TET Natural Reliability XTP Series User manual

Ecostream Primer Pump

INSTRUCTION MANUAL

MODEL

DATE

MARCH 2021 v1.0

Teton Dynamics

P.O. Box 1077

San Leandro, CA 94577

XTP SERIES

XTP3900

XTP5600

XTP7400

XTP9200

XTP10500

XTP12000

ECOSTREAM PRIMER PUMP

XTP3900/5600/7400/9200/10500/12000

VERSION March 2021

www.tetonus.com

800.752.0399

info@tetonus.com

WELCOME TO THE WORLD OF TETON,

NATURAL RELIABILITY™!

You Made The Right Choice Investing In This Quality

Product. Thank You And Enjoy.

BEFORE USING THIS PRODUCT, PLEASE READ

THESE INSTRUCTIONS CAREFULLY AND

FAMILIARIZE YOURSELF WITH THE UNIT. PLEASE

KEEP THESE INSTRUCTIONS IN A SAFE PLACE

FOR FUTURE REFERENCE.

TECHNICAL SPECIFICATIONS

MODEL NO. XTP3900 XTP5600 XTP7400 XTP10500 XTP12000

MAX FLOW RATE 3900 GPH

MAX HEAD

HEIGHT

WATTS

(MAX)

AMPS

VOLTS

OUTPUT HP

INTAKE/DISCHARGE

UNIONS INCLUDED

CORD

LENGTH

XTP9200

(14750 LPH)

5600 GPH

(21200 LPH)

7400 GPH

(28000 LPH)

9200 GPH

(34825 LPH)

10500 GPH

(39750 LPH)

12000 GPH

(45425 LPH)

195 350 600 620 830 970

1.8 5.3 5.6 7.3 8.6

115 115 115 115 115 115

1/8 1/4 1/2 1/2 3/4 1

2”

(5 cm)

2”

(5 cm)

2”

(5 cm)

3”

(7.5 cm)

3”

(7.5 cm)

3”

(7.5 cm)

8 ft

(2.4 m)

8 ft

(2.4 m)

8 ft

(2.4 m)

8 ft

(2.4 m)

8 ft

(2.4 m)

8 ft

(2.4 m)

17 ft

(5.2 m)

23 ft

(7.0 m)

26 ft

(7.9 m)

24 ft

(7.3 m)

23 ft

(7.0 m)

24 ft

(7.3 m)

3.2

Teton Page 2

UNDERSTAND PRIMING AND PUMP OPERATION

kinetic energy into static pressure allowing the pump to maintain pressure and is then forced out of the pumps discharge

port resulting in continuous water flow for your waterscape oasis.

The Teton® XTP Ecostream Primer Pump is considered a “true” self-priming pump. This means it is designed to prime and operate at

varying heights up to 9 feet above the water source surface as well as varying horizontal lengths. It is important to note that

operating at maximum suction lift height may negatively affect the pumps overall performance. If after starting the pump you

notice it takes more than three minutes for water to start flowing into the priming pot after being filled with water and energized,

it is recommended to install a rubber flapper type swing check valve. The valve should be as low and as close to your source

water as possible to maintain constant pressure and shorten prime time. The best location can even be underwater when

possible as this can provide an airtight fit even without PVC adhesive. Some swing check valves have true union connection

fittings that offer easier access for cleaning when needed.

What to expect for priming cycle with swing check valve installed.

Essentially, when utilizing a properly installed swing check valve the priming process is less time consuming and is more effcient.

When installing a swing check valve, be sure your connections are properly seated and airtight. Then, simply fill the priming pot

with water until the intake plumbing and priming pot are full. Replace the lid, securing tightly and turn on your pump. With the

swing check valve in place your pump is fully primed from the beginning. However, if after running your pump you observe the

water level in the strainer pot decreasing continuously, this indicates there is either a blockage limiting the flow or a union fitting,

connection on the intake pipe or lid is not airtight. Check all connections for debris, crimping, or cracking and re-tighten or

replace parts as needed.

The Basics

The Prime

With Valve

No Valve

Teton Page 3

Your pump is powered by an electric motor that directly affects your water flow rate. When the electric motor is turned on it

utilizes centrifugal force to generate velocity of the water. The water then flows into the strainer pot from the water source,

filtering out debris. Water continues its flow into the eye of the impeller where the water meets the impeller vanes and converts

What to expect for priming cycle without a swing check valve installed.

In installation applications where the pump and plumbing are above the water level and no swing check valve is installed, the

priming process will work as listed in the installation instructions on page 5. In this application the internal pressure in the pipe

drops below outside barometric pressure which allows this pressure to slowly push water toward the pump. This slow push

results in a longer priming cycle. It is important to note that the incoming water flow may initially be very little or non-existent

for the first few minutes. If three minutes pass with no water flowing into the priming pot, the pump should be shut off,

connections rechecked, water refilled and system restarted.

With a valve or without a valve, the time it takes for your pump to complete the prime cycle is based on a variety of factors

including pipe type, diameter, suction lift height, horizontal distance, motor speed and horsepower. The entire cycle can range

from one to fifteen minutes to complete; however, as noted above, you should see water flowing into the pump within three

minutes or less.

Never use a spring loaded check valve as it will reduce or stop flow.

For system specifc assessments including suction lift and friction loss guidance and operating questions,

IMPORTANT SAFEGUARDS

Please read the operating instructions and familiarize yourself with the equipment before

placing it in service. Correct and safe use of the system requires strict compliance with these

safety instructions. For safety reasons, persons less than 16 years of age or persons that are

not familiar with these instructions, should not use this equipment.

•

•

•

•

•

For 3 phase motors, ensure proper rotation. In

freezing environments it is advisable to winterize

your pump to prevent damange.

•

•

This pump and motor unit should be installed

by a qualified electrician or serviceperson in

accordance with the National Electrical Code.

Improper installation may create a mechanical

or electrical hazard which could cause damage

to property and could result in serious injury or

death.

In order to avoid serious injury or death, always

disconnect power to the motor before servicing

the pump and follow all instructions in this manual.

Always use the schematic on the motor for all

electrical connections.

Never run the pump dry. The priming pot must be

filled with water and lid secured before starting the

the motor. Running dry will void the warranty and

can result in permanent damage to the pump

unit.

To prevent incorrect motor rotation, install a ball

or swing type check valve. Do not use spring

check valves.

Maintain a minimum flow rate of at least two

gallons per minute of once per week.

Visually inspect the pump and motor a minimum

of once per week. If any leakage between the

motor and pump housing is present, replace the

mechanical seal. The seal faces wear similar to car

tires and must be replacedperiodically. For critical

applications, replace the mechanical seal yearly.

If your pump is excessively noisy, shut it down and

contact support.

Do not allow pump or system plumping to freeze,

as freezing can cause damage that may lead to

equipment failure or possible inury and will void

the warranty.

Pressure Hazard!

Do not run your pump

with discharge ports

closed or blocked.

Be sure to release

system pressure before

working on the pump.

Electrical Hazard!

Ground pump

before connecting

to power supply!

Risk of shock, burn

or death if not

handled properly.

Burn Hazard!

Operating motor can be

very hot. Do not touch

motor while running.

Allow to cool 30 minutes

after shut down before

handling. Risk of burn.

•

•

PRODUCT SPECIFIC SAFEGUARDS

Open the pump box when received and inspect for evidence of rough handling or damage to the pump and verify

the product ordered. If damage is found, notify the freight carrier and contact the vendor purchased from immediately.

For order discrepancies, contact the vendor purchased from immediately.

Be sure your installation location is no higher than 9 feet above the water surface level.

If using smaller than 3” pipe, excessive fittings such as elbows, sweeps or reducers, using an excessively long pipe run,

using additional strainers or any other water flow restriction device, can increase the prime cycle time.

Refer to the Pump Operation information on page 3.

GENERAL TIPS

Position the pump as near to the water and as

low as is practical. This will help reduce priming

time, avoid cavitation, and maximize your pumps

performance. Minimize friction loss by using the appropriate

diameter pipe determined by gallons per minute flow,

reducing run length, and minimizing the number of

elbows and fittings as much as possible.

Mount the motor to a stable base where it will

not get submerged. Use caution when installing

in a vault. Be sure proper drainage is in place to

prevent flooding. A sturdy pedastal under the

the pump is beneficial in a vault application to maximize

space to the ground. Ensure the vault is properly

ventilated.

•

•

•

•

•

WARNING WARNING

WARNING

Teton Page 4

Before Installation

INSTALLATION

After thorough inspection, carefully remove the

pump from the box.

Secure the pump on a flat, solid foundation. A

covered location is always best and care should

be taken to ensure adequate ventilation. See

installation tips for beneficial tips.

Install a ball or swing type check valve as needed

to facilitate pump disconnection, flow control and

servicing.

Connect plumbing to the pump by dry fit testing

first to ensure proper fit and proper pipe alignment.

Be sure the union nut is on the union tail piece

before gluing in place.

Once proper fit and alignment is established, use

proper pipe sealant designed for plastic pipe.

Support plumbing as needed to prevent strain

and damage. Do not over tighten the nut included

with the pump in the quick connect fittings. Hand

tightening is sufficient.

Wiring of the pump should be in accordance with

the wiring diagram located on the motor. Ensure

the pump is wired for the correct supply voltage

and is supplied by no smaller than 16 gauge wire

and should be based on horsepower. See

Maitenance. The circuit breaker should be 20 amp

but no less than 15 amp. It is recommended that

wiring be performed by a licensed electrician. For

3 phase wiring, see Electrical.

If your pump will be hardwired, be sure to ground the

motor correctly by connecting code compliant wiring

to the green ground screw located under the wiring

plate.

When wiring is complete, double check intake and discharge

fittings to esure a snug fit.

Note: There may be installations in which plumbing allows for

trapped air in the system. If this happens, priming will be

difficult. In this case, loosen the discharge fitting slightly to

allow trapped air to bleed off. Once primed tighten the

discharge fitting.

On flooded suction systems where the water source is higher

than the pump, the pump will fill with water once the supply

valve is opened. However, on both flooded and non-flooded

system, it is recommended to open the strainer pot lid,

fill with water, ensure the lid o-ring is clean of any debris

and close the lid securely prior to starting.

Once priming pot is filled and supply valves (if present) are

opened, your pump is now ready to prime. Turn the motor

on by plugging in the unit or switching on the power supply.

Priming will vary in length. Water should continue to flow

into the basket as the pump goes through the priming

process. The priming process should not take longer than

15 minutes. The pump should never run dry. If water stops

flowing into the strainer pot, shut the pump off immediately

and see Troubleshooting (Page 13) for more information.

Note: At initial start up, the water level in the pump housing,

as seen through the clear lid should drop rapidly and have

a small amount of water entering the pump in less than

3 minutes. There is no need to be alarmed as this is normal.

If no air leaks are present the small amount of water flow

will continue to gradually increase resulting in a fully

primed pump operating at maximum performance.

Maximize your pumps service life by protecting

the motor from the elements by ensuring it is

well covered and adequately ventilated .

Exposing your pump to excessive heat or

moisture will shorten the life of the motor.

Protect the motor against dirt, water, and all

foreign matter. If the motor has been flooded,

do not operate it until it has been checked by an

authorized motor technician and has been found to

be safe to operate. If the motor is damaged by dirt,

moisture, foreign matter or corrosion, it is not

covered by the warranty.

The pump ports are 3” slip on both the inlet and discharge

ports. The Teton®XTP Ecostream Primer Pump series offer

2” or 3” fitting sizes. The fittings included with your pump

should connect to PVC or flex pipe plumbing. All plumbing

lines should be self supported and properly aligned. This

will prevent undue stress to the housing and fittings. We

recommend using a good primer and PVC cement to

glue the pipe to the tailpiece fittings.

Installations in which the water level is elevated above the

pump it is highly recommended to use a ball or swing type

check valve to prevent back flow and possible reverse

rotation. A ball valve will supplement a swing check valve

and allow flow adjustments.

FILL THE PRIMING POT WITH WATER BEFORE STARTING

THE PUMP.

When determining pump placement, it is important

to consider the distance and height from the

water source. To ensure reasonable prime time

without an inline swing type check valve, position the

pump no higher than 9 feet from the water source.

Positioning is also important to maintain the pumps ability

to stay primed and minimize cavitation. Do not use spring

loaded check valves!

•

•

•

•

•

•

•

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Teton Page 5

ELECTRICAL

1. Inspect the motors internal wiring to ensure voltage supply is matched between the motor and the power source.

If voltage does not match, it will damage the motor and void the warranty.

Example:

2. Supply voltage must be within +/- 10% of nameplate voltage indicated on the motor. Incorrect voltage supply may

to connect your pump to a ground fault circuit interrupter (GFCI) for safety.

arrangements. If a cord has been preinstalled the connection was completed at the factory.

5. Be sure all connections are clean and tight. Ensure the motor is properly grounded. Typically a green ground terminal

is located inside the motor connection box. The ground wire must be properly connected to an electrical

service ground to safely operate.

6. The pump must be connected to an adequately sized circuit. It is recommended to have a dedicated circuit that will

prevent voltage drop from other loads as occurs on shared circuits.

7.

Before wiring any part of the motor be sure the power is disconnected.

It is recommended that wiring be performed by a licensed electrician or professional serviceperson.

If pump has a factory preinstalled cord, wiring has already been set and this step is not needed; unless

voltage change is required in which case the cord will need to be removed and steps followed below.

result in fire or damaged motor and voids the warranty. If you are not certain, please consult with a licensed electrician.

Use designated supply wire size specified in the chart below. Correct wire size is necessary to avoid electrical

insufficiencies, allowing the motor to run cooler, more efficiently and eliminating line voltage loss. It is important

Wire motor following the connection diagram located on the motor. Note differences in high and low voltage

3.

4.

* Risk of shock! Connect only to a ground fault circuit interrupter (GFCI). Contact an electrician if uncertain.

* Replace damaged cords immediately to minimize risk of electric shock.

* Do not use extension cords to supply electricity to the pump.

CIRCUIT DATA

HP CIRCUIT VOLTS/Hz/PH

WIRE GAUGE 25-50 ft 100 ft 150ft 200ft 250ft

1/4 15 Amp 115 or 230/60/1

1/3 15 Amp 115 or 230/60/1

1/2 15 Amp 115 or 230/60/1

3/4 15 Amp 115 or 230/60/1

1 15 Amp 115 or 230/60/1

16

RECOMMENDED WIRING AND CIRCUIT BREAKER DATA FOR TETON® XTP ECOSTREAM PRIMER PUMP

14

12

10

13 amps 10 amps * * *

15 amps 13 amps 7 amps * *

20 amps 15 amps 10 amps 8 amps 7 amps

20 amps 20 amps 15 amps 10 amps 10 amps

*Not recommended for use at this length. Note: The longer the wiring length the lower the amp conductibility due to voltage drop.

* Do not bury electrical cord unless installed in certified conduit. Locate the cord safely to minimize accidental damage

WIRING DATA

WIRING SIZE PER AMPERAGE CAPACITY

Teton Page 6

If connecting your pump to a 115V circuit, make sure the motor connections match the 115V wiring diagram

listed on your particular motor.

When using 3 phase power the motor leads must be energized in the correct sequence to provide the correct motor

rotation. When viewed from the back end (opposite drive end), the motor must rotate clockwise. Incorrect rotation

could destroy the pump and void the warranty. If sequence of the incoming electrical supply lines is not known,

briefly connect the power for a second or two to determine the rotation while looking at the fan through the motor

end plate on the back end (opposite drive end) of the motor. If you are unable to see the fan you will need to remove

the drip cover (solid plate) on the back end of the motor (opposite drive end) in order to see the motor shaft as this

unit type will not have a visable fan. If the rotation is incorrect, exchange any two of the connected leads and retest.

Cleaning the basket:

The strainer basket in the priming pot should be inspected and cleaned at least one (1) time per week, more often if excessive

debris is present in the operating environment.

2. If you have a ball valve placed at the return side of your pump, be sure to close the valve to prevent backflow.

3. Remove the black clamp ring by holding the tabs and turning the clamp ring counter clockwise. Take care if the clamp

ring is too tight. Slightly bumping the tabs may aid in releasing the grip.

Remove the lid and clean out the basket. It is recommended to clean out the basket using a sprayer on a garden

hose and a brush as needed. Do not hit the basket on any hard surface as this will weaken and damage the basket.

4. Reinstall the basket so that the tab under the basket locks in place.

5. Fill priming pot (basket section) with water.

6. Replace the lid securely.

7. Open ball valve (if present).

8. Connect power and start the pump.

Pump seals and bearings experience normal wear and degrade over time. It is recommended to change pump seals every

three (3) to four (4) years for fresh water applications and every year for salt water applications. The frequency of

replacement will be determinate upon environment and water quality. If leakage is noticed at anytime, check troubleshooting

tips and contact us for parts and advice. If the pump becomes abnormally noisy, this could be a sign that the bearings are

failing and need replacement. There are a few options for repair when this occurs.

1. Contact Teton to obtain a return authorization and ship the pump to us for repair.

2. Contact Teton for a list of authorized motor repair centers near you. Note that this option may not honor any warranty

but may provide a good alternative.

3. If you are mechanically minded, the option to order bearings and a seal kit from Teton or your local dealer is available

to perform the repair.

1. Turn off your pump and disconnect from the electrical source by unplugging or turning off the breaker.

If the pump has been running with no incoming water flow for more than five (5) minutes, it is important

to immediately turn the pump off by disconnecting the unit from the power supply.

If the volute (main pump housing) is hot, allow the pump a minimum of one hour or more to cool down

before opening the lid. The volute housing/strainer pot should be cool to the touch before opening.

Danger of burn if opened when hot.

Seals and Bearings

Winterizing your pump is necessary if freezing temperatures occur in your geographic area for extended periods of time.

If freezing tempuratures are not common but may on occassion drop below freezing, it is advised to follow winterization

procedure to protect your pump.

Freezing tempuratures cause water to expand and may result in damage to the pump, plumbing, and other

connected components resulting in costly repairs.

MAINTENANCE

WINTERIZATION

Teton Page 7

Full disconnection method:

This method is best for pumps situated outside without protection of a building or vault.

2. Close all necessary valves on inlet and discharges lines and drain the pump by removing both drain plugs. As the pump

drains, the lid may be loosened to facilitate better drainage. Tip: Store drain plugs in a resealable bag and tape the

bag to the pump or store inside the pump basket to prevent loss.

3. Once drained, loosen the intake and discharge ports by turning the union nut counter-clockwise until loose.

4. The pump can now be removed. Be sure the pump is fully drained and lid removed before being stored. The lid may stay

secured if prior to storage the lid is removed and fully dried. Store with drain plugs removed. Your pump is now ready for

storage in a dry, warm location such as a garage.

**Be sure to drain the water from the plumbing on your system and related components to prevent damage.

Connected method:

This method is best for pumps situated in a vault, shed or other covered outdoor location that may be difficult to fully remove.

1. Follow steps 1, 2 and 3 above.

2. Once drained, remove and dry the lid and place over the top without latching.

3. Drain all plumbing lines on your system.

4. Insulate the pump and exposed pipes, fully covering to prevent moisture intrusion and freezing tempurature exposure.

Do not directly cover with plastic sheeting as this can create condensation that can result in damage.

1. Disconnect the pump from the power source by unplugging or turning off at the circuit breaker

Note: If hardwired, you may either disconnect the electrical connection (a qualified electrician should perform this)

or leave the motor connected and disconnect the pump end. If you choose this option, please follow pump disassembly

instructions and insulate and cover the motor for protection.

PERFORMANCE DATA

Teton Page 8

24

22

20

18

16

14

12

10

8

6

4

2

00 1500 3000 4500 6000 7500 9000 10500 12000 13500

HEAD (FT)

XTP3900

XTP5600

XTP7400

XTP9200

XTP10500

XTP12000

GPH

26

PARTS BREAKDOWN - XTP3900/5600/7400

ITEM DESCRIPTION P

Bracket

Bracket

Bracket Bore O-Ring

Bracket Bore O-Ring

Bracket O-Ring

Diffuser O-Ring

Diffuser Diffuser Large Vane (for #4 - 7 Impellers)

Diffuser XL Vane (for #8 - 9 Impellers)

Impeller

Impeller for XTP3900 T: 4.35

Impeller for XTP5600 T: 4.92

Impeller for XTP7400 T: 4.92

Drain Plug

Polypropylene Drain Plug with Buna O-Ring (1)

Hardware

Stainless Steel Hardware Set (All except 1.5 - 3 HF)

Diffuser Set Screw Set Screw for Diffuser (All except 1.5 - 3hp HF)

Bearings

Motor Bearings - 03

Set Screw for Diffuser (1.5 - 3 hp HF)

Stainless Steel Hardware Set (1.5 - 3 HF only)

Impeller Set Screw Impeller reverse set screw with gasket (3450 RPM only)

Lid

Seal - Mechanical 316 Stainless Steel Carbon vs. Ceramic with Buna

PTFE Coated S.S. with SIC Faces, Buna Trim

Motor Base Plastic Motor Base

Union Assembly 2” Nut(a), Tail Piece(b) & O-Ring(c)

Seal Kit Includes (2) Drain plug O-rings, (1) Lid, Diffuser,

Bracket & Bracket bore O-rings, (1) 513 Mechanical seal,

(1) Reverse set screw washer, (2) Tailpiece O-rings

Seal Kit - Salt Includes (2) Drain plug O-rings, (1) Lid, Diffuser,

Bracket &Bracket bore O-rings, (1) 517 Mechanical seal,

(1) Reverse set screw washer, (2) Tailpiece O-rings

O-Ring for Lexan™ Lid

Clear Lexan™ Lid

Lid O-Ring

Quick Clamp Quick clamp for Volute

Strainer Basket Strainer Basket for Volute

Volute Volute Housing (Polypropylene)

AVAILABLE REPLACEMENT PARTS - XTP3900/5600/7400

NO. DESCRIPTION

Bracket O-Ring

O-Ring for Diffuser Nose

ITEM DESCRIPTION P

NO. ITEM DESCRIPTION

Teton Page 9

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

PARTS BREAKDOWN - XTP9200/10500/12000

AVAILABLE REPLACEMENT PARTS - XTP9200/10500/12000

NO. DESCRIPTION

Bracket Bracket

Bracket Bore O-Ring

Bracket Bore O-Ring

Bracket O-Ring

Diffuser O-Ring O-Ring for Diffuser Nose

Diffuser Diffuser Regular Vane (for #4 - 7 Impellers)

Diffuser High Volume Vane (for #8 - 10 Impellers)

Impeller

Drain Plug

Polypropylene Drain Plug with Buna O-Ring (1)

Hardware

Stainless Hardware Set (All except 1/4 & 1/3 L,

1-3HH, 1/2HF)

Diffuser Set Screw

Set Screw for Diffuser (All except 1/4 & 1/3 Low,

1-3 HH, 1/2 HF)

Bearings Motor Bearings - 03

Set Screw for Diffuser (For 1/4 & 1/3 Low, 1-3 HH,

1/2 HF)

Stainless Hardware Set (1/4 & 1/3 L, 1-3HH, 1/2HF)

Impeller Set Screw

Lid

Seal - Mechanical

316 Stainless Steel Carbon vs. Ceramic with Buna

PTFE Coated S.S. with SIC Faces, Buna Trim

Motor Base Plastic Motor Base

O-Ring for Lexan™ Lid

Clear Lexan™ Lid

Lid O-Ring

Quick Clamp

Quick clamp for Volute

Bracket O-Ring

T = 5.00

T = 5.00

T = 5.12

Impeller reverse set screw with gasket

(3450 RPM only)

Union Assembly 2” Tail Piece(a), Nut(b) & O-Ring(c)

Seal Kit Bracket bore O-rings, (1) 513 Mechanical seal,

(1) Reverse set screw washer, (2) Tailpiece O-rings

Seal Kit - Salt

Includes (2) Drain plug O-rings, (1) Lid, Diffuser, Bracket &

Bracket bore O-rings, (1) 517 Mechanical seal,

(1) Reverse set screw washer, (2) Tailpiece O-rings

Strainer Basket Strainer Basket for Volute

Volute Volute Housing (Polypropylene)

3” Tail Piece(a), Nut(b) & O-Ring(c)

Bracket & Bracket bore O-rings, (1) 513 Mechanical seal,

Bracket &Bracket bore O-rings, (1) 517 Mechanical seal,

Teton Page 10

Impeller for XTP9200

Impeller for XTP10500

Impeller for XTP12000

ITEM NO. DESCRIPTION

ITEM

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

All moving parts are located in the rear sub-assembly of this pump.

Tools required:

1. 3/32 inch Allen wrench

2. 7/16 inch open end wrench

3. 9/16 inch open end wrench

5. #3 Phillips screw driver

Disassembly and repair of the motor sub-assembly can be made as follows:

2. Close all necessary valves on inlet and discharge lines and drain the pump by removing both drain

plugs.

3.

Loosen and remove the six (6) 1-1/8” hex bolts that hold the volute and the bracket together.

4.

Pull the rear sub-assembly away from the volute. The volute may remain attached to the plumbing.

5.

6.

Remove the set screw from the impeller eye, if present. To remove, hold the impeller stationary and

turn the set screw clockwise to loosen (screw is left-hand threaded).

7. Hold the motor shaft stationary by removing the cap on the opposite end of the motor and inserting a screwdriver

in the slot or use a wrench on the flat spot on the motor shaft depending on the motor design and unscrew the

impeller by turning it counter-clockwise.

8. Loosen and remove the four (4) 7/8” hex-bolts that hold the bracket to the motor face.

10. Clean the bracket, seal bore housing and the motor shaft as necessary. Remove slinger if replacing bearings.

1.

Rear Sub-assembly

Disconnect the pump from the power souce by unplugging or turn off at the circuit breaker.

Loosen and remove the two (2) diffuser set screws that hold the diffuser to the bracket.

4. Small and large flathead screwdrivers

9. To remove the shaft seal, place the bracket face down on a flat surface and press out the carbon/spring seal from the

back side. Never try to pry it our from the front. Carefully remove the ceramic seal from the back of the impeller hub

by carefully prying up with a small flathead screwdriver.

PUMP DISASSEMBLY

Teton Page 11

To install a new shaft seal, clean or replace the bracket bore o-ring. Moisten bracket bore o-ring with water prior

to installing to prevent rolling.

2. Press the seal into the bore without touching or putting pressure on the delicate carbon face by pushing on the

stainless steel collar. (A large socket or pipe nipple may be used to facilitate installation.)

3. Clean as necessary the impeller hub and press in the ceramic part (see tip). Make sure that it is sitting flat.

Tip: Moistening the rubber boot with water prior to installation aids in proper seating.

4. Install the slinger rubber washer on the motor shaft. Install the bracket to the motor.

Mount the diffuser onto the bracket fitting the plastic pins into the holes in the bracket, then tighten both diffuser

tighten both diffuser set screws.

tighten the four (4) 7/8” hex bolts.

5. Screw the impeller clockwise onto the motor shaft while holding the motor shaft stationary until it makes firm

contact.

* Handle the mechanical seal with care to protect the polished and lapped faces of the seal from damage.

PARTS REPLACEMENT AND PUMP ASSEMBLY

8. Assemble the motor sub-assembly to the volute using the six (6) 1-1/8” hex bolts. Do not tighten until all six (6)

hex bolts are in place and hand tightened, then tighten all six (6) bolts uniformly in an alternating opposing

sides pattern.

10. Reinstall the lid and clamp ring, turning clockwise until snug.

11. Open all valves on the system, if present, and reconnect the power to start. Wait for the pump to prime. Monitor water

level in the volute/basket area to ensure water is always present. If the pump has been running with no incoming water

The polised white ceramic face must be face out, not the rubber boot!

6.

Make sure the diffuser o-ring and bracket gasket are clean and properly seated.

9. Insert both drain plugs with o-rings installed and tighten. Install strainer basket and fill the volute/strainer pot with water.

7.

flow for more than 15 minutes, shut the system off immediately and call PerformancePro pumps for technical assistance.

* DO NOT RUN THE PUMP DRY. Pump must be filled with water and sealed before it is turned on.

1.

Teton Page 12

TROUBLESHOOTING

PROBLEM REASON SOLUTION

PUMP NOT PRIMING No power Fill strainer pot with water and close lid.

Ensure plumbing valves are open.

Check basket to make sure seated correctly and reinstall lid.

Check lid for cracks and lid o-ring for flat spots or cracking.

Check intake and discharge union fittings for cracks or

loose connection. Replace or tighten. Connections must

be alright.

MOTOR IS NOT

TURNING

Circuit breaker has

tripped or has no

power

Reset circuit breaker and/or GFCI.

Check electric supply to verify power supply is present.

Test a secondary location if needed.

Capacitor failure. This may be tested. Call for details.

Bearing seized. Rotate motor shaft by hand to test.

If shaft does not freely spin, replace bearings.

LOW FLOW Water flow has slowed

or is intermittent

Low water

in the strainer pot

Clean filter basket of debris.

Check for impeller clog. See disassembly instructions or

call for details.

Check for leaks in volute housing, lid and union connections.

Check for obstructions in plumbing and clear if found.

Seems overly hot and is

shutting down or

shutting off and on

intermittenly

MOTOR

OVERHEATING

Possible incorrect wiring. Have an electrician test.

Test breaker. Replace if needed.

Increase airflow if restricted.

If pump is located in direct sunlight, try providing a properly

vented shade covering.

Water leaking between

motor and pump

housing

Water leaking at

lid or union

Replace mechanical seal and bracket o-ring.

Inspect brass inserts in volute housing.

Check lid or union nut for cracks. Replace if needed.

Check lid or union o-rings for cracking or flat spots.

Replace if needed.

PUMP IS

LEAKING

Teton Page 13

WARRANTY

• This product is warranted to the initial purchaser

to be free of defects in materials and manufacture

workmanship at the time of initial purchase and for

a period of 2 years after. Some parts are consumable

(e.g. rubber gaskets and o-rings) and may need to

be replaced as part of ongoing product maintenance

and are not covered by this Warranty. In the event

this unit malfunctions within 2 years from the date

of purchase, the sole obligation of Teton Dynamics

(hereinafter referred to as Teton) will be to repair

the unit or replace with an equivalent new or factory

refurbished unit at Teton’s discretion, subject to the

following condition:

• The malfunction is proved attributable to a

defect in materials or manufacture workmanship,

including repairs performed under this warranty.

Malfunction for any other reason including but

not limited to misuse, negligence, accident, or

tampering with parts, incorrect wiring, or im

proper installation will not be remedied under

this warranty.

• Teton specifically does not guarantee chemical

compatibility, and expressly does not warrant

units from any problems caused by chemical

attack or failure due to incompatibility of fluid

used near this aeration system.

• All warranty repairs must be performed by Teton

or a Teton authorized company.

• Purchaser must retain the purchase receipt

and present it with this certificate as proof of

ownership and entitlement to warranty repairs.

Unauthorized repairs will not be compensated

by Teton, and are not the responsibility of Teton,

and if such repairs damage the product, such

damages are not remedied under this warranty.

• Purchaser shall bear all onsite labor, shipping,

packing and insurance costs and all other costs,

excluding in house labor and parts necessary to

effectuate repairs under this warranty.

• This warranty is in lieu of all other express

warranties which now or hereafter might otherwise

arise with respect to this product. Any and all

limited warranties, including the warranties of

merchantability and fitness for particular

purpose, shall have no greater duration than the

duration period of the express written warranty

applicable to this product, and shall terminate

automatically the expiration of such duration

period.

•Some states do not allow limitations on how

long an implied warranty lasts, so the above

limitation may not apply to you. No action shall

be brought for breach of any implied or

express warranty after one year subsequent to the

expiration of the duration period of the express

written warranty.

•Incidental and consequential damages caused

by malfunction, defect, or otherwise, and with

respect to breach of any express or implied

warranty, are not the responsibility of Teton, and to

the extent permitted by law, are hereby excluded

for property damage, loss of livestock and, to the

extent not unconscionable, for personal injury

damage. Some states do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation or exclusion may

not apply to you.

•This warranty does not apply to any malfunction

arising out of any application of this product

other than normal use, unless such application is

upon request specifically approved in writing by

Teton.

•The provisions of this warranty are severable

and if any provision shall be deemed invalid, the

remaining provisions shall remain in full force and

effect.

•Rights under this warranty are not assignable

without the express prior consent in writing

by Teton and, regardless of the terms of such

consent in writing, such assignee shall have no

greater rights than his assignor had against

Teton.

Please consult your retailer for quality original Teton® replacement parts.

Visit www.tetonus.com for your nearest dealer.

800.752.0399

info@tetonus.com

Teton Page 14

THIS SECTION IS INTENTIONALLY LEFT BLANK.

Teton Dynamics

P.O. Box 3031

San Leandro, CA 94578-0031

800.752.0399

info@tetonus.com

This manual suits for next models

6

Table of contents

Popular Water Pump manuals by other brands

Elektro Maschinen

Elektro Maschinen WPEm 7000/50R Operating instruction

Wilo

Wilo HiMulti 3 P Series Installation and operating instructions

Williamson

Williamson 400 Series Operator's guide

Regulus

Regulus Solar 1 manual

salmson

salmson Claris home Installation and starting instructions

Grundfos

Grundfos MAGNA1 D Installation and operating instructions

D-D The Aquarium Solution

D-D The Aquarium Solution Funktion Product user manual

Bosch

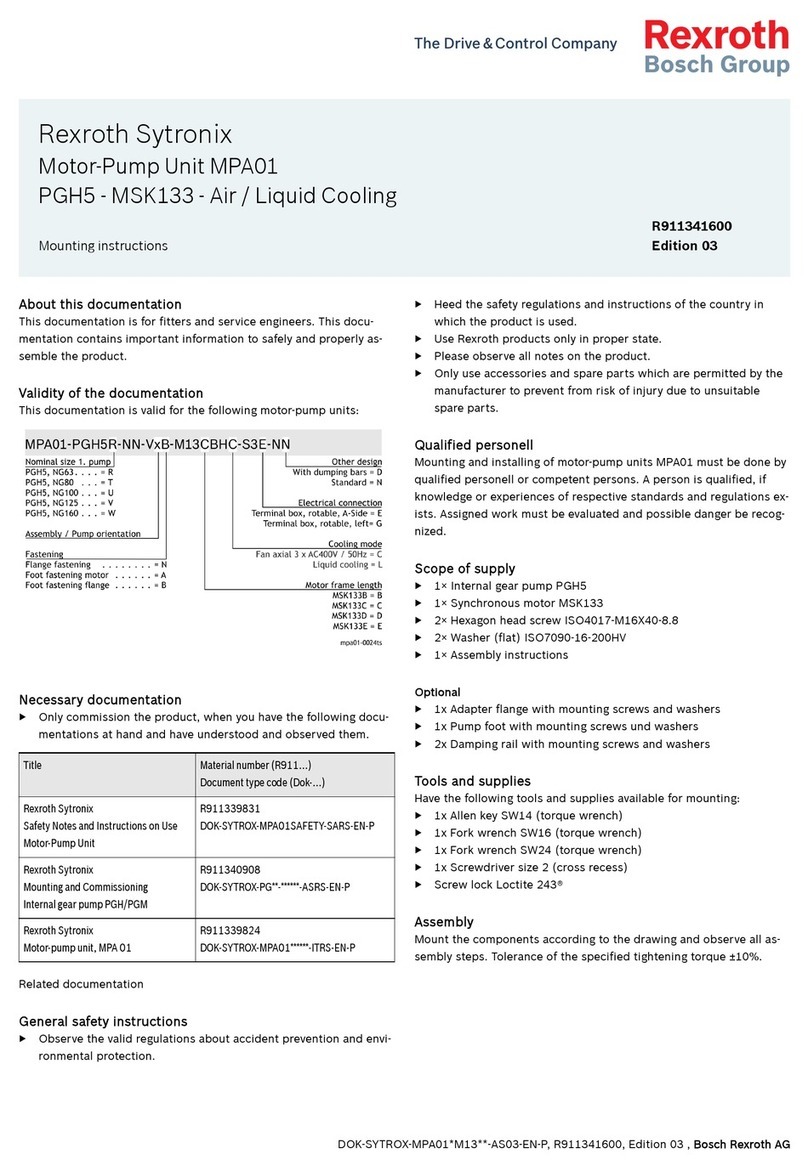

Bosch Rexroth PGH5-MSK133-Air Mounting instructions

Intex

Intex 602 owner's manual

Watson Marlow Pumps

Watson Marlow Pumps 730 En Installation, operating and maintenance manual

Pumpex

Pumpex K 152 Service instructions

DINKO Instruments

DINKO Instruments A-60-F manual