Thermo Electron Polysonics SX30 User manual

Analyze · Detect · Measure · ControlTM

Polysonics SX30

Portable Doppler Flowmeter

User Guide

P/N 1-0563-007

Revision F

HDS MESSTECHNIK

Franz-Kissing-Straße 7

58706 Menden

Tel.: 02373 / 1341

Fax: 02373 / 2488

www.hds-messtechnik.de

Polysonics SX30

Portable Doppler Flowmeter

User Guide

P/N 1-0563-007

Revision F

2005© Thermo Electron Corporation. All rights reserved.

“Sil-Glyde” is a registered trademark of American Grease Stick Company.

All other trademarks are the property of Thermo Electron Corporation and its subsidiaries.

Thermo Electron Corporation (Thermo) makes every effort to ensure the accuracy and completeness of this

manual. However, we cannot be responsible for errors, omissions, or any loss of data as the result of errors or

omissions. Thermo reserves the right to make changes to the manual or improvements to the product at any time

without notice.

The material in this manual is proprietary and cannot be reproduced in any form without express written consent

from Thermo.

This page intentionally left blank.

Thermo Electron Corporation Polysonics SX30 User Guide ii

Contents

Product Overview..............................................................................................1-1

Introduction........................................................................................ 1-1

Ordering Information ......................................................................... 1-1

Specifications ...................................................................................... 1-2

Performance..................................................................................... 1-2

Physical............................................................................................ 1-2

Functional........................................................................................ 1-3

Environmental ................................................................................. 1-4

Approvals ......................................................................................... 1-4

Installation & Wiring........................................................................................2-1

Installing the Transducers ................................................................... 2-1

Wiring ................................................................................................ 2-4

DC Auxiliary Power......................................................................... 2-4

Transducers...................................................................................... 2-5

4–20 mA Current Loop ................................................................... 2-5

Operation & Configuration ..............................................................................3-1

The Interface....................................................................................... 3-1

Screen Contrast................................................................................ 3-1

Configuration ..................................................................................... 3-2

Auto Mode....................................................................................... 3-2

Manual Mode .................................................................................. 3-3

HydraScan .......................................................................................... 3-5

Flow Menu Items...............................................................................................4-1

Setup................................................................................................... 4-1

Reset ................................................................................................ 4-1

Config.............................................................................................. 4-1

FFT..................................................................................................... 4-1

Logset ................................................................................................. 4-1

Accessing, Saving, & Loading Log Files............................................ 4-1

Trend.................................................................................................. 4-2

Rate.................................................................................................. 4-2

Max.................................................................................................. 4-2

Troubleshooting & Maintenance ...................................................................5-1

General Troubleshooting .................................................................... 5-1

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Contents

iii Polysonics SX30 User Guide Thermo Electron Corporation

Learn Mode Warnings ..................................................................... 5-1

Operating Mode Warnings .............................................................. 5-2

Checking the FFT............................................................................ 5-3

Signal Quality & Strength................................................................... 5-5

Maintenance ....................................................................................... 5-5

General ............................................................................................ 5-5

Upgrades............................................................................................. 5-6

Service & Returns ............................................................................... 5-6

Warranty............................................................................................. 5-7

Obtaining Pipe ID............................................................................................. A-1

Appendix A

Thermo Electron Corporation Polysonics SX30 User Guide 1-1

Chapter 1

Product Overview

Thermo’s Polysonics SX30 Portable Doppler Flowmeter generates two

independent ultrasonic signals at different frequencies. By correlating these

frequencies, the instrument automatically identifies and eliminates noise

errors from sources such as variable frequency drives.

In addition, operation of the instrument is enhanced by an Expert System

which allows the flowmeter to automatically “learn” the application

parameters. As a result, the flowmeter can be easily commissioned in a

fraction of the time required to configure competitive ultrasonic

flowmeters.

Refer to the following list of part numbers to order spare parts for your

instrument.

Table 1–1.

Part Number Description

22767-0001 Poly CD, specification sheet, meter installation video CD

1-0563-007 User guide

1-0561-005 HydraScan software manual

01008-0006 RS232 cable, standard serial, 6-ft, female to male, DB9

10228-0002 Power adapter, 90–264 Vac input, 15 Vdc output

10312-0001 Battery, 12 V, 7.0 A-hr, 24-hour continuous operation

10312-0002 Battery, 12 V, 7.0 A-hr, 12-hour continuous operation

10435-0007 Cable coupling, BNC (to extend 22688-0001, 2 required)

10520-0005 Thermo Electron accessory bag with shoulder strap

10605-0001 Pipe strap, SS, 32-inch with 3/8 SS screw

10605-0003 Pipe strap, SS, 67-inch with 3/8 SS screw

10705-0003 Nut driver, 3/8-inch

10808-0002 Coupling compound, silicone RTV108, 2.8 oz

10823-0005 Coupling compound, Sil-Glyde®, 4-oz

20192-0001 SS tag

20336-0001 Quick mount clamp assembly (set of 2)

Introduction

Ordering Information

Product Overview

Specifications

1-2 Polysonics SX30 User Guide Thermo Electron Corporation

Part Number Description

22366-0002 Cable adapter, dedicated transducer to portable meter

22490-0001 Cable adapter set, portable transducer to dedicated meter

22686-0002 PCB assembly, Doppler

22688-0002 Transducer cables (set), 16 feet with BNC connectors

22689-0002 PCB assembly, motherboard

22702-0001 Front panel assembly, includes keypad and display

22703-0001 Transducer assembly (set of 2), 15-ft cable length

22705-0002 PCB assembly, CPU

22262-0006 4–20 mA board

Velocity Range: 0.2–18 ft/s (0.06–5.5 m/s)

Accuracy: ±1% of velocity full scale

Fluids: Liquids containing particulate or entrained gas bubbles

Pipe Size: 0.5–200 in (12–5000 mm)

Transmitter: NEMA 6 (IP67), environmentally sealed, waterproof against

accidental immersion, splash proof with lid open

Transducers

Two encapsulated dual frequency sensor heads

Encased in stainless steel shrouds, with stainless steel straps and quick

clamps

Cable length: 16 ft (5 m)

Weight: 11 lb (4.9 kg) with 12-hr battery

Dimensions: Refer to the Figure 1–1

Specifications

Performance

Physical

Product Overview

Specifications

Thermo Electron Corporation Polysonics SX30 User Guide 1-3

Figure 1–1.

Outputs: 4–20 mA (into 750 ohms), 12-bit, 5 kV opto-isolated; loop

powered

Power Supply: Built-in lead acid gel battery, 90–264 Vac, 50/60 Hz

Standard: 12 hours continuous operation

Optional: 24 hours continuous operation

Charger

15 V at 1 A typical input supply voltage

2 A maximum

Mains supply voltage fluctuations to charger not to exceed ±10% of

nominal supply voltage

Auxiliary Supply

12–15 Vdc auxiliary power port

15 V at 2 A typical supply voltage

Must be an SELV source: Auxiliary terminals are

supplied from the SELV source as per IEC1010-1

Annex H

Keypad: 21-key with tactile action

Display: Backlit, 240 x 60 dot, high resolution graphics display

Data Logger

90000-point data logger

Programmable in intervals of 30 s, 1, 5, 15, 30, and 60 min

Programming: Via HydraScan software or integral keypad

Functional

Product Overview

Specifications

1-4 Polysonics SX30 User Guide Thermo Electron Corporation

Serial Interface: RS232 with DB9 connector

Temperature Range

Transducers: -40°F to 250°F (-40°C to 121°C)

Electronics:

With CSA approval: 41°F to 104°F (5°C to 40°C)

Without CSA approval: -4°F to 140°F (-20°C to 60°C)

Pollution degree: 2

Installation category: I for meter; II for battery charger

Non-Hazardous Area Certification: Designed to meet CE and NRTL/C

(CSA) for non-hazardous areas

Environmental

Approvals

Thermo Electron Corporation Polysonics SX30 User Guide 2-1

Chapter 2

Installation & Wiring

1. Select an installation site:

Keep the following questions in mind when choosing a proper

installation site:

●Is the chosen section of pipe always full of liquid?

●Are there at least 5 pipe diameters upstream and 3 pipe diameters

downstream from any directional changes, pipe joints, or

narrowing/widening of the pipe?

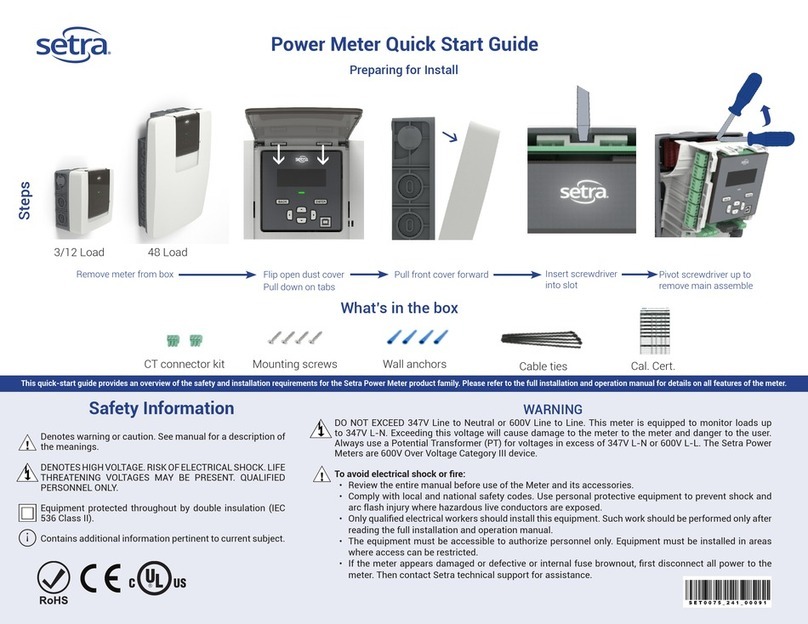

Figure 2–1.

Conditions at locations A, B, C, D, and E can interfere with the

transmission of the ultrasonic wave and yield inaccurate or unreliable

flow readings:

●A: Pipe may not be full

●B: Down flow

●C: Too close to elbow

●D: Air collects at the top of the horizontal pipe

●E: Sediment collects at the bottom of the horizontal pipe

Note Selecting the proper installation location is essential to flow

measurement reliability. Each application is unique and may require a

variation of installation locations. ▲

Installing the

Transducers

Installation & Wiring

Installing the Transducers

2-2 Polysonics SX30 User Guide Thermo Electron Corporation

2. Select a transducer orientation:

Refer to Figure 2–2. If your application allows, install the transducers at

the 3 and 9 o’clock locations. Ensure the transducers are parallel to

each other along the pipe circumference.

Figure 2–2.

3. Attach the transducers to the pipe strap:

a. Use a screwdriver to loosen the mounting screw and slide the lock

back on each transducer.

Figure 2–3.

Installation & Wiring

Installing the Transducers

Thermo Electron Corporation Polysonics SX30 User Guide 2-3

b. Place the pipe strap across the mounting, and slide the lock back

into place.

Figure 2–4.

c. Tighten the screws.

Figure 2–5.

4. Mount the transducers, ensuring the transducers face the same

direction (as shown in Figure 2–6):

a. Wrap the pipe strap around the pipe, and slide the end of the pipe

strap through the tension nut assembly.

b. Pull the strap tightly, and clamp the tension nut down to secure the

strap to the pipe.

c. Loosen the mounting screw of a transducer, and move the

transducer to the 3 o’clock position on the pipe. Tighten the

mounting screw to secure the transducer.

d. Loosen the mounting screw of the second transducer, and move the

transducer to the 9 o’clock position. Tighten the mounting screw

to secure the transducer.

e. Remove the strap from the pipe, and apply sonic coupling

compound to each transducer surface.

f. Reposition the strap on the pipe, placing the transducers in the

proper positions.

Installation & Wiring

Wiring

2-4 Polysonics SX30 User Guide Thermo Electron Corporation

g. Tighten the tension nut assembly with a 3/8-inch hex nut driver to

secure the strap.

Note Increasing the pipe strap tension improves signal transmission. ▲

Figure 2–6.

Wiring is accomplished using the connections on the side of the instrument

enclosure. Refer to Figure 2–7 and the following directions.

Figure 2–7.

Locate the auxiliary power connector on the side of the instrument, and

connect a minimum 10.5-V power supply that supplies 0.25 A.

Note The battery will not charge while the unit is operating from the

auxiliary power source. ▲

W

iring

DC Auxiliary Power

Installation & Wiring

Wiring

Thermo Electron Corporation Polysonics SX30 User Guide 2-5

Caution Avoid damaging the instrument: Do not use power supplies

greater than 18 V. ▲

Refer to Figure 2–7 to locate the transducer cable connections on the side

of the instrument.

Locate the red (in) and black (out) 4-20 mA connectors on the side of the

instrument. Connect as shown in Figure 2–8.

Figure 2–8.

Transducers

4–20 mA Current Loop

This page intentionally left blank.

Thermo Electron Corporation Polysonics SX30 User Guide 3-1

Chapter 3

Operation & Configuration

Figure 3–1. Keypad features

Following is a description of the components called out in Figure 3–1.

●LCD: Displays menu items.

●Scroll: Press to scroll to the next parameter displayed on the LCD

●Enter: Press once you have made an entry.

●Backspace: Deletes the last value entered.

●Numeric keys: Use to enter values when configuring the meter

●Menu selection keys: Press to select the corresponding menu item

displayed on the LCD

1. Press the +/- key.

2. When the Adjust Contrast screen appears, press the +/- key again, and

the software scrolls through the levels of contrast. Press the +/- key to

stop the scrolling.

3. Use the scroll and backspace keys to make fine adjustments to the

contrast.

The Interface

Screen Contrast

Operation & Configuration

Configuration

3-2 Polysonics SX30 User Guide Thermo Electron Corporation

Note the following before configuring the meter:

●You must know the pipe internal diameter (ID) to ensure reliable flow

measurements. If you do not know the pipe ID, go to Appendix A.

●There must be flow in the pipe when you start the meter.

There are two modes of operation. Consider using auto mode if your

application is a constant process. The instrument default is the auto mode.

Apply power to the meter, and begin the configuration process by selecting

Auto or Manual operating mode. Once you have completed the

configuration process, you can access these screens from the Flow screen by

selecting Setup, Config.

1. Pipe ID screen:

a. Enter the pipe ID, and press Enter.

b. Use the scroll key to select the measurement units (inches, mm).

Press Enter to select the unit.

c. Select Next to move to the next screen.

2. Flow Units screen:

a. Use the scroll key to select the flow units (US gallons, million

gallons, cubic meters, oil barrels, Imperial gallons, cubic feet, liters,

liquid barrels), and press Enter.

b. Use the scroll key to select the time base for flow measurement

(seconds, minutes, hours, days), and press Enter.

c. Select Next to enter learn mode.

3. The meter displays status of the learning process. Refer to “Learn Mode

Warnings” (Table 6–2 in Chapter 6) if you receive one of the following

messages:

●Invalid Signal, Can’t Learn

●No Flow, Can’t Learn

●Warning Low S Strength

●Warning Poor S Strength

Configuration

Auto Mode

Operation & Configuration

Configuration

Thermo Electron Corporation Polysonics SX30 User Guide 3-3

4. Once the meter completes the learning process, the Flow screen

appears.

a. If the flow reading is not accurate and you can verify the flow from

a calibrated flowmeter or other certified source, perform a

calibration.

b. Refer to “Operating Mode Warnings” (Table 6–3 in Chapter 6) if

the meter displays any of the following warnings:

●Warning

●Alarm

●Failed/No Flow

1. Pipe ID screen:

a. Enter the pipe ID, and press Enter.

b. Use the scroll key to select the measurement units (inches, mm).

Press Enter to select the unit.

c. Select Next to move to the next screen.

2. At the Flow Units screen:

a. Use the scroll key to select the flow units (US gallons, million

gallons, cubic meters, oil barrels, Imperial gallons, cubic feet, liters,

liquid barrels), and press Enter.

b. Use the scroll key to select the time base for flow measurement

(seconds, minutes, hours, days), and press Enter.

c. Select Next to continue.

3. Enter the Maximum Flow Rate. Select Next.

4. At this screen:

a. Scroll through the options available for the Velocity Range (2, 4, 8,

16, 32 ft/s) and press Enter to select. Scroll to the next parameter.

b. Enter a damping coefficient (0–99, 1 unit = 15 s). Press Enter, and

scroll to the next parameter.

The damping coefficient suppresses short term fluctuations in the

indicated flow rate. Increasing the coefficient increases the response

time to changes. Keep damping at a minimum unless the flow rate

fluctuates wildly. In this case, increase damping just enough to

reduce the fluctuation to an acceptable degree.

Manual Mode

Table of contents

Other Thermo Electron Measuring Instrument manuals

Thermo Electron

Thermo Electron Orion Star Series User manual

Thermo Electron

Thermo Electron Nicolet 380 User manual

Thermo Electron

Thermo Electron Orion 920Aplus User manual

Thermo Electron

Thermo Electron EPD MK2 User manual

Thermo Electron

Thermo Electron Evolution 300 User manual

Thermo Electron

Thermo Electron 96-09 User manual

Thermo Electron

Thermo Electron Nicolet 4700 User manual

Thermo Electron

Thermo Electron ELECTRA User manual

Thermo Electron

Thermo Electron Cahn C-34 User manual

Thermo Electron

Thermo Electron 48C User manual