Theraplay IMP User manual

TRICYCLES

IMP - TERRIER - TMX - TRACKER

Congratulations!

Recommended Use

OWNER'S RESPONSIBILITY

BE SURE TO READ AND CARRY OUT THE FOLLOWING BEFORE THETRICYCLE IS USED

THE USE OF AWELL FITTED CYCLE HELMET IS RECOMMENDED

You have made an excellent investment in your child's health and happiness.Our tricycles offer

valuable exercise and therapy by providing cardiovascular fitness and increased muscle strength.

This range of tricycles is designed for recreation and therapy of children with special needs.Riders

must have fair head and trunk control to operate the trike effectively.

The tricycle is chain driven and has a fixed gear arrangement which helps to promote muscle development and

coordination.Additional supports can be added to the tricycle to tailor it to each child's needs.

The following instructions will give you advice on the adjustments and maintenance procedures to enable you to keep your

tricycle in the best possible condition.We do,however, recommend that a regular service is carried out by your appointed

dealer or a reputable local bicycle shop.The small cost will help to ensure rider safety and long life of the tricycle.

Please keep this manual in a safe place for future reference.

1. READ THE INSTRUCTIONS CAREFULLY AND KNOW HOW TO PROPERLY OPERATE

ALL STANDARD AND ACCESSORY EQUIPMENT FURNISHEDWITH YOUR TRICYCLE

2. MAKE SURE THAT THE SADDLE AND THE HANDLEBARS ARE POSITIONED TO

PROVIDE THE MAXIMUM SAFETYAND COMFORT.

3. BEFORE RIDING THE TRICYCLE, BE SURE THAT THE BRAKES ARE CORRECTLY

ADJUSTED AND FUNCTION PROPERLY. BE SURE TO TEST THAT YOUR TRICYCLE

OPERATES SAFELY ANDTHAT IT CAN BE BROUGHTTOA SMOOTH SAFE STOP.

4. WE RECOMMEND THE USE OF A CYCLE HELMET, IF ONE IS USED, BE SURE IT FITS

COMFORTABLY AND SECURELY AND DOES NOT IN ANY WAY INTERFERE WITH

VISION OR HEARING.

5. OUR TRIKESARE DESIGNED WITHA LOW CENTRE OF GRAVITY, BROADWHEELBASE,

AND AN ADJUSTABLE STEERING STOPTO MINIMISETHE RISK OF THEMTIPPING OVER,

HOWEVER, ALL TRIKES CAN BE TIPPED OVER. ENSURE THAT THE RIDER IS

PROFICIENT IN HANDLING THE TRICYCLE ESPECIALLY WHEN CORNERING. IT IS

BEST TO CORNER SLOWLY UNTIL CONFIDENCE IS GAINED IN HANDLING THE

TRIKE.

6. CHECK TYRES FOR PROPER INFLATION PRESSURE AS INDICATED ON THE SIDEWALL.

7. ALL TRICYCLESARE MADE AND ARE INTENDED FOR ONLY ONE PERSONTO RIDE,

SITTING PROPERLY ON THE SEAT.

8. MAKE SURE THAT ALL NUTS,BOLTS,AND SCREWS ARE SECURELY TIGHTENED.

9. THE MANUFACTURER IS NOT RESPONSIBLE FOR FAILURE, INJURY, OR DAMAGE

CAUSED BY IMPROPER COMPLETION OFASSEMBLY OR IMPROPER MAINTENANCE

AFTER SHIPMENT.

10. SINCE NORMAL WEAR OF SUCH PARTSAS TYRES,TUBES,BRAKE BLOCK ASSEMBLIES,

CABLES, ETC.WILL NECESSITATE REPLACEMENT FROMTIME TO TIME,PLEASE REFER

TO YOUR DEALER OR A REPUTABLE BICYCLE SHOP FOR WHATEVER ITEMS ARE

REQUIRED.

11. INSURE YOUR TRICYCLE

12. RETAINTHESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE.

• USE UNDER SUPERVISION

• THE RIDER SHOULD WEAR PROTECTIVE HEADGEAR AND ALWAYS WEAR SHOES

• DO NOT USE NEAR STEPS,SLOPING DRIVEWAYS, ROADWAYS,OR SWIMMING POOLS

• ALTHOUGH OUR PRODUCTS ARE DESIGNEDWITH SAFETY IN MIND,WE CANNOT

GUARANTEE FREEDOM FROM INJURY. THE USERASSUMES ALL RISK OF INJURY OR

SUITABILITY FOR A PARTICULAR CLIENT.

SAFETY CONSIDERATIONS

Owner’s Manual

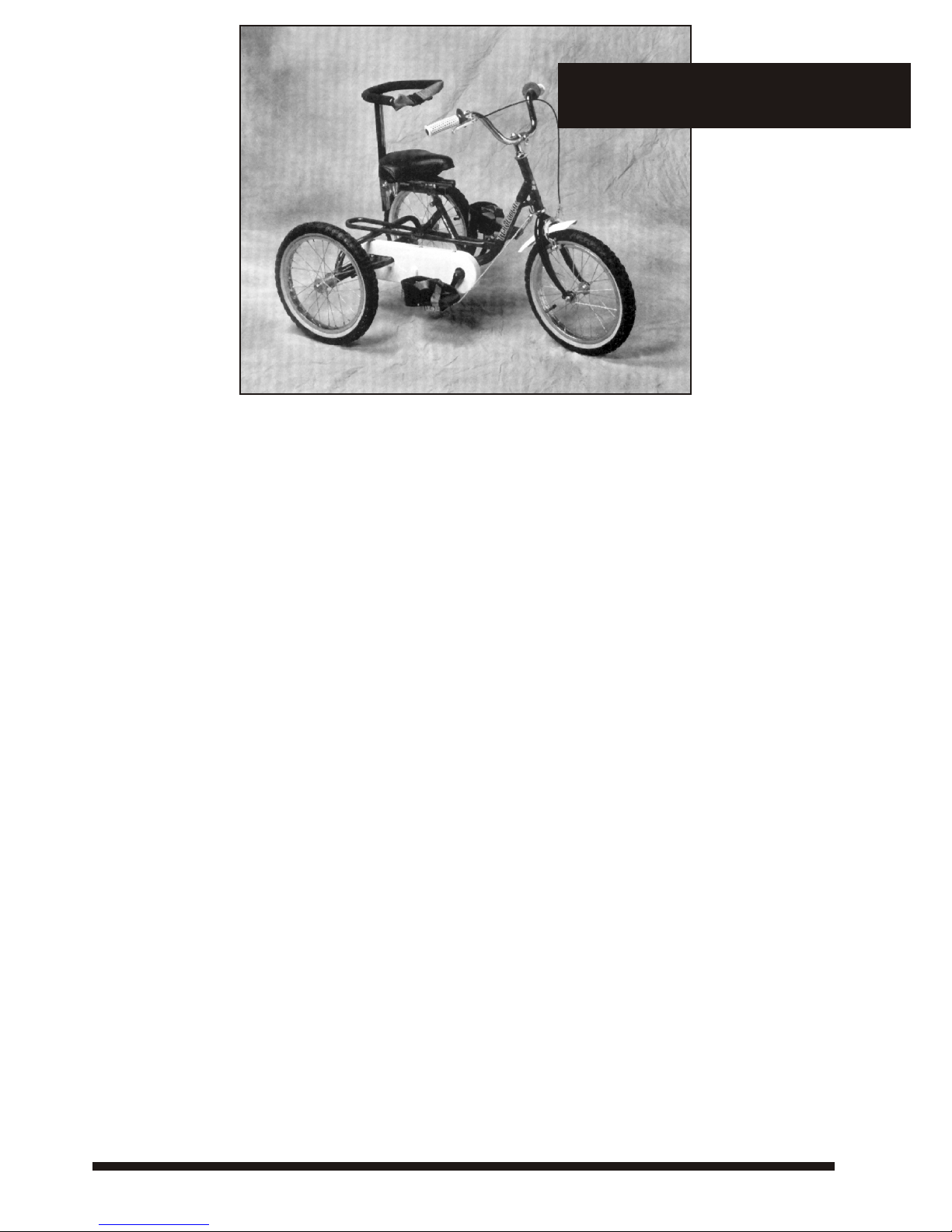

YOUR NEW TRICYCLE

The IMP, Terrier,TMX andTracker models are designed to grow with

the rider.Saddle and handlebar adjustments combine with low fixed

gearing to ensure that each tricycle will give many years of fun and

exercise.

Front Fork Unit:

This unit comprises of; front wheel, fork,brake, mudguard, handlebars and

stem.

Mainframe:

This is the central frame of the tricycle and it comprises of; Bottom

Bracket assembly, and Headset Bearing assembly. Some models of the

tricycle are fitted with a Frame Folding Mechanism which allows the

Mainframe to be separated into two sections.

Rear Unit:

This section carriers the rear axles and comprises of;drive axle and wheel,

free axle and wheel, axle bearings and rear drive cog.

M12 Frame Stud Nuts (See Diagram 2):

These are located to the rear of the Mainframe and are used to connect

the Mainframe and Rear Unit.

M8 Frame Cap Screw (See Diagram2)

This is located to the rear of the Mainframe and is used to connect the

Mainframe and Rear Unit.

Parking Brake:

A caliper brake is fitted to all ourTricycles except theTracker model which

has a ‘V’ type brake fitted. AllTricycle models, with the exception of the

Imp, have a locking brake lever. To operate pull the brake lever whilst

pushing down on the silver button,until engaged. To release simply pull on

the brake lever.

Wheels:

The Imp has 12 ½" x 2 1/4" Wheels,The Terrier has 16" x 2.125 Wheels,

TMX has 20" x 2.125Wheels andTheTracker has 24" x 2"Wheels. The left

rear wheel is the DriveWheel.The right rear wheel is the FreeWheel.

Steering Stop:

A steering limitation device is fitted to each tricycle.

Optional Equipment

If you have ordered any of the following accessories please ensure that they have

been included. If any of the parts are missing,contact the customer help line.

Adjustable Back/Trunk Support

This item provides greater sitting stability. It has a U-shaped frame with a

waist strap.It is adjustable in height and depth.

Footsandals c/w Pulley System:

Designed to provide assistance in keeping feet on the pedals.The pulley

system helps to maintain the foot in a comfortable position.

Comfi-Grip Handlebar:

A multi adjustable handlebar made in 2 separate halves thus allowing any

number of set -up options.

Looped Handlebar:

Oval shaped handlebar allowing different hand grasp position over

conventional type handlebars.

Frame Folding Mechanism:

This item permits the front section of the frame to be folded or detached

from the rear for storage or transportation.

Pelvic Strap:

An addition strap which is used in conjunction with a Back/Trunk Support

to provide a greater degree of positioning support.

Rear Steering Mechanism:

Allows complete parent/carer control of the tricycle by means of a rear

mounted pole which controls steering of the tricycle.

Not available onTracker model.

Leg Calipers:

Attachment which is used in conjunction with Footsandals to prevent the

scissoring action of legs.

Push/Pull Bar:

This is a detachable guidance pole which can be fitted to the rear of the

tricycle for control or the front for steering.

‘In-Line’Trunk Support:

A trunk support which provides maximum positioning control. It has

adjustable wings which swingaway for transfer.

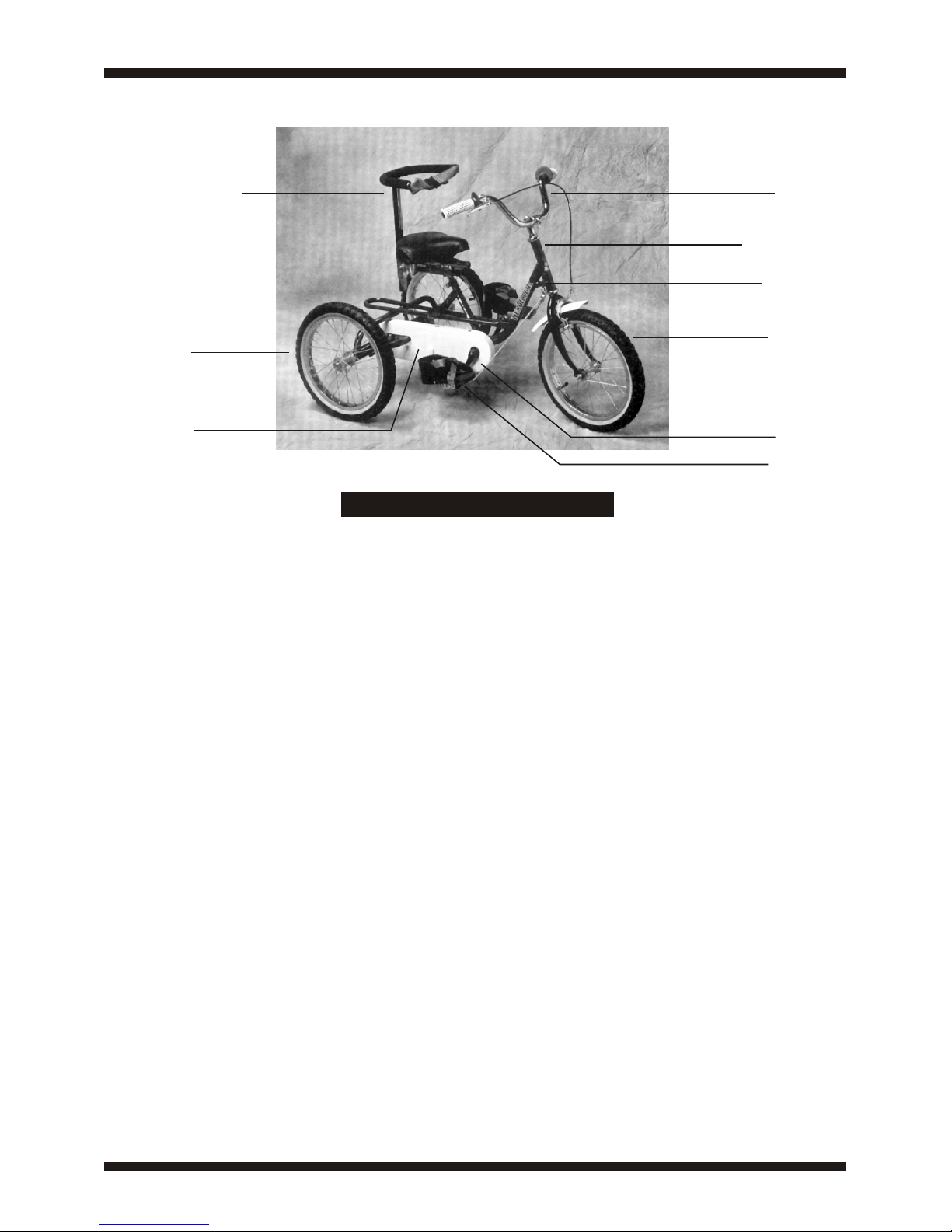

DIAGRAM 1

Back/Trunk Support Handlebars

Steering Column

Steering Stop

Front Wheel

Crank Arm

Foot Sandals

Drive Wheel

Free Wheel

Chain Guard

Rear Unit

Frame Studs

Mainframe

M8 frame

cap screw

M12 frame

stud nuts

DIAGRAM 2

DIAGRAM 3

YOURTRICYCLE COMES PARTIALLYASSEMBLED AND IF BOXED

REQUIRES ONE OR MORE OFTHE FOLLOWING STEPS.

1. Carefully remove the polythene wrapping using a sharp knife and

any other packaging material. Care should be taken not to damage

the upholstery,tyres and paintwork.

2.The tricycle mainframe is split into two parts; the Mainframe Unit

and the Rear Unit (see Diagram 2). To assemble these parts first

remove the M8 cap screw from the Mainframe Unit using the allen

wrench provided and then slide this fully into the Rear Unit.Refit the

M8 cap screw but do not tighten anything at this stage.

*We recommend that before attempting the next stages you protect

your clothes and floorcovering as this part contain grease*

3. CHAIN: To fit the chain, place it onto the front chainring and then

fit it onto the rear cog.If you are unable to fit the chain fully onto the

rear cog then place as much chain onto the teeth of the cog as

possible and then turn the rear drive wheel (rear left) which will feed

the chain onto the cog.

4A. ATTACHING FRONTWHEEL/FORK TO REAR OFTRIKE (IMP

AND TERRIER MODELS ONLY) (See Diagram 3):To attach front

wheel and fork to the rear of tricycle, first remove the two lock nuts

at the top of the threaded steering column. Leave one set of ball

bearings at the base of the steering column. Insert front wheel and

fork upwards into front of tricycle. Fit the other set of ball bearings

over the steering column with the ball bearings facing downwards and

replace locknuts on the threaded column,the broad flat lock nut first,

followed by the spacer washer (if fitted) and the smaller lock nut.

Tighten until the steering can be turned easily. Overtightening will

make the steering stiff.

4B. ATTACHING FRONT WHEEL/FORK TO REAR OF TRIKE

(FRAME FOLDING MODELS ONLY):The frame folding mechanism

enables the Tricycle to be split into 2 parts for storage and

transportation.To join the parts together,remove the black knob and

washer from the front section and the black knob with the threaded

stud and washer from the rear section.Bring both halves together and

reattach the black knobs.

5. HANDLEBARS: Fit the Handlebars and stem into the Steering

Column and secure with theAllen key bolt at the top of the Handlebar

Stem. Swing the Handlebars into desired position and secure with the

Allen key bolt on the underside of the Handlebar Stem. The

Handlebars are height adjustable. HINT: Loosen the bolt and then tap

the bolt head, this will dislodge the locking mechanism, then secure

tightly in place.

6. CHAINTENSION (See Diagram 2): To tension the chain, pull the

Rear Unit back whilst holding the Mainframe Unit, this will effectively

stretch the chain. Tighten the M8 Frame Cap Screw with the allen

wrench and then securely tighten the M12 Frame Stud Nuts with a 3/4

or 19MM wrench.Turn the pedal to ensure that the chain is running

smoothly. The chain tension is correct when the chain has 1/4” of slack

in the middle.

7. CHAIN GUARD: The plastic chainguard is pre-drilled and should be

fixed to the trike using the self tapping screws which will be attached to

the frame.

ASSEMBLY

Small lock nut

Broad flat lock nut

Ball Bearings

Collar

Front Fork

MAINTENANCE

8. SADDLE: Fit the saddle into the seat post and secure with the

locking lever/nut.The saddle is height adjustable but should NOT be

extended further than the marker hole on the seat post.The correct

saddle height should allow for a slight bend at the knee,when the ball

of the foot is on the pedal at its lowest position.The saddle can also be

moved horizontally along the seat post or tilted backwards or

forwards. The clamp located under the saddle controls this

movement.

9. BACK/TRUNK SUPPORT: If your tricycle is supplied with this

accessory this unit slides into the square location tubing and secures

beneath the saddle.This may be adjusted in depth.The trunk support

can be moved vertically.This must be secured in place with the M8

Cap Screws.

10. FOOTSANDALS WITH PULLEY SYSTEM: If your tricycle is

supplied with this accessory all fittings are provided.Secure with nuts

and plate to the underside of the pedal.The pulley wheel should be

attached to the frame hook.The cord runs through the pulley wheel

and is secured to the underside of each footsandal.The cord can be

adjusted in length to suit the riders requirements or removed.

11. KICK STAND: This is fitted to TMX and Tracker tricycles with

folding frame option. NOTE: Do not sit on tricycle when removing

the front section of the tricycle as the kick stand is not designed to

support the riders weight.The purpose of the kick stand is to assist

assembly/disassembly of the folding option.

Our products are designed to require the minimum of maintenance:

however the following maintenance procedures will help to ensure

the safe and efficient operation of the tricycle.

1 HAND BRAKES

Squirt a few drops of oil on pivot and hand lever. Do not wax or oil

rim.Always ensure that your brake blocks are free from oil or grease

and regularly check them for wear. If brake blocks are worn they

should be replaced.When fitting new brake blocks, ensure that they

are the right way up,(narrow edge to the top of the rim nearest to the

tyre).Apply the brakes and position the blocks so that they hit the rim

squarely and tighten.

2 CONTROL CABLES

Remove cable from the casing and grease inner cable.Replace worn

or damaged cables. Do not kink cables.Cables stretch with use, so

regular adjustment is necessary.

3 BEARING ADJUSTMENTS

Head bearings - Keep tight and well lubricated.The handlebars must

turn freely without any side to side play. Bottom Bracket bearings -

The crank assembly should turn freely without side to side play. Keep

the locknut tight and ensure the bearings are clean and well adjusted.

NOTE: if the Bottom Bracket bearings are not maintained this can

result in the chain becoming loose and may result in the Bottom

Bracket axle having to be replaced.

4 WHEEL ADJUSTMENTS

Front Wheel - Keep axle nuts tight.There should be no side to side

play and the wheel should run smoothly.Adjustments can be made by

tensioning or loosening the axle cones.The wheel should be centred

in the fork and sitting securely in the fork drop-out.Ensure spokes are

tight and the wheel is properly aligned.

DriveWheel (Riders left hand rear wheel) -This wheel is connected

to the axle by an internal thread. This wheel is secured in place with a

M14 Nyloc nut which has been cross drilled and pinned.Ensure that

the pin is completely removed before attempting to remove the

wheel nut and wheel. Ensure that the spokes are tight and the wheel is

properly aligned.

FreeWheel (Riders right hand rear wheel) -This wheel rotates on the

axle.The wheel and axle are secured in place by M12 Nyloc Nuts. If

there is side to side movement on this wheel,this can be eliminated

by tightening the M12 lock nuts. Ensure that the spokes are tight and

the wheel is properly aligned.

5 CRANKARMS

The crank arms are fixed onto the Bottom Bracket Axle by cap

Screws, these are located under the black plastic cap on the crank

arm. Ifeither crank feels loose,tighten securely with the M6Allen key

provided. NOTE: Failure to maintainthe crank arms can result in the

crank arms and the Bottom Bracket axlebeing damaged.

6 PEDALS

Each pedal has a different thread. Forcing the wrong pedal into the

wrong crank arm will destroy the threads in the crank arm.To prevent

this error, insert the“L” marked pedal into the left crank arm and“R”

into the right.Then tighten securely with the wrench.

NOTE:Left and Right are determined from the riding position on the

tricycle. Pedal sandals if fitted should be tightened against pedals using

the brackets and nuts.The brackets fit to the underside of the pedals

and they should be securely tightened in place.

7 CHAIN(See Diagram 2)

It is recommended that a 3 in 1 or similar oil is used to lubricate the

chain. Ensure that the chain is properly tensioned,if there is more than

1/4" slack in the middle of the chain then it needs tensioned. This can

be achieved by loosen the M12 Nyloc Frame Stud Nuts and the M8

Frame Cap Screw and then pulling the mainframe and rear axle in

opposite directions and then tighten the M12 lock nut and M8 screw.

Care should be taken not to overtighten the chain as this will make

the tricycle difficult to pedal.

8 HANDLEBARS

Ensure that the handlebars and handlebar stem are securedtightly.It is

dangerous to ride a tricycle if either is not properly secured. Do not

adjust handlebars beyond the maximum mark.

9 SADDLE

Ensure the seat pillar is secured tightly.The saddle should sit squarely

on the seat pillar and should not be extended beyond the maximum

marker hole.

10 TYRES

Check tyres for proper inflation pressure as indicated on the sidewall.

If the tyre is worn or the inner tube is punctured,repairs can be made

to the rear wheels without removing the wheel from the axle. The

front wheel will need to be removed from the front fork.

11 POSITIONING SUPPORT

Ensure that all positioning supports are properly secured.All screws

should be tightened.

12 PULLEY CORD

The footsandal pulley cord is madeof nylon.Should the cord start to

wear, heat slowly with a match or candle, until the cord bonds

together. Do not overheat or the cord will melt. Regular checks

prolong the life of the cord. Ensure that it is running freely through

the pulley wheel.A siliconespray ensures a smootheroperation.

13 ADJUSTABLE STEERING STOP

Ensure that this is adjusted to suitthe riders ability.

MAINTENANCE INTERVALS

Keep all painted parts cleaned andwaxed for a long lasting lustre.

B1 -WEEKLY

• Spray all chrome parts with aprotective spray.

• Lubricate the following: Pivot bolt on brake lever

Top of bolt on caliper brake

Inside bearing on both pedals

Chain-turn pedal crank and spray freely

Axle drive cog and axle

• Check tyre pressure

• Check for loose bolts and nuts

• Crank arms

3-6 MONTHS

• Check tyres for wear

• Check wheel alignment and for loose spokes

• Check brakes for adjustment,worn cable and worn brake blocks

• Clean and adjust all bearings and cones

• Check chain for adjustment and grime

• Check for loose bolts and nuts

• Check FreeWheel for excessive side-to-side movement

• Check DriveWheel for slippage

WARNING! Like any mechanical device, a tricycle and its

components are subject to wear and stress. Different materials and

mechanisms wear or fatigue at different rates and have different life

cycles. If a component's life cycle is exceeded, the component can

suddenly fail, causing serious injury. Scratches, cracks and

discolouration are signs of stress-caused fatigue and indicate that a

part is at the end of its useful life andneeds to be replaced.

USA GREAT BRITAIN

TRIAID Inc

PO Box 1364

Cumberland

MD21501 - 1364

USA

Tel: 301 759 3525

Fax: 301 759 3525

www.triaid.com

THERAPLAY Ltd.

32 Welbeck Road

Darnley Ind. Est.

Glasgow

G53 7SD

Tel: 0141 876 9177

Fax: 0141 876 9039

This manual suits for next models

3

Table of contents

Other Theraplay Bicycle manuals