TGW IntelliROL Power Supply 1166694PULS Use and maintenance manual

Application Control Guidelines

IntelliROL®Power Supply™

P/N 1176718

Revision Date: February 17, 2021

P/N: 1176718 REV: 02/17/2021 Page 2of 32

TABLE OF CONTENTS

LIST OF TABLES ......................................................................................................................................... 3

1.1: TGW SAFETY RECOMMENDATION ......................................................................................................... 4

CHAPTER 2: WARNINGS AND SAFETY INSTRUCTIONS ....................................................................... 6

CHAPTER 3: INTRODUCTION .................................................................................................................... 7

3.1: OVERVIEW ........................................................................................................................................... 7

CHAPTER 4: TGW PARTS LIST ................................................................................................................. 8

CHAPTER 5: FEATURES .......................................................................................................................... 11

5.1: ALL INTELLIROL POWER SUPPLIES ..................................................................................................... 11

5.2: POWER SUPPLY FEATURES................................................................................................................. 12

5.3: DIAGNOSTIC RELAY ............................................................................................................................ 13

5.4: TERMINAL STRIP CONNECTIONS .......................................................................................................... 14

CHAPTER 6: ITR COMBINATION POWER SUPPLIES ........................................................................... 15

CHAPTER 7: CONNECTIONS ................................................................................................................... 17

7.1: INTERNAL TO POWER SUPPLY ............................................................................................................. 17

7.2: AT CONVEYOR EQUIPMENT ................................................................................................................. 18

CHAPTER 8: APPLICATION ..................................................................................................................... 19

CHAPTER 9: STATUS INDICATORS........................................................................................................ 20

CHAPTER 10: TROUBLESHOOTING GUIDE .......................................................................................... 21

10.1: INTELLIROL STANDARD AND COMBINATION POWER SUPPLIES............................................................ 21

10.2: INTELLIROL COMBINATION POWER SUPPLIES.................................................................................... 23

CHAPTER 11: SPECIFICATIONS ............................................................................................................. 26

11.1: ITR STANDARD AND COMBINATION (480VAC INPUT) ......................................................................... 26

11.2: ITR STANDARD AND COMBINATION (208/240VAC INPUT) .................................................................. 27

11.3: ITR STANDARD AND COMBINATION (120VAC INPUT) ......................................................................... 28

11.4: CLASS 2PROTECTION MODULE......................................................................................................... 29

11.5: CRUZCONTROL TECHNICAL DATA..................................................................................................... 30

WORKS CITED........................................................................................................................................... 31

TGW GENERAL INFORMATION ................................................................................................................... 31

TGW SYSTEMS INFORMATION ............................................................................................................... 32

P/N: 1176718 REV: 02/17/2021 Page 3of 32

LIST OF TABLES

Table 1: IntelliROL Power Supply Listing ....................................................................................8

Table 2: IntelliROL Standard Power Supply Status Indicators ...................................................20

Table 3: IntelliROL Combination Power Supply Status Indicators .............................................20

Table 4: IntelliROL Standard and Combination Power Supply Troubleshooting Guide ..............21

Table 5: IntelliROL Combination Power Supply Troubleshooting Guide ....................................23

Table 6: IntelliROL Standard and Combination Power Supplies (480VAC Input).......................26

P/N: 1176718 REV: 02/17/2021 Page 4of 32

1.1: TGW SAFETY RECOMMENDATION

TGW Systems Equipment Warranty

TGW Systems warrants that the material and

workmanship entering into its equipment is

merchantable and will be furnished in accordance with

the specifications stated.

TGW Systems agrees to furnish the purchaser without

charge any part proved defective within 2 years from

date of shipment provided the purchaser gives TGW

Systems immediate notice in writing and examination

proves the claim that such materials or parts were

defective when furnished. For drive components

specific to XenoROL® (i.e. Xeno belts, slave Xeno

belts, drive spools, standard and speed-up, and

spacers), this warranty shall be extended to five years

of running use, provided the conveyors are applied,

installed and maintained in accordance with TGW

Systems published standards. Other than the above,

there are no warranties which extend beyond the

description on the face hereof. Consequential damages

of any sort are wholly excluded.

The liability of TGW Systems will be limited to the

replacement cost of any defective part. All freight and

installation costs relative to any warranted part will be at

the expense of the purchaser. Any liability of TGW

Systems under the warranties specified above is

conditioned upon the equipment being installed,

handled, operated, and maintained in accordance with

the written instructions provided or approved in writing

by TGW Systems.

The warranties specified above do not cover, and TGW

Systems makes no warranties which extend to, damage

to the equipment due to deterioration or wear

occasioned by chemicals, abrasion, corrosion or

erosion; Purchaser's misapplication, abuse, alteration,

operation or maintenance; abnormal conditions of

temperature or dirt; or operation of the equipment

above rated capacities or in an otherwise improper

manner.

THERE ARE NO WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, EXTENDING

BEYOND THOSE SET FORTH IN THIS STATEMENT

OF WARRANTY.

Rev 03/01/2019

TGW Environment Standards

TGW equipment is designed to be installed in

a clean, dry warehouse environment.

Exposure to extreme humidly, direct sunlight,

blowing dirt or rain can permanently damage

some components of TGW conveyor. In

particular, the curing agents in concrete are

known to attack and degrade the urethane

conveyor components.

When installing conveyor on a new

construction site, be sure that the concrete is

properly cured before setting conveyor on it.

In addition, if conveyors are stored in the

proximity of curing concrete, proper

ventilation must be used to direct the curing

agent fumes away from the conveyor.

Failure to comply with these guidelines will

void the TGW warranty on any failed

components that result from these

environment issues.

03/01/2019

P/N: 1176718 REV: 02/17/2021 Page 5of 32

•Safety: Always lock out power source and follow recommended safety

procedures.

WARNING

P/N: 1176718 REV: 02/17/2021 Page 6of 32

Chapter 2: WARNINGS AND SAFETY INSTRUCTIONS

Failure to follow the instructions and

cautions throughout this manual and

warning label on the conveyor may

result in injury to personnel or damage

to the equipment.

Your TGW Systems conveyor is

powered by a motor and can be stopped

only by turning off electrical power to the

motor. As with all powered machinery,

the drive-related components – including

sprockets, chains, shafts, universal

joints, and pneumatic devices – can be

dangerous. We have installed or

provided guards to prevent accidental

contact with these parts, along with

warning labels to identify the hazards.

Special attention must be paid to the

following areas of this manual:

•Indicates a potentially hazardous

situation, which, if not avoided,

could result in death or serious

injury.

•Indicates a situation, which, if not avoided,

could result in property damage.

WARNING

CAUTION

P/N: 1176718 REV: 02/17/2021 Page 7of 32

Chapter 3: INTRODUCTION

3.1: OVERVIEW

The IntelliROL product line includes power supplies that convert various AC power sources to

24VDC power sources. These power supplies are used to supply power to the motorized roller

components included in our IntelliROL product line. Power supplies are available for most

standard input voltages. Available output currents include 10, 20, 40 and 80 amperes.

IntelliROL power supplies are available with internal branch circuit protection. If branch circuit

protection is already provided upstream by others, IntelliROL power supplies are available

without internal branch circuit protection at a lower cost. All IntelliROL power supplies are

designed and built to UL508A standards. Refer to Table 1: IntelliROL Power Supply Listing for

a list of available power supplies.

P/N: 1176718 REV: 02/17/2021 Page 8of 32

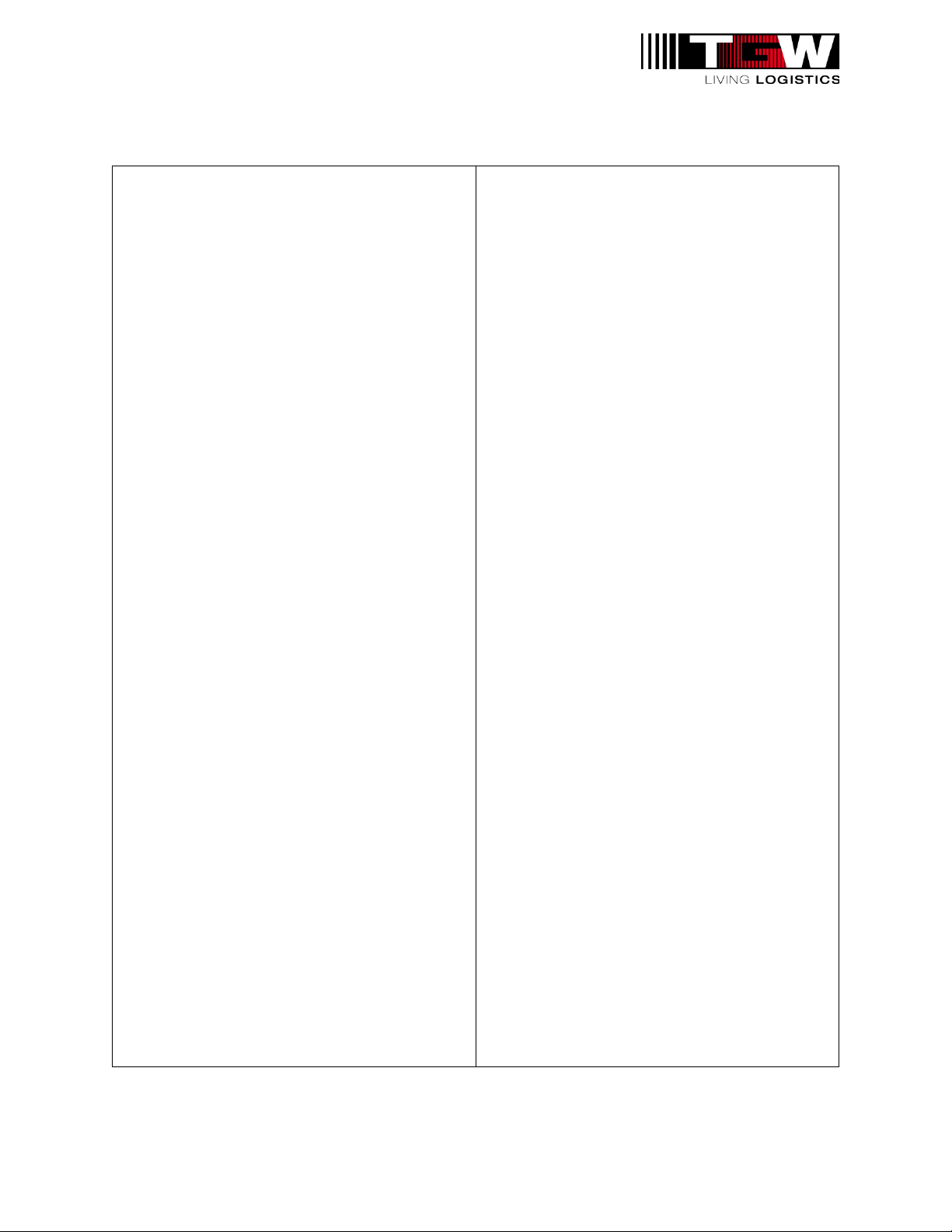

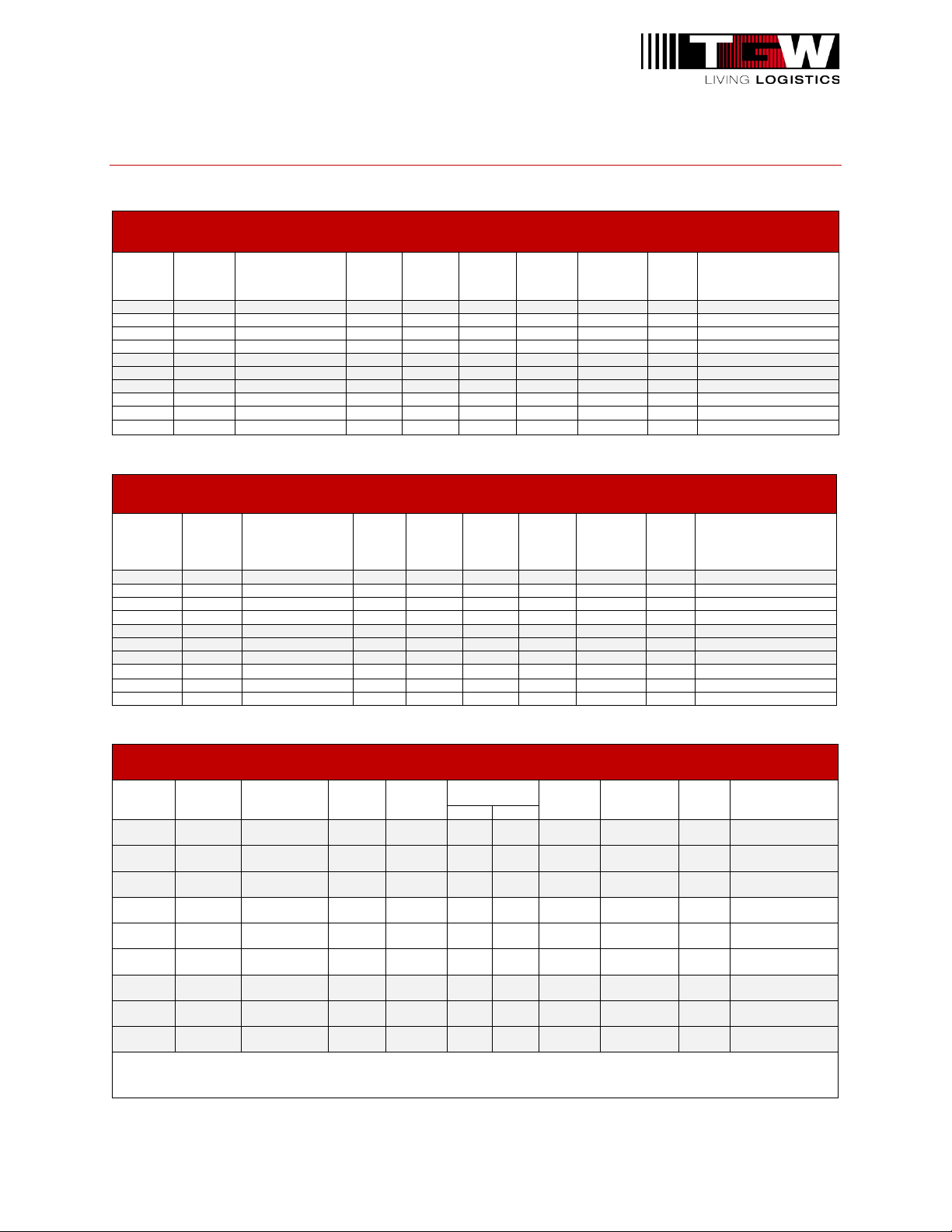

Chapter 4: TGW PARTS LIST

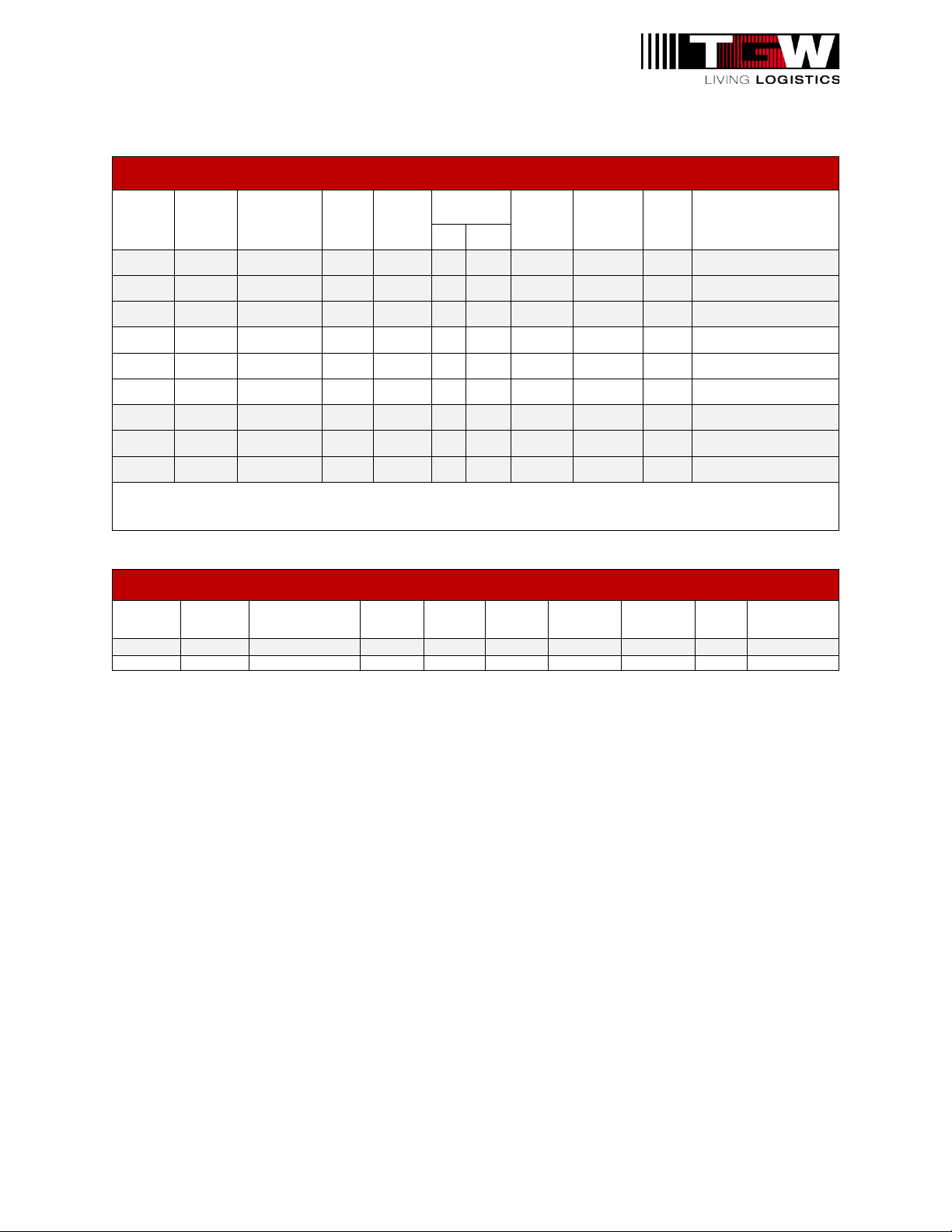

Table 1: IntelliROL Power Supply Listing

24VDC STANDARD POWER SUPPLIES WITH BRANCH CIRCUIT PROTECTION FOR INTELLIROL

TGW

Item

Number

Drawing

Number

Input Voltage

Power

Supply

Size

Input

Current

Output

Current

Number

of MDR

Enclosure

Type

UL

Listed

Enclosure Dimensions

(H x W x D)

1176603

130E233

480VAC/3PH/60HZ

80A

2.8A

80A

36

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160913

130E115

480VAC/3PH/60HZ

40A

1.4A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160948

130E117

240VAC/3PH/60HZ

40A

4.5A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160950

130E119

120VAC/1PH/60HZ

40A

8.6A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160915

130E116

480VAC/3PH/60HZ

20A

0.65A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160949

130E118

240VAC/3PH/60HZ

20A

2.23A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160951

130E120

120VAC/1PH/60HZ

20A

4.64A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166694

130E174

480VAC/3PH/60HZ

10A

0.6A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166695

130E175

240VAC/2PH/60HZ

10A

1.13A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166696

130E176

120VAC/1PH/60HZ

10A

2.15A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

24VDC STANDARD POWER SUPPLIES WITHOUT BRANCH CIRCUIT PROTECTION FOR INTELLIROL

TGW Item

Number

Drawing

Number Input Voltage

Power

Supply

Size

Input

Current

Output

Current Number

of MDR

Enclosure

Type

UL

Listed

Enclosure Dimensions

(H x W x D)

1176628

130E234

480VAC/3PH/60HZ

80A

2.8A

80A

36

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1159645

130E121

480VAC/3PH/60HZ

40A

1.4A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160953

130E123

240VAC/2PH/60HZ

40A

4.5A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160955

130E125

120VAC/1PH/60HZ

40A

8.6A

40A

18

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1159647

130E122

480VAC/3PH/60HZ

20A

0.65A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160954

130E124

240VAC/2PH/60HZ

20A

2.23A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160956

130E126

120VAC/1PH/60HZ

20A

4.64A

20A

9

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166697

130E177

480VAC/3PH/60HZ

10A

0.6A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166698

130E178

240VAC/2PH/60HZ

10A

1.13A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166699

130E179

120VAC/1PH/60HZ

10A

2.15A

10A

3

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

24VDC COMBINATION POWER SUPPLIES WITH BRANCH CIRCUIT PROTECTION FOR INTELLIROL AND CRUZCONTROL

TGW

Item

Number

Drawing

Number Input Voltage

Power

Supply

Size

Input

Current

Output

Current

Number

of MDR

Enclosure

Type

UL

Listed

Enclosure

Dimensions

(H x W x D)

ITR

CRUZ

1160917

130E103

480VAC/3PH/

60HZ

40A

1.4A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1160919

130E105

240VAC/2PH/

60HZ

40A

4.5A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1160921

130E107

120VAC/1PH/

60HZ

40A

8.6A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1160918

130E104

480VAC/3PH/

60HZ

20A

0.65A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1160920

130E106

240VAC/2PH/

60HZ

20A

2.23A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1160922

130E108

120VAC/1PH/

60HZ

20A

4.64A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1166700

130E180

480VAC/3PH/

60HZ

10A

0.6A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1166701

130E181

240VAC/2PH/

60HZ

10A

1.13A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

1166702

130E182

120VAC/1PH/

60HZ

10A

2.15A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4"

X 7-7/8"

Combination power supplies split the output current between the MDR supply and the Class 2 supply. The Class 2 supply can use up to

3.7A, in which case the MDR supply would have 36.3A available from a 40A supply.

P/N: 1176718 REV: 02/17/2021 Page 9of 32

24VDC COMBINATION POWER SUPPLIES WITHOUT BRANCH CIRCUIT PROTECTION FOR INTELLIROL AND CRUZCONTROL

TGW

Item

Number

Drawing

Number

Input

Voltage

Power

Suppl

y Size

Input

Current

Output

Current

Number

of MDR

Enclosure

Type

UL

Listed

Enclosure Dimensions

(H x W x D)

IT

R

CRU

Z

1160923

130E109

480VAC/3PH/

60HZ

40A

1.4A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160925

130E111

240VAC/2PH/

60HZ

40A

4.5A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160927

130E113

120VAC/1PH/

60HZ

40A

8.6A

36

4

17

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160924

130E110

480VAC/3PH/

60HZ

20A

0.65A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160926

130E112

240VAC/2PH/

60HZ

20A

2.23A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1160928

130E114

120VAC/1PH/

60HZ

20A

4.64A

16

4

8

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166703

130E183

480VAC/3PH/

60HZ

10A

0.6A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166704

130E184

240VAC/2PH/

60HZ

10A

1.13A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

1166705

130E185

120VAC/1PH/

60HZ

10A

2.15A

6

4

2

Type 12

Yes

15-3/4" X 15-3/4" X 7-7/8"

Combination power supplies split the output current between the MDR supply and the Class 2 supply. The Class 2 supply can use up to

3.7A, in which case the MDR supply would have 36.3A available from a 40A supply.

MOTOR CONTROL 24VDC POWER SUPPLIES FOR INTELLIROL (USED ONLY WITH MOTORS W/O VFD)

TGW Item

Number

Drawing

Number Input Voltage

Power

Supply

Size

Input

Current

Output

Current

Number of

MDR

Enclosure

Type

UL

Listed

Enclosure

Dimensions

(H x W x D)

1145931

130E043

480VAC/3PH/60HZ

20A

0.65A

20A

9

Type 12

Yes

12"X 12" X 8"

1145930

130E042

480VAC/3PH/60HZ

10A

0.6A

10A

3

Type 12

Yes

12"X 12" X 8"

P/N: 1176718 REV: 02/17/2021 Page 10 of 32

IntelliROL Standard Power Supply,

External View

IntelliROL Standard Power Supply, Internal View

P/N: 1176718 REV: 02/17/2021 Page 11 of 32

Chapter 5: FEATURES

5.1: ALL INTELLIROL POWER SUPPLIES

Lockable Disconnect Switch

All IntelliROL power supplies include a lockable disconnect switch. This allows for lockout/tagout at the

power supply.

IntelliROL Power Supply Lockable Disconnect Switch

Internal Branch Circuit Protection

IntelliROL power supplies are available with internal branch circuit protection. If proper branch

circuit protection is not available upstream of the IntelliROL power supply, the power supply

should be purchased with branch circuit protection built in.

Output Current Boost

Each IntelliROL power supply can provide a boost in output current over its nominal rating. The

extra current is available for a short period of time. Since IntelliROL conveyor draws maximum

current at startup, this current boost is a definite advantage.

P/N: 1176718 REV: 02/17/2021 Page 13 of 32

5.3: DIAGNOSTIC RELAY

The power supply unit inside each IntelliROL power supply has a diagnostic relay that can be

used to monitor the status of the unit. When the unit is powered and functioning properly, the

diagnostic relay contact will be closed.

Adjustable Output Voltage

The output voltage of the power supply units is adjustable from 24V to 28.8V. This can be used

to possibly overcome a low voltage condition, as long as the maximum voltage at any point in

the system does not exceed specifications.

Status Indicators

Status indicators are provided on the front of the power supply units internal to every IntelliROL

power supply. The Uout status indicator will be illuminated green if the output voltage is 21.6V

or greater. It will be illuminated red if the output voltage is less than 21.6V and greater than or

equal to 7V. If the output voltage is less than 7V, the indicator will not be illuminated at all.

There is also an Iout status indicator on the front of the power supply units. It will be illuminated

green if the output current is less than or equal to the rated output current. If the output current

is greater than the rated output current, the indicator will be illuminated orange. The indicator

will be illuminated red if the unit is shut off and in protection mode due to excessive output

current.

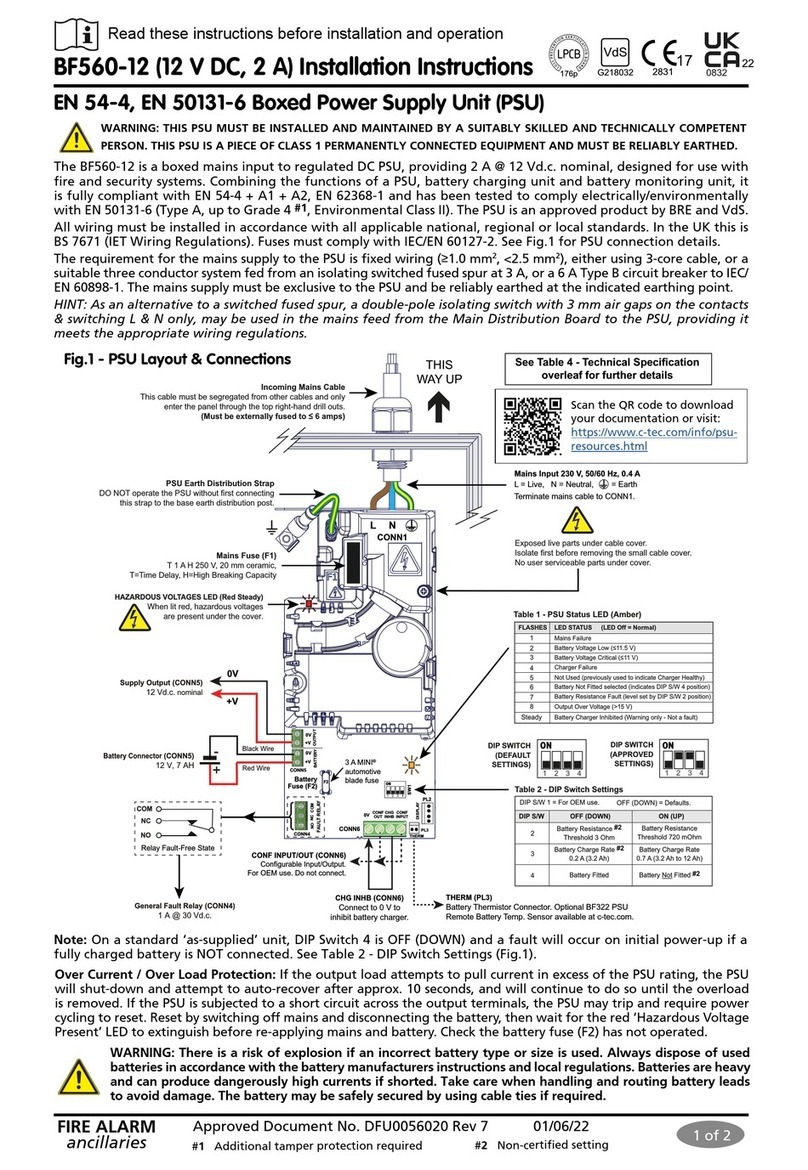

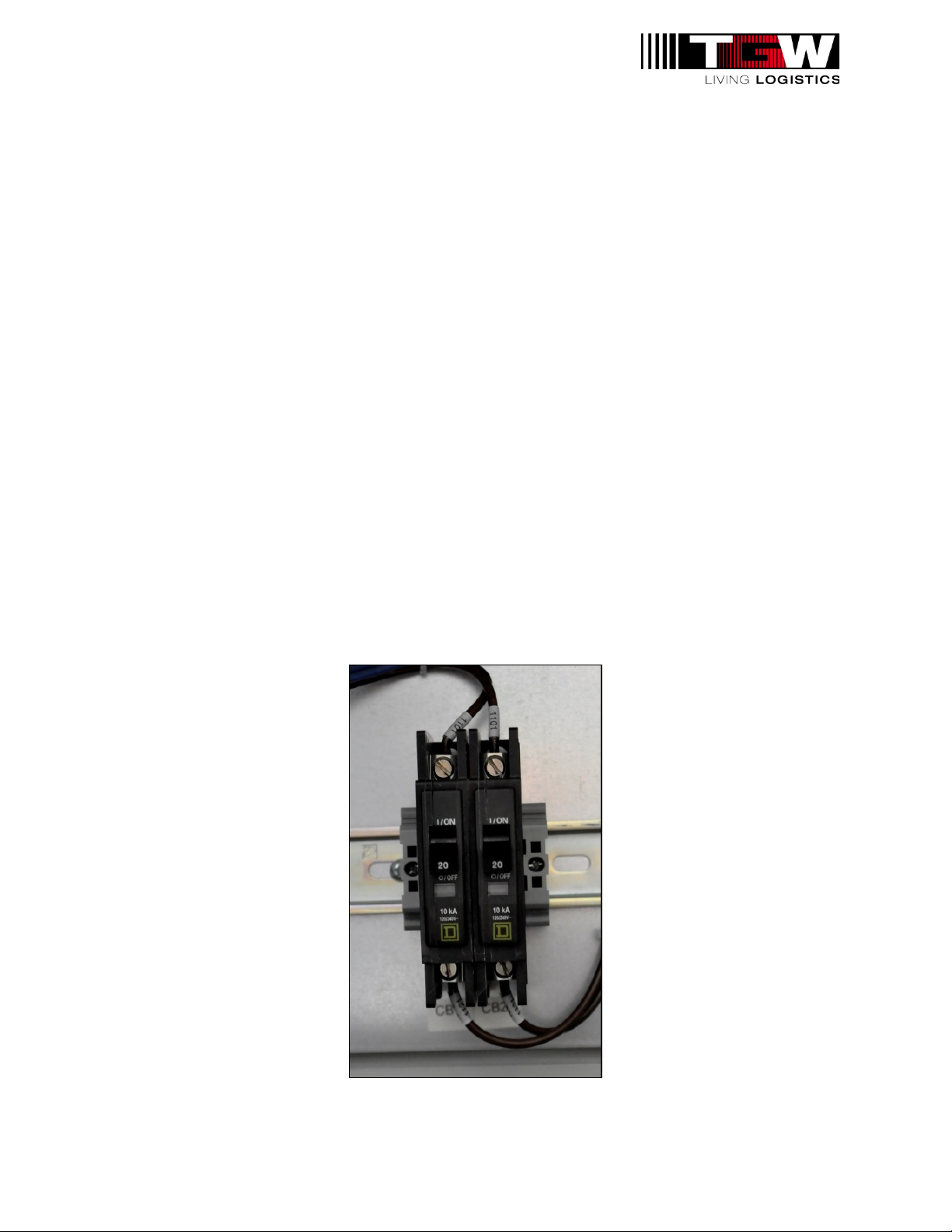

Output Circuit Protection

Every IntelliROL power supply includes circuit breaker protection of the output circuits. Power

supplies with a 10A output rating have one 10A circuit breaker. Units with a 20A output rating

have one 20A circuit breaker. Those with a 40A rating have two 20A circuit breakers, while

80A-rated units have four 20A circuit breakers.

Output Circuit Protection

P/N: 1176718 REV: 02/17/2021 Page 14 of 32

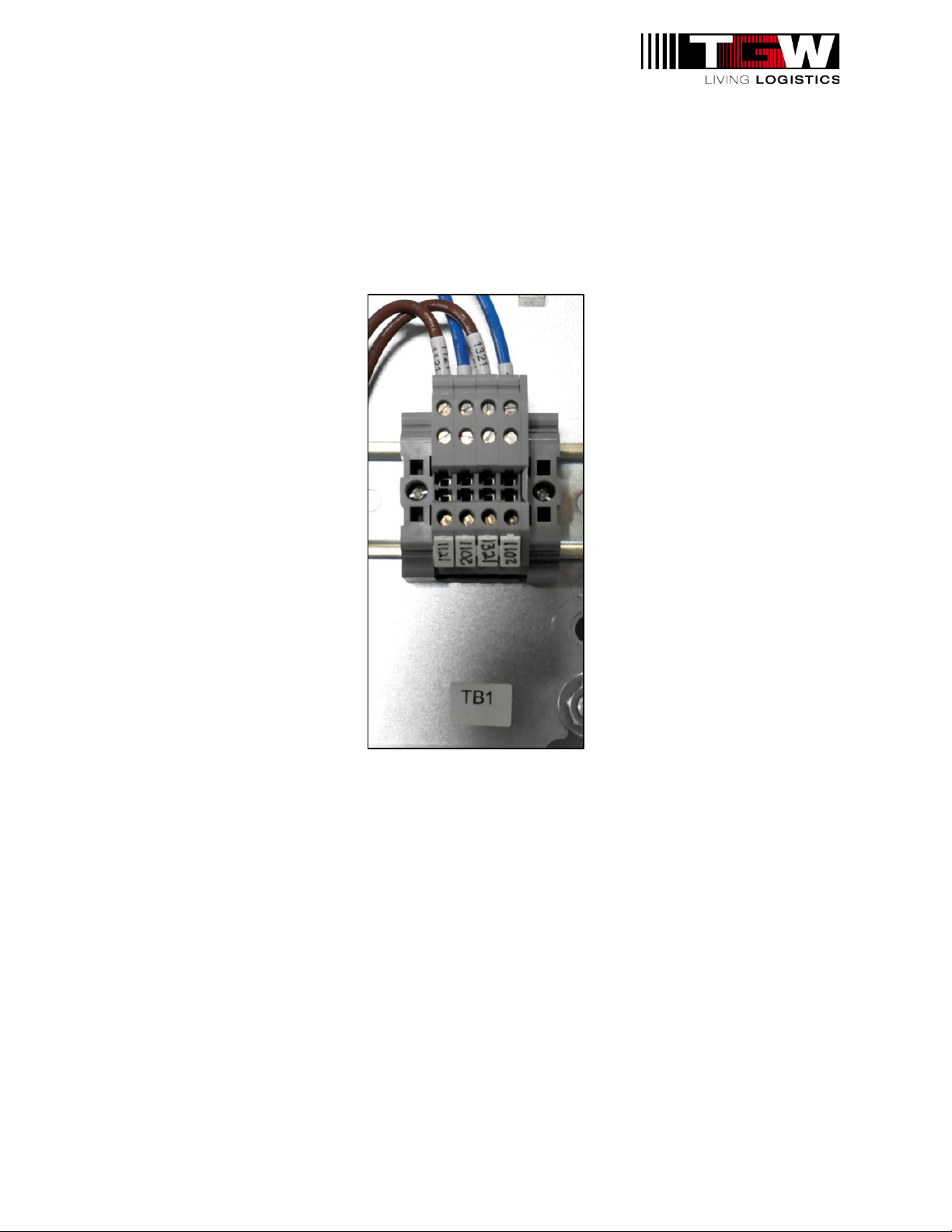

5.4: TERMINAL STRIP CONNECTIONS

All output circuit connections are made at a terminal strip. Each IntelliROL power supply has

separate terminals for two Class 1 circuits to supply power to the motorized rollers. For the

Combination power supplies, there are terminals for one Class 2 circuit to supply power to

nearby CRUZcontrol. A power harness is included with each IntelliROL power supply. This can

be used to connect the Class 1 circuits of the power supply to the power harness installed on

the IntelliROL conveyor.

IntelliROL Power Supply Terminal Strip

Splice Kit

A power splice kit is included with each IntelliROL power supply. The splice kit is used to

connect the Class 1 circuits of the power supply to the power harness installed on the IntelliROL

conveyor. These are used only in rare cases when a power supply is not installed at the bed

joint. Reference the manual drawing inside the kit for installation instructions.

Common Carrier Power Cable

A common only power cable is included with each IntelliROL power supply. This is used to keep

a common connection between separate power supplies.

P/N: 1176718 REV: 02/17/2021 Page 15 of 32

Chapter 6: ITR COMBINATION POWER SUPPLIES

Class 2 Output Circuit

IntelliROL Combination power supplies include a 24VDC Class 2 output circuit, in addition to the

Class 1 20A circuit(s). For systems with only IntelliROL products, a Standard power supply is

all that is needed. However, if a system has a mixture of IntelliROL and CRUZcontrol (NBC or

XP43), a Combination power supply can be used to power both the IntelliROL and the

CRUZcontrol. A CRUZcontrol tee cable is included with each IntelliROL Combination power

supply.

The Class 2 circuit is created by diverting some of the 24VDC power from the main power

supply unit to a Class 2 protection module. The protection module can provide up to four Class

2 circuits at 3.7A each. Only one of these circuits is wired to the terminal strip. Keep in mind,

each Class 2 circuits can use up to 3.7A from the main power supply unit. This means there is

less current available for the motorized rollers.

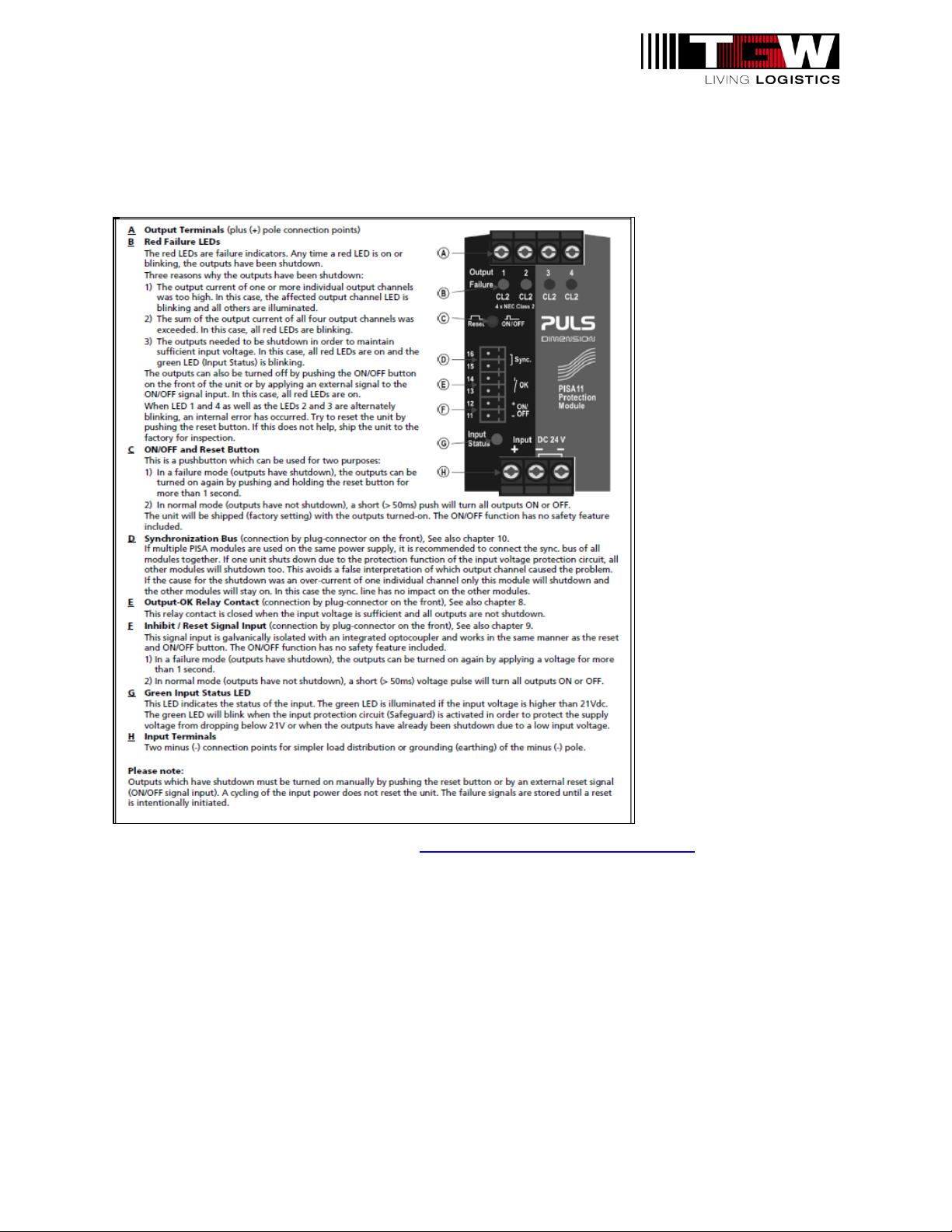

Status Indicators

The Class 2 protection module internal to each IntelliROL Combination power supply has status

indicators for the input and outputs. The Input Status indicator will be illuminated solid green

when the input voltage is above 21V. The input protection circuit will be activated if the input

voltage drops to 21V or less. If this occurs, the Input Status indicator will be flashing green.

The indicator will be off if there is no input voltage.

There are four Output Failure indicators, one for each Class 2 output circuit, on the Class 2

protection module. The status of the indicators is as follows:

•One is flashing red and the others are on solid red – excessive output current was

sensed on the output associated with the flashing indicator.

•All four are flashing red – the output current sum for all four outputs was excessive.

•All four are on solid red and the Input Status indication is flashing green – the input

voltage has dropped below 21V and the module is in input protection mode.

•All four are on solid red and the Input Status indication is on solid green – the outputs

have been turned off via the ON/OFF button or ON/OFF signal input.

•The indicators associated with outputs 1 and 4, as well as the indicators for outputs 2

and 3 are alternately flashing red – an error internal to the protection module has

occurred.

ON/OFF and Rest Button

The Class 2 protection module has one push button that serves two purposes. If the module is

faulted but the fault condition has been resolved, press and hold the ON/OFF – Reset button for

more than 1 second to reset the module. If this same button is pressed for more than 50

milliseconds, but less than 1 second, the Class 2 output circuit will switch from on to off or off to

on, depending upon their current state.

I/O Connector

An I/O connector is located on the front of the Class 2 protection module in every IntelliROL

Combination power supply. There are three functions controlled via this connector. First, the

ON/OFF – Reset function can be controller through terminals 11 and 12 of the connector. It

functions in the same manner as the push button. Second, the status of the protection module

can be monitored via the Output-OK relay. A set of dry contacts is available through terminals

P/N: 1176718 REV: 02/17/2021 Page 16 of 32

13 and 14. When the module is operating properly, the contacts will be closed. Third, multiple

modules can be synchronized using the Synchronization Bus through terminals 15 and 16. If a

module shuts down due to entering input protection mode, all synchronized modules will shut

down together.

For Puls Power Supply Information visit: http://www.pulspower.com/us/home/

P/N: 1176718 REV: 02/17/2021 Page 17 of 32

Chapter 7: CONNECTIONS

7.1: INTERNAL TO POWER SUPPLY

Incoming Power Circuits

All IntelliROL power supplies have a removable plate on the bottom of the enclosure. This plate

can be used as the entry point for cable, conduit, etc. by cutting holes in it for incoming and

outgoing power and signals. The incoming power connections are made at the line side of the

disconnect switch. There is also a ground lug for connecting the ground wire from the power

source. For power supplies that operate on 120VAC, a terminal block is provided for connection

of the neutral wire from the source of power.

Class 1 Circuits (Motorized Roller Power)

The outgoing power connections are made at the terminal strip inside the IntelliROL power

supply enclosure. Class 1 Circuit 1 is used to supply power to motorized rollers in an IntelliROL

conveyor. The power harness on the conveyor is made up of 10AWG brown and blue wires.

The brown wire should be connected to the terminal labeled 1121 on the terminal strip. The

blue wire should be connected to the terminal labeled 1102 to the right of the terminal labeled

1121 terminal on the terminal strip. A second Class 1 circuit is available at the terminal strip as

well. Class 1 Circuit 2 can also be used to supply power to motorized rollers that are separate

from Class 1 Circuit 1. The brown wire of the power harness for the second set of rollers should

be connected to the terminal labeled 1321 on the terminal strip. The blue wire should be

connected to the terminal labeled 1102 to the right of the terminal labeled 1321 on the terminal

strip. The power harness included with every IntelliROL power supply can be used to make

these connections. Be sure to follow all applicable codes governing the electrical installation of

your IntelliROL conveyor system.

Class 2 Circuit (CRUZcontrol Power)

The connections for the Class 2 Circuit found in each IntelliROL Combination power supply are

made at the terminal strip inside the IntelliROL power supply enclosure. A CRUZcontrol tee

cable is used to make the connection between an IntelliROL Combination power supply and a

CRUZcontrol system on an XP43 or NBC conveyor system. The tee cable contains four color-

coded wires; brown, blue, white and black. The black and white wires are not used when

connecting to the power supply. They should be separately insulated against contact with

anything else inside the power supply enclosure. The brown wire from the tee cable should be

connected to the terminal labeled 1201 on the terminal strip. The blue wire should be

connected to the terminal labeled 1102 to the right of the terminal labeled 1201 terminal on the

terminal strip.

P/N: 1176718 REV: 02/17/2021 Page 18 of 32

7.2: AT CONVEYOR EQUIPMENT

Class 1 Circuits (Motorized Roller Power)

The power harness included with each IntelliROL power supply has a connector at each end.

One connector is female and the other is male. The harness can be cut in the middle and used

to connect two Class 1 circuits to the power harnesses of two IntelliROL conveyor systems.

This should be done at the joint between two conveyor beds. Instead of connecting the power

harnesses from the two beds together, connect them to the two pieces of harness from the

power supply via the male and female connectors. The cut ends of the harness pieces should

be connected to the power supply terminal strip as described above. Be sure to follow all

applicable codes governing the electrical installation of your IntelliROL conveyor system.

Class 2 Circuit (CRUZcontrol Power)

A CRUZcontrol tee cable is used to connect an IntelliROL Combination power supply to a

CRUZcontrol system on an XP43 or NBC conveyor system. For an end-fed system, either the

male or female connector on the tee cable is connected the compatible connector on the end of

the CRUZcontrol interconnection cable. For a center-fed system, both connectors of the tee

cable are used to connect to the interconnect cables of two adjacent CRUZcontrol devices.

Simply disconnect the two interconnect cables and connect them to the tee cable. For more

information, refer to the TGW IOM manual for your CRUZcontrol product.

P/N: 1176718 REV: 02/17/2021 Page 19 of 32

Chapter 8: APPLICATION

Number of Rollers per Power Supply

The number of motorized rollers used on each Class 1 circuit is a very important aspect of

applying an IntelliROL power supply to a conveyor system. The answer depends upon several

characteristics of each specific application, such as conveyor speed, product weight,

transportation conveyor versus accumulation conveyor, singulated versus slug release, etc. As

a general rule of thumb, a 10A circuit can supply power for up to three motorized rollers, while

each 20A circuit can power up to nine motorized rollers. This means a power supply rated for

40A output can provide power for up to 18 motorized rollers. A unit rated for 80A can feed up to

36 motorized rollers. Make sure the 36 rollers are evenly distributed amongst the four 20A

circuits. No more than nine motorized rollers per 20A circuit. Keep in mind the first 20A circuit

in a combination power supply also supplies power for the Class 2 circuit feeding CRUZcontrol.

This will reduce the motorized roller count on that first 20A circuit by at least one. The amount

of current diverted from the first 20A circuit to the Class 2 circuit depends upon the number of

zones of CRUZcontrol being powered by the Class 2 circuit. Please refer to the TGW

application guidelines for your specific equipment.

P/N: 1176718 REV: 02/17/2021 Page 20 of 32

Chapter 9: STATUS INDICATORS

Standard Power Supplies

The table below lists the expected state of each indicator for all IntelliROL Standard power

supplies when they are powered and in normal operation. These indicators can be found on the

power supply unit internal to the power supply enclosure. Refer to Table 2: IntelliROL Standard

Power Supply Status Indicators.

Indicator

Expected State

Diagnostic Relay

Contact Closed

DC OK

Solid Green

Table 2: IntelliROL Standard Power Supply Status Indicators

Combination Power Supplies

The table below lists the expected state of each indicator for all IntelliROL Combination power

supplies when they are powered and in normal operation. These indicators can be found on the

Class 2 protection module internal to the power supply enclosure. Refer to Table 3: IntelliROL

Combination Power Supply Status Indicators.

Indicator

Expected State

Output-OK Relay

Contact Closed

CL2 Output 1

Off

CL2 Output 2

Off

CL2 Output 3

Off

CL2 Output 4

Off

Table 3: IntelliROL Combination Power Supply Status Indicators

This manual suits for next models

51

Table of contents