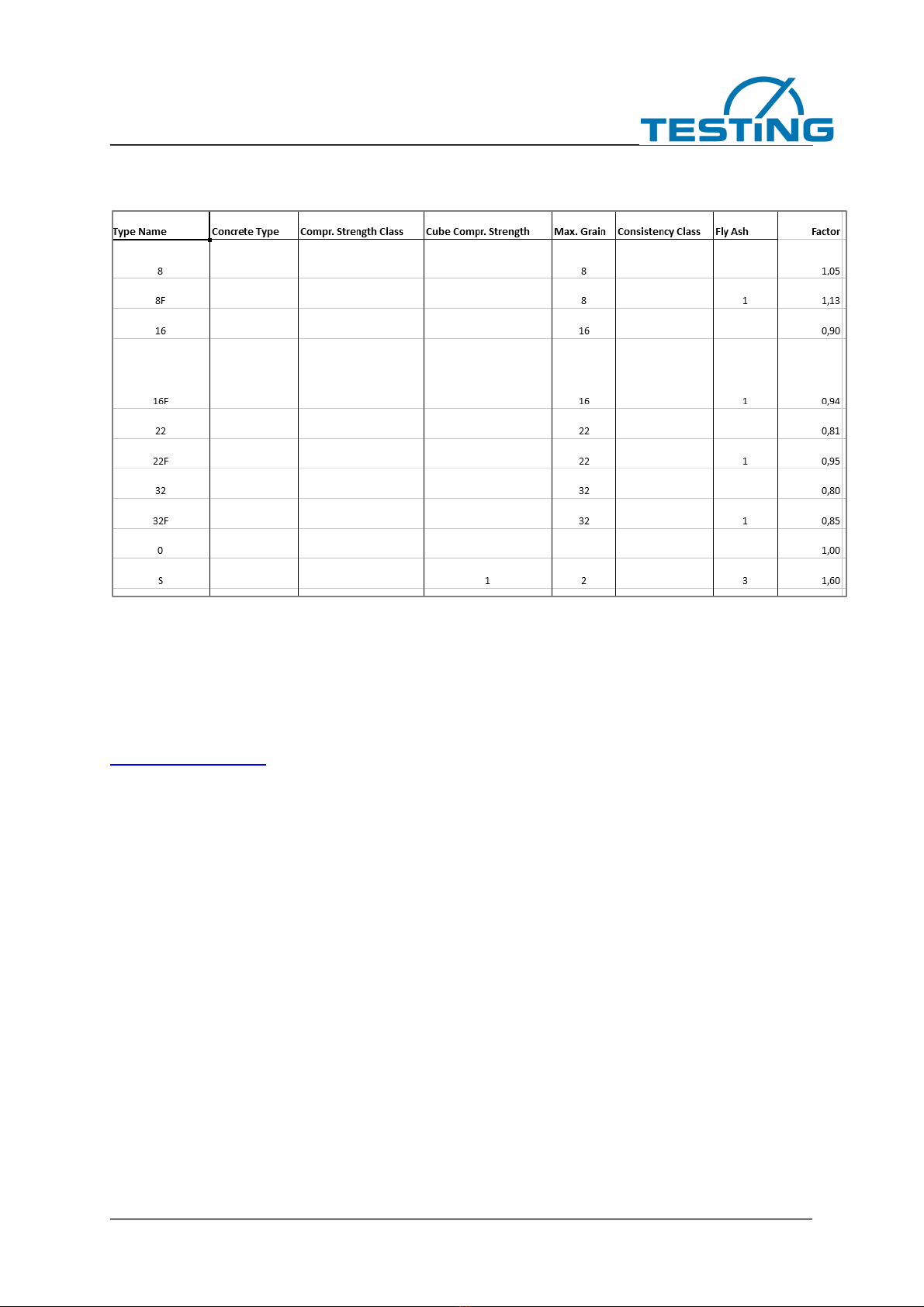

4.4. Tab “Concrete Types”

Exemplary excerpt from a stored list of varieties

If a variety list of types is stored, additional details can be used for the display and calculation.

If you have any questions, please contact us:

RA 100 Concrete

Model 1.0390

15

5. Troubleshooting

Issue:

As soon as you click on "Start measurement" - the software immediately jumps to "process".

Solution:

USB microphone of the test stand not connected.

OR

Correct the trigger limit upwards in the "Settings" tab.

Issue:

The software does not start processing after the ball is dropped.

Solution:

Correct the trigger limit downwards in the "Settings" tab.

If you have any questions, please contact us:

This manual suits for next models

1

Table of contents

Other TESTING Test Equipment manuals