Greenlee / A Textron Company 2 4455BoeingDr.•Rockford,IL61109-2988USA•815-397-7070

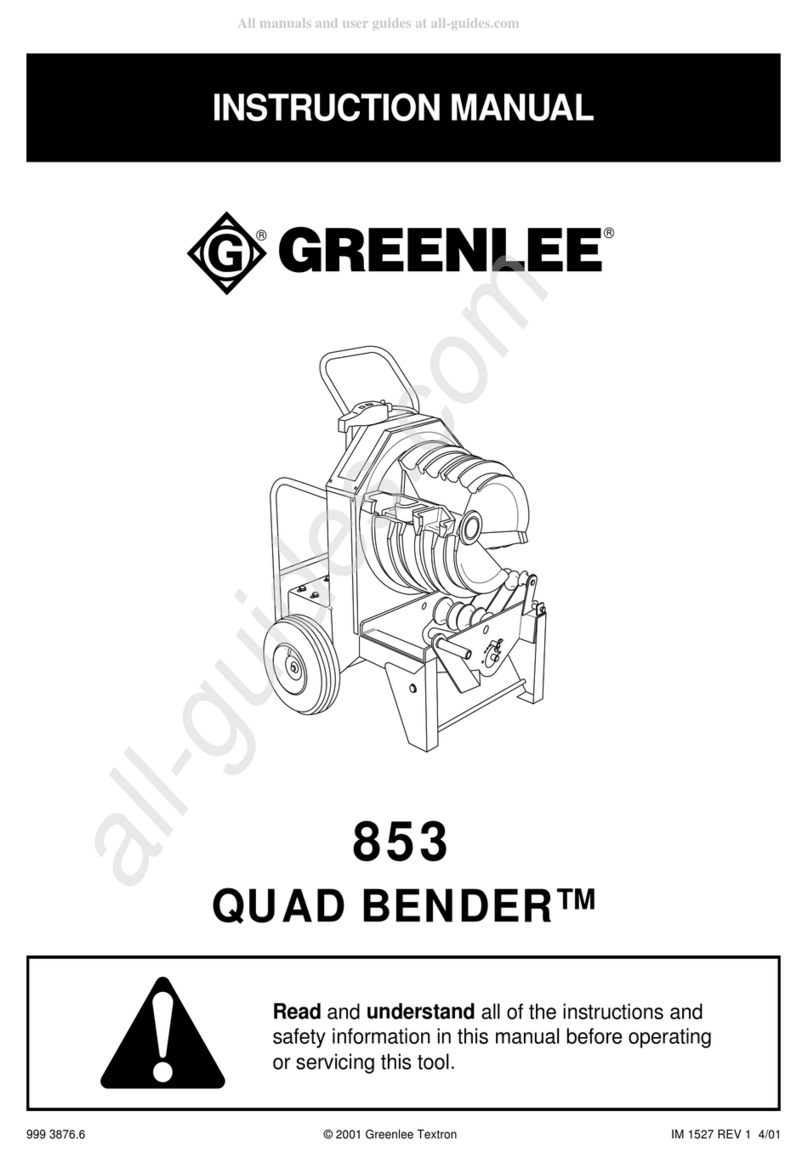

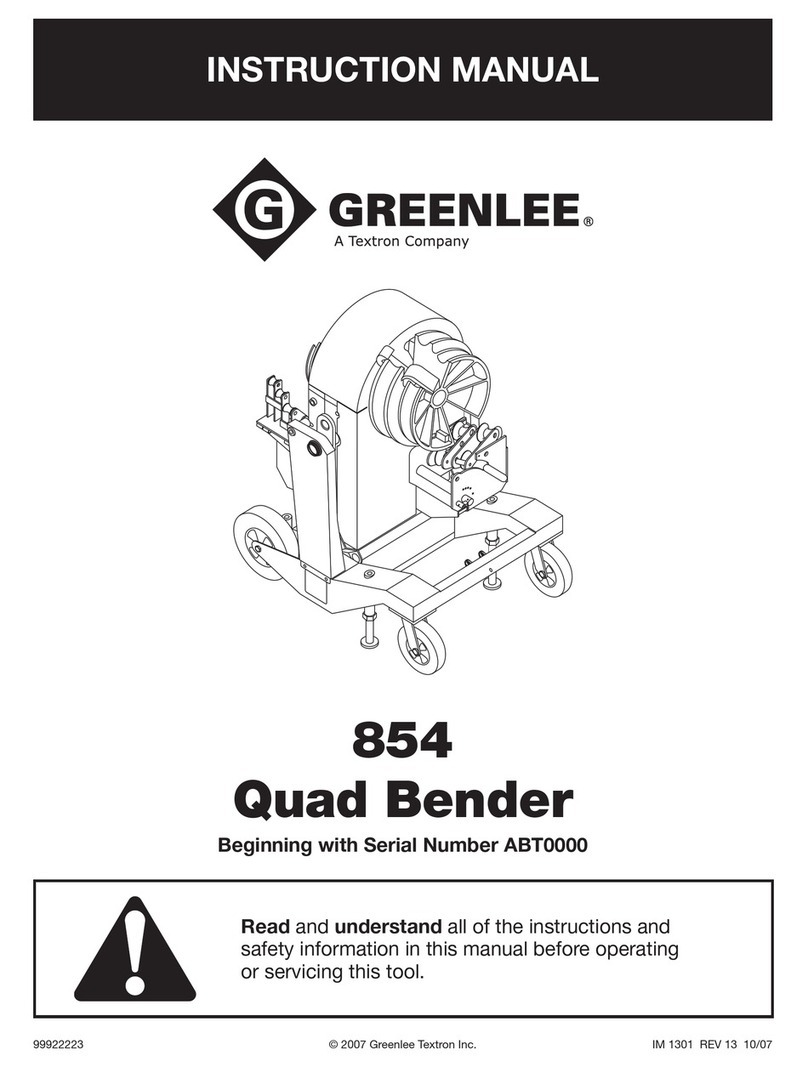

1818 Mechanical Bender

Allspecicationsarenominalandmaychangeasdesignimprove-

ments occur. Greenlee Textron Inc. shall not be liable for damages

resulting from misapplication or misuse of its products.

KEEP THIS MANUAL

Table of Contents

Description ..................................................................... 2

Safety ............................................................................. 2

Purpose of this Manual .................................................. 2

ImportantSafetyInformation ......................................... 3

Instructions for Bending..............................................4-8

SpecialBendingInformation .....................................9-11

SpecialBendingInformationCharts .......................12-17

French .....................................................................19-35

Illustration..................................................................... 37

PartsList ...................................................................... 38

Description

Capacity

3/4"–2"EMT

1/2"–1-1/4"IMC

1/2"–1-1/2"GalvanizedRigidConduit

2"Aluminum(only)RigidConduit

Note: Radius of bend is clearly marked on each

bending shoe.

The1818MechanicalBenderisdesignedforyearsof

dependabletrouble-freeservice.

Thesefeaturesmakethe1818benderoneofthemost

versatiletimesavingtoolsonthemarket.

• Built-InRatchet—letsyouapplyshort,powerful

strokesforfasterbending.

• ShoeLocator—makesloadingeasy.Shoerotationis

restricted.

• BendingDegreeIndicator—helpsassureaccurate

bends every time.

• FollowBars—producesmoothbendsin1-1/4",

1-1/2"and2"EMTwithoutkinksorwrinkles.

• RubberWheels—provideeasyportabilityintheshop

or on the jobsite.

• StrongFrame—keepsbenderinplaceduring

bending.

• Speed-bendMode—bypassesratchetforfast,direct

bendingofsmallersizesofconduit.

Features that make the 1818 superior

• Nostorageboxrequired.Alloftheshoesmaybe

stored on the bender.

Note: Bender holds follow bars, rollers and pins so the

complete unit may be chained to a post for security.

• Thecarriageminimizesdeectionwhenbendinglarger

conduit.

• Thesteelmainframedoesnotrequireatiebartosup-

port the bending system.

• Theshoeandratchetsegmentunitisautomatically

retainedbythefrictionbuttonwhenloadingthecon-

duit.Thelocksystemreleasesautomatically.

• Theframeunitacceptsexisting1818shoes,cushion

rollerandfollowbars.

Safety

Safetyisessentialintheuseandmaintenanceof

Greenleetoolsandequipment.Thisinstructionmanual

andanymarkingsonthetoolprovideinformationfor

avoidinghazardsandunsafepracticesrelatedtothe

use of this tool. Observe all of the safety information

provided.

Purpose of this Manual

Thisinstructionmanualisintendedtofamiliarizeperson-

nelwiththesafeoperationandmaintenanceprocedures

fortheGreenlee1818MechanicalBender.

Keep this manual available to all personnel.

Replacementmanualsareavailableuponrequest

atnochargeatwww.greenlee.com.