Thermo IEC Micromax 3590 User manual

SERVICE

MANUAL

SM3590

Revision 2

Micromax

Ventilated Microcentrifuge

Cat. No. 3590 -- For 120 VAC, 60 Hz

Cat. No. 3591 -- For 220 - 240 VAC, 50/60 Hz

Cat. No. 3595 -- For 100 VAC, 50/60 Hz

Refrigerated Microcentrifuge

Cat. No. 3592 -- For 120 VAC, 60 Hz

Cat. No. 3593 -- For 220 - 240 VAC, 50 Hz

Cat. No. 3594 -- For 220 - 230 VAC, 60 Hz

Cat. No. 3596 -- For 100 VAC, 50/60 Hz

300 Second Ave.

Needham Heights, MA 02429

Tel. (781) 448-8060

Fax (781) 444-6743

www.thermoiec.com

TABLE OF CONTENTS

1 INTRODUCTION..................................................................................................... 1

2 INSTALLATION ...................................................................................................... 2

2.1 Receiving the Unit ....................................................................................................2

2.2 Site Preparation........................................................................................................2

2.3 Power Configuration.................................................................................................3

2.4 Moving the Unit.........................................................................................................5

2.5 Front Panel ...............................................................................................................5

2.6 Refrigeration (RF only) .............................................................................................8

2.7 First Run ...................................................................................................................9

3 OPERATION ......................................................................................................... 10

3.1 Rotors and Accessories ...........................................................................................10

3.2 Operating Modes ......................................................................................................11

3.3 Warning Messages and Error Codes .......................................................................13

4 APPLICATIONS...................................................................................................... 15

4.1 Speed and Force Table............................................................................................16

4.2 Chemical Resistance Table......................................................................................17

4.3 Decontamination Table ............................................................................................18

5 MAINTENANCE...................................................................................................... 19

5.1 Cleaning ...................................................................................................................19

5.2 Cover Interlock Bypass ............................................................................................20

5.3 Troubleshooting........................................................................................................20

5.4 Table of Spare Parts.................................................................................................21

5.5 Fuses Not Replaceable By Operator .......................................................................21

5.6 Warranty ...................................................................................................................22

5.7 Condition of Returned Equipment ............................................................................22

6 SPECIFICATIONS .................................................................................................. 23

7 SERVICE ......................................................................................................... 25

7.1 Warnings ad Cautions ..............................................................................................25

7.2 Special Tools ............................................................................................................26

7.3 Troubleshooting........................................................................................................26

8 CABINET ......................................................................................................... 28

8.1 Cover Assembly .......................................................................................................28

8.2 Cabinet Housing .......................................................................................................29

8.3 Gaskets ....................................................................................................................30

8.4 Latch Assembly ........................................................................................................31

9 POWER CIRCUIT ................................................................................................... 33

9.1 General33

9.2 Troubleshooting........................................................................................................33

10 CIRCUIT BOARDS ................................................................................................. 35

10.1 General35

10.2 LEDs & Test Points ..................................................................................................36

10.3 Replacing the Circuit Boards....................................................................................37

11 DRIVE ASSEMBLY ................................................................................................ 39

11.1 Motor .....................................................................................................................39

11.2 Speed Sensor...........................................................................................................40

11.3 Brake .....................................................................................................................41

12 REFRIGERATION................................................................................................... 43

12.1 General43

12.2 Condensing Unit .......................................................................................................44

12.3 Refrigeration Relay...................................................................................................45

12.4 Thermistor ................................................................................................................45

12.5 Pressure Switch........................................................................................................46

13 DRAWINGS ......................................................................................................... 47

1 INTRODUCTION

The Micromax microcentrifuge is a quiet, high-speed bench-top

centrifuge for medical, industrial, and scientific laboratories. The

unit can achieve centrifugal force of up to 21,000 xg, making it

ideal for sedimentation of protein precipitates and separation of

blood serum.

NOTE: The Micromax microcentrifuge is available in two versions,

ventilated and refrigerated. The parts of this manual that apply to

the refrigerated version will be identified as RF only.

The unit reaches full speed within 15 seconds, even when fully

loaded, and brakes to a stop in approximately 15 seconds. It

features a maintenance-free, brushless motor and an easy-to-use

front panel which provides three versatile modes of operation:

automatic timed run, momentary spin (pulse) and continuous

operation (hold mode). Acceleration and deceleration rates may

be controlled to optimize runs - rapid for fast separations or slow

for delicate samples. Repeat runs with precisely the same speed

and time settings may be achieved at the touch of a button.

Micromax is a variable-speed unit with a range of 1000 to 15,000

RPM. The unit accommodates lightweight, dynamically-balanced

polypropylene rotors. The rotors cannot corrode, offer excellent

acceleration and deceleration characteristics and totally contain

tubes, allowing complete sample recovery even if a tube breaks.

The 891 rotor holds up to 24 sample tubes and provides aerosol

containment for biological samples. The 851 rotor holds up to 24

x 1.5-2 mL and 24 x 0.5 mL sample tubes, the 852 rotor holds up

to 48 x 0.5 mL or 24 x Microtainer tubes and the 853 rotor holds

up to 40 x 0.25 mL/0.4 mL or 6 x 50 mm glass tubes. Also, the

851 rotor has room to accommodate screw-cap microtubes,

microtube filters, and micro spin-columns. Section 4.1 provides a

speed and force table for these rotors.

A fail-safe cover interlock ensures that the cover is closed before

a run can begin and keeps the cover closed until the rotor has

reached a safe low speed (below 150 rpm), even in the event of a

power failure.

Micromax Series 1 Service Manual

2 INSTALLATION

2.1 Receiving the Unit

IEC ships the centrifuge in a carton that protects it from

shipping hazards. Retain the carton and packing material

through the warranty period in case you need to ship or

return the unit. Please be sure to complete the Warranty

Registration Card and return it to IEC.

2.2 Site Preparation

The unit normally resides on a bench-top. The Micromax

(ventilated model) can be placed in a cold room (no colder

than 0°C) for processing temperature-sensitive samples.

When you remove the centrifuge from a cold environment,

allow at least two hours for any condensate to evaporate

before using.

Note: When used in a cold room environment, some

bearing noise may become evident. The bearing lubricant

thickens at low temperatures. As the centrifuge speeds

up, it is thinned and distributed more evenly. Once this

occurs, any noise should subside.

The Specifications at the end of this manual give the

dimensions of the unit. Provide clearance of 8 cm (3

inches) at the rear and on both sides for heat dissipation.

Provide clearance of 28 cm (11 inches) above the unit to

open the cover.

Place the unit on a clean, dry surface to ensure that the

suction feet grip the surface firmly. Be sure that the area

beneath the unit is clear of debris and loose materials such

as paper. The surface must be level to ensure quiet,

vibration-free operation. A stable location is important

since an improperly-loaded unit can vibrate and the

centrifuge must not be permitted to move during operation.

Micromax Series 2 Service Manual

2.3 Power Configuration

The Micromax model numbers, and voltage and frequency

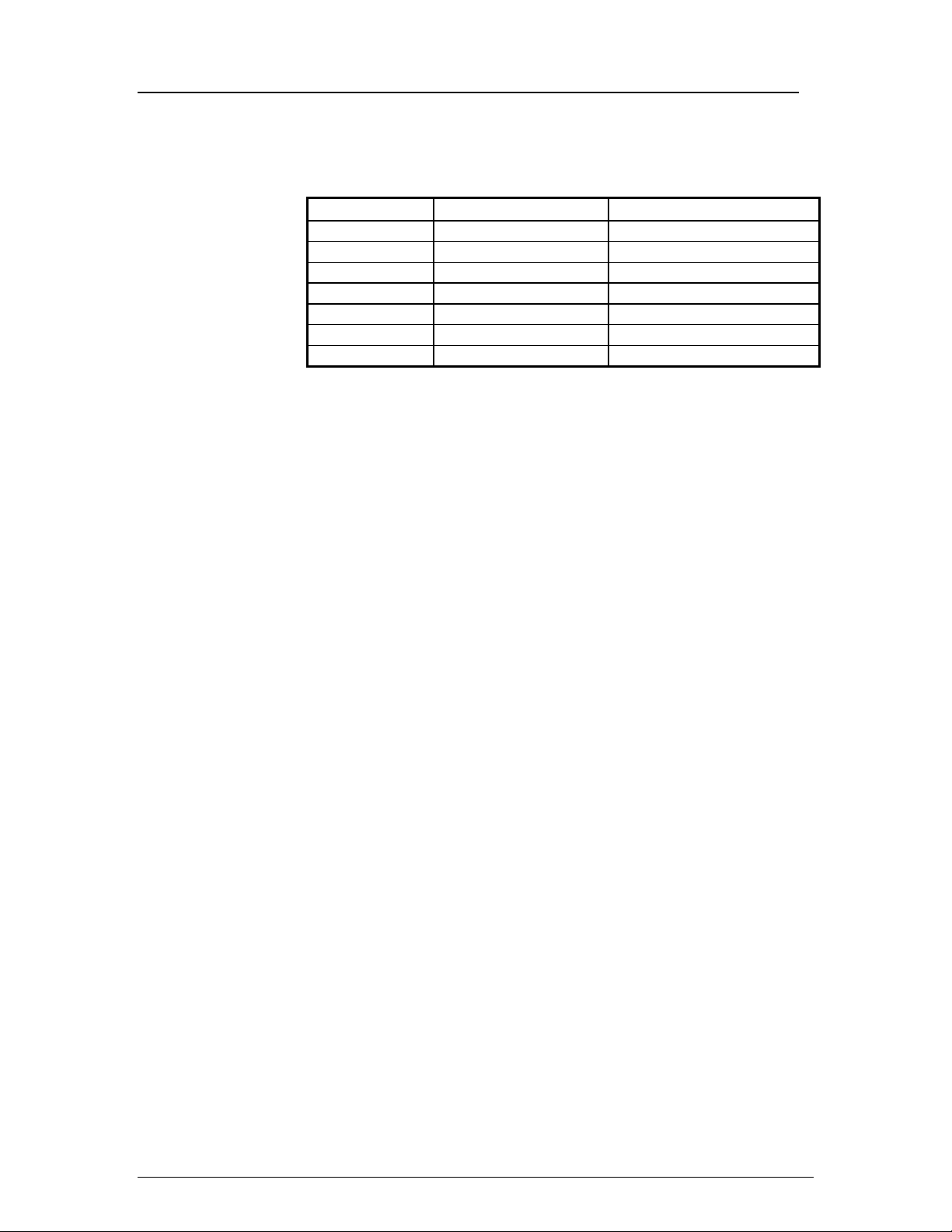

requirements are listed in the table below.

MODEL VOLTAGE FREQUENCY

3590 120 60 Hz

3591 220 - 240 50/60 Hz

3592 (RF) 120 60 Hz

3593 (RF) 220 - 240 50 Hz

3594 (RF) 220,230 60 Hz

3595 100 50/60

3596 (RF) 100 50/60 Hz*

Ensure that your site is configured to match the

centrifuge's power requirements. Plugging the Micromax

into incorrect voltage or frequency will void your

warranty.

* Line Frequency Selection

(3596, Micromax RF)

Locate the 50/60 Hz selector switch to the left of the power

receptacle at the rear of the centrifuge. Adjust this switch

to match the line frequency at the site.

Fuses Fuses are located at the back of the unit.

To install fuses:

Locate the power entry module on the back side of the

unit. The removable fuse drawer is located in the

module. A small latch holds the drawer in place. Press

this latch, then slide the drawer out.

• Cat. No. 3590: The fuse drawer will have one spare

and one active fuse installed at the factory. Fuse is

rated for 6.25 Amps (part no. 50606B).

• Cat. No. 3591: The fuse drawer will have two active

fuses installed at the factory. Fuse is rated for 4.0

Amps (part no. 43689).

• Cat. No. 3592: The fuse drawer will have one spare

and one active fuse installed at the factory. Fuse is

rated for 8 Amps (part no. 50606A).

Micromax Series 3 Service Manual

• Cat. No. 3593, 3594: The fuse drawer will have two

active fuses installed at the factory. Fuse is rated for

6.3 Amps (part no. 50607A).

• Cat No. 3595: The fuse drawer will have one spare and

one active fuse installed at the factory. Fuse is rated for

8.0 Amps (part no. 50021).

• Cat No. 3596: The fuse drawer will have one spare and

one active fuse installed at the factory. Fuse is rated for

10.0 Amps (part no. 49998). Note that the frequency

selector adjacent to the power entry module must be

set for the correct frequency.

Ensure that the fuses are securely in place and reinstall

the entire drawer into the power entry module.

Power Cord IEC provides a power cord with each Micromax centrifuge.

The unit requires a grounded power supply (3-prong power

outlet). If your facility does not have properly grounded

power outlets, arrange for proper grounding. Do not

remove the grounding pin from the centrifuge power cord.

Do not use an adapter to connect to a 2-prong outlet.

Micromax Series 4 Service Manual

2.4 Moving the Unit

Suction cups located on the base of the unit are a safety

feature which adhere it to the work surface to prevent it

from moving. To move the unit to another location, insert

an object such as a tongue depressor under each suction

cup to break the vacuum seal of that cup (taking care not

to damage the suction cup surface). When all four cups

are disabled, you can easily lift the unit. When the unit is

in its new location, ensure that the suction cups fully

contact the benchtop again.

2.5 Front Panel

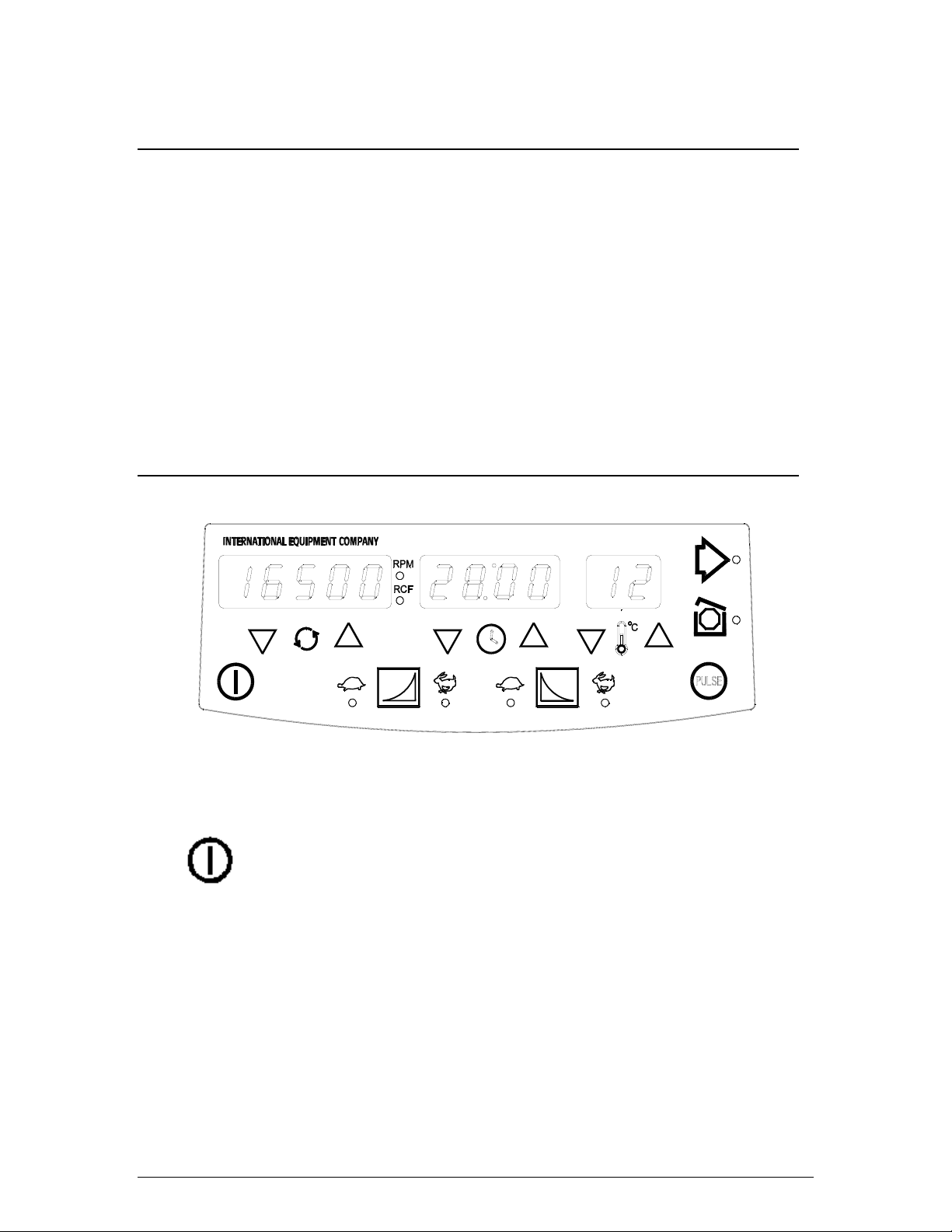

Figure 1: The Front Control Panel

The On/Off button must be on to use the unit. This button

applies power to the control panel and refrigeration system

(RF only). The red STOP light indicates that the centrifuge

is plugged in. (In RF models, temperature is displayed

whenever the unit is plugged in.) The On/Off button is

inoperative during the actual run. Shut off refrigeration with

the On/Off button, but stop a run with the STOP button.

The control panel contains numeric displays for RPM/RCF

(SPEED/FORCE), TIME and TEMPERATURE (RF only).

These displays have two states or modes: Actual and Set.

In the Actual mode, they indicate current run conditions

such as:

Micromax Series 5 Service Manual

• rotor speed or force

• elapsed time of, or time remaining in, the run

• actual temperature (RF only).

The display in the Set mode indicates the desired settings

for the run and is operative:

• whenever you use the up and down arrows

• briefly at the start of a run

• briefly after the unit is switched ON

When the display shows Actual parameters, the numbers

are bright; when the display shows Set parameters, the

numbers are dim. The numeric displays can also display

warning or error messages (see Section 3.3). Descriptions

of the displays appear below.

The displays for the Micromax are:

Speed/Force display: The number in the display above

this symbol represents the rotor speed in RPM or force in

RCF. When RPM is selected the display indicates

revolutions per minute. When RCF is selected the display

indicates relative centrifugal force. Press this button to

toggle between RPM and RCF. Use the arrow buttons to

change the set speed or force. The display shows speed

within 100 RPM and never requires calibration. Select

speed in increments of 100 RPM from 1000 through

15,000 RPM. Select RCF in increments from 1 - 1000 xg

by 50 xg, from 1,000 - 10,000 xg by 100 xg, and from

10,000 - 21,000 by 200 xg.

Time display: The number in the display above this

symbol indicates time. Time is displayed as

minutes:seconds. You can set time from 1 second to 99

minutes using the arrow buttons. In normal timed mode,

the system counts down from set point. In continuous or

momentary spin modes, the system counts up.

Temperature display: The number above this symbol

represents temperature in whole degrees Celsius from -

9 °C through 40 °C (RF only).

Micromax Series 6 Service Manual

Use the arrow buttons to view or change the Set

parameters for Speed/Force, Time or Temperature (RF

only). The first time the button is pressed, the numeric

display simply switches from Actual readings to Set

parameters, without changing them. If you press the

button again, the selected parameter increases or

decreases once for each press. If you hold the button

down, the setting changes repeatedly until you release the

button.

The longer you hold the button down, the more rapidly the

setting changes. Usually, you hold a button down to

approach a desired setting, then press the up or down

button repeatedly to select the exact setting. When you

release the arrow buttons for 3 seconds, the display

returns to the Actual readings.

Acceleration/Deceleration: The user has the option of

setting either full (rapid) or gentle acceleration and braking.

The gentle option may be used to avoid mixing of density

gradients or breakup of pellets. A description of the two

options follows:

This button is used to increase rotor acceleration (up to

1500 RPM) or rotor deceleration. If the yellow light over

the rabbit is lit, then full acceleration/deceleration is

selected.

This button is used to decrease rotor acceleration or

deceleration. If the yellow light over the turtle is lit, then

slow acceleration/deceleration is selected. Slow

acceleration takes from 5 to 10 seconds to achieve 1500

RPM, depending on the rotor and its contents. In slow

braking, the rotor will coast down from 1500 RPM. If no

light is lit, the rotor coasts naturally to a stop.

When using the 851, 852 , 853 or 891 rotors the difference

in time between full and slow braking is approximately a

half second.

This button starts a run. The run is governed by the Set

parameters. The associated green light blinks until the

rotor reaches the set run speed. Then the light stays on

until the end of the run. On some ventilated units only, the

cover opens at the end of a run.

Micromax Series 7 Service Manual

This button stops the run, and unlocks the cover when the

rotor has slowed to below 150 rpm. (A run will also stop

automatically when the set time has elapsed or the

momentary run button is released.) The red light will flash

as an indication that the rotor is still slowing down

(braking). When the run ends, the red light stays on,

indicating that the rotor has stopped and the cover can be

opened.

The centrifuge will run up to set speed while this button is

pressed, and stop when it is released.

2.6 Refrigeration (RF only)

Models 3592, 3593, 3594 and 3596 are refrigerated

models. Whenever the cover of one of these units is

closed and the unit is switched ON, the refrigeration

system begins to cool the rotor chamber to the set

temperature.

Note: The unit is not designed for use as a refrigerator.

The natural fanning action of rotor serves to maintain a

uniform temperature distribution inside the chamber.

Therefore, at zero RPM, there is no correlation between

set and actual chamber temperatures.

If a run begins and the rotor chamber is not at the specified

temperature, the run will not be aborted. If desired, press

STOP to discontinue the run and pre-cool the chamber by

spinning the rotor (empty) until you are satisfied with the

temperature.

If a temperature higher than ambient is specified, the units

will not heat the rotor chamber except through the normal

heating effect of the equipment (friction and motor heat).

Remove frost or condensation from the rotor chamber by

first allowing it to melt and then removing it with a sponge

or cloth. When a centrifuge is not in use, turn it off or leave

the cover open (disables refrigeration).

Micromax Series 8 Service Manual

2.7 First Run

Plug in the centrifuge. If an arrow key is pressed first, the

display will briefly show 10,000 RPM, 1:00 minute and 25

°C (RF only) the default set values. Press the Stop/Open

Cover button to release the cover interlock. Open the

cover. Remove any loose material from the rotor chamber.

Install a rotor, as described in Section 3.1. Close the cover

and press it down until it latches.

Use the up or down arrow buttons to select Set

parameters. Experiment with the buttons to see how they

control the displayed settings. Press and hold a button to

scroll quickly. This does not activate the rotor. Note that,

when you release all buttons for over 3 seconds, the

display returns to Actual readings.

Select an appropriate time, speed and temperature (RF

only) and then press the START button. The rotor will

accelerate to set speed, spin for the set time, and brake to

a stop. Press the Stop/Open Cover button to release the

safety interlock.

Micromax Series 9 Service Manual

3 OPERATION

3.1 Rotor and Accessories

A balanced load is essential with all high-speed

centrifuges. An unbalanced load produces vibration and

causes excessive wear of motor bearings. Therefore,

always load the rotor symmetrically. When using tube

adapters, install an adapter in the opposite tube position.

The total weight of samples loaded in opposing positions

must be equal in weight to within 1.0 gram. The position

numbers, present on rotors, identify opposing tube

positions.

Samples of different specific gravities can be processed in

the same run, provided that the samples of a given type

are balanced around the rotor as though they were the

only ones in the rotor.

Rotor Installation To install the rotor, lower it straight onto the shaft. Align the

holes in the rotor with the positioning pins on the shaft. To

do this, hold the rotor in one hand and hold the shaft, as it

protrudes through the rotor, with the other hand. Rotate

them in opposite directions until the pins line up with the

holes and the rotor drops down into position. Do not apply

excessive force. Screw the metal locking nut (clockwise)

on the shaft to hold the rotor down. Be sure the orange

rubber ring is facing downward. Hold the rotor and tighten

the nut moderately with your fingers; do not over tighten it.

The 891 rotor cover must be installed prior to the rotor

being placed in the centrifuge. Verify that the o-ring seals

(2) are in place around the outer and inner perimeters of

the rotor. To install the cover, place the rotor on a flat

surface and then place the rotor cover on top of the rotor.

Using the palm of your hand(s), press down evenly around

the cover to fully engage the seals.

The 851, 852 and 853 rotor covers prevent generation of

aerodynamic noise during the spin. It also prevents gross

aerosol effects in the event of tube failure. It fits snugly

over the rotor and pulls off easily. To place it properly,

rotate the cover until it drops easily onto the adapter

spline. Press down until the rim of the cover contacts the

rotor. The spline at the top of the shaft adapter drives the

lid during rotation.

Micromax Series 10 Service Manual

Caution: Improper placement of the cover may allow it

to come off during a spin.

Rotor Removal To remove the rotor, first remove the cover (851, 852 or

853 only). Then unscrew (counterclockwise) and remove

the metal locking nut. The rotor can now be lifted straight

out of the rotor chamber. You can refrigerate the rotor

without removing the tubes but do not operate the rotor

when the rotor temperature is below 0°C.

To remove the 891 rotor cover, place the rotor on a flat

surface. Place your thumbs on the inner perimeter of the

cover, and your fingers on the outer edge. Pry it up from

the outer edges.

3.2 Operating Modes

The Micromax Models offer three operating modes: Timed,

Continuous (Hold), and Momentary.

Timed Run To start a timed run or spin:

Select the Set parameters using the control panel buttons

(refer to Section 2.5) and then press START.

• To view the set parameters at any time, press any

arrow key.

• The spin duration may be changed at any time, even

during the spin, by pressing the arrow keys until the

new desired setting(s) is displayed. If a time less than

the elapsed time is programmed (for example, one

second), the spin ends immediately. If a time greater

than the elapsed time is programmed, the elapsed time

continues until the newly selected time is reached (the

time does not reset).

The speed and temperature (RF only) may similarly be

changed during a run. Three seconds after the

parameter's arrow key is released, the centrifuge will

adjust to the newly set parameter.

Micromax Series 11 Service Manual

Hold Mode To set Hold (continuous) mode:

Select the Set parameters using the control panel buttons

(refer to Section 2.5). Scroll down through zero time on

the Time display until the word Hold appears in the display.

This mode is used for runs greater than 99 minutes.

Momentary To operate in the momentary mode:

Select the Set parameters using the control panel buttons

(refer to Section 2.5). Press and hold the PULSE button.

The run begins when you press the button and ends when

you release the button.

NOTE: In this mode the unit displays Set parameters for

three seconds, the time display counts upward and

displays the elapsed time since you pressed the PULSE

button.

In this mode very quick separations can be performed, or

you may closely monitor the progress of a run. (This is

useful for easily separated samples, for simultaneous

mixing of samples, and to deposit condensate droplets at

the bottom of the tube.)

Micromax Series 12 Service Manual

3.3 Warning Messages and Error Codes

The beeper sounds in three situations:

• Two times on power up.

• Three times at the end of a spin.

• When a warning occurs (three times).

Warnings appear in place of the numeric displays in the

following cases:

HEAD This appears if a run is started without

loading a rotor into the chamber. Opening the cover resets

this warning. This warning is disabled when slow

acceleration is selected.

Lld This appears briefly if you press the START

button but the cover is not closed. Closing the cover resets

the warning.

PFAIL This appears at the end of a power failure

that interrupts a run if the rotor is still spinning when power

is restored. Press STOP to reset this warning.

Error Codes require factory-authorized maintenance. A

typical error means the internal microprocessor has

detected impermissible readings or a failure elsewhere in

the unit. An error code number appears on the front panel.

When an error code is displayed first unplug and reconnect

the unit to power and try the run again. If the error code

reappears, tell the service personnel which number

appeared when you report the problem.

Micromax Series 13 Service Manual

Err 1 No Tachometer

Tachometer signals were not present during run. The rotor

coasts to a stop. Cover opening is inhibited after this error.

OSPd Overspeed

Speed is 15,200 RPM. The rotor will brake to a stop

run A Runaway

During stopping, rotor has not been decelerating for 8

seconds, or when at standby, rotor speed exceeds 600

RPM. The rotor coasts to a stop.

rEFr Refrigeration Failure (RF only)

The unit displays this code if the measured temperature

exceeds 45 °C at any time during the run.

FSAFE Fail-safe Time-out

Independent circuitry on the circuit board has sensed a

lack of activity from the control microprocessor. All power

outputs are disabled (including motor, latch solenoid, etc.).

COPF COP Watchdog/OpCode Trap Error

The microprocessor itself has sensed a lack of activity

from the program that controls the centrifuge. The rotor

coasts to a stop.

COP COP Watchdog Not Enabled

The microprocessor COP is not enabled. The rotor coasts

to a stop.

UndFI Undefined Interrupt

The microprocessor was interrupted by an undefined

source. The rotor coasts to a stop.

ILLOP Op-Code Trap Error

The rotor coasts to a stop.

Warnings during a spin. The "HEAd", "Lld", "PFAIL" and

"Error” messages can occur during a spin. In this case, the

rotor brakes or coasts to a stop and the run ends.

Micromax Series 14 Service Manual

4 APPLICATIONS

Misapplication of any tube can cause tube rupture. To

avoid this, never spin tubes faster than their recommended

G-force, and never centrifuge disposable tubes more than

once. If the tubes are not rated for the needed force, use

more suitable tubes. If breakage does occur, residue will

be captive in the tube cavity in the rotor. You may be able

to recover it by pipetting.

Corrosive solvents Your IEC centrifuge is made of materials designed to resist

attack from common laboratory chemicals. The rotor and

lid are made of polypropylene and the interior of the rotor

chamber is stainless steel. Use covered sample tubes if

the samples contain acids or solvents known to attack

these materials. Promptly cleaning spills from the rotor

and from the sample chamber minimizes the effects of

corrosive chemicals. Replace any component that exhibits

crazing, frosting, peeling, or similar faults. Do so before

any resulting vibration requires more expensive repair.

Replace the shaft adapter, rotor, lid, or metal locking nut if

they become cracked, scratched, or gouged.

Sample Heating The rotor chambers of Models 3590 and 3591 centrifuges

are ventilated during operation. However, during very long

runs, some heat inevitably travels to the samples. You can

minimize sample heating by placing the unit in a refrigerator

or cold room.

Micromax Series 15 Service Manual

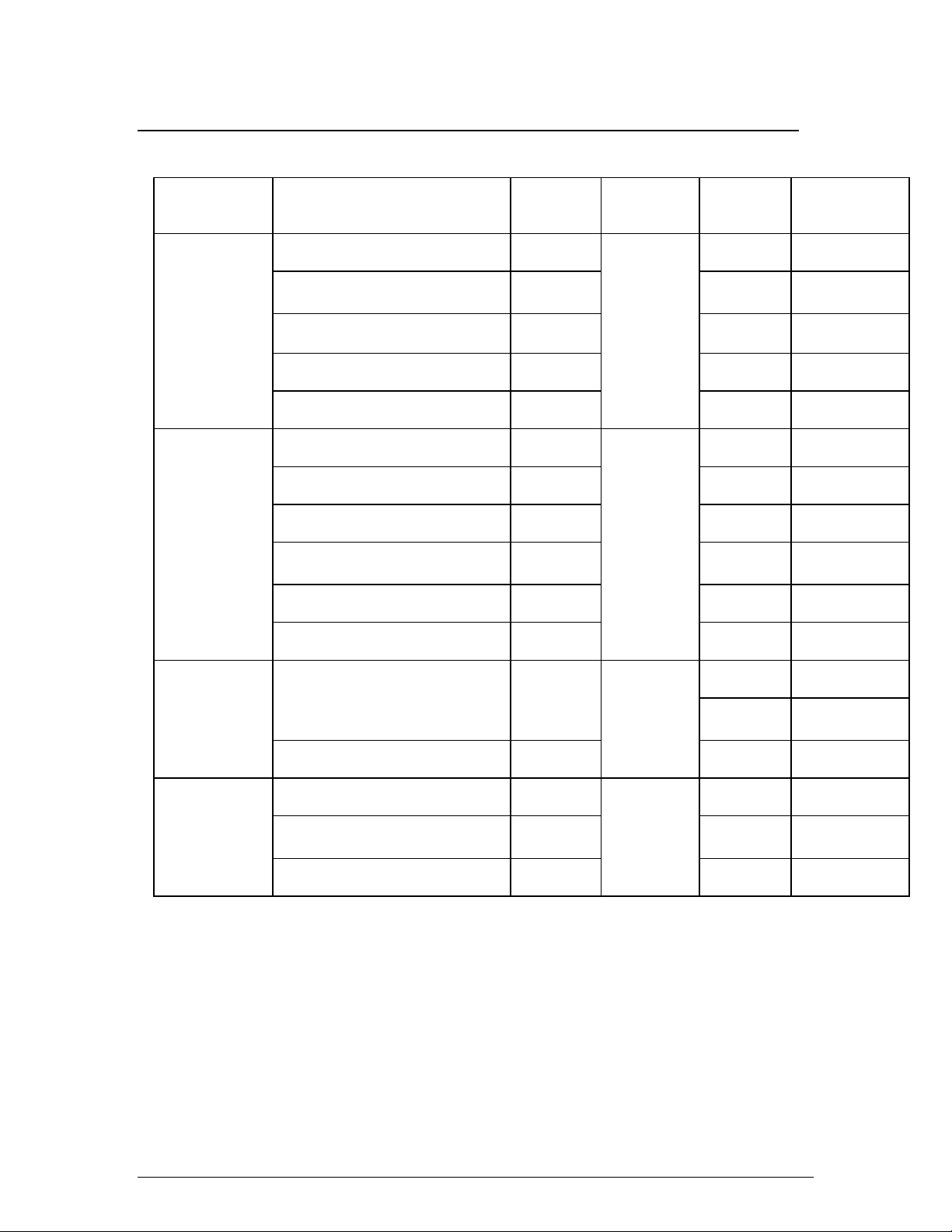

4.1 Speed and Force Table

Rotor Cat. No. No. of Tubes and Tube Size Adapter

Cat. No

Max Speed

(RPM)

Max RCF

(xg)

Radius (cm)

24 x 1.5ml - 21004 8.35

891124 x 0.6ml B/D Microtainers™ 5763** 21256 8.45

(Aerosol 24 x 0.5ml PCR microtubes 5763** 15000 18740 7.45

Contained) 24 x 0.4ml microtubes 5764** 21004 8.35

24 x 0.25ml microtubes 5764** 18237 7.25

24 x 1.5ml - 21004 8.35

24 x 0.6ml B/D Microtainers™ 5763** 21256 8.45

24 x 0.5 ml microtubes - 17432 6.93

851224 x 0.5ml PCR microtubes 5763** 15000 18740 7.45

24 x 0.4ml microtubes 5764** 21004 8.35

24 x 0.25ml microtubes 5764** 18237 7.25

48 x 0.5ml PCR microtubes - 20124 8.00†

852215000 18866 7.50‡

24 x B/D Microtainers™ - 21633 8.60†

40 x 0.4ml microtubes - 21130 8.40

853240 x 0.25ml microtubes - 15000 18866 7.50

40 x 0.8ml (6x50mm) glass - 21382 8.50

Microtainers™ is a trademark of Becton Dickinson

* RCF displayed on control panel is based upon radius of rotation for 891 and 851 rotors for 1.5/2.0ml

tubes (8.35cm).

** Order 2 pks of adapters separately. IEC 5763 and 5764 are packaged 12/pk.

† Outer row holds 24 tubes

‡ Inner row holds 24 tubes

1IEC 891 Rotor

Provides Aerosol Containment and has been tested for microbiological containment by PHLS-

CAMR, Porton Down. Meets requirements of US OSHA Bloodborne Pathogen Final Rule:

(Regulation 29 CFR Part 1910.1030. Complete with IEC 50417 Aerosol Containment Cover, IEC

50525 Inner and IEC 36597 Outer rubber O-ring seals.

2IEC 851, 852, 853 rotors

Micromax Series 16 Service Manual

4.2 Chemical Resistance Table

Plastic Metal Other

PA PC PE PP PU NL DN CN NN PS TI SS AL MB MG RR BN VN PF

Acids,diluteorweak EEEEGEFNFEGGFFNFEEE

Acids*, strong or conc. E N E E F N N N N F N N N N N N F G N

Alcohols, aliphatic E G E E F E E E N E E E E E F E E G E

Aldehydes G F G G G G G G F N E E E E E E N E E

Bases ENEENGNGFEEEEEEGGNN

Esters GNGGNEGGE NE E EE ENNNE

Hydrocarbons, aliphatic G F G G E N E E E N E E E E E N E E E

Hydrocarbons, aromatic F N G F N N E E E N E E E E E N N E E

Hydrocarbons, halogenated F N F F N N G E G N E E E E N N N F E

Ketones GNGGNNEEENEGGGENNNE

OxidizingAgents,strong FNF FNNNNNNEFNNNNFEE

Salts EEEEEEEEEEEFFFNEEEE

*For Oxidizing Acids, see "Oxidizing Agents, strong".

PA - POLYALLOMER TI - TITANIUM

PC - POLYCARBONATE SS - STAINLESS STEEL

PE - POLYETHYLENE AL - ALUMINUM

PP - POLYPROPYLENE MB - MANGANESE BRONZE

PU - POLYURETHANE MG - MAGNESIUM

NL - MODIFIED PHENYLENE OXIDE (NORYL) RR - RUBBER

DN - ACETAL HOMOPOLYMER (DELRIN) BN - BUNA-N

CN - ACETAL COPOLYMER (CELCON) VN - VITON

NN - NYLON PF - PHENOLIC FIBER

PS - POLYSTYRENE

Classification of Resistance

E= Excellent

G= Good

F= Fair

N= Not Recommended

Micromax Series 17 Service Manual

4.3 Decontamination Table

Compatible Processes For Decontamination

Sterilization Methods Plastic Metal Other

PA PC PE PP PU NL CNDN NN PS TI SS AL MGMB RR BN VN PF PT

Mechanical

Chemical

Autoclave*

Ethylene Oxide Gas

Dry Heat 160°C@2Hrs.

Ethanol

40% Formalin

Methanol

2-Propanol

5% Sodium Hypochlorite**

3% Hydrogen Peroxide

100% Hydrogen Peroxide

5% Phenol Solution

SMUSMUSSSU

SSSSSSSSSS

UUUUUUUUUU

SSSSS

SSSSS

SS

S

SSU

SSMSM

UUSSS

UUUUU

SSSSSSSSSSSSSSUSSSUM

SSSSUSSSSUSSSSSSUSSS

SMSSMSSSUMSSSSSSSUSS

SSSSMSSSUSSSSSMSSSSS

SSSSUSUUUSSMUUUSUSSM

SSSSSSMSUSSSSSUSSSSM

SSSSSUUUUSSSSSSUUSSU

MUU UUMMU MMMMMMMUS S U

PA - POLYALLOMER

PC - POLYCARBONATE

PE - POLYETHYLENE

PP - POLYPROPYLENE

PU - POLYURETHANE

NL - MODIFIED PHENYLENE OXIDE (NORYL)

DN - ACETAL HOMOPOLYMER (DELRIN)

CN - ACETAL COPOLYMER (CELCON)

NN - NYLON

PS - POLYSTYRENE

TI - TITANIUM

SS - STAINLESS STEEL

AL - ALUMINUM

MB - MANGANESE BRONZE

MG - MAGNESIUM

RR - RUBBER

BN - BUNA-N

VN - VITON

PT - PAINTED SURFACES

PF - PHENOLIC FIBER

*Autoclaving

121°C 20 min.@

2 ATM (15 PSIG)

**Household Bleach

S=SATISFACTORY

M=MARGINAL

U=UNSATISFACTORY

WARNING:

This chart describes the material compatibility of various sterilization methods. It does not specify the

adequacy of sterilization. Refer to section 4.3 Chemical Resistance Table for material compatibility

during centrifugation.

Micromax Series 18 Service Manual

This manual suits for next models

6

Table of contents

Other Thermo IEC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

V&P Scientific

V&P Scientific SpinVessel VP 418SV3-1-850RB-CC operating instructions

Tecno-gaz

Tecno-gaz Multisteril Fast Technical manual

Waters

Waters Xevo TQD Overview and maintenance guide

Intellinet

Intellinet 561518 instructions

Waters

Waters Xevo TQD IVD Overview and maintenance guide

CAPP

CAPP PA-100 Operation manual