Thermo IEC Centra-CL2 User manual

Thermo

IECIEC

Centra-CL2

Centrifuge

Cat. No. 426 -- For 120 VAC, 50/60 Hz

Cat. No. 427 -- For 240 VAC, 50/60 Hz

INSTRUCTION

MANUAL

IM-426

Revision 6

ThermoThermo IECIEC

300 Second Ave.300 Second Ave.

Needham Heights, MA 02494Needham Heights, MA 02494

Tel. (781) 449-8060 Toll Free: (800) 843-1113 Fax (781) 444-6743Tel. (781) 449-8060 Toll Free: (800) 843-1113 Fax (781) 444-6743

Website:www.labcentrifuge.com email:[email protected]

Centra-CL2 Instruction Manual 1

Table of Contents

1INTRODUCTION ...............................................................................................2

2INSTALLATION .................................................................................................3

3OPERATION......................................................................................................4

3.1 Warnings and Cautions..............................................................................4

3.2 Opening The Cover ....................................................................................4

3.3 Rotor Installation .......................................................................................5

3.4 Starting And Stopping A Run .....................................................................5

3.5 Rotor Removal ...........................................................................................5

3.6 Balance ......................................................................................................6

4APPLICATIONS.................................................................................................7

4.1 Speed And Force Tables ...........................................................................8

4.2 Derating Table for Dense Samples............................................................10

4.3 Chemical Resistance Table .......................................................................11

4.4 Compatible Processes For Decontamination.............................................12

4.5 Nomograph.................................................................................................13

5MAINTENANCE.................................................................................................14

5.1 Cleaning .....................................................................................................14

5.2 Brush Replacement....................................................................................15

5.3 Fuse Replacement .....................................................................................16

5.4 Cover Interlock Bypass ..............................................................................16

5.5 Calibration ..................................................................................................16

5.6 Power Cord Replacement ..........................................................................16

5.7 Warranty.....................................................................................................17

5.8 Condition of Returned Equipment..............................................................17

6SPECIFICATIONS.............................................................................................18

7SERVICE ...........................................................................................................19

7.1 Warning Messages and Error Codes........................................................19

7.2 General.......................................................................................................19

7.3 Disassembly For Service............................................................................20

7.4 Interlock......................................................................................................20

7.5 Timer PCB..................................................................................................21

7.6 Motor ..........................................................................................................21

7.7 Interlock PCB .............................................................................................22

8DRAWINGS .......................................................................................................23

IMPORTANT

Thismanualmaynotcontaininformationonallchangesthathaveoccurredtothesubjectinstrumentsince

the manual issue date. It was prepared for use by IEC authorized factory-trained service or dealer

personnelwhoarekeptcurrentthroughaprogramofservicelettersandbulletinsandtrainingseminars.

This manual contains warnings against operating procedures which could result in an accident and/or

personal injury. It also contains cautions against procedures which could result in damage to your

centrifuge or accessory equipment. Read this manual thoroughly before operating or servicing this

centrifuge.

Centra-CL2 Instruction Manual

2

1 INTRODUCTION

The IEC Centra-CL2 is a compact benchtop centrifuge designed for

multipurposeuseinmedical, industrial, and scientificlaboratories.

There are two models:

•Cat. No. 426 for 120 V, 50/60 Hz

•Cat. No. 427 for 240 V, 50/60 Hz

The Centra-CL2 accommodates a wide variety of rotors, including fixed angle

and horizontal (swinging bucket). IEC AeroCarriers™ provide aerosol

containment along with autoclaveability. The CL2 can handle up to 300 ml

(801 rotor), and reach maximum speeds of up to 8500 rpm (841 fixed angle

rotor) and 3900 rpm (236 horizontal rotor).

Other important features of the CL2 are a cover interlock for safety, and a

'glove-friendly' membrane control panel with digital speed and time displays.

An 'At Speed' timer mode allowing for accurate separations, and a continuous

'hold' mode are also featured.

Centra-CL2 Instruction Manual 3

2 INSTALLATION

After unpacking, place the unit on a clean, level surface. The

surface must be level to ensure quiet, vibration-free operation. A

rigid, stable location is important since an improperly loaded unit can

vibrate or even move. Allow a space of 3 in. (7.6 cm) on each side and 4 in.

(10.2 cm) in the rear of the unit for ventilation. Ensure that the suction cup

feet grip the surface firmly.

Using a voltmeter, measure the line voltage to ensure it is within the limits for

your model. For Cat. No. 426 the line voltage should be between 108 and

132 VAC. For Cat. No. 427 the line voltage should be between 216 and 264

VAC. Variations in line voltage or frequency will affect the unit’s speed and

acceleration.

Before moving, unplug the centrifuge and remove all accessories and the

rotor.

Clearance Envelope InternationalElectrotechnical Commission standard 1010part 2-20 limits

the permitted movement of a laboratory centrifuge to 300mm in the event of a

disruption. The user should therefore mark the clearance envelope boundary

around the centrifuge, or laboratory management procedures should require

that no person or any hazardous materials are within such a boundary while

thecentrifuge is operating.

Centra-CL2 Instruction Manual

4

3 OPERATION

3.1 Warnings and Cautions

Warnings To Avoid Electric Shock:

•Plug the power cord into a grounded outlet.

•Never remove the grounding prong from the power plug, or use any

adapter which does not complete the grounding circuit.

•Always unplug the power cord before attempting to clean or service

thecentrifuge.

Cautions •DO NOT exceed maximum rated speed for each rotor/accessory

combination. Maximum speeds can be found in Section 4.1 Speed

And Force Tables. All IEC rotors and accessories are stamped with

their cat. no. for easy identification.

•Samples of specific gravity higher than 1.2 require the maximum

speed to be derated.

•Ensure that loads are properly balanced around the rotor to minimize

vibration. All IEC accessories are stamped with their weight for easy

balancing.

•Do not block the vents, otherwise, airflow will be restricted.

•Be sure the rotor and accessories are properly installed before

attempting to start a run.

3.2 Opening The Cover

Once the red light over the STOP button is steadily illuminated (no longer

flashing) pressing the COVER OPEN button on the control panel will release

the interlock, allowing the cover to be opened.

STOP/COVER

OPEN

Centra-CL2 Instruction Manual 5

3.3 Rotor Installation

When the unit has power, the red light over the STOP button is illuminated.

This is also an indication that the rotor is stopped and the cover can be

opened. Push the COVER OPEN lever to the right and lift the cover. Lower

the rotor straight onto the shaft. Screw the knurled metal locking nut

(clockwise) onto the shaft to hold the rotor down (on some rotors, you must

remove any sample tubes first.). Tighten the nut with your fingers; do not use

atool.

Rotors with or without a keyway can be used on the Centra-CL2 since there

is no key on the shaft.

3.4 Starting And Stopping A Run

To start a run, use the ARROW buttons to set the desired run time (0 to 60

minutes) in the TIME display, and the desired rpm in the SPEED display.

Press the START button. The green light under the START button will

illuminate, and the time display will begin counting down. The actual speed is

displayed in the SPEED display. The centrifuge will run for the set duration

and decelerate to a stop. To terminate a run before time expires, press the

STOP button. The red light over the STOP button illuminates when STOP is

pressed or time expires, and it flashes until the rotor comes to a stop.

Note: The cover may be opened when the rotor speed is below 20 RPM.

The time and speed settings cannot be changed during a run. A new run

cannot be started until the rotor has come to a complete stop.

For infinite spins (hold mode), use the arrow keys to scroll up past 30

minutes. The word 'HOLD' appears in the display. Pressing the START

button will begin a run which can only be terminated by pressing the STOP

button. In the hold mode, the timer counts up.

To select the timing mode, use the arrow buttons to scroll down past 0

seconds. The letters 'Spd' or 'Acc' will appear. Press the arrow buttons to

toggle between the two timing modes. 'Spd' is the 'At Speed' timing mode

where the timer starts counting down when rotor reaches 95% of set speed.

'Acc' is the normal timing mode where the timer begins to count down as

soon as the run button is pressed.

3.5 Rotor Removal

To remove a rotor, first remove any sample tubes, shields, and other

accessories from the rotor. Next, unscrew (counterclockwise) approximately

one full turn the knurled locking nut. Then place both thumbs on the knurled

locking nut and grip the rotor with the fingers. Push your thumbs down and at

the same time pull the rotor up with your fingers. This should dislodge the

rotor from the shaft. If unsuccessful, lightly tap the knurled metal locking nut

with a rubber/plastic mallet or other similar object. The nut and the rotor can

now be removed from the shaft.

START

STOP

SPEED

TIME

ARROW

Centra-CL2 Instruction Manual

6

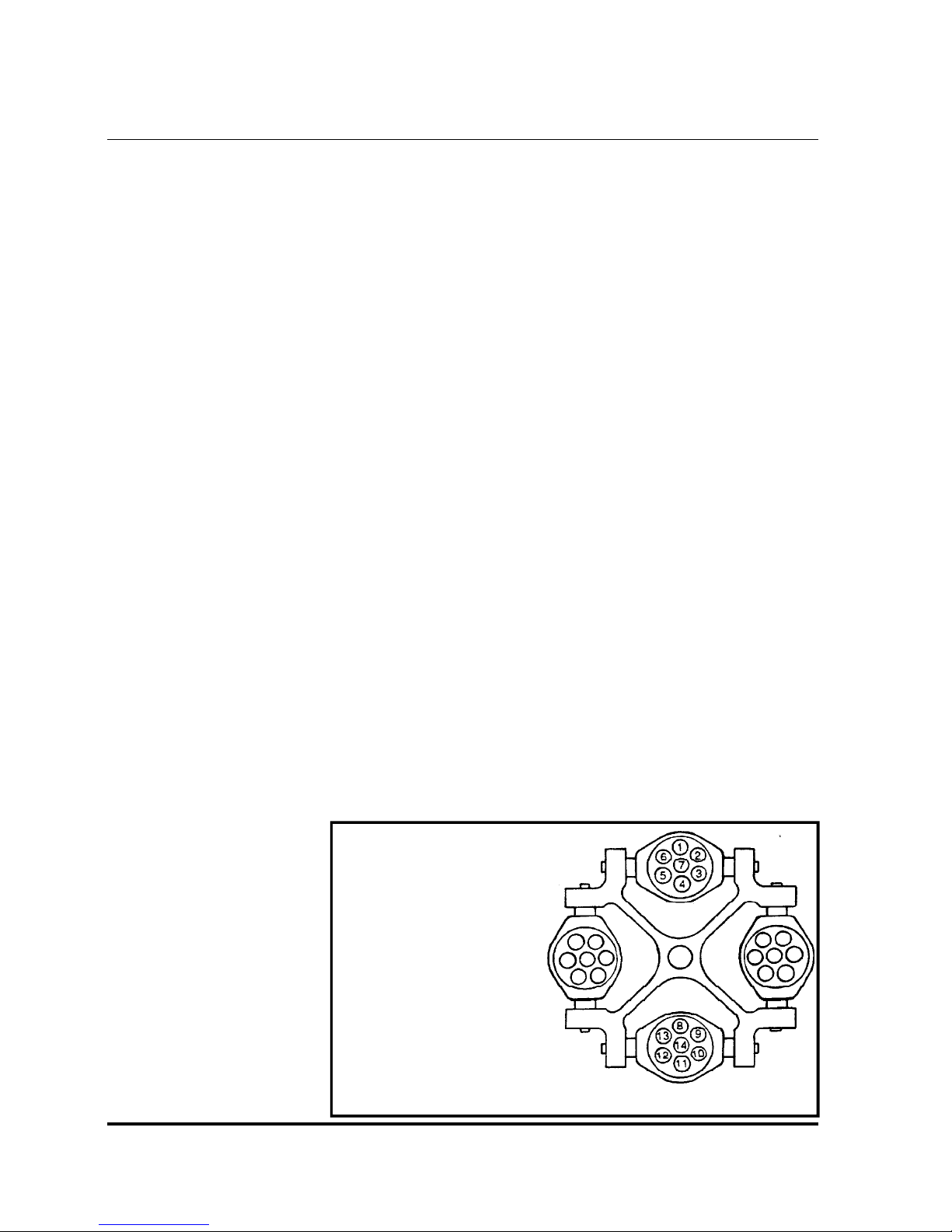

3.6 Balance

A balanced load is essential with all centrifuges. An unbalanced load

produces vibration and can damage the unit. A 2-gram load imbalance, at a

speed of 4600 rpm, imparts force equivalent to 9.1 kg at rest (20 pounds).

Therefore, always ensure that the rotor is loaded symmetrically and with a full

(or paired) set of tubes. Tube adapters should also be installed

symmetrically.

IEC rotors are dynamically balanced at the factory. IEC matches removable

parts (trunnion rings, shields, cups and carriers) to within 1 gram and stamps

the weight on each piece. Check these markings whenever you interchange

parts, to ensure that opposite parts are matched. Ensure that the total weight

of samples and removable parts loaded in opposing positions are equal in

weight to within 1 gram. The position numbers, present on many rotors and

adapters,identifyopposingtubepositions.

To obtain good dynamic balance, the opposite loads must not only be equal in

mass, but must also have the same center of gravity. Opposing containers

must be alike in shape, thickness, and distribution of glass or plastic. This is

especiallyimportantforlargecontainers.

Tubes loaded into swinging bucket rotors must likewise be symmetric around

the axis of rotation. Verify this by rotating the entire rotor 180° by hand: the

loads should be in the same apparent positions (not in the mirror image). In

addition, the loads within each bucket must also be symmetric around the

bucket’s pivot axis. Verify this by ensuring that each bucket is loaded so that

it does not tilt from the vertical when the rotor is at rest. Maintaining balance

within each bucket ensures that the bucket and the tubes swing out to

horizontal when the rotor reaches operating speed, applying centrifugal force

toward the bottom of the tubes. Failure to achieve full swing-out causes

vibration and premature wear.

Samples of different specific gravities can be processed in the same run,

provided that the samples of a given type are balanced around the rotor as

though they were the only ones in the rotor.

For example, load tubes in the

followingmanner:

1. Load four tubes.

Positions 3, 6, 10, 13

or2,5,9,12

or1,4,8,11

2. Load six tubes.

Positions6,7,3,13,14,10

or5,7,2,12,14,9

or1,7,4,8,14,11

3. Load an odd number of tubes.

Not recommended (unless a

dummy tube is used for balance.)

Centra-CL2 Instruction Manual 7

4 APPLICATIONS

This section describes the use of specific rotors and accessories. More

detailed information is often shipped with the rotor or accessory itself. This

sectioncontains four reference tables:

4.1 Speed And Force Table

4.2 Derating Table for Dense Samples

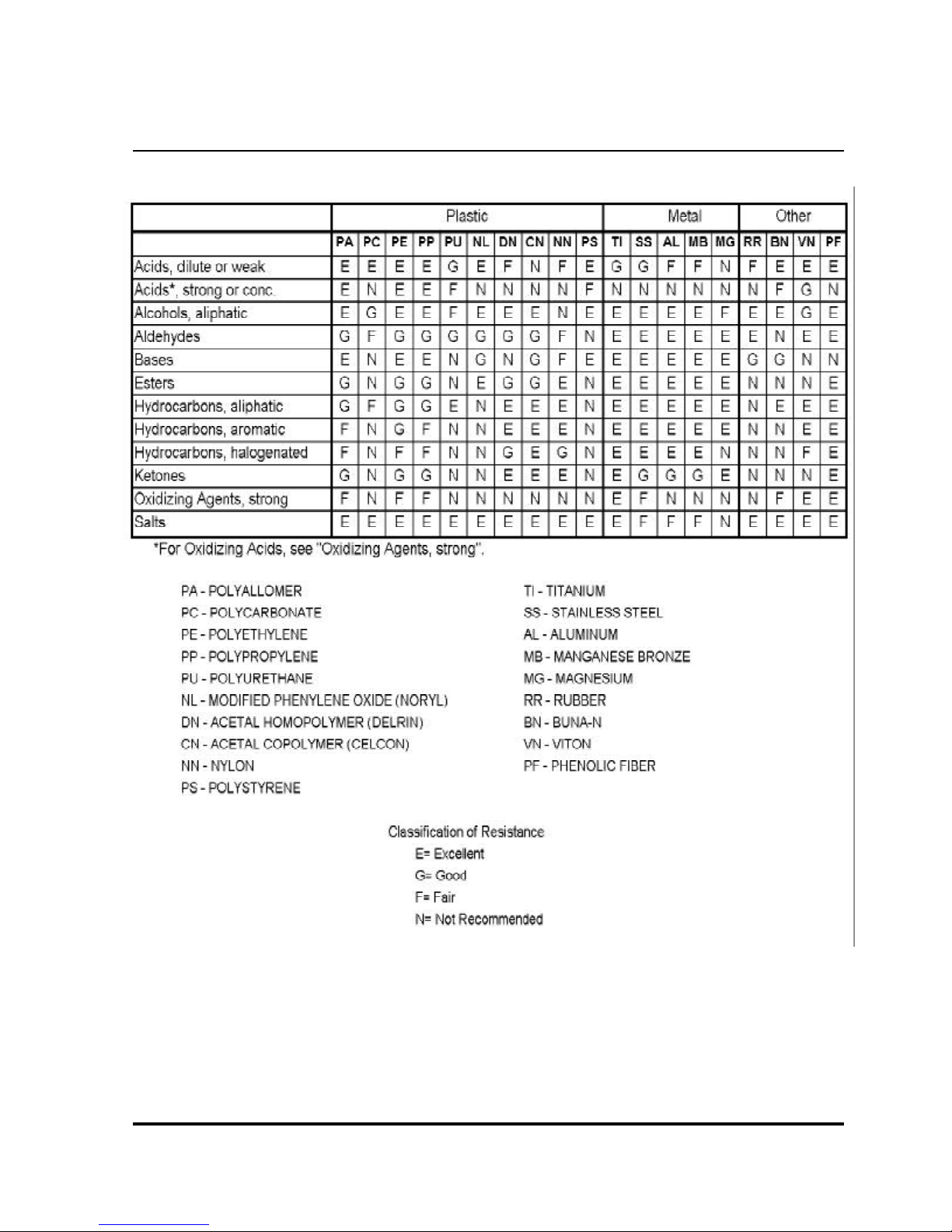

4.3 ChemicalResistanceTable

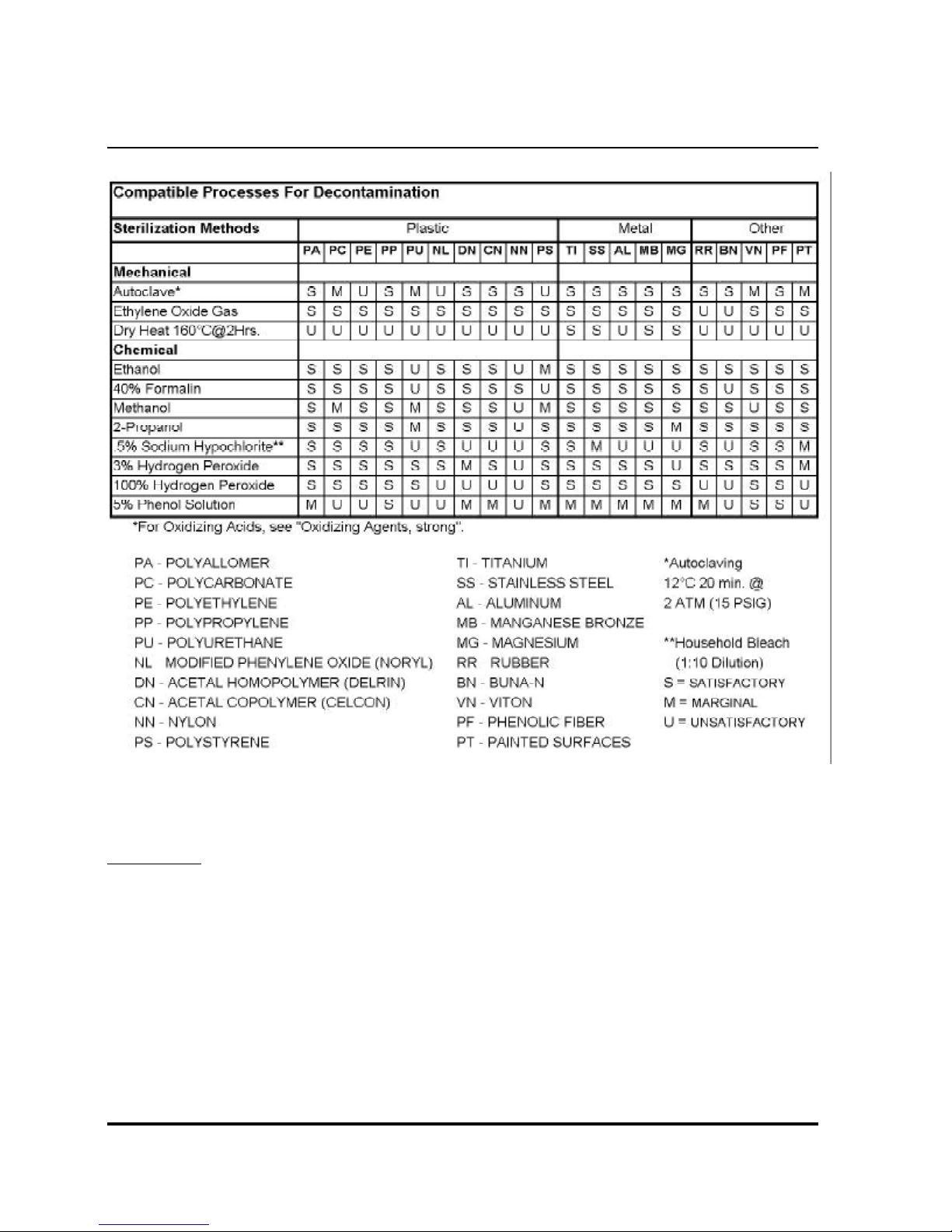

4.4 DecontaminationTable

4.5 Nomograph

Relative centrifugal force (RCF or G-force) at a given speed varies with the

rotor, and with the length of the sample tube, because the distance of the

tube’s tip from the center of rotation is different. The Speed and Force Table

indicates the maximum speed and RCF the Centra-CL2 can achieve with

variousrotor/accessorycombinations.

The Derating Table specifies reductions in rpm when spinning samples with

specificgravity above 1.2.

Misapplication of any tube can cause tube rupture. To avoid this, compare

the G forces specified in the Speed and Force Table with the ratings for the

tubes you are using. If the tubes are not rated for the force the centrifuge will

apply, reduce the speed to the G force limit of your tubes.

Your IEC centrifuge is made of materials designed to resist attack from most

laboratory chemicals. The interior of the rotor chamber is Painted steel.

Rotors and accessories placed in the chamber are made of a variety of

materials,including aluminum and polypropylene. The Chemical Resistance

Table shows the suitability of each material with different classes of reagents.

TheDecontamination Table lists compatiblemethods of decontamination

which may be used on the IEC Centra-CL2 centrifuge.

The Nomograph provides an easy method of converting RPM to RCF (or xg).

Section 5.1 describes how to clean and remove corrosion from the chamber,

rotors, and accessories. Follow these instructions, and clean spills promptly,

to minimize the effects of corrosive chemicals, before any resulting chemical

attack requires more expensive repair. Replace metal locking nut, rotors, or

accessories if they become cracked, deformed, or gouged.

Centra-CL2 Instruction Manual

8

4.1 Speed And Force Tables

Rotor 215 4-Place Swinging Bucket Rotor

Tube Maximum Shield or

No. x Vol. (ml) Tube RPM /RCF Radius Tr Ring Carrier Adapter Cushion

8x50ml Falcon/Corning conical plastic 3100 1510 14.1 4x326 8x320 -8x315

8x50ml Corning 8300-50 conical glass 3100 1510 14.1 4x326 8x320 -571

8x15ml Falcon/Corning conical plastic 3100 1510 14.1 4x326 8x320 8x1106 570

4x50ml Falcon/Corning conical plastic 3350 1750 13.9 4x325 4x320 -4x315

4x50ml Corning 8300-50 conical glass 3350 1750 13.9 4x325 4x320 -571

4x15ml Falcon/Corning conical plastic 3350 1750 13.9 4x325 4x320 4x1106 570

4x50ml sealed Falcon/Corning conical plastic 3175 1750 15.4 4x350 4x323 315

4x15ml sealed Falcon/Corning conical plastic 3350 1750 13.9 4x325 4x320 4x1106 4x668

4x15ml sealed Falcon/Corning 3175 1710 15.2 4x350 4x7323 1106 4x571

4x10-15ml sealed Vacutainer 16x100-125mm 3175 1710 15.2 4x350 4x7323 1106 4x668

4x7ml sealed Vacutainer 13x100mm 3175 1710 15.2 4x350 4x7323 4x1105 4x571

12x10ml 16x100mm 3450 1725 12.9 4x366 4x1013 -570

12x7ml 16x75mm 3450 1725 12.9 4x366 4x1013 -570

16x7ml 13x100mm 3450 1700 12.8 4x366 4x1018 -667

16x5ml 13x75mm 3450 1700 12.8 4x366 4x1018 -667

20x5ml 12x75mm 4000 1975 11.1 4x366 4x369 -567

20x3ml 10x75mm 4000 1975 11.1 4x366 4x369 -567

Rotor 221 6-place Fixed Trunnion Swinging Bucket

Tube Maximum Shield or

No. x Vol. (ml) Tube RPM /RCF Radius Tr Ring Carrier Adapter Cushion

6x15ml Falcon/Corning 3100 1650 15.4 fixed 6x303 -668

6x12.5ml Kimble 45170-125 3100 1650 15.4 fixed 6x303 -668

6x12ml IEC 1629, 1649 3100 1570 14.6 fixed 6x303 -570

6x10ml Corning 8080-10 3500 1890 13.8 fixed 6x356 -668

6x10ml IEC 2046, 2067 3500 1780 13.0 fixed 6x356 -570

Rotor 236 4-place Aerocarrier Horizontal Swing-Out Rotor

Tube Maximum Aero

No. x Vol. (ml) Tube RPM /RCF Radius Tr Ring carrier Adapter Cushion

4x50ml Falcon/Corning 3400 1950 15.0 fixed 4x2091S - -

8x15ml Falcon/Corning 3400 2000 15.5 fixed 4x2092S - -

8x10ml Kova/UriSystem 3400 2000 15.5 fixed 4x2092S - -

16x10ml Vacutainer 16x100mm 3700 2200 14.3 fixed 4x2093S - -

16x7ml Vacutainer 13x100mm 3700 2200 14.3 fixed 4x2093s - -

16x7ml Hemogard Vacutainer 13x100mm 3700 2200 14.3 fixed 4x2093s - -

28x7ml Vacutainer 16x75mm 3900 2150 12.7 fixed 4x2094S - -

28x5ml Vacutainer 13x75mm 3900 2150 12.7 fixed 4x2094s - -

28x5ml Hemogard Vacutainer 13x75mm 3900 2150 12.7 fixed 4x2094s - -

Centra-CL2 Instruction Manual 9

Rotor 801 6-Place 45 degree Fixed Angle Rotor

Tube Maximum

No. x Vol. (ml) Tube RPM /RCF Radius Shield Adapter Cushion

6x50ml Falcon/Corning conical plastic 3900 2050 12.1 6x305 -6x315

6x50ml Corning 8300-50 conical glass 3900 2050 12.1 6x305 -571

6x15ml Falcon/Corning conical plastic 3900 2050 12.1 6x305 6x1106 570

6x50ml Falcon/Corning conical plastic 4500 2450 10.8 6x320 -6x315

6x50ml Corning 8300-50 conical glass 4500 2450 10.8 6x320 -571

6x15ml Falcon/Corning conical plastic 4500 2450 10.8 6x320 6x1106 570

Rotor 804S 4-Place 40 degree Fixed Angle Rotor

Complete with 4 x 323 Sealed Buckets

Tube Maximum

No. x Vol. (ml) Tube RPM /RCF Radius Shield Adapter Cushion

4x50ml Falcon/Corning conical plastic 4200 2270 11.5 323 -315

4x50ml Corning 8300-50 conical glass 4200 2270 11.5 323 -571

4x15ml Falcon/Corning conical plastic 4200 2270 11.5 323 6x1106 570

4x60ml Corning 8540-60 2500 1000 14.3 4x341 -572

Rotor 809 12-Place 45 degree Fixed Angle Rotor

Tube Maximum

No. x Vol. (ml) Tube RPM /RCF Radius Shield Adapter Cushion

12x15ml Falcon/Corning conical plastic 3800 2150 13.3 302 -668

12x15ml Corning 8080-15 conical glass 3800 2050 12.7 302 -570

126xDevice Amicon Filtration Device 3900 2050 13.4 302 - -

12x10ml Corning 8080-10 4500 2310 10.2 12x356 -570

12xDevice Filtron or Millipore Devices 4500 2490 11.0 12x356 - -

12x10ml Corning 8080-10 4100 2270 12.1 12x303 -12x668

12x10ml 17x102mm 4100 2120 11.3 12x303 -570

Rotor 841 12-Place 45 degree Fixed Angle Rotor

Tube Maximum Use

No. x Vol. (ml) Tube RPM /RCF Radius Adapter

12x1.5-2.0ml microtubes 8500 4680 5.8 -

12x0.7ml microtubes 8500 4770 5.9 5763

12x0.5ml microtubes 8500 3960 4.9 5763

12x0.4ml microtubes 8500 4680 5.8 5764

12x0.25ml microtubes 8500 3630 4.5 5764

Centra-CL2 Instruction Manual

10

4.2 Derating Table for Dense Samples

The Speed and Force Table lists the Maximum speed for each rotor/

accessory combination in the Centra-CL2. IEC guarantees that the units can

achieve these speeds when used at nominal voltage.

These speeds are guaranteed only with samples whose specific gravity is not

greaterthan:

1.2 for swinging bucket rotors

1.5 for angle rotors

For denser samples, the maximum guaranteed speed is reduced (derated) by

a factor from the table below:

Derating Factor for:

SpecificGravity SwingingBucket Fixed Angle

1.2 1 1

1.3 .960 1

1.4 .925 1

1.5 .894 1

1.6 .866 .967

1.7 .839 .939

1.8 .816 .912

1.9 .794 .888

2.0 .774 .866

2.1 .755 .844

2.2 .738 .825

2.3 .721 .807

2.4 .707 .790

2.5 .692 .774

2.6 .678 .758

2.7 .666 .744

2.8 .654 .731

2.9 .642 .719

3.0 .632 .707

Example. An angle rotor rated for 5,000 rpm, used with samples with a

specific gravity of 1.6, should not be spun faster than (5,000 x .967 =) 4,835

rpm.

Specific gravities greater than 3.0. This table is based on the formula:

√(s0/sa)

...where s0is the maximum specific gravity allowed before derating (1.2 or

1.5, depending on the type of rotor), and sais the actual specific gravity of the

sample in question. You can use the same formula to compute derating

factors for specific gravities greater than 3.0.

Centra-CL2 Instruction Manual 11

4.3 Chemical Resistance Table

Centra-CL2 Instruction Manual

12

4.4 Compatible Processes For Decontamination

WARNING:

This chart describes the material compatibility of various sterilization methods. It does not specify

the adequacy of sterilization. Refer to section 4.3 Chemical Resistance Table for material

compatibilityduringcentrifugation.

Centra-MP4/MP4R Operation Manual 29

4.5RCF Nomograph

Centra-CL2 Instruction Manual

14

5 MAINTENANCE

5.1 Cleaning

Keep your centrifuge clean to ensure good operation and to extend its life.

Clean the entire sample chamber, rotor, and lid at the end of each workday,

and also right after any spill.

To clean the sample chamber, use a damp sponge, warm water, and a mild

liquid detergent suitable for washing dishes by hand, such as Ivory® liquid.

Do not use caustic detergents or detergents that contain chlorine ions, since

these attack metals. Remove stubborn stains with a plastic scrub pad. Do

not use steel wool, wire brushes, abrasives, or sandpaper, since they create

corrosion sites. Never pour water directly into the sample chamber. Scrub

the rotor’s tube cavities with a stiff test-tube brush that has end bristles and a

nonmetallic tip. After cleaning any part, dry it properly, preferably using a

clean,absorbenttowel.

Corrosion IEC manufactures and finishes rotors and structural accessories to give

maximum resistance to corrosion. However, maximum equipment life

requires that you continually inspect the rotor cavities for corrosion, especially

after using chloride ion solutions, such as sodium chloride (saline), and

sodium hypochlorite (household bleach). These solutions attack most metals.

Clean the rotor, rotor chamber, and accessories (particularly the sample

compartments and bucket cups) thoroughly after each such use. Inspect all

surfaces under bright light for corrosion; small crevices will grow deeper and

causefailure.

If you see any corrosion, remove it immediately as follows:

1. Follow the cleaning procedure at the start of this section. Soak the

part in the mild hand-dishwashing detergent. Scrub the part

thoroughly with a stiff test-tube brush having end bristles and a non-

metallictip.

2. Soak the part again in clear warm water for at least an hour.

3. Rinse the part thoroughly in warm water first, then in distilled water.

4. Dry the part thoroughly with a clean, absorbent cloth.

5. If this procedure does not remove the corrosion, discontinue use of

the part.

Storage Store parts on a soft surface to avoid damaging finished surfaces. Rotors

and other parts should be clean and dry for storage. Store them open to the

atmosphere, not in a plastic bag, so that any residual moisture will evaporate.

The parts should face downward to avoid retaining moisture in the cavities.

Centra-CL2 Instruction Manual 15

Decontamination Decontaminationiscalledforiftubebreakageoccursandinfectious,

pathogenic, or radioactive material is released into the unit. Some rotors or

accessories totally contain the sample tubes. In this case, spillage is usually

confined, and it may be sufficient to decontaminate only the rotor or

accessory.

The Decontamination Table lists the sensitivity of various materials to

common sterilization procedures. When using a 1-to-10 dilution of household

bleach (sodium hypochlorite) to decontaminate metal rotors or accessories,

followdecontamination by the corrosion cleaningprocedure given earlier,

since chloride ions attack most metals.

Always decontaminate for the minimum recommended time. If you observe

corrosion, remove it as described earlier, discontinue use of the sterilization

method,and use an alternate decontamination procedure.

Sterilization of polypropylene rotors can be done by autoclaving. Remove

any sample tubes before autoclaving, unless they are completely full of

sample, or remove caps, stoppers, and other tube closures, before

autoclaving to keep the tubes from collapsing under pressure. Autoclave the

rotor and accessories at 121° C @ 15 psig for 20 minutes. Do not stack

polypropylene rotors during autoclaving. After the rotor is cool to the touch,

do a normal cleaning operation as described above.

Repeated autoclaving will seriously degrade the performance of

polycarbonatematerials.

5.2 Brush Replacement

Refer servicing to qualified personnel only. Brush replacement is required

when the length of the brush not including the spring is less than 1/4 inch

long. Order additional sets as IEC Part Number 1780A.

WARNING DISCONNECT POWER CORD BEFORE REMOVING THE

BRUSHES.

First, remove all rotor and accessories from the chamber. Gently tilt the unit

onto its side and remove the four screws which secure the baseplate. The

brush caps are located on either side of the motor housing. Unscrew each

cap with your fingers (or use a small flat screwdriver) and remove the

brushes. There are two black caps which can be removed from the housing

to allow use of a large screwdriver. Measure the length of the brushes and

replace both brushes if either one is less than 1/4 of an inch long. Be sure to

reinstall all parts removed.

It is important to check the brushes periodically since damage to the motor

can occur if the brush is allowed to wear down to the spring.

Centra-CL2 Instruction Manual

16

CAUTION: WHEN REINSTALLING INSPECTED BRUSHES

When brush replacement is not required, it is important that the brush be

inserted in the same position as it was removed. The trailing edge of the

brush must be positioned properly. The trailing edge may be identified by the

presenceofadarkdeposit ofcarbonalongthatside.

Note: Newbrushesmayrequireaburn-inperiodofuptoahalf hour.

5.3 Fuse Replacement

Referservicingtoqualifiedpersonnelonly. First,removeallrotorand

accessories from the chamber. Gently tilt the unit onto its side and remove

the four hex head screws which secure the baseplate. Unscrew and remove

the four rubber feet and lift the baseplate off. The fuse(s) is mounted to the

cabinet housing. Replace fuse(s) with:

For 100/120 VAC 1 - 4A, .25 x 1.25 in. IEC part no. 40340

For 220/240 VAC 2 - 2A, .25 x 1.25 in. IEC part no. 40794

5.4 Cover Interlock Bypass

The Centra-CL2 has an interlock bypass for easy sample retrieval in the

event of a power failure. To bypass the safety interlock, unplug the centrifuge

and pry off the plastic plug located on the bottom of the control panel. Pull

downward on the cord to release the interlock. Do not perform this bypass

routinely. The cover interlock provides user safety and allows the cover to be

openedpromptly wheneverrotation has stopped.

5.5 Calibration

The speed sensor used in the Centra-CL2 requires no calibration. IEC

recommends verifying its speed once every 24 months. This can be done

easily using an optical tachometer through the clear plastic viewport in the lid.

Ifthismeasurementindicatesinstrumentfailure,pleasenotifyIECTechnical

Service.

5.6 Power Cord Replacement

Inspectthepowercordeveryfourmonthsforsignsofwear. Referservicingto

qualifiedpersonnelonly. ReplacepowercordwithIECpartnumber44392

only.

Centra-CL2 Instruction Manual 17

5.7 Warranty

IEC wants you to be satisfied with the quality of your Centra-CL2 centrifuge.

We warrantee your IEC centrifuge for one year and IEC rotors for seven

years. We will repair or replace a product that fails, within this period from the

date of its delivery, due to defects in material and workmanship, and we will

ship you the repaired product or its replacement at our expense. You must

use IEC approved accessories and genuine IEC spare parts. This warranty

does not apply to any instrument that has been abused or repaired without

authorization.

THE FOREGOING OBLIGATIONS ARE IN LIEU OF ALL OTHER

OBLIGATIONS AND LIABILITIES INCLUDING NEGLIGENCE, AND ALL

WARRANTIES, OF MERCHANTABILITY OR OTHERWISE, EXPRESSED

OR IMPLIED IN FACT OR BY LAW. THE FOREGOING STATES OUR

ENTIRE AND EXCLUSIVE LIABILITY, AND BUYER’S EXCLUSIVE

REMEDY, FOR ANY CLAIM OR DAMAGES IN CONNECTION WITH THE

SALE OR FURNISHING OF GOODS OR PARTS, THEIR DESIGN,

SUITABILITY FOR USE, INSTALLATION, OR OPERATION. IEC WILL IN

NO EVENT BE LIABLE FOR ANY SPECIAL OR CONSEQUENTIAL

DAMAGES WHATSOEVER, AND OUR LIABILITY UNDER NO

CIRCUMSTANCES WILL EXCEED THE PURCHASE PRICE FOR THE

GOODS FOR WHICH LIABILITY IS CLAIMED. IN SOME INSTANCES,

UNITS MAY CONTAIN RECONDITIONED (AS NEW) PARTS.

5.8 Condition of Returned Equipment

Before returning equipment to IEC, you must contact IEC or your dealer and

receive a return goods authorization (RGA). All returned units must be

decontaminated, free of radioactivity, and free of hazardous and

infectious materials. The RGA paperwork includes a Certificate of

Decontamination for you to sign indicating that you have performed these

steps. IEC will not accept the shipment until this signed certificate is

received.

You must prepay transportation to the service depot.

Centra-CL2 Instruction Manual

18

6 SPECIFICATIONS

RotationSpeed 8500 rpm (Angle Rotor No. 841)

3900 rpm (Horizontal Rotor No. 236)

Maximum RCF 4775 xg (Angle Rotor No. 841)

2200 xg (Horizontal Rotor No. 236)

Maximum Volume 400 mL (8 x 50 mL)

Timer

Range 0 to 30 minutes

Increments 0 to 1 minute by 5 seconds

1 to 5 minutes by 15 seconds

5 to 30 minutes by 1 minute

HOLD mode up to 99 min., 99 sec.

'At Speed' Timing Mode

Accuracy ±1.0%

Speed

Range 1000 to 8500 rpm by 100 rpm

Accuracy ±100rpm

PowerRequirement 120 VAC ± 10%, 60 Hz (Cat. No. 426)

240 VAC ± 10%, 50 Hz (Cat. No. 427)

Heat Output (typical) 175 Watts (600 Btu/hr.)

SoundLevel 52 dB(A)

Height

CoverClosed: 11 in. (28 cm)

CoverOpened: 24 in. (61 cm)

Width 13 in. (34 cm)

Depth 16 in. (40 cm)

NetWeight 11 kg (24 lbs.)

ShippingWeight 13 kg (29 lbs.)

Specifications Subject To Change Without Notice

Centra-CL2 Instruction Manual 19

7SERVICE

7.1 Warning Messages and Error Codes

ThefollowingWarningMessagesandErrorCodescanappearinthedisplayof

theCentra-CL2. AWarningMessageindicatesimproperopeartion,andmay

beclearedbyopeningthelid,correctingtheproblem,and then using the

centrifuge. ErrorCodesindicateamalfunctionofthecentrifuge. Theyare

clearedbydisconnectingandreconnectingpowertothecentrifuge. IfanError

CodeorWarningMessagepersist,servicemayberequired.

WarningMessages:

LId: Thecoverwasnotproperlyclosedwhenthestartbuttonwas

pressed,orthecoverwasopenedduringarun.

PFL: Powertothe centrifuge was lostduringarun.

ErrorCodes:

Er1: Tachometersignalnotpresentduringarun.

Er2: Speedis500RPMoversetspeedandnotdeceleratingformore

than 2 seconds, or speed is over 9000 RPM at any time.

Er10: Themotorvoltagewasdetectedtobeoverthemaximum limit

(94volts).

7.2 General

Trouble Shooting Ifthecentrifugewon’tstart,check the following in order toisolateaproblem:

Ifthe rotorstopped indicator (red LED) is lit, there is power to thecentrifuge. If

not,unplugthecentrifugeandcheckthefuse(s)perSection5.3.

Spintherotor by handtosee that the rotorstopped indicator begins flashing,

andlistenforthelatch to engage. This will verifythefunctionofthe tachometer

andlatch.

Warnings: ThefollowinghazardsexistinservicingtheCenta-CL2:

Table of contents

Other Thermo IEC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Chemglass Life Sciences

Chemglass Life Sciences Dura-Mag CLS-4100-A2 Operation manual

Festivo

Festivo MED Installation and operation manual

Metrohm

Metrohm 916 Ti-Touch Tutorial

Orbis

Orbis AirSTAR Operation manual

minipcr

minipcr bio H Series manual

National Instruments

National Instruments SCXI-1141 CALIBRATION PROCEDURE

iSNATCH

iSNATCH 64.2506.20 user manual

OHAUS

OHAUS VXHDDG instruction manual

Pacific Sun

Pacific Sun Phytoplankton Reactor user manual

Reverberi

Reverberi SERENA Use and maintenance manual for the technician

PASCO

PASCO PS-3519 instruction sheet

Quantifi Photonics

Quantifi Photonics LASER 1100 Series user manual