Thermo Electron Corporation Polysonics SX40 User Guide ii

Contents

Product Overview..............................................................................................1-1

Introduction........................................................................................ 1-1

Ordering Information ......................................................................... 1-1

Specifications ...................................................................................... 1-2

Performance..................................................................................... 1-2

Physical............................................................................................ 1-2

Functional........................................................................................ 1-3

Approvals ......................................................................................... 1-4

Installation & Wiring........................................................................................2-1

Installing the Transducers ................................................................... 2-1

Mounting the Enclosure...................................................................... 2-4

Wiring ................................................................................................ 2-5

AC Power......................................................................................... 2-5

DC Power........................................................................................ 2-6

Transducers..................................................................................... 2-7

Relays............................................................................................... 2-9

4–20 mA Current Loop (Rev. F or Earlier) .................................... 2-11

4–20 mA Current Loop (Rev. G or Later)...................................... 2-13

Connecting a Switch to Remote Zero Feature................................ 2-14

Operation & Configuration ..............................................................................3-1

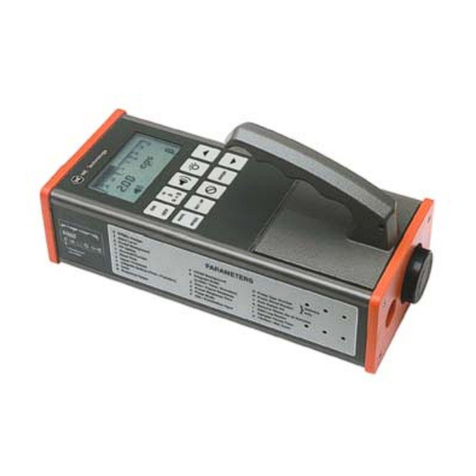

The Interface....................................................................................... 3-1

Screen Contrast................................................................................ 3-1

Configuration ..................................................................................... 3-2

Auto Mode....................................................................................... 3-2

Manual Mode .................................................................................. 3-3

HydraScan .......................................................................................... 3-6

Setup Items.........................................................................................................4-1

Reset ................................................................................................... 4-1

Config................................................................................................. 4-1

I/O Test.............................................................................................. 4-1

Relays............................................................................................... 4-1

4–20 mA Loop Calibration .............................................................. 4-1

4–20 mA Loop Test ......................................................................... 4-2

Flow.................................................................................................... 4-2

Rate.................................................................................................. 4-2

Chapter 1

Chapter 2

Chapter 3

Chapter 4