The Table Stable TCF-1 User manual

Instruction manual

Im Grindel 6

8932 Mettmenstetten-Switzerland

Phone: +41 44 776 33 66

Fax: +41 44 776 33 65

Internet: www.tablestable.com

TEMPERATURE CONTROLLED LASER

FILTER

TCF-1 / TCF-2

______________________________________________________________

2

Table of Contents

Safety Instructions....................................................................................... 2

Notes on equipment safety.......................................................................... 2

The need for a laser filter............................................................................. 3

Instrument layout and general description of a TCF-1 .............................. 4

Output stabiliser for TCF-2.......................................................................... 5

Device alignment and installation............................................................... 6

Temperature tuning and device operation ................................................. 7

Stabilised filter version (TCF-2) operation.................................................. 8

Device transmittance optimization.............................................................. 9

Etalon replacement and wavelength ranges .............................................. 9

Specifications............................................................................................. 10

Safety Instructions

If you suspect the system to be in any way unsafe, unplug and prevent any

possible accidental usage. Contact your nearest service centre.

Before switching on this apparatus, make surethat it is connected to the correct

mains voltage. Do not remove any cover or allow any metal objects to enter the

ventilation slits.

Disconnect from mains before removing any covers. Refer servicing to qualified

personnel. Do not use in potentially explosive surroundings.

Make sure the ventilation slits in the power unit are not covered and that air can

freely circulate. Blocking the slits can lead to overheating which could cause a

fire.

For indoor use only.

Notes on equipment safety

The TCF-1 and TCF-2 devices have been designed, manufactured, and tested

to conform to the safety regulations for measurement- and control-equipment

DIN EN 61010-1 (IEC 1010-1) and satisfies the relevant requirements of EEC

Directive 73/23.

The system conforms to EEC Directive 89/336 (electro-magnetic compatibility).

The operator should read this manual, which contains important warnings and

information.

______________________________________________________________

3

The need for a laser filter

The TCF is a temperature stabilised etalon device, designed to reduce the

intensity ofspurious secondary laser modes found onmanymoderncommercial

solid state laser light sources. These secondary modes are very weak, with an

intensity typically 10-8 to 10-11 of the laser intensity, but unfortunately they lie in

the region of interest for Brillouin spectroscopy measurements.

Fig. 1.Shows the spectrum of a 532 nm solid state laser source measured using

the JRS high contrast tandem interferometer TFP-1. The main laser peak has

been strongly attenuated relative to the secondary peaks. A Brillouin spectrum

measured in the presence of a strong elastic component will inevitably show

these secondary peaks in the background, making interpretation of the

spectrum difficult.

The TCF strongly attenuates these modes, in many cases reducing them below

the detection threshold.

The largest attenuation provided by this filter for the unwanted modes is close

to 600. As shown also in Fig. 1, the device is expected to provide an extinction

factor of 2 for components as close as 1.8 GHz from the primary radiation and

-40 -30 -20 -10 0 10 20 30 40

101

102

103

104

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

intensity (PMT counts)

frequency shift (GHz)

TCF-1 etalon transmittance

Fig. 1 : A dramatic need for a spectral cleaning. Violet curve shows the

spectrum of a commercial laser source, showing several additional modes

extending out as far as 100 GHz,as seen bymeans of a high contrast Fabry-

Pérot interferometer. The red curve shows the theoretical transmission

curve of a TCF-1 unit.

______________________________________________________________

4

to reach 99% of the maximum attenuation already around a 9 GHz frequency

shift.

This device is optimized to be operated at the widely used wavelength of 532

nm, produced by most commercial DPSS Nd-YAG laser sources, but will give

satisfactory performance for all wavelengths in the range from 490 nm to 550

nm.

The unit should not require any kind of maintenance, excluding periodical

checks on the correct tuning to the laser source frequency.

Instrument layout and general description of a TCF-1

Fig. 2 : images of the TCF-1 device; letters indicate the various

components described in the text.

Images of the device are shown in Fig. 2: the small etalon plate is mounted and

sealed in a container, fixed inside a cylindrical cavity in the main unit body (A).

The body can be placed at a variable height by loosening the plastic screw (B)

and sliding the block vertically along the 15 mm diameter post; a movable

height-fixing ring (C) is provided to ease the adjustment. To move the support

ring, use a small screwdriver to loosen or tighten the locking screw.

Rotation around the horizontal axis is also possible, by loosening the screw (D)

on the instrument back, and tightening again in the desired position. The active

body is connected to the instrument control box by a wire and an M8 connector

(E).

The power supply socket (F) is located on the backside of thecontrol box, while

the temperature control knob, the stability indicator and the power supply LED

are located on the top of it (G). The stability indicator reports the activity of the

instrument: when it is in the red part of the scale, the etalon head is heating up

while when in the green part, it is cooling down; a stable condition at the set

point has thus been reached when the indicator is close to the middle line. The

red LED is always lit when the instrument is correctly powered.

______________________________________________________________

5

On most recent TCF units, the power supply LED and the analogue indicator

have been replaced by amulticolour LED. The LED indicator is lit whenever the

device is powered up; a red or blue colour indicates that the TCF head is being

heated up or cooled down respectively; a green colour indicates that the

temperature of the headis within arelativelynarrow interval around the setpoint.

The BNC connector (J) on the right wall of the instrument can be used to input

an external current (< 0.5 A) to the device in order to dynamically change and

control the equilibrium temperature. This is the input used for the stabiliser in

the TCF-2 device. Please refer to JRS for detailed information on the use this

input.

A small alignment and centring tool (H) is provided to help with initial alignment

of the device with the laser beam. Before and after use, the alignment tool can

be fixed on the top of the vertical post by means of an M2 screw. After

alignment, always place back the centring tool over the post to prevent losses

of laser power.

The device can be fixed to the optical workbench by clamping the base plate or

using screws through the holes (I), with the longer side of the base plate either

orthogonal or parallel to the beam direction. The device plate can be used with

metric or imperial optical breadboards.

The Peltier module inside the head of the instrument (A) is very fragile.

Please handle the head gently and do not remove it from the post if not

strictly necessary. Falling or dropping the head will easily lead to

unrecoverable damage of the thermoelectric device.

Output stabiliser for TCF-2

The TCF-2 is an evolution of the basic device, including an additional

component: the stabiliser. The stabiliser provides additional stability of the

output with respect to temperature and slow beam wavelength fluctuations.

TCF-1 units can be upgraded

to TCF-2 by adding the

stabiliser.

The stabiliser is mounted by

inserting the cylindrical part

on the output hole of the TCF

unit. The two O-rings will

keep the stabiliser in

position. A rotation of the

stabiliser with respect to the

main TCF head does not

alter the performance.

The stabiliser is powered by

means of the TCF supply

doubler cable, while the BNC

output must be connected to

the side socket on the TCF

main box. The switch on the stabiliser allows switching on and off, while the

green LED indicates the activity of the device.

It is suggested to align the TCF with the stabiliser in place, so that the insertion

of the stabiliser will not alter the position of the TCF head.

Fig. 3 : Output stabiliser

______________________________________________________________

6

Device alignment and installation

The TCF has been calibrated at the factory and mounted before shipping. In

order to use the device, users only need to align it correctly with the laser beam

and carefully regulate the temperature set point.

In order to obtain the best performance, the etalon plate needs to be aligned

orthogonally to the laser beam and the temperature precisely tuned on a

transmission maximum. It is very important that the laser beam waist is as small

as possible when passing inside the device: using the device with a beam

diameter larger than 2 mm will noticeably decrease the throughput. A low beam

divergence is also required to obtain the best transmittance, which will decrease

otherwise. We thus suggest to position the unit as close as possible to the laser

source output and/or to use an initial collimation lens between the source and

the TCF, to obtain the lowest possible power loss and reduce the need of

alignment checks. JRS can provide an extension cable for the device head, if it

should be necessary to detach it from the control box and place it in a narrow

space or in a difficult to reach position.

In order to align the TCF unit, unscrew

the alignment tool and slide it inside the

etalon hole as shown in Fig. 4: it will

provide a guide for alignment. It is

usually advisable, forsafety of operation,

to dim the incoming laser beam in this

phase.

At first, place the device on the optical

table and fix the base in a temporary

position, as close as possible to the

correct one. The holes on the base allow

the device to be moved sideways as

required. The first phase of alignment consists in fixing the operating height.

Under the active head, a plasticsupport ring is provided tofix a reference height

on the post: at first, loosen the white fixing screw on the plastic support ring with

a screwdriver and slide it downwards so that the active head can move freely

along the post.

Slide the base on thebench horizontally andmove vertically the active head (by

loosening the lateral big plastic screw, too) until the alignment tool hole is at the

same height of the incoming laser beam. After fixing temporarily the active head

in this position, move the support ring upwards against the active head bottom

and lock it into this new position: at this point, the active head will not be able to

move downwards anymore.

As a second step, move and rotate the device in order to have the beam

entering the centring tool and to see a laser light back reflection on some

distance surface. Move the device (and rotate the active head if needed) in

order to reflect the laser beam back to itself on the horizontal plane; fix it to the

optical workbench when a good approximation alignment has been reached.

The etalon can also be rotated around the horizontal axis by loosening and then

tightening again the active head fixing screw (letter D in Fig. 2). By using all

Fig. 4 : centering tool

positioned for alignment.

______________________________________________________________

7

these degrees of freedom, a perfect superimposition of the back reflected laser

spot with the incoming beamshould be reached.When the alignment is perfect,

some laser sources could start having large power fluctuations on the output: if

this happens, rotate slightly the head so that the back reflected beam does not

fool the laser source feedback circuitry. Such a small misalignment will not

affect the power output.

After alignment,the centring tool must be placed again onthe top of the support

post. There should be no need to change the alignment unless the incoming

laser beam is moved or additional components are placed on the light path

before the TCF.

Temperature tuning and device operation

The main TCF device does not have a power switch: by plugging the power

supply into the device socket, the etalon temperature will be changed and

stabilised to a set point, ranging approximately from 10 to 41 °C. During this

phase, the indicator on the top of the control box should graduallymove towards

middle of its range, which indicates a stable condition. On units equipped with

an RGB LED indicator, the latter will instead change from red (or blue) to green

when the stability is approached.

The etalon set point is fixed by rotating the device knob: the lower the setting,

the lower is also the set-point temperature. Each subdivision on the multi-turn

knob scale corresponds theoretically to about 6·10-2 °C.

The etalon is such that the temperature interval among transmission maxima is

about 17.5 °C: given the temperature range accessible to the device, up to two

maxima can thus be reached. The position of these transmission maxima (in

terms of temperature and with reference to the knob scale) and their

transmission intensity, as measured at factory after production, are reported as

calibration at the end of this manual. The position and spacing of the maxima

will change slightly using a different laser source due to small differences in the

wavelength. For this reason, the user should consider the reported values as a

first guess and will need to find the correct maxima positions for his source.

Many modern laser sources are specified to operate within a few tenths of a

nanometer from the nominal wavelength, and could slightly change the

operating frequency in this range (usually between a session of work and

another). When this happens a decrease in the output power from the etalon

will result and the device will need to be adjusted on the new laser operating

frequency.

The optimization of the set-point value should be done only after allowing a

sufficient warm-up time to the laser source, so that it has reached a stable

condition. The laser filter can initially be positioned at one of the factory

calibrated set-point. After a relevant change in temperature, the device is

usually get close to a stable enough condition within 10 minutes. A power meter

or photodiode sensor should be placed after the TCF and monitored in order to

verify the changes in transmittance of the device. By moving the set-point knob

by small steps, the user should be able to follow the variation of light

transmission and search for a position of maximum. While doing so, it is useful

______________________________________________________________

8

to check the device indicator, which should be at the middle position when an

equilibrium has been reached. To allow a complete stabilisation and find a

precise stable condition, check again the transmission after 20-25’: if

decreased, adjust again the set-point knob. By repeating this procedure 2 or 3

times, a precise tuning of the transmission maximum will be obtained. The user

could also eventually choose to lock the knob into position, using the knob stop

lever.

The instrument transmission stability in time will depend on the temperature

stability of the etalon. A relevant change in the room temperature or in the

convection efficiency with respect to first optimization can negatively affect the

performance; for this reason, it is advisable to use the TCF in a stable

temperature environment. Place the device as far as possiblefrom heat sources

and heat sinks, and far from ventilation sources like fans and windows.

Stability tests performed at production indicate a maximum decrease up to 2%

of the optimized transmittance when temperature stays within ± 1°C from the

optimized conditions. The loss of performance is expected to increase to 5%

with changes of temperature of ± 2°C.

Stabilised filter version (TCF-2) operation

The stabiliser optimises the output of the TCF, allowing increased tolerance

against small changes in room temperature and laser frequency. This will

greatly reduce the need of manual set point adjustments. The stabiliser unit

should be mounted and connected to the TCF before switching it on.

At first installation, keep the stabiliser off (switch lever in the lower position) and

get as close as possible to the maximum using the knob.

When the stabiliser is powered on, independently by the switch position, it will

remain idle (with LED off) for about 8 minutes. This delay is useful to allow the

TCF to reach the set point determined by the knob position after power up. After

this start-up delay, the stabiliser will react immediately to the switch and will

start to operate if the lever is in the top position. When the stabiliser is active,

a very slow sinusoidal modulation of the TCF head temperature will take place,

and the laser power output will be driven to maximum. When the maximum is

reached, the effect of the modulation on the light output will be negligible.

The efficiency of the stabiliser is lower when the set point is close to the limits

of the TCF scale (i.e. very hot or very cold). In these conditions, the time

required to optimise the output is longer: it is thus advisable to use a set point

close to room temperature.

If the laser beam is switched off, the TCF stabiliser should be also turned off:

the stabiliser will be fooled by a sudden drop of the laser power, and will require

time to stabilise again.

______________________________________________________________

9

If the knob set point gets too far from the maximum output setting, the stabiliser

could be unable to reach the maximum output. In this case, switch it off and

adjust the knob manually.

It is possible that the RGB LED indicator turns red or blue if the correction

voltage provided by the stabiliser is relatively large: this is not an indication of

problems in the TCF circuitry, but could also be a reason to adjust the static set

point position.

Device transmittance optimization

When the device is perfectly tuned to the laser frequency, the transmittance

should be quite high and comparable to the values obtained in the test sheet.

The most common cause for a decreased performance transmittance at

maximum are an insufficient beam collimation or a slightly skew incidence of

the beam on the etalon. Both these effects are never completely avoidable, due

to the dependence of the etalon transmittance on the light’s incidence angle,

and the non-ideality of the light source.

If the beam divergence is not low enough to obtain a satisfying transmission,, a

simple attempt to improve can be the use of a positive achromatic lens before

the TCF, having the focus approximately coincident with the laser source’s

virtual point. A 400÷500 mm focal length lens could reduce enough the

divergence without requiring too much free space on the experimental setup.

Setting a normal incidence is always possible by means of the alignment

procedure described in this manual. In this configuration the device will attain

the best transmission, but the light back reflected by the etalon will be fed back

to the laser unit, and the interference of this light beam with the out coming one

could perturb the stability of some laser sources. In this case, it might be

necessary to accept a small misalignment of the TCF or use an optical isolator

to avoid the effect.

Etalon replacement and wavelength ranges

Three different types of etalon, coated for the most common green, red and blue

wavelengths ranges, are available from stock at Tablestable. Each etalon is

usable within ±20 nm from the design wavelength and is mounted in a sealed

cylindrical container.

It is possible to replace the TCF etalon in order to use the same device

alternatively on different laser wavelengths.

In the case of a TCF-2 unit, it is necessary to remove the stabiliser unit in order

to access the etalon. The stabiliser unit is held in position by the friction of two

O-rings: to remove the stabiliser, pull it very gently and slowly outside, easing

the movement by mean of an alternate rotation. On more recent units, an

additional grub screw on the TCF head keeps the stabiliser locked in position:

this must be loosened by means of a 1.5 mm hex key before pulling the

stabiliser out.

______________________________________________________________

10

Once the stabiliser is removed, use a M1.5 hex key to loosen the retaining grub

screw on the TCF head, whose pressure keeps the etalon container in position.

Pull the etalon container by means of a soft tip and slide it out from the TCF

head; store the etalon container appropriately.

To insert the new etalon, reverse the previous process. The orientation of the

etalon holder is not relevant. For a TCF-2, pay attention that enough space is

left free for the stabiliser. Plug the stabiliser slowly and gently, rotating if

necessary. The stabiliser can only be installed on the head side opposite to the

connector.

Beam power limitations

The TCF is expected to work correctly for laser power up to 300 mW. Over this

limit, the etalon transmission may start to reduce significantly due to laser

heating; the device performance will be severely limited at power comparable

or higher than 3W.

The stabiliser should not be used with a beam power larger than 1.8 W; over

this limit, the performance may degrade and there is a possibility of damage in

the stabiliser electronic circuit.

In order to overcome these limitations, a high power version of the stabiliser and

special coated etalons have beenprepared. Please ask Tablestable if you need

to have your TCF or TCF-2 upgraded for high power use.

Specifications

Etalon material: fused silica

Etalon thickness: 1.509 ± 0.001 mm

Surfaces reflectance (at design wavelength) 94 ± 1 %

Effective average finesse: 38.11

Average contrast: ~ 590

Maximum transmittance: > 80 %

Maximum power consumption: 2 W

Power supply voltage range: 6 ÷ 8 VDC

This manual suits for next models

1

Table of contents

Popular Water Filtration System manuals by other brands

Franklin Water Treatment

Franklin Water Treatment SBF1 Series Installation instructions and owner's manual

Advantech

Advantech L3P Series Operation/setup manual

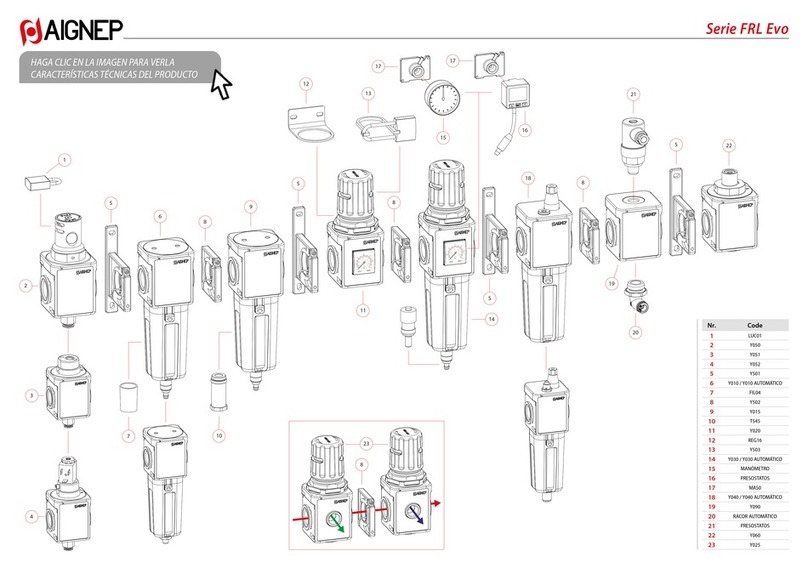

AIGNEP

AIGNEP FRL Evo Series instructions

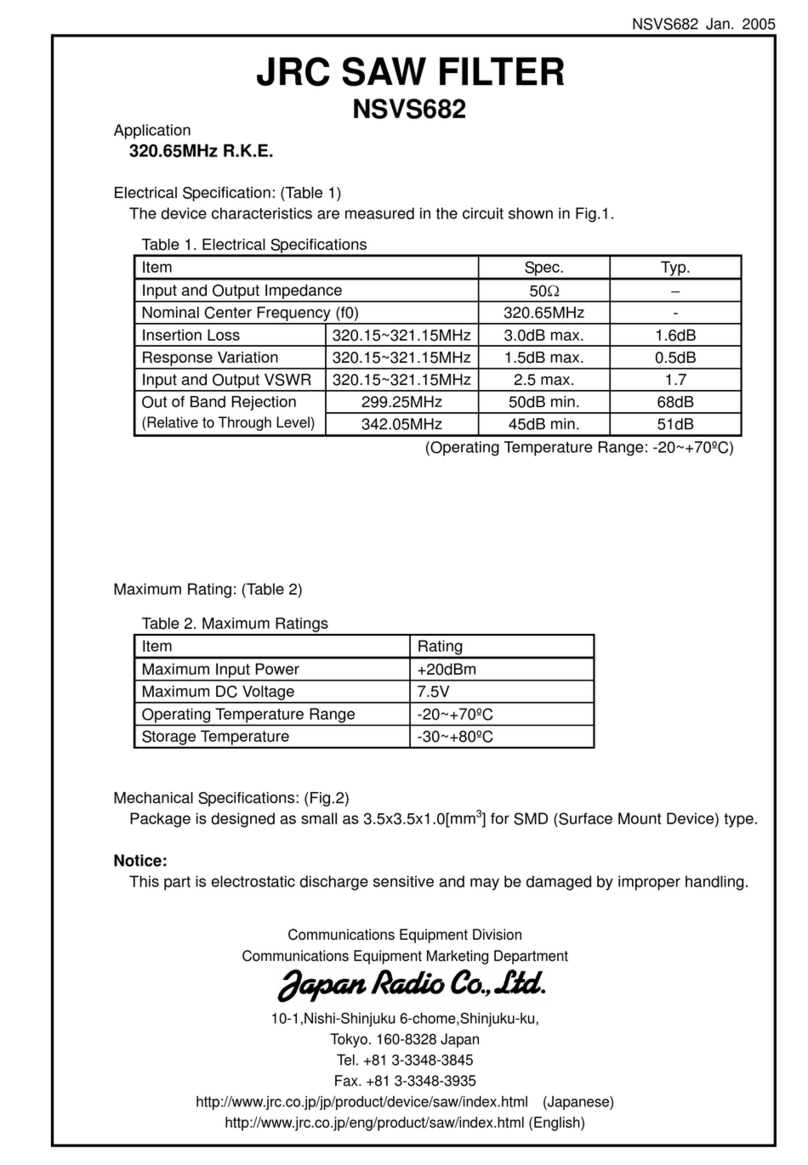

JRC

JRC NSVS682 manual

3M

3M 3MDW201 Installation and operating instruction

Panasonic

Panasonic TK6305P instruction manual