Page 7

SAFETY INSTRUCTIONS

• Read and understand the owner’s manual and the labels afxed to the electric tiller.

Learn its application and limitations as well as the specic potential hazards. Retain

these instructions for reference.

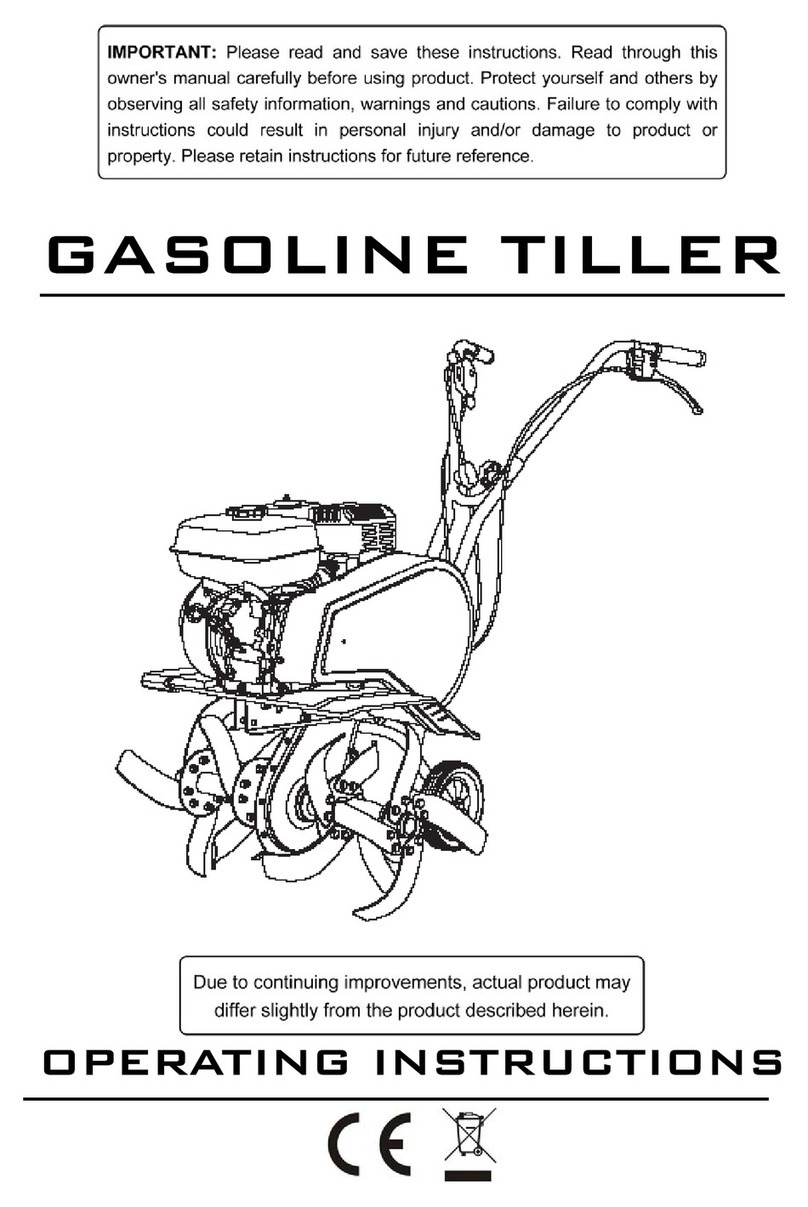

• Check your tiller before use. Keep guards in place and in working order. You should only

work with a machine that is in good condition. If you notice any defect on the machine

that may cause damage to the operator, do NOT operate until faults have been rectied.

Replace worn or damaged parts using only original spare parts.

• Do NOT operate the electric tiller whilst under the inuence of drugs, alcohol or any

medication that could affect your ability to use the apparatus correctly.

• Dress appropriately – do NOT wear loose clothing, ties, jewellery or anything that could be

caught in the moving tines. Use of gloves and strong footwear are recommended.

• Only work in daylight or sufciently good articial light.

• Keep children and pets away from the tiller at all times and do NOT operate near

underground electric cables, telephone lines, pipes or hoses.

• Wear eye protection and a face or dust mask if working in dusty conditions.

• Before use make sure the socket ratings are correct and correspond to those indicated on

the rating label on the tiller.

• Do NOT operate on a slope that is too steep for safe operation. When on slopes, slow

down and make sure you have good footing.

• Never operate the machine with one hand and be aware that, if the tines hit stones, frozen

ground or buried roots and stumps, then it may unexpectedly bounce upward and jump

forward.

• Be aware of the extension lead and be careful not to trip over it or pass the tiller over it.

Always guide the lead away from the tines at all times and keep behind your back.

• If the tines hit a large stone, stump or other obstacle immediately turn off the machine

and check for any damage to the tines. If the machine starts to vibrate abnormally switch

off the motor immediately and check for causes.

• Always switch off the machine, disconnect the plug and wait for the tines to stop turning

before carrying out any inspection or maintenance. The tines will not stop immediately

after switching off.

• It is prohibited to move or modify any of the electrical and mechanical safety devices.

Electrical Safety:-

• The mains voltage must correspond to the one marked on the technical data plate

(230V-50Hz). Do not use any other source of power. The use of a circuit breaker is

recommended for an intervention range of 10 to 30 rated mA.

• Make sure you always know where the cable is and never pass the tiller over the cable to

avoid cutting the cable with the tines.

• Do NOT use the machine in the rain and do NOT leave it outside overnight. Try to prevent

it getting wet or being exposed to humidity.

• Check the power cable regularly to ensure it is not damaged. Only use an extension

cable which is suitable for outdoor use. If the cable is damaged arrange for a replacement

before further use.

• The mobile socket of the extension cable should be splash proof in compliance with

DIN57282 and VDE 0282 regulations; the cross section of the wire (max length 75m)

should be at least 1.5mm². Use H07RN-F harmonised cable.