The Handy THMC User manual

Page 2

CONTENTS

SAFETY INSTRUCTIONS 3

SPECIFICATIONS 4

FUEL 5

MAJOR PARTS 6-7

ASSEMBLY 8-12

REPLACEMENT OF SPOOL,LINE AND CHAIN 13-14

OPERATION 15

MAINTENANCE 16

TROUBLE SHOOTING 17

PARTS DIAGRAMS AND LISTS 18-22

EC DECLARATION OF CONFORMITY 23

Page 3

SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels afxed

to the multicutter. Learn its application and limitations as well

as the specic potential hazards. Retain these instructions for

reference.

• Use sturdy footwear and a helmet with eye and ear protection.

Protect exposed parts of your body. Wear heavy duty gloves,

preferably made of leather.

• Do not wear loose clothing or jewellery. Keep hair, clothing and

gloves away from moving parts.

• Do not operate the multicutter if you are tired, ill or under the

inuence of alcohol or drugs.

• Do not smoke when using the multicutter and ensure caution

when handling fuel. We recommend you fuel the machine at least

3m away from where you wish to work in case any spilt fuel ignites

when starting the engine.

• Ensure that bystanders, children and pets keep well away when

starting or trimming - at least 15m.

• Inspectthemachineandallattachmentsbeforeuseforanywornor

damaged parts. Do not use until the parts are repaired or replaced.

• Before starting the engine make sure the attachment is not in

contact with anything and have a clear work area and secure

footing.

• The multicutter should not be exposed to high

temperatures or damp and wet conditions.

• Clean the multicutter after each use and, if storing for a pro-

longed period, drain down the fuel in the tank. Remove the spark

plug and put a few drops of oil into the cylinder before pulling the

starter a couple of times to distribute the oil evenly. Replace the

spark plug.

• Regularly check that screws, bolts and nuts are correctly fitted.

Page 4

SPECIFICATIONS

MODEL THMC

Engine Displacement 25.4cm³

Max Output Power 0.75Kw/7800 minˉ¹

Fuel Tank Capacity 0.6L

Bore and Stroke 34 x 28mm

Fuel Type Unleaded

Fuel Mixture Unleaded Petrol/Oil 25:1 Mineral Oil (see below for synthetic)

Equivalent Spark Plug Champion RCJ6Y or NGK BPMR7A

Max Engine Idling Speed 3200/min

Min Clutch Engagement Speed 4200/min

Engine Max Speed 9000/min

Fuel Consumption at max engine speed 569g/kw.h

Special Fuel Consumption at max engine

speed 0.56 Kg/h

ATTACHMENT B/CUTTER LINE TRIMMER PRUNER HEDGETRIMMER

Cutting Diam-

eter 205mm 381mm 24mm

Cutting Length 250mm 370mm

Chain Bar Type 10”

Shaft Straight Curve Straight Straight

Blade 3 segment

brush blade

Blade Diameter 205mm

Spool Type Bump feed, twin

line

Line Diameter 2mm Only

Line Length 2mm x 3m

Net Weight

(empty tank) 5.7kg 4.7kg 5.8kg 5.8kg

Declared

Sound Pressure

Level

96 dB(A) 96 dB(A) 98 dB(A) 98 dB(A)

Declared

Sound Power

Level

106 dB(A) 106 dB(A) 108 dB(A) 108 dB(A)

Vibration 8 m/s² 8 m/s² 6.5 m/s² 6.5 m/s²

Gear Ratio 23:17 1:1 19:15 4.25:1

Max Cutting

Speed 6600 rpm 7800/min 14 m/s 2000 rpm

ATTACHMENTS

Page 5

FUEL

Petrol is very ammable. Do not use or fuel the multicutter near a

ame, sparks or while smoking. Allow the engine to cool before

re-fuelling. Fuel the engine at least 3m away from your work area.

• Use a ratio of 25:1 unleaded petrol to mineral oil. Mix well in an

appropriate mixing bottle. For semi-synthetic or synthetic oils check

the oil manufacturer's guidelines to determine the correct ratio.

• Unscrew the fuel cap, and fuel the machine to 80% capacity. Fas-

ten the fuel cap tightly and wipe up any spillage.

• Ensure that any stored petrol/oil mixture (2-stroke) is clearly

marked in a separate can and only stored for 4-6 weeks. If the

multicutter is not going to be used for a long period, drain the

mixture from the fuel tank, start the engine and drain the

carburettor of any remaining fuel.

• Dispose of any unwanted 2-stroke mixture at an authorised recy-

cling point.

Page6

MAJORPARTS

Page 7

MAJOR PARTS

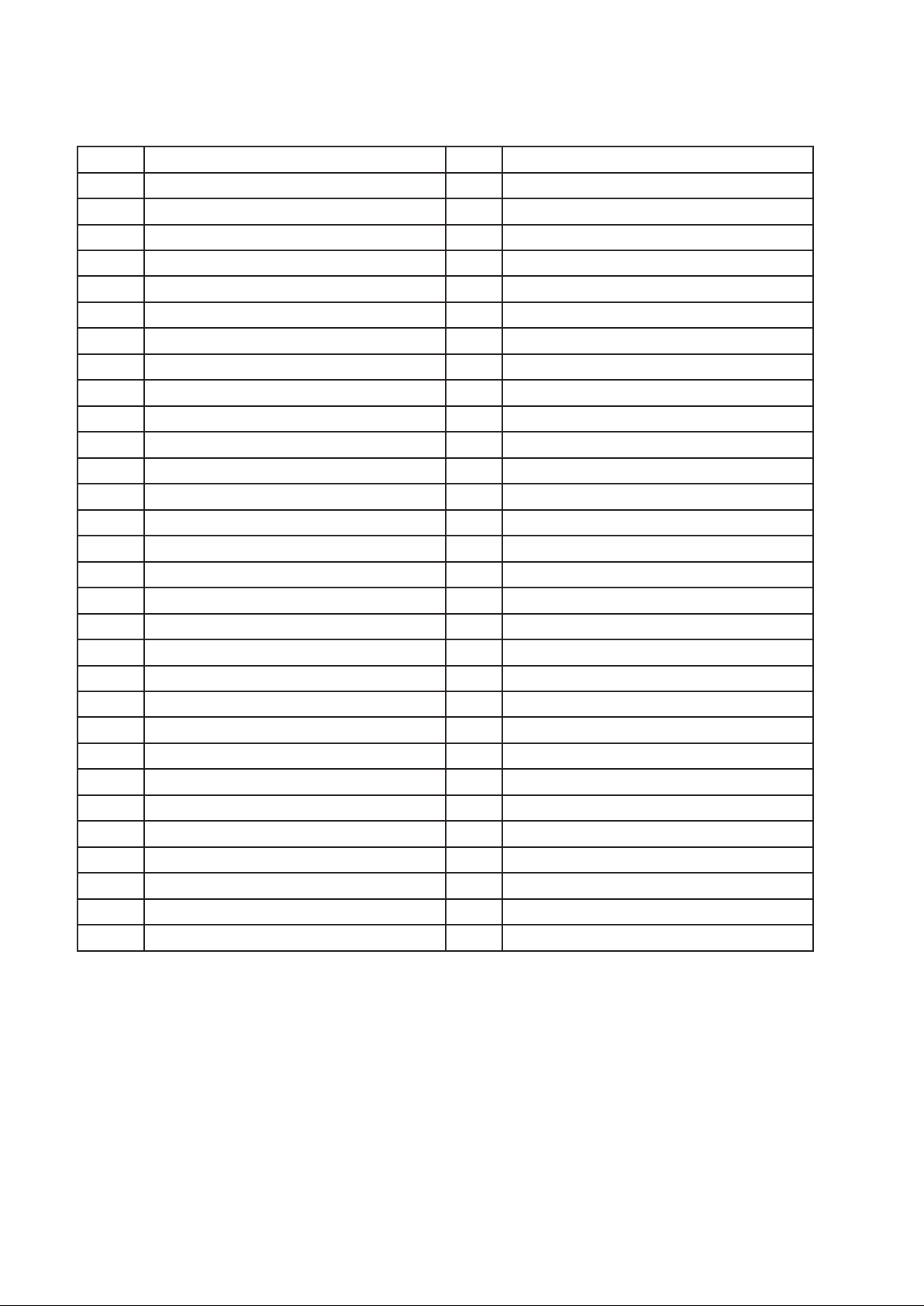

No Description No Description

1Hedgetrimmer Cutting Blade 31 Throttle Lock Button

2 Gear Head 32 Fuel Tank Cap

3 Locking Screw 33 Heat Insulation Protector

4 Locking Knob 34 Sprocket Wheel Cover

5 Adjusting Bracket 35 Guide Bar Nut

6 Assistant Gear Head 36 Sprocket

7 Special Spanner 37 Guide Bar Stud

8Pruner Gear Head 38 Oil Ducts

9 Upper Shaft of Engine 39 Chain Tensioner

10 Hedgetrimmer Shaft 40 Stop

11 Harness Bracket 41 Guide Bar

12 Fuel Tank 42 Saw Chain

13 Throttle Trigger 43 Chain Bar Sheath

14 Recoil Starter 44 Line Trimmer Cutting Head

15 Primer Bulb 45 Line Trimmer Shaft

16 Spark Plug 46 Wing Nut

17 Air Filter Cover 47 Bolt

18 Safety Lever 48 Shield

19 Choke Lever 49 Cut-off Blade

20 Spark Plug Spanner 50 Brushcutter Guard

21 Carry Strap 51 Bruchcutter Cutting Blade

22 Engine Cover 52 Allen Key

23 Ignition Switch 53 Blade Guard Screw x 3

24 Guide Bar Hole 54 Spring Washer + Flat Washer x 3

25 Fixed Adjusted Bracket Screw x 255 Brushcutter Head Shaft

26 Flat Washer x 2 56 Handle Base

27 Locking Button Hole 57 Upper Barrier Handle

28 Rotating Knob 58 Fixed Handle Screw x4

29 Coupler 59 Flat Washer + Spring Washer x4

30 Exhaust

Page 8

ASSEMBLY

Modern production techniques mean that there is very little likelihood of there

being any parts missing in the carton supplied. However please check the box

carefully before commencing any assembly. If you are missing any parts please

call our spares helpline: 01793-333212.

Contents:

Power Unit; Spark Plug Wrench; Carry Strap.

Hedgetrimmer Cutting Head; Adjusting Bracket; Screw x2; Flat Washer x2;Spring

Washer x2; Locking Knob.

Brushcutter Head; Metal Guard; Allen Key; Cutting Blade; Blade Retaining Nut; Flange

Washer; Clamp Washer; Cupped Washer.

Pruner Cutting Head; Chain Bar Cover; Chain Bar; Chain; Special Spanner.

Line Trimmer Head; Shield Kit.

Barrier Handle (two sections) with 4 screws and nuts.

Assembling the Loop Handle:

• Disassemble the loop handle.

• Position the upper handle over the upper shaft just in front of

the xed rubber grip. The lower handle locates on the under-

side of the shaft and should line up with the four screw holes

on the upper handle. Secure with four screws, washers and

nuts. Nuts are usually already fitted in the lower handle.

Washers should be located under the screw heads.

Attaching the Shoulder Harness:

• Connect the latch on the shoulder harness to the harness loop,

located on the upper shaft.

• Adjust the strap length to a comfortable position, making sure that

any excess strap is secure.

Fitting the Attachments:

• The attachments connect to the power unit by means of a coupler device.

• Loosen the rotating knob on the coupler of the power unit shaft.

• Push in the button on the attachment shaft.

• Align the button with the guide recess on the coupler and slide the two shafts together

to connect the slot and socket inside the shafts.

• Rotate the attachment shaft until the button locks in the positioning hole.

• Tighten the rotating knob securely.

Note: If the button does not release completely in the positioning hole, the shafts

are not locked in place. Slightly rotate from side to side until the button locks.

Page 9

ASSEMBLY, cont’d

Hedgetrimmer Attachment:

• Locate the bracket on the plane of the gear head and position the locking screw (3) through

the adjusting hole in the bracket.

• Use the two Screws (25) and at washer (26) to attach the bracket to the gear head.

• Use the locking knob (4) to fasten the bracket onto the assistant gear head (6).

Check the tightness of the bracket locking screws (25) before every use of the

hedgetrimmer.

The hedgetrimmer can be adjusted to six different cutting angles to suit all applications.

Operating the Hedgetrimmer:

• Always have a rm footing and use two hands.

• It is advisable to cut a hedge from the bottom up sweeping the cutter bar in an arc as you

move along the hedge. The double edged cutter blades allows use by left or right handed

operators.

• To cut the top of the hedge, hold the cutter bar at an angle of 0-10 degrees as you swing

the hedge trimmer horizontally. Sweep the cutter bar in an arc towards the outside of the

hedge so that the cuttings are swept onto the ground.

• Pay special attention when cutting hedges which are laid out along a wire fence. If the

blades make contact with the wire damage may occur.

• Do not use the hedge trimmer for long periods of time - take a break of 10-15 mins after

every 50 mins of use or after using one tank of fuel.

• If the blades hit a stone, wire or other foreign object, turn off the engine and check for any

damage to the blades immediately. Replace any damaged blades before continuing.

• Do not attempt to remove any twigs or branches jammed in the cutter blades without rst

turning the engine off.

Page10

ASSEMBLY,cont’d

Remove the Blade Nut, this nut has a left hand thread so should be turned

clockwise to undo it.

Remove the Cupped Washer, Clamp Washer and Flanged Washer.

Remove the 3 Blade Guard Screws with the Allen key.

Position the Blade Guard over the Blade Guard Screw holes, insert and

tighten the screws.

Fit the Flanged Washer.

Fit the Blade over the raised section of the Flanged Washer.

Fit the Clamp Washer.

Fit the Cupped Washer.

Fit the Blade Nut, this nut has a left hand thread so should be turned anti-

clockwise to tighten it.

Locate the Allen key in the locking hole to stop the shaft rotating and firmly

tighten the Blade Nut with the spanner supplied.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Brushcutter Attachment:

Page 11

ASSEMBLY, cont’d

Operating the Brushcutter:

• Operate the throttle trigger with your right hand and hold the barrier handle with your left

hand.

• Always keep a rm grip with both hands during operation.

• The brushcutter should be held at a comfortable position with the trigger handle about hip

height. Adjust the harness to suit.

• Maintain a rm footing in case the machine hits a solid object and kicks back.

• Do not use the brushcutter near fencing, posts, buildings or other immoveable objects -

use the line trimmer attachment.

• Best results are obtained if you cut from right to left in a broad sweeping action.

• If a hard object is hit, stop the machine and inspect for any damage straight away.

• Never attempt to sharpen the blade. It is reversible so should be turned over when blunt.

The blade must remain balanced. Always check for any damage before use and replace

a damaged blade immediately.

To avoid burns from the hot engine, never operate the unit with the bottom of the

engine above waist level or on the operator's left side.Always position the unit on the

user's right side.

Page 12

ASSEMBLY, cont’d

Line Trimmer Attachment:

• Slide the shield onto the attachment shaft and t over

the bracket, as in Fig. 11.

• Fix the bolt through the holes in the tabs on the shield

and the slots in the bracket on the attachment shaft.

• Secure, as shown in Fig. 11, using the at washer,

lock washer and nut.

• Tighten securely and remove the protective packaging

from the line cut-off blade.

Operating the Line Trimmer:

• Operate the throttle trigger with your right hand and hold the barrier handle with your

left hand.

• Always keep a rm grip with both hands during operation.

• The line trimmer should be held at a comfortable position with the trigger handle about

hip height. Adjust the harness to suit.

• Maintain a rm footing in case the machine hits a solid object and kicks back.

• Cut tall grass from the top down to prevent the grass wrapping around the shaft

housing and string head which may cause overheating and damage. If grass becomes

entangled stop the engine completely and remove the grass.

• Always position the unit on the operator’s right side. Using it on the left side will

expose the user to the exhaust and hot surfaces which can result in burns.

Page 13

To replace the line or spool:

• Stop the engine.

• Lay the trimmer on the oor so that the cutting head is facing up.

• Remove the bump knob/retaining cap by turning it anti-clockwise.

• Remove the empty spool being careful not to lose the spring behind

the head.

• Clean the head thoroughly and inspect for any worn or damaged

parts.

To reload the spool with line:-

• Cut two lengths of spare line 3 metres long.

• Position each line in the two holes located in the centre of the spool,

as in Fig. 13, and wind in the direction of the arrow on the spool

(see Fig. 12) keeping the line tight at all times, as in Fig.14.

• Wind the line on until you have about 15cm left then secure the lines

into the slots on the tabs, as shown in Fig. 15.

• Insert the lines on the spool into the eyelets on the trimmer head as

in Fig. 16

• Place the spool on the drive shaft.

• Release the lines from the tabs by sharply pulling each line while

pushing down on the spool.

• Push down on the spool to reveal the drive shaft then place the

bump knob/retaining cap onto the drive shaft as in Fig. 17.

• Secure the knob/retaining cap by turning it clockwise.

If you need to replace the whole spool, follow the instructions above,

omitting the references to relling the line.

REPLACEMENT OF SPOOL AND LINE

Page 14

REPLACEMENT OF PRUNER CHAIN

• Remove the sprocket wheel cover (34).

• Remove the guide bar and chain.

• Remove the old chain and replace with the new chain.

• Mount the guide bar and then t the saw chain around the bar and sprocket, paying

particular attention to the correct direction of the chain.

• Fit the chain tensioner into the lower hole of the guide bar (24).

• Attach the sprocket wheel cover and loosely tighten the nut.

• Turn the chain tensioner clockwise until the chain ts snugly onto the guide bar.

• Tighten the sprocket wheel cover nut, then using gloves, pull the chain around the guide

bar to check that the chain has the correct tension without any tight spots.

• Fill the chain oil reservoir with chain oil and before cutting,run the chain at medium

speed to make sure chain oil is thrown off. This ensures that the chain is being

lubricated.

It is very important to maintain proper chain tension as incorrect chain tension can

cause the guide bar to wear and the chain to come off.

Operating the Pruner:

• The Pruner is equipped with a low kickback chain, however, sometimes kickback can

occur so always hold the unit rmly in both hands.

• Thin branches can be cut off with a single cut but if the branch is long it is preferable to

cut it off in several pieces.

• For larger branches follow the diagrams below for a safe clean cut. Make the rst cut

from underneath and cut through one third to half ofthe branch.

• Do not work at an angle higher than 60 degrees as there is a danger of being injured by

branches falling without warning.

Before every use, check the level of the chain oil in the reservoir.

Page 15

Starting the Multicutter:

• Move the ignition switch to the “on” position (Fig. O).

• Move the choke lever upwards to the “start” position (for cold start only) (Fig. P).

• Push the primer bulb 10 times until the petrol/oil mixture lls the primer bulb (Fig. Q).

• Squeeze the safety lever, then the throttle; push in the throttle lock button with your

thumb.

• Pull the recoil starter 2-3 times until the engine res (Fig R).

• Push the choke lever down to the “run” position and pull the starter again until the

engine starts. Squeeze the throttle to release the throttle lock.

Warning: failure to push the choke to the "run" position after the engine has fired

will flood the engine.

• Allow the engine to run idle for about 10 seconds to warm it up.

Note: If restarting a warm engine there is no need to move the choke lever or

prime the primer bulb.

Stopping the Multicutter:

• Release the throttle trigger and allow the engine to idle for a few moments.

• Move the ignition switch to the “off” position (Fig. T).

Note: The attachments may continue to rotate for a few seconds after the engine

has stopped.

During the rst 10 hours of work run the engine at a moderate speed.

Ensure that all nuts, bolts and screws are securely tightened before every use of the

Multicutter.

Always position the unit on the operator’s right side. Using it on the left side will

expose the user to the exhaust and hot surfaces which can result in burns.

OPERATION

Page 16

MAINTENANCE

The engine of the multicutter must be at a complete stop during assembling,

cleaning and any maintenance that may be necessary.

Air Filter:

Accumulated dust in the air lter will reduce engine efciency, increase fuel consumption

and allow abrasive particles to pass into the engine.

Remove and clean the air lter regularly to ensure optimum performance.

• Remove the air lter cover by releasing the securing screws and lifting it off.

• Tap the lter to remove light surface dust.

• Heavy deposits should be washed out in soapy water. Allow the filter to dry

completely.

Fuel Filter:

Check the fuel lter periodically but be careful not to allow dust to enter the fuel tank.

• The fuel tank is tted with a lter which is situated at the free end of the fuel pipe and

can be extracted by using a piece of hooked wire.

• If the lter is dirty replace it straightaway.

• If the inside of the fuel tank is dirty rinse out with petrol.

Spark Plug:

Check the spark plug after every 10-15 hours of use.

• Remove the spark plug cover.

• Using the plug spanner supplied, remove the spark plug by turning it anti-clockwise.

• Clean and adjust the gap to 0.6-0.7mm.

• Replace any damaged or visibly worn spark plug.

• Install the new/cleaned spark plug to nger tightness and tighten fully with the spanner.

Servicing:

• We recommend that your petrol multicutter is serviced after 15 hours of use and

thereafter every 2 years.

When you nish working, clean the multicutter completely, removing any dirt and making

sure there is no grass wrapped around the cutting tools. Replace the blade covers on the

hedgetrimmer and pruner.

Be careful not to hit or damage the fuel tank when you put the machine on the ground.

Store away from direct sunlight and preferably hang the multicutter off the oor by the top

handgrip.

If storing for a long period, drain completely of fuel and oil all metal engine parts to protect

them from rusting.

Remove the spark plug, put a few drops of oil into the cylinder and pull the recoil starter a

few times to distribute the oil. Replace the spark plug.

You must periodically check that all screws are securely tightened. Failure to regularly check

the machine may affect performance and operator safety.

Page17

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Power loss or sudden

stopping. 1. Fuel Tank is empty.

2. Mixture not reaching

carburettor.

3. Water in the mixture.

4. The air filter is dirty.

5. Carbon deposits in

cylinder, exhaust pipe

or muffler.

1. Add fuel.

2. Drain and rinse out fuel

system.

3. Clean fuel filter.

4. Clean air filter.

5. Clean all affected parts

or change muffler.

Engine runs but blade will

not turn. Possible clutch failure. Take to authorised repair

agent, your service dealer or

call customer services on

01793 333212.

Unit is smoking. Incorrect fuel/oil ratio. Use 25 parts fuel to 1 part

mineral oil.For synthetic oils

use the manufacturer's ratio.

Line will not advance when

restarting engine. 1. Line is welded to itself.

2. Not enough line on

spool.

3. Line has worn too

short.

4. Line is tangled on

spool.

1. Lubricate with silicone

spray.

2. Add more line.

3. Pull lines alternately

pressing down on and

releasing bump button.

4. Remove line from spool

and rewind.

Trimmer head is hard to turn. Grass wrapped or build up

around the head. Clean affected parts.

Grass wraps round

attachment shaft and head

assembly.

Cutting tall grass at ground

level. Cut tall grass from the top

down.

It is hard to cut branches or

blade smoking. 1. No lubrication on the

blade.

2. Blade is blunt.

1. Lubricate after each

use with oil or spray

lubricant.

2. Take to authorised

repair agent or your

service dealer to

change the blade.

Pruner chain does not turn. Chain too tight. Check the tension of chain

and adjust accordingly (see

page 14).

Idle is lumpy. Idler screw not positioned

correctly. Adjust idler screw on the

carburettor. Tighten screw,

then loosen it 1 and 1/4 turns

for optimum performance.

Page 18

PARTS DIAGRAM AND LIST - ENGINE

No Part No Desc Qty No Part No Desc Qty

1 TH132-1 Screw 2 25 TH132-25 Flat Washer 2

2 TH132-2 Spring Washer 2 26 TH132-26 Heat Shield 1

3 TH132-3 Flat Washer 2 27 TH132-27 Exhaust 1

4 TH132-4 Filter Housing 1 28 TH132-28 Exhaust Gasket 1

5 TH132-5 Carburettor 1 29 TH132-29 Clips 1

6 TH132-6 Gasket 1 30 TH132-30 Screw 3

7 TH132-7 Screw 2 31 TH132-31 Spring Washer 3

8 TH132-8 Spring Washer 2 32 TH132-32 Flat Washer 3

9 TH132-9 Flat Washer 2 33 TH132-33 Fuel Tank 1

10 TH132-10 Insulator 1 34 TH132-34 Fly Wheel Key 1

11 TH132-11 Gasket 1 35 TH132-35 Fly Wheel 1

12 TH132-12 Spark Plug (ngkbpmr7a) 1 36 TH136-36 Nut 1

13 TH132-13 Engine Cowl 1 37 TH132-37 Spring 2

14 TH132-14 Flat Washer 1 38 TH132-38 Clutch Shoes (Pair) 1

15 TH132-15 Spring Washer 1 39 TH132-39 Washer 2

16 TH132-16 Screw 1 40 TH132-40 Bolt 2

17 TH132-17 Short Engine 1 41 TH132-41 Clutch Drum 1

18 TH132-18 Starter Pawl 1 42 TH132-42 Cir Clip 1

19 TH132-19 Recoil Assy 1 43 TH132-43 Bearing 1

20 TH132-20 Flat Washer 4 44 TH132-44 Screw 2

21 TH132-21 Spring Washer 4 45 TH132-45 Spring Washer 2

22 TH132-22 Screw 4 46 TH132-46 Flat Washer 2

23 TH132-23 Screw 2 47 TH132-47 Coil 1

24 TH132-24 Spring Washer 2

Page 19

PARTS DIAGRAM AND LIST - LINE TRIMMER (THLTATT)

Line Trimmer Parts:

No Part No Description Qty

2 TH131-2 Bracket 1

3 TH131-3 Screw 1

4 TH131-4 Nut 1

6 TH131-6 Spool & Cap Assembly 1

7 TH131-7 Shield 1

8 TH131-8 Knob 1

9 TH131-9 Washer 1

Page 20

PARTS DIAGRAM AND LIST - BRUSHCUTTER (THBCATT)

No Part No Description Qty

1 TH130-1 Shield 1

2 TH130-2 Flat Washer 3

3 TH130-3 Spring Washer 3

4 TH130-4 Screw 3

5 TH130-5 Blade Boss Outer 1

6 TH130-6 Nut Cover 1

7 TH130-7 Lock Nut (Left Hand) 1

8 TH130-8 Blade Boss Inner 1

Page 21

PARTS DIAGRAM AND LIST - HEDGETRIMMER (THHTATT)

No Part No Description Qty

1 TH128-1 Angle Bracket Assy 1

2 TH128-2 Blade Assembly 1

Table of contents

Popular Cutter manuals by other brands

CUTRA

CUTRA Wondercutter instruction manual

Linkoln Electric

Linkoln Electric EASYTOME 1020 Safety instruction for use and maintenance

Enerpac

Enerpac ECSE300 instruction sheet

Makita

Makita CC300D instruction manual

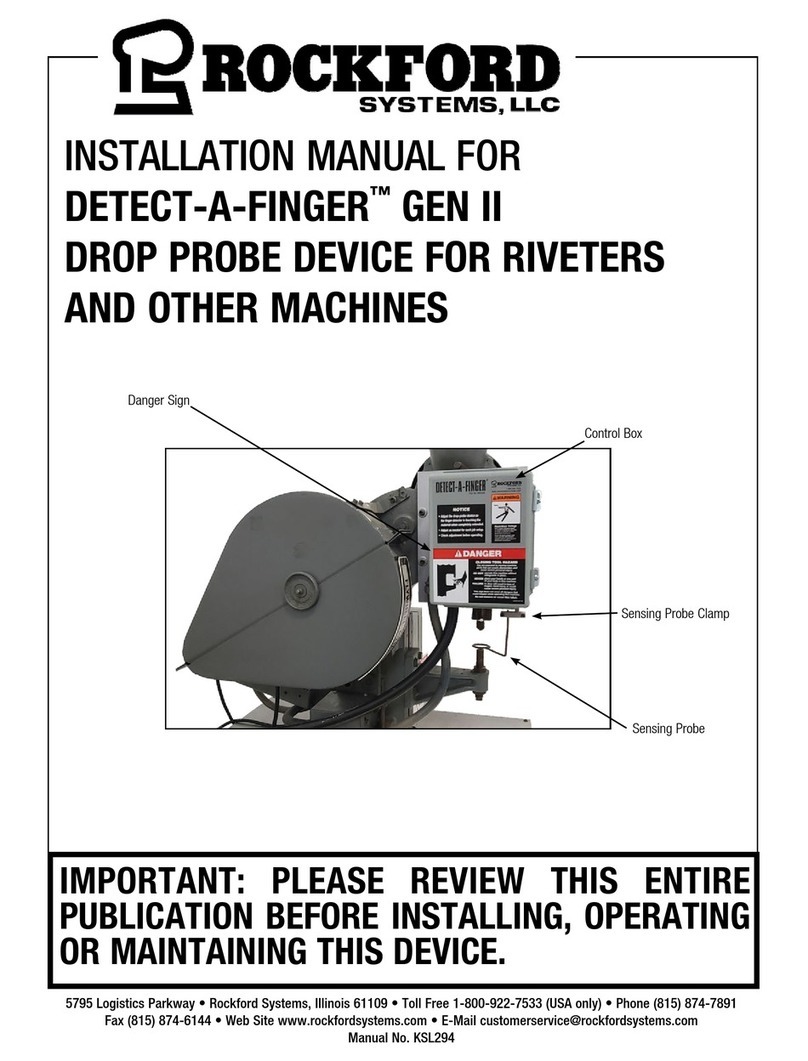

Rockford Systems

Rockford Systems DETECT-A-FINGER GEN II installation manual

Maktec

Maktec MT410 instruction manual