Streck ESR-Auto Plus 506 User manual

ESR-Auto Plus®Operator’s Manual

Model 506, v 1.0-2.0

ESR-Auto Plus Operator’s Manual I

Thank you for choosing the ESR-Auto Plus®, the most

accurate, reliable and user-friendly automated ESR

analyzer available today! Our dedicated employees

are here to make your ESR-Auto Plus experience as

simple as possible.

This manual covers the operation and conguration

of the ESR-Auto Plus Model 506, the ESR-657 Mixer

and the ESR Barcode Scanner.

The following item is included with this manual for your

convenience:

QUICK REFERENCE GUIDE

A simple, condensed guide to the most common

instrument functions.

TECHNICAL SERVICE DEPARTMENT

800.843.0912 (ext. 7510)

technicalservic[email protected]

The ESR-Auto Plus is supported by a staff of

experienced Medical Laboratory Scientists who

welcome the opportunity to assist you. Our on-

site Technical Service Representatives have

immediate access to the ESR-Auto Plus, and they

are an excellent resource to answer your product

questions.

Contact Streck for:

• Assistance with implementation of the ESR-Auto Plus

• Technical support for the entire ESR product line

• Processing ESR-Auto Plus correlation data

We want your relationship with our company to

extend beyond being satised with our product. It

is our privilege to serve you, and we are looking

forward to your next call.

STANDARD WARRANTY

Streck warrants the ESR-Auto Plus, ESR-657 Mixer

and ESR Barcode Scanner to be free from defects in

workmanship and materials during normal use for a

period of one year from the date of purchase. If any

defects occur during the warranty period, contact

Streck Technical Service Department. This warranty

does not cover defects or malfunctions which occur

due to instrument abuse, improper maintenance or

unauthorized repairs.

INSTRUMENT RETURN POLICY

Any claim for credit or return of instruments for any

reason must be made within 30 days of receipt of

the instrument. Returns executed within 30 days of

receipt will result in an automatic reassignment of the

instrument title back to Streck. The customer will be

responsible for return freight charges on all customer-

initiated instrument returns. All instruments approved

for return will be subject to a $100 return fee.

• The customer must repackage the instrument(s) in

its original packaging to ensure that the components

do not shift during shipment. Refer to Section 9.7 for

repackaging instructions.

• The customer must contact their Streck Sales

Representative to obtain a return authorization

number, which must be clearly marked on the

outside of the package.

Manufactured For:

Streck

7002 S. 109 Street

La Vista, NE USA 68128

800-843-0912

402-333-1982

Welcome to Streck!

320597-3 - NOVEMBER 2016

II ESR-Auto Plus Operator’s Manual

Table of Contents

1Introduction

1.1 ESR Components 1

1.2 Unpacking Instructions 2

1.3 Barcode Scanner Installation 2

1.4 Cable Connections 2

1.5 Barcode Scanner Calibration 2

1.6 Installing Printer Paper 3

1.7 Removing Paper 3

1.8 Instrument Set-up 3

2Sample Preparation & Analysis 5

2.1 ESR-Vacuum Tubes 7

2.2 Sample Collection 7

2.3 Phlebotomy Guideline 8

2.4 Mixing a Sample 8

2.5 Secondary Patient Labels 9

2.6 ESR Tube Labeling Sleeves 10

2.7 Starting a Sample 11

2.8 Reporting Results 11

2.9 Canceling a Sample 11

3 Keypad & Menu Overview 13

3.1 Keypad Overview 15

3.2 Menu Diagram 15

4Menu Functions 1-5 17

4.1 Standby Menu 19

4.2 Menu 1: Search Sample 19

4.3 Menu 2: Check Position 20

4.4 Sample Status 20

4.5 Menu 3: Print Log File 21

4.6 Menu 4: Control Samples 22

Run, Show, Register and Edit Controls

4.7 Menu 5: Run Test Rack 27

5Menu Function 6 - User Cong. Menu 29

5.1 Accessing Menu 31

5.2 Print Set Up 31

5.3 Set Date and Time 32

5.4 Set Audible Alarm 32

5.5 Set Printer Function 33

5.6 Set Print Style 33

5.7 Set Access Code 34

ESR-Auto Plus Operator’s Manual III

6 Menu Function 6 - Service Menu 35

6.1 Accessing Menu 37

6.2 Set Language 37

6.3 Set Date and Time Style Formats 38

6.4 Registering Test Rack 39

6.5 Set Tube Type 40

6.6 Set Calibration 40

6.7 Set Test Mode 41

6.8 Set Access Code 41

6.9 See Temperature 41

6.10 RAM Reset 42

7Background of the ESR Test 43

7.1 The History 45

7.2 The Original 200mm System 45

7.3 The 100mm Vacuum System 45

7.4 BD Standard Scale vs. QuickMode Method 45

7.5 The ESR-Vacuum Tube 46

7.6 A Typical ESR Reaction 47

7.7 ESR Reference Ranges / Values 47

8Performance & Technical Specications 49

8.1 Overview 51

8.2 Measuring Abnormal Samples 51

8.3 Fill Level 51

8.4 Temperature Compensation 52

8.5 ESR-Auto Plus Precision 52

8.6 Preventive Maintenance 52

8.7 Cleaning Instructions 52

8.8 Barcode Scanner 53

8.9 Data Output 53

8.10 Technical Specications, ESR-Auto Plus 54

8.11 Environmental Conditions 55

8.12 Transportation Environment 55

8.13 Technical Specications, ESR-657 Mixer 56

8.14 Disclaimer 56

9Safety Precautions 57

9.1 User Precautions 59

9.2 Electrical Equipment 59

9.3 Disconnect Device 59

9.4 Sample Analysis 59

9.5 Application of Secondary Labels 59

9.6 Removal of ESR-Vacuum Tubes 60

9.7 Repackaging Instructions 60

9.8 Glossary of Safety Symbols 60

10 Troubleshooting 61

10.1 Error Codes 63

10.2 Status Codes 64

10.3 Troubleshooting Guide 65

11 Quick Reference Guide 67

11.1 Standby Screen 69

11.2 Sample Mixing 69

11.3 Run Test Rack 69

11.4 Register New Lot of QC 69

11.5 Run QC Sample 70

11.6 Run Patient Sample 70

11.7 Cancel Measurement 70

11.8 Predict Sample Result 70

11.9 Re-Register Test Rack 71

QC Maintenance Record 73

1

Introduction

ESR-Auto Plus Operator’s Manual 1

The ESR-Auto Plus®is designed to accurately and precisely

measure the sedimentation rate of erythrocytes (red

blood cells) in Streck ESR-Vacuum Tubes. The results are

recorded as millimeters (mm) per hour (Westergren Method)

by converting to the QuickMode method, a scientically

developed method for measuring ESR in only 30 minutes.

The instrument compensates for temperatures above 26° C

(79° F).

Results are automatically reported to an internal printer.

The instrument may also be interfaced with a Laboratory

Information System (LIS) or a computer. To reduce errors

with patient identication and labeling, the instrument can be

equipped with a barcode scanner.

The mixing process prior to evaluation of an ESR sample is

critical. For this reason, the ESR-657 Mixer is available as

an additional accessory. The ESR-657 Mixer operates using

a slow 360° rotation, which ensures complete mixing and

more accurate results.

The ESR-Auto Plus and ESR-657 Mixer are IVD Medical

Instruments.

1.1 ESR Components

ESR-Auto Plus (Figure 1a)

The ESR-Auto Plus analyzer can process up to 20 samples

per hour. Samples are read by infrared light using a

measuring arm, which is controlled by a motor.

ESR-657 Mixer (Figure 1b)

The ESR-657 Mixer is designed to mix Streck ESR-Vacuum

Tubes prior to evaluation. Its unique motion ensures proper

mixing of samples. The ESR-657 Mixer can hold up to 10

ESR-Vacuum Tubes.

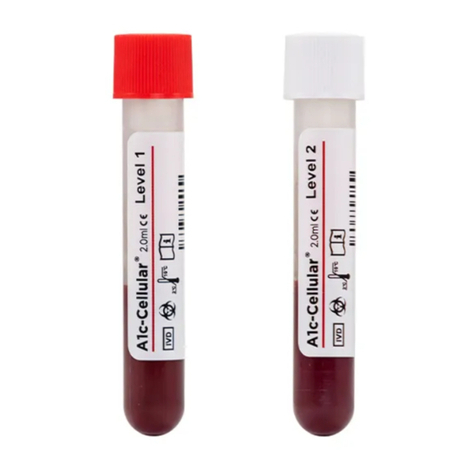

ESR-Vacuum Tubes (Figure 1c)

ESR-Vacuum Tubes are available in 1.2ml and 2.0ml vacuum

draw sizes and are designed specically for use with the

ESR-Auto Plus, ESR-657 Mixer and ESR-10 Manual Rack.

High Altitude and Safety Coated 1.2ml tube congurations

are also available.

ESR Barcode Scanner (Figure 1d)

Symbol barcode scanner (catalog #240329, mfr. part #

LS2208-SR20001) connects to the ESR-Auto Plus using a

USB cable, (mfr. part #CBA-U21-S07ZAR). It is compatible

with most available barcodes: EAN, UPC, Codabar, Code

39, Code 93, Code 128, Interleaved 2 of 5, and several more.

The barcode scanners are considered to be Class 2 lasers

that emit Class 2 laser light.

Chapter 1 |Introduction

Figure 1a:

ESR-Auto Plus

Figure 1b:

ESR-657 Mixer

Figure 1c:

ESR-Vacuum Tubes

Figure 1d:

ESR Barcode Scanner

320597-3 - NOVEMBER 2016

2 ESR-Auto Plus Operator’s Manual

1.2 Unpacking Instructions

Retain all packaging materials for shipping, moving or

storing the instrument.

1. Open the box and remove the top foam piece, which

contains accessories such as the ESR-657 Mixer,

barcode scanner, power cords and paper.

2. Carefully lift the instrument out of the bottom foam piece

and remove the anti-static shipping bag.

3. Install the ESR-Auto Plus and ESR-657 Mixer on a level,

supported surface that is free from any vibrations or

temperature uctuations.

Important! Vibrations and temperature

uctuations may adversely affect ESR results.

Refer to Section 8.4 for more information on the

impact of temperatures on ESR results.

1.3 Barcode Scanner Installation

1. Line up holes in barcode scanner bracket with pre-drilled

holes on the right side of the ESR-Auto Plus (Figure 2a).

2. Tighten the screws using the 3mm allen wrench

(provided). Do not over-tighten screws (Figure 2a).

3. Connect the barcode scanner to the socket marked

“Barcode Input” on the back of the instrument (Figure 2b).

4. Place the barcode scanner in the barcode scanner

bracket as shown (Figure 2c).

1.4 Cable Connections (Figure 3)

1. Connect the external printer cable or mainframe computer

cable (LIS) to the USB port marked “Data Output”

(optional).

2. Connect the AC power cord to the power inlet on the

back of the ESR-Auto Plus.

3. Connect the 24V AC power cable to the ESR-657 Mixer.

The mixer will rotate continuously when the power switch

is on.

Important! Plug the instrument and mixer power

cords into a power surge protector to guard

against power surges and uctuations.

1.5 Barcode Scanner Calibration

1. Scan a patient barcode three times to calibrate the

barcode scanner.

2. If the barcode scanner is unplugged, scan a barcode three

times to re-calibrate before scanning a patient sample.

Important! The barcode scanner has been pre-

programmed and is ready to use. If you encounter

any problems with the operation of the barcode

scanner, contact Technical Service.

Figure 2a

Figure 2b

Figure 2c

Figure 3

AC

Power

ESR-Auto Plus Operator’s Manual 3

CAUTION: Use care to avoid cutting nger on

paper cutter.

1.6 Installing Printer Paper (Figure 4)

1. Before installing the paper, remove any residual glue or

tape sealing the new roll.

2. Pull up the lever on the printer lid to release the paper

cover lock (Figure 4a).

3. Place a roll of paper in the printer with the paper extending

out of the printer toward the front of the ESR-Auto Plus

(Figure 4b).

4. Press rmly on the paper cover to close the printer lid

(Figure 4c).

5. Press the paper feed button on the printer to advance

the paper and verify the paper roll is installed correctly. If

the paper does not feed properly, open the printer lid and

realign the paper.

Important! Streck thermal paper is specically

approved for use with the ESR-Auto Plus printer

and should be used to prevent damage to the

print head. Alternate paper may have different

technical specications that cause premature

wear and tear.

1.7 Removing Paper

1. Open the printer lid.

2. Remove the paper and close the printer lid.

1.8 Instrument Set-up

This section outlines the menus to review before getting

started. A thorough review of the Operator’s Manual is

strongly advised prior to reporting patient results. Refer

to Chapter 3 for a menu diagram and an overview of the

keypad.

1. Date & Time: Set the date and time in the User

Conguration Menu (see Section 5.3). The default date

format is YYYY-MM-DD. The default time format is 24-

hour. Time can be displayed in a 12-hour (AM/PM) or 24-

hour format.

2. Print Style: Set the print style in the User Conguration

Menu (see Section 5.6). The default print setting is

Autoprint in Ticket Style. Log or Ticket print styles are

available.

3. Register the Test Rack: Register the test rack in the

Service Menu (see Section 6.4).

4. Tube Type Size: Select an alternate tube size in the

Service Menu (see Section 6.5). The default ESR-

Vacuum Tube size is 1.2ml.

5. Register QC Material: Register a new lot of ESR-Chex

control in the QC Menu (see Section 4.6.3).

Figure 4b

Figure 4c

Figure 4a

2

Sample Preparation & Analysis

ESR-Auto Plus Operator’s Manual 7

Chapter 2 |Sample Preparation & Analysis

2.1 ESR-Vacuum Tubes

The ESR-Auto Plus is intended for use with Streck 1.2ml

ESR-Vacuum Tubes. ESR-Vacuum Tubes are also available

in High Altitude and Safety Coated 1.2ml congurations.

2.0ml ESR-Vacuum Tubes may be used by selecting the

alternate tube size in the User Conguration Menu.

All Streck ESR-Vacuum Tubes preserve the integrity of the

patient sample for up to 72 hours from the time of blood

collection when transported or stored at 2-10° C, or up to 4

hours at 18-30° C.

Follow the Clinical Laboratory Standards Institute (CLSI)

Procedures for the Erythrocyte Sedimentation Rate Test;

Approved Standard, CLSI Document H02, for stability of

specimens collected in EDTA tubes.

2.2 Sample Collection

Patient samples may be drawn directly into the Streck

ESR-Vacuum Tube or transferred from an EDTA vacuum

tube. When using an EDTA tube, transfer the well-mixed

patient sample into the Streck ESR-Vacuum Tube. Do not

remove the sodium citrate in the ESR-Vacuum Tube. Fill the

ESR-Vacuum Tube to the ll line.

ESR-Vacuum Tubes contain liquid anticoagulant and must

be thoroughly mixed with the blood sample immediately after

the tube has lled. Failure to mix the sample completely and

immediately may result in the formation of microscopic blood

clots/aggregates that could alter results. Proper collection

and preparation of the ESR sample is critical to obtain

accurate results. Inaccurate results are most often a result

of improper sample handling.

CAUTION! Handle all biological samples and

blood collection sharps according to your

standard laboratory procedures. Seek medical

attention in the case of exposure to biological

specimens.

Follow CLSI Procedures for the Collection of Diagnostic

Blood Specimens by Venipuncture; Approved Standard,

CLSI document GP41, for guidance with sample handling.

320597-3 - NOVEMBER 2016

8 ESR-Auto Plus Operator’s Manual

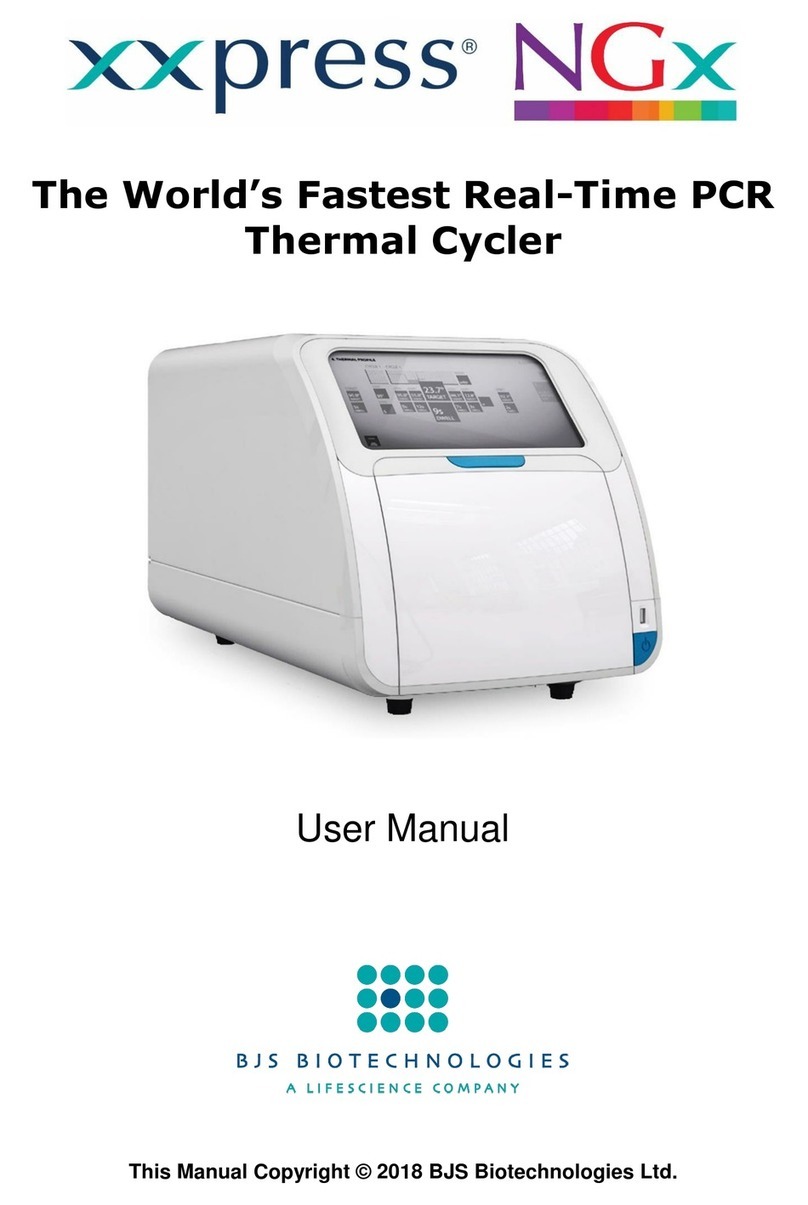

2.3 Phlebotomy Guideline

1. Insert the ESR-Vacuum Tube into the plastic holder

(Figure 5a). Hold the tube so the cap is ush against the

needle holder as the sample is collected.

2. Angle the tube so the blood stream hits the tube wall

before mixing with the citrate solution to minimize the

formation of bubbles.

3. Watch for an air bubble to rise in the sample as the tube

lls to indicate the draw is complete and remove the tube

immediately.

4. The ideal ll level and acceptable ll range are indicated

on the tube.

• 1.2ml ESR-Vacuum Tubes: 60mm ± 5mm

• 2.0ml ESR-Vacuum Tubes: 100mm ± 8mm

5. It is especially important to mix Streck ESR-Vacuum

Tubes thoroughly by inverting a minimum of 8 times due

to their smaller tube diameter and draw volumes (1.2ml

and 2.0ml) compared to an EDTA tube (Figure 5b).

6. Prior to analysis, thoroughly mix the sample again.

Rotate the tubes on the ESR-657 Mixer for a minimum

of three minutes, or hand-mix a minimum of 8 complete

inversions.

7. Samples can be maintained from the time of blood

collection for up to 72 hours prior to analysis when

transported and stored at 2-10° C, or up to 4 hours at 18-

30° C.

8. Refer to the ESR-Vacuum Tube Instructions For Use

(IFU) for more details.

Important: The mixing procedure is very

important! If the citrate is not properly mixed with

the blood, clots/aggregates may form and cause a

falsely elevated result.

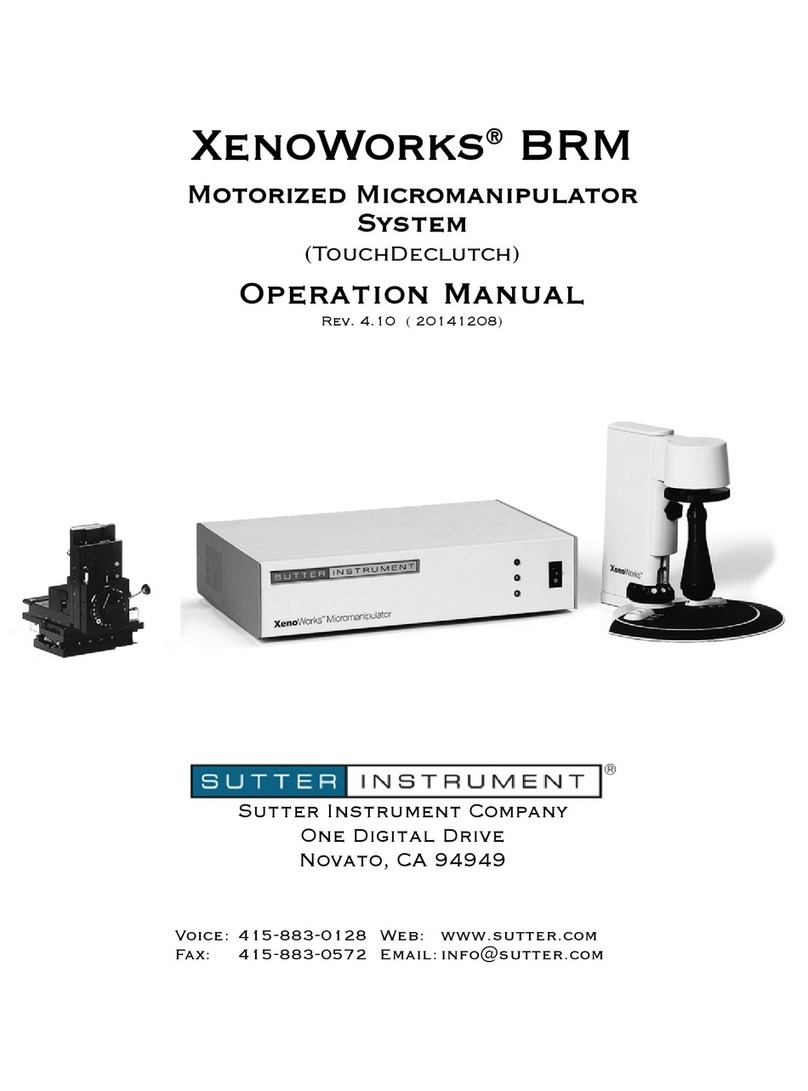

2.4 Mixing a Sample

Samples must be thoroughly mixed prior to analysis. The

ESR-657 Mixer is an optional accessory designed to

accompany the ESR-Auto Plus (Figure 6). The automated

mixer holds up to 10 ESR-Vacuum Tubes at one time.

1. Place the mixer on a level surface.

2. Stop the mixer to remove or add tubes. Gently snap ESR-

Vacuum Tube samples into the numbered slots on the

mixer (Figure 6).

3. Locate the power switch on the top of the mixer to turn

the unit “on.”

4. The ESR-657 Mixer operates using a slow 360° rotation

to ensure complete mixing.

5. Allow the samples to rotate for a minimum of 3 minutes

before analyzing.

Figure 5a

Figure 5b

CORRECT

INCORRECT

Invert a

minimum

of 8 times.

ESR-Auto Plus Operator’s Manual 9

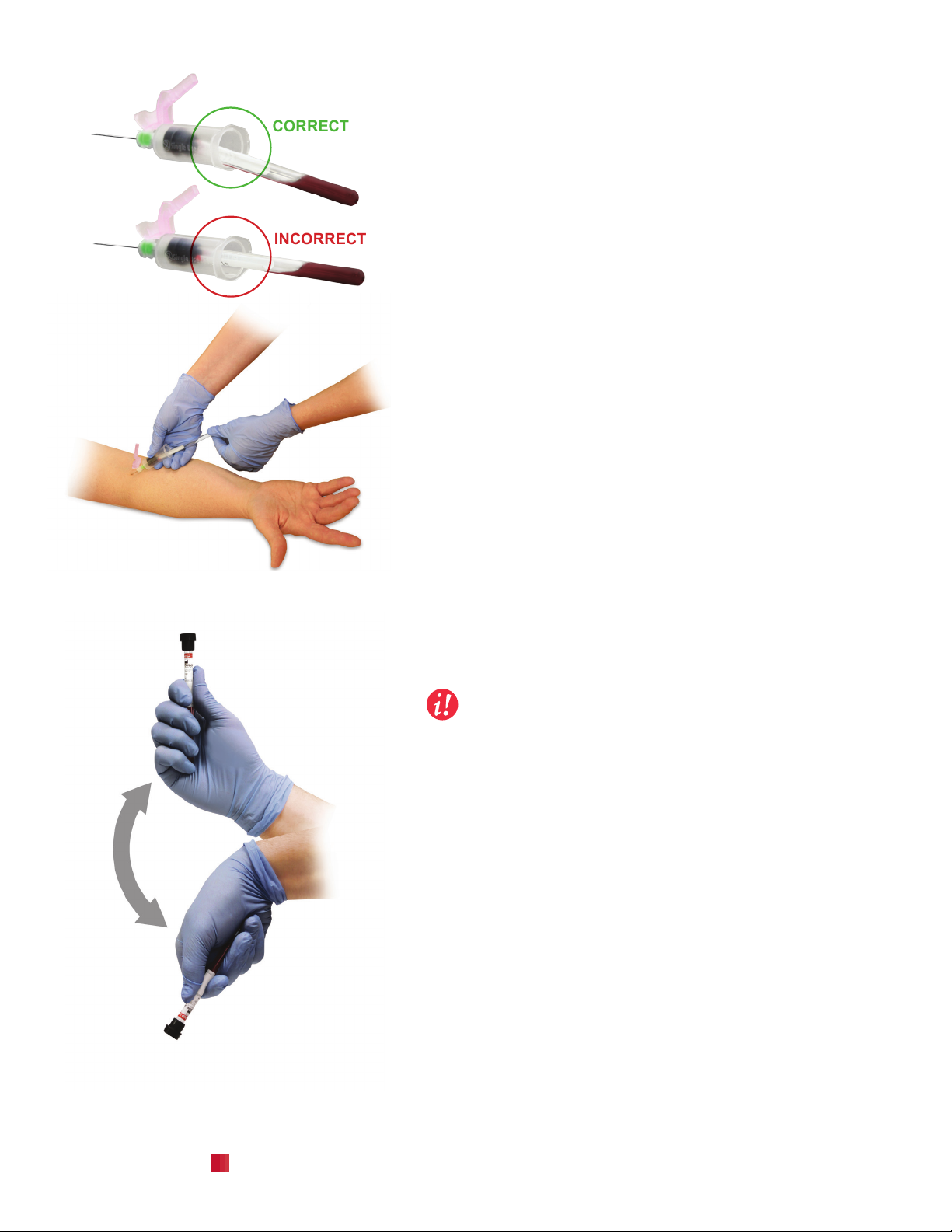

2.5 Secondary Patient Labels

The ESR-Auto Plus reads the sample using infrared light.

This light is very strong and can typically read through one

layer of most commonly used labels.

Caution must be taken when applying additional patient

labels to ESR-Vacuum Tubes. Excessive label thickness,

wrinkling or agging may increase the outer diameter of the

tube enough to wedge it in the instrument. If the operator

experiences resistance when inserting a tube containing a

secondary label, they should remove the tube before it is fully

inserted and remove the additional label before proceeding.

Secondary labels must be positioned correctly and

completely adhered to the tube surface to prevent label

fragments or label adhesive build-up in the instrument well,

which could obstruct sample analysis.

Important: Samples with a ll level outside the ll

range alarm limits will abort immediately. Refer

to section 10.1.

1.2ml Tubes (Figure 7a)

The 1.2ml ESR-Vacuum Tube is the primary tube used in

ESR-Auto Plus.

1. The ideal ll level of the 1.2ml tube is 60mm ± 5mm from

the bottom of the tube. The ideal ll level and range are

printed on the tube label. The ll range can extend to as

much as ± 9mm from the ll line without compromising

the integrity of the sample.

2. Additional labels should be applied facing the same

direction as the original label and as close to the cap as

possible, leaving a label-free gap on the back of the tube.

3. Insert the tube in the ESR-Auto Plus with the label facing

forward.

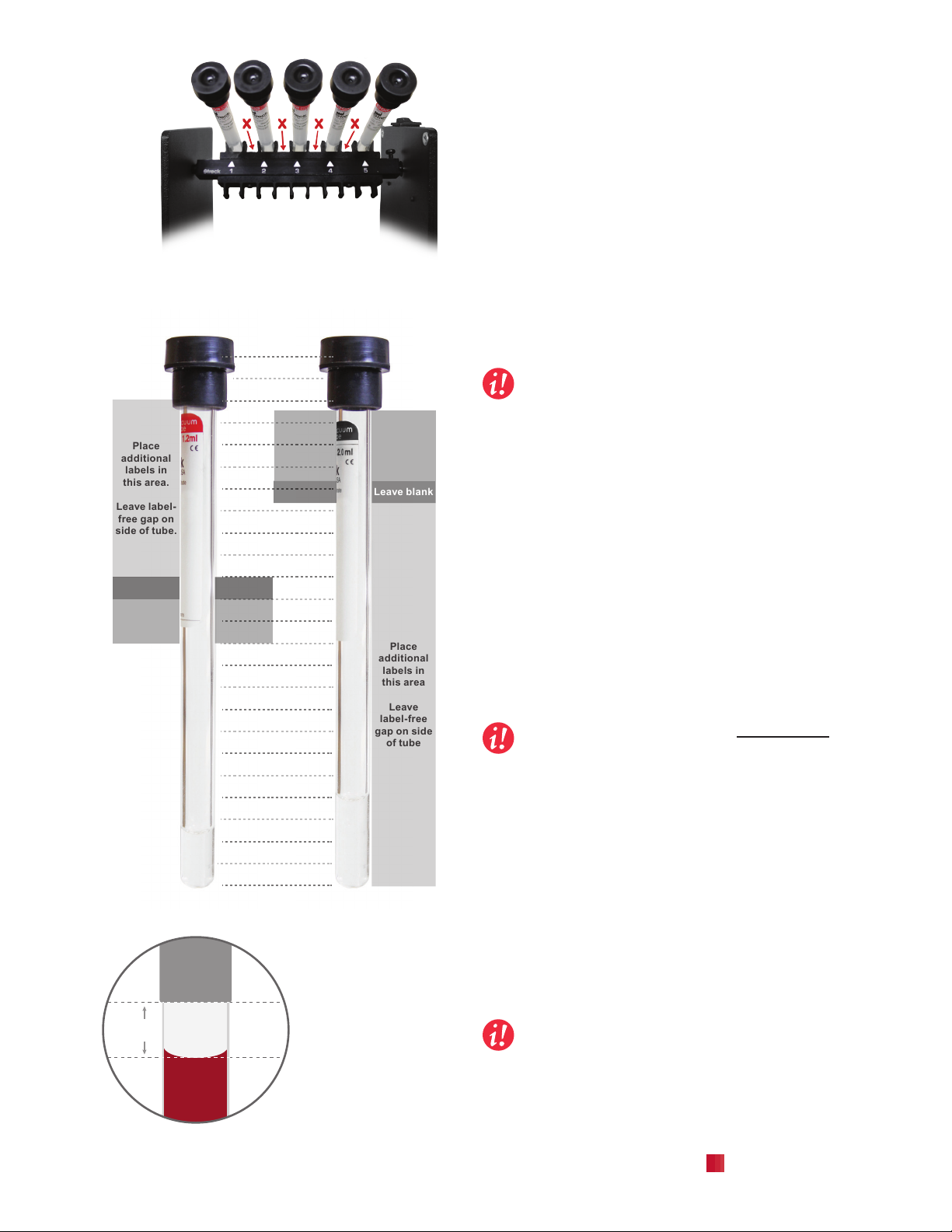

Important: Leave a space of at least 5mm between

the blood level in the tube and any additional

labels to ensure accurate reading of the sample

(Figure 7b).

2.0ml Tubes (Figure 7a)

The 2.0ml ESR-Vacuum Tube can be used in the ESR-Auto

Plus as long as the tube is inserted in the ESR-Auto Plus

correctly and additional labels are applied correctly.

1. The ideal ll level of the 2.0ml tube is 100mm ± 8mm.

2. Do not place additional labels above the ll level printed

at the top of the original label.

3. Place additional labels facing the same direction as the

original label, creating a label-free gap on one side of the tube.

Important: This gap is critical to allow accurate

measurement of the level of blood in the tube.

4. Insert the tube in the ESR-Auto Plus with the label facing

forward, leaving the label-free side at the rear to ensure

accurate reading of the sample.

1.2ml

tube

2.0ml

tube

Leave blank

Leave blank

Ideal ll

range

Ideal ll

range

120

110

100

90

80

70

60

50

40

30

20

10

0mm

Place

additional

labels in

this area.

Leave label-

free gap on

side of tube.

Place

additional

labels in

this area

Leave

label-free

gap on side

of tube

70

65

55

108

92

87

Figure 7a: Label Placement (to scale)

Figure 6: Correct tube placement in mixer

blood

secondary

label

blank

space

5 mm

CORRECT

blood

secondary

label

blank

space

3 mm

INCORRECT

Figure 7b: Secondary

label positioning, 1.2ml

tubes (enlarged to

show detail)

320597-3 - NOVEMBER 2016

10 ESR-Auto Plus Operator’s Manual

2.6 ESR Tube Labeling Sleeves

ESR tube labeling sleeves (Streck catalog # 240363) are

available to accommodate very long barcode labels. Such

labels may obstruct the blood column during analysis,

leading to inaccurate results. The labeling sleeves help

reduce any errors and facilitate proper patient identication.

1. Remove all 5 labeling sleeves from the sheet by folding

along the perforated edges. Separate the individual

labeling sleeves by folding along the perforated lines

between each sleeve.

2. Collect or transfer a valid blood specimen into an ESR-

Vacuum Tube.

3. Bend both sides of the labeling sleeve by creasing the

tabs along the scored lines (Figure 8a).

4. Insert the tube through the hole in the labeling sleeve with

the tabs pointing up around the rubber stopper (Figure 8b).

5. Apply the patient-specic identication label across both

tabs of the labeling sleeve (Figure 8c).

Important: The patient-specic identication

label may extend beyond the end of the labeling

sleeve, depending on the size of the patient label.

Additional identication labels placed on the

tube must be placed outside the scanning area of

the tube. Refer to Section 2.5.

Bend at scored lines

Figure 8a

Figure 8b

Figure 8c

ESR-Auto Plus Operator’s Manual 11

Figure 9a

2.7 Starting a Sample

12:00

next sample...

The ESR-Auto Plus is ready to accept a sample when

the “Next Sample” standby mode appears in the display

window. Scan the patient barcode with the barcode

scanner, or enter the sample ID code manually on the

keypad. An ID code is required to run a sample.

enter id:

12345_

An ID code may contain up to 13 digits. When manually

entering an ID code, press to delete incorrect digits and

to conrm the code. The instrument will automatically

add the signal when using the barcode scanner.

insert 12345

in free position

After the barcode is scanned or the ID code is entered,

insert the well-mixed, room temperature sample in any

free position as indicated by a green light (Figure 9a).

The position light will turn red and the ESR-Auto Plus will

initiate testing.

Important! Samples may be loaded until motor

initiates. Wait until the unit returns to standby to

continue loading samples.

Important! All samples should be properly mixed

and at room temperature before analyzing. A

sedimented sample may require several minutes

of mixing. Refer to Section 2.4.

2.8 Reporting Results

It is good laboratory practice to visually correlate the level of

sedimentation in the sample tube to the printed result. After

measurement is complete, the ESR-Auto Plus automatically

prints results on the internal printer and the DATA OUTPUT

port. The internal printer can be congured in the software.

Refer to Section 5.5.

2.9 Canceling a Sample

Important! Disturbing a sample during the

analysis period may invalidate results. If a sample

is moved during the analysis period, re-mix the

sample and restart the test from the beginning.

To cancel a sample, remove the tube from its position or

press and hold the keypad number corresponding to the

tube position. Press to abort. Aborted samples will not

be stored in the instrument log le.

– abort sample –

pos 1 aborted.

The display will show that the sample has been aborted.

The red light will change to green on the position indicator

and an ESR result will print with a blank ESR value and an

error code of 4 (Figure 9b).

********* ESR RESULT *********

YYYY-MM-DD HH:MM SERIAL NO. 506-0000

SOFTWARE VERSION: v00.0 (YYYY-MM-DD)

POS: 1 ERROR: 4 STATUS: 1

PATIENT NAME: ___________________________

PATIENT ID: 123456789

ESR: --- MM WESTERGREN (QM 1.2 ml)

ALARMS:

-SAMPLE ABORTED

Figure 9b: ESR Result Printout

Table of contents

Other Streck Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Sakura

Sakura Tissue-Tek Prisma Plus operating manual

Fluke

Fluke TiR4 user manual

De La Rosa Research

De La Rosa Research 14012A user guide

Thermo Scientific

Thermo Scientific BIOShield 1000A instruction manual

Agilent Technologies

Agilent Technologies ZORBAX RRHT Series user guide

Metrohm

Metrohm 930 Compact IC Flex ChS/Deg manual