SUMMARY

REVISION OF THE MANUAL..................................................................5

INTRODUCTION......................................................................................6

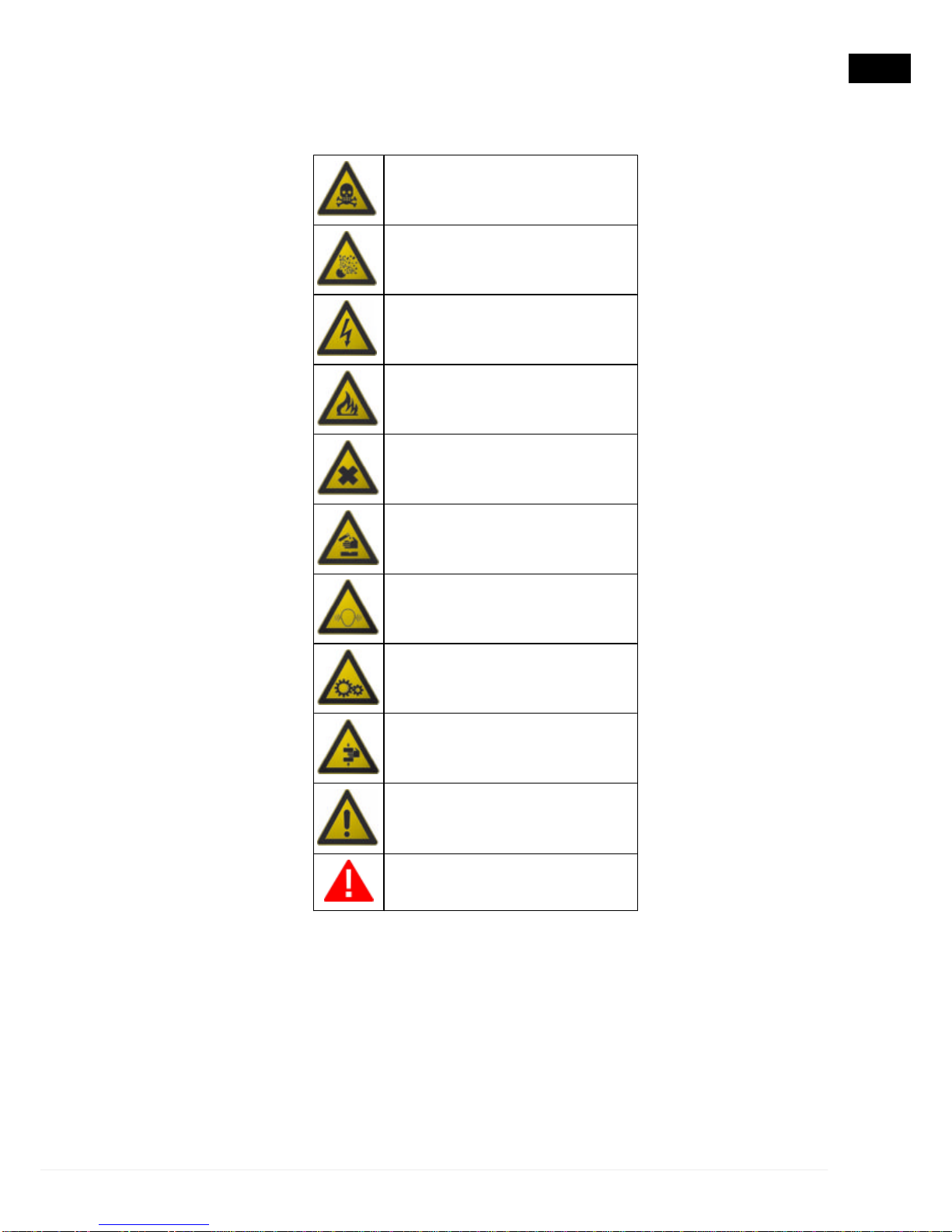

1 LEGEND OF THE SYMBOLS USED..................................................7

2 GENERAL SAFETY REGULATIONS.................................................8

2.1 Glossary.................................................................................................8

2.2 Operator Safety Regulations..................................................................8

2.2.1 General Safety Regulations........................................................................8

2.2.2 Risk of Asphyxiation...................................................................................8

2.2.3 Risk of Impact and Crushing.......................................................................8

2.2.4 Hazards Caused by Moving Parts..............................................................9

2.2.5 Risk of Burning or Scalding........................................................................9

2.2.6 Fire and Explosion Hazard.......................................................................10

2.2.7 Noise Hazard............................................................................................10

2.2.8 High Voltage Hazard.................................................................................10

2.2.9 Poisoning Hazard.....................................................................................11

2.3 General User and Maintenance Warnings...........................................11

3 SPECIFIC USER SAFETY RULES FOR RDC Tool.........................12

3.1 Glossary...............................................................................................12

3.2 General Rules......................................................................................12

3.3 Operator Safety....................................................................................12

3.4 Tool Safety...........................................................................................12

4 NORMATIVE INFORMATION...........................................................14

5 RDC Tool..........................................................................................16

6 DESCRIPTION..................................................................................17

7 TECHNICAL FEATURES..................................................................18

8 CONNECTIVITY ..............................................................................20

9 User Instructions...............................................................................21

9.1 Power supply........................................................................................21

9.2 Charge..................................................................................................22

9.2.1 Charging from the Mains..........................................................................23

3

en