User's Guide

SLUUA25C–October 2012–Revised June 2013

bq51050BEVM-764, Integrated Wireless Power Li-Ion

Charger Receiver

The bq51050BEVM (HPA764-002) wireless power receiver evaluation kit from TI is a high-performance,

easy-to-use development kit for the design of wireless power solutions. It helps designers to evaluate the

operation and performance of the bq51050B (WCSP package), a direct Li-Ion charge controller for

wireless power transfer. The bq51050B device provides the AC/DC power conversion, integrates the

digital controller required to comply with the Qi v1.1 communication protocol, and Li-Ion charge controller.

The kit speeds up the development of end-use applications.

Contents

1 Introduction .................................................................................................................. 2

2 Considerations with this EVM ............................................................................................. 2

3 Modifications ................................................................................................................. 2

4 Recommended Operation Condition ..................................................................................... 3

5 Equipment and EVM setup ................................................................................................ 3

5.1 Schematic ........................................................................................................... 3

5.2 Connector and Test Point Descriptions ......................................................................... 4

5.3 Jumpers and Switches ............................................................................................ 4

5.4 Test Point Descriptions ............................................................................................ 4

5.5 Pin Description of the IC .......................................................................................... 6

6 Test Procedure .............................................................................................................. 6

6.1 Definition ............................................................................................................ 6

6.2 Recommended Test Equipment ................................................................................. 7

6.3 Equipment Setup ................................................................................................... 7

6.4 Procedure ........................................................................................................... 9

7 Test Results ................................................................................................................ 10

7.1 Start up to Fast-Charge Mode .................................................................................. 10

7.2 Start up to Pre-Charge Mode ................................................................................... 10

7.3 Pre-charge to Fast-Charge Transition ......................................................................... 11

7.4 Fast Charge to Taper and Termination Transition ........................................................... 11

7.5 Efficiency Data .................................................................................................... 12

7.6 Thermal Performance ............................................................................................ 13

8 Layout and Bill of Material ................................................................................................ 14

8.1 Layout .............................................................................................................. 14

8.2 Bill of Materials (BOM) ........................................................................................... 20

List of Figures

1 HPA764-Revision B Schematic ........................................................................................... 3

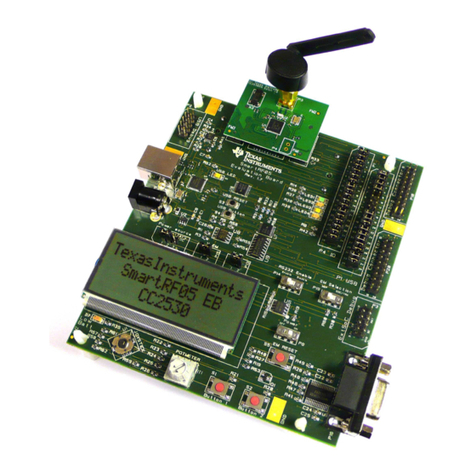

2 Test Set up .................................................................................................................. 7

3 Battery Emulator ........................................................................................................... 8

4 Start-Up to Fast-Charge Mode .......................................................................................... 10

5 Start-Up to Pre-charge Mode ........................................................................................... 10

6 Pre-charge to Fast-Charge Transition ................................................................................. 11

7 Fast Charge to Taper and Termination Transition ................................................................... 11

8 Efficiency Versus Output Power (AC Input to DC Output)........................................................... 12

bqTESLA is a trademark of Texas Instruments, Inc..

1

SLUUA25C–October 2012–Revised June 2013 bq51050BEVM-764, Integrated Wireless Power Li-Ion Charger Receiver

Submit Documentation Feedback Copyright © 2012–2013, Texas Instruments Incorporated