Thermo SAFE 2010 User manual

81-09-IM.doc – Revision 4

INSTRUCTION MANUAL

SAFE 2010 & Maxi SAFE 2010

ID 807233

Page 2 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

Important user information

Please read this entire manual to fully understand the safe and effective use of this product.

In case you have any comments about this manual we will appreciate receiving them at the

address below.

Warranty and Liability

Jouan Nordic A/S guaranties that the product delivered has been thoroughly tested to ensure that it

meets its published specifications. The warranty included in the conditions of delivery is valid only if

the product has been installed and used in accordance with the instructions supplied by Jouan

Nordic A/S.

Jouan Nordic A/S shall in no event be liable for incidental or consequential damages, including

without limitation, lost profits, loss of income, loss of business opportunities, loss of use, and other

related exposures, caused by e.g. incorrect use of the product.

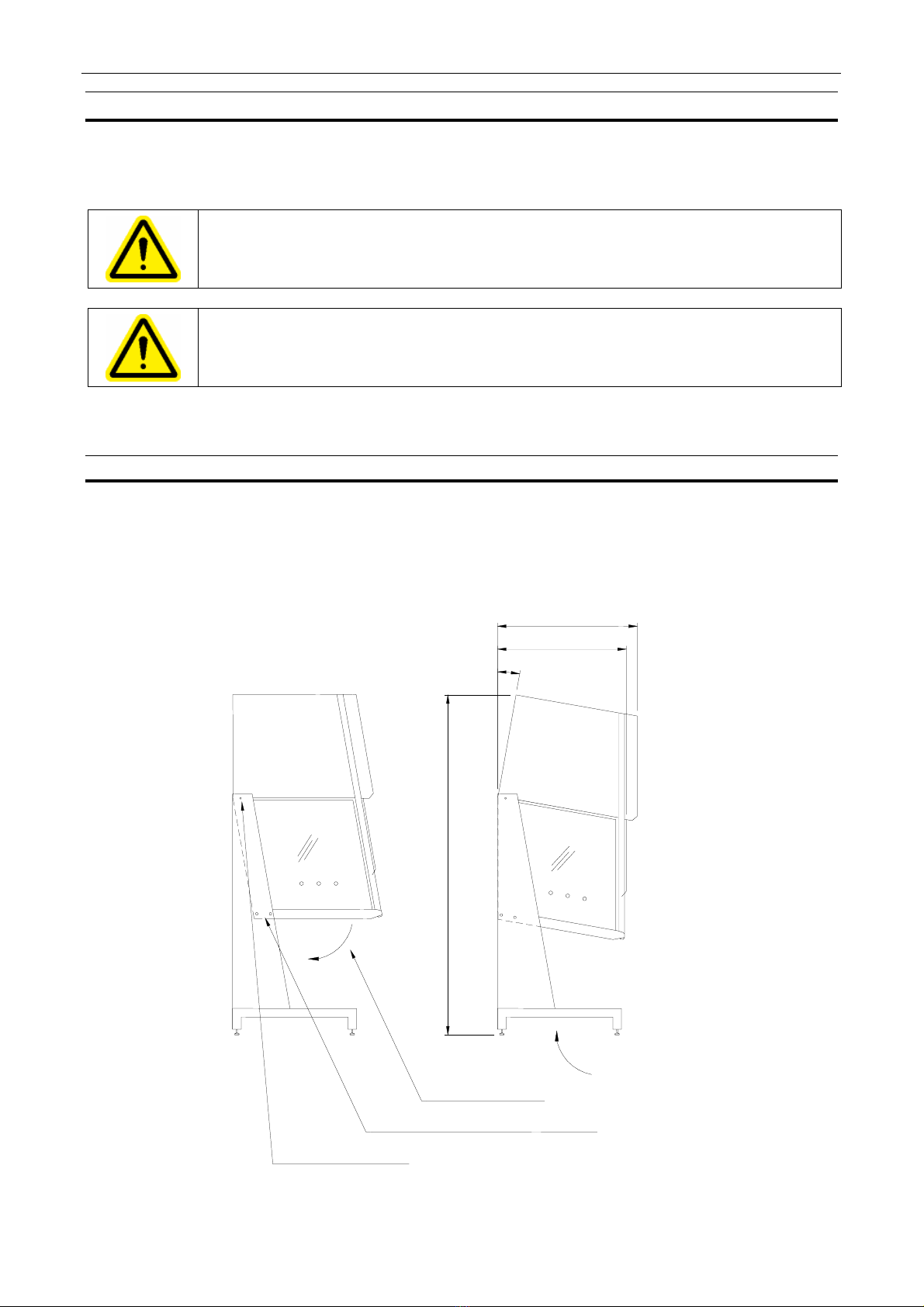

Symbols used in this manual

WARNING

Used in case of danger of a serious accident or when documentation needs to be

consulted.

.NOTE

Used to direct attention to a special item.

© Copyright 2003

Jouan Nordic A/S

Gydevang 17-19

DK-3450 Allerød

Denmark

Telephone +45 48 16 62 00

Fax +45 48 16 62 97

e-mail info.dk@thermo.com

Home page: http://www.jouannordic.com

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 3 of 35

81-09-IM.doc

Table of contents

1. Introduction ...................................................................................................4

2. Safety precautions ........................................................................................4

3. Description.....................................................................................................5

3.1. Working principle.............................................................................................5

3.2. Air filtration ......................................................................................................5

3.3. Air velocity monitoring .....................................................................................5

3.4. Airflow diagram................................................................................................6

3.5. Design.............................................................................................................6

4. EN 12469 approvals.......................................................................................8

5. Technical specifications...............................................................................9

5.1. Property of materials .....................................................................................11

6. Installation ...................................................................................................12

6.1. Transport through passage narrower than 900 mm. ......................................12

6.2. Preparation....................................................................................................13

6.3. Connections ..................................................................................................14

7. Testing .........................................................................................................14

7.1. Air velocity in laminar flow .............................................................................15

7.2. Air velocity in inlet and exhaust opening ........................................................15

7.3. Airflow patterns, visualisation ........................................................................16

7.4. Test of filters..................................................................................................16

7.5. Test of the retention at front opening .............................................................17

8. Work rules....................................................................................................17

8.1. Before start-up...............................................................................................17

8.2. While working ................................................................................................18

8.3. After work ......................................................................................................18

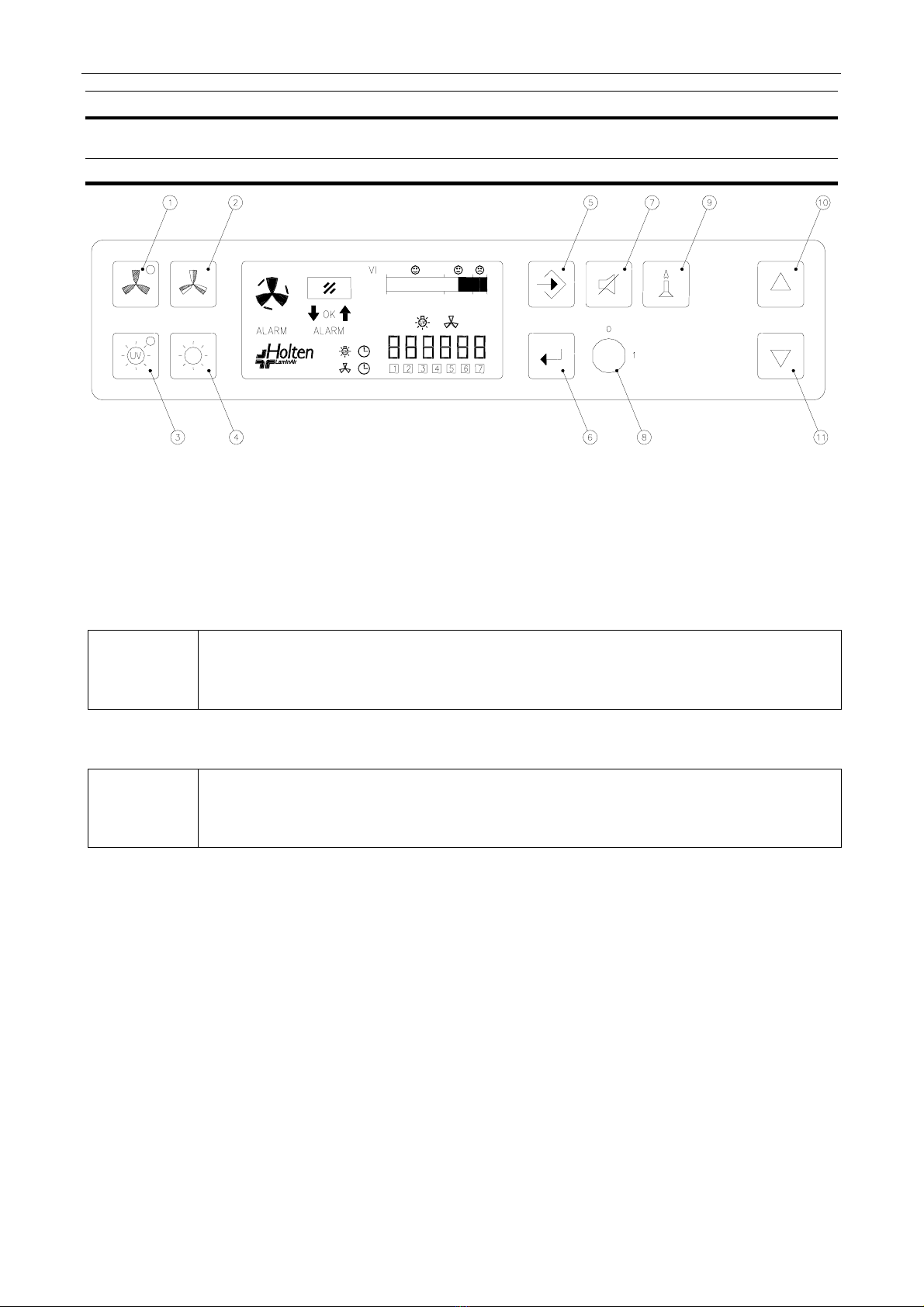

9. Control Panel...............................................................................................19

9.1. Control Panel.................................................................................................19

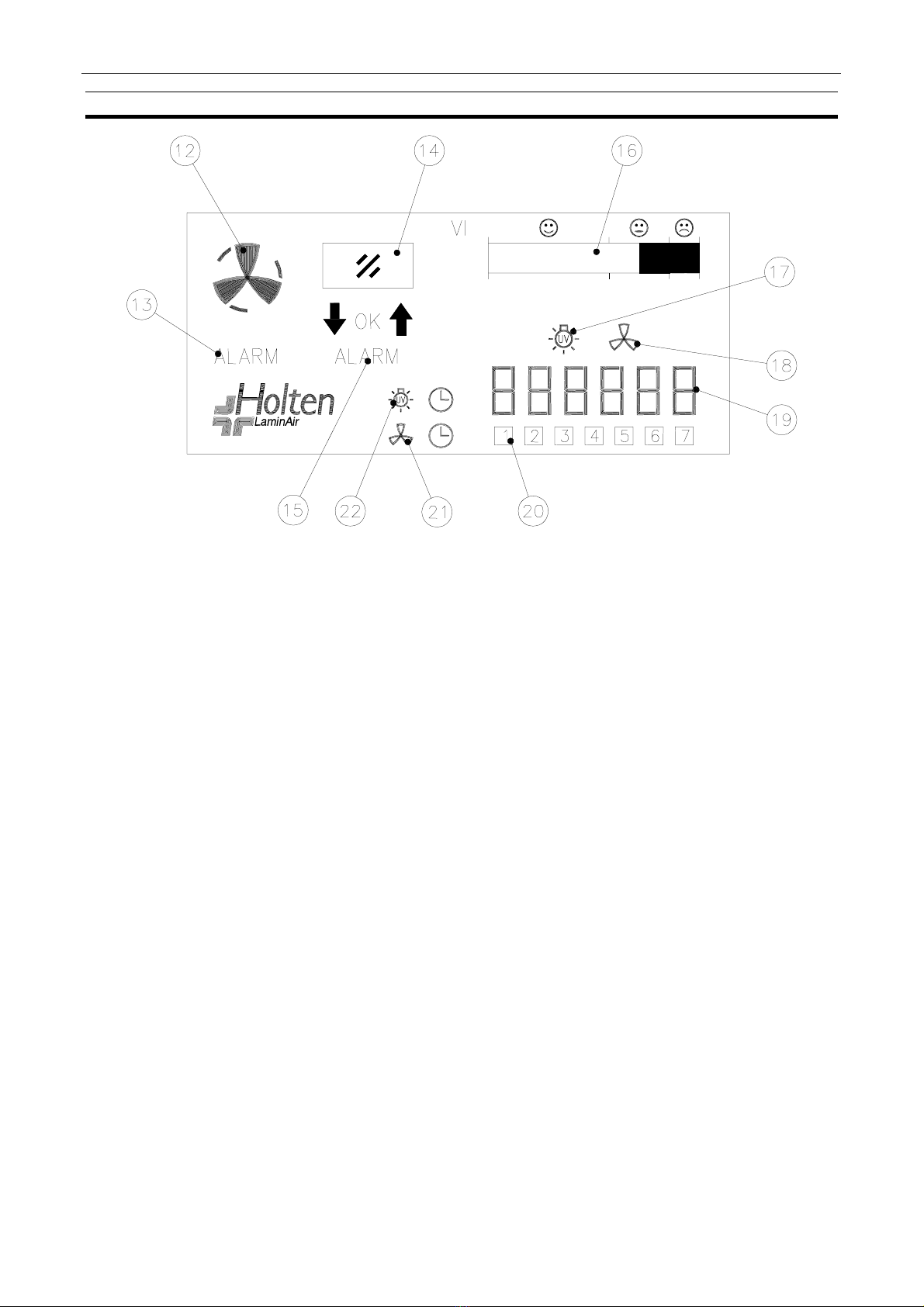

9.2. LCD Display ..................................................................................................20

9.3. Bar graph ......................................................................................................21

9.4. Operation ......................................................................................................21

9.5. Supervision - Alarm .......................................................................................22

10. Cleaning and decontamination...................................................................23

10.1. Daily ..............................................................................................................23

10.2. Weekly ..........................................................................................................24

10.3. Regularly .......................................................................................................24

10.4. Decontamination by use of formaldehyde......................................................24

11. Maintenance.................................................................................................26

11.1. Filters ............................................................................................................26

11.1.1. Main and exhaust filter exchange ..................................................................26

11.1.2. Procedure for replacement of main filter ........................................................27

11.1.3. Procedure for replacement of exhaust filter ...................................................28

11.1.4. Pre-filter (MaxiSAFE Only) ............................................................................29

11.2. Part list for filter .............................................................................................29

11.3. Activated charcoal filters (Optional equipment)..............................................30

11.4. Fuses ............................................................................................................31

11.5. Fluorescent light tube ....................................................................................32

11.6. Starter ...........................................................................................................33

11.7. Electrical spare parts .....................................................................................33

12. Logbook.......................................................................................................34

13. Statement.....................................................................................................35

Enclosure: Declaration of conformity

Page 4 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

1. Introduction

You are now in possession of a high quality microprocessor-controlled Class II cabinet, Holten

SAFE 2010/MaxiSAFE 2010, designed to provide protection of the operator, the environment, and

the processed product against particle-/microbiological contamination.

The cabinet complies with the requirements stipulated in EN 12469 for SAFE 2010 and DIN 12980

for MaxiSAFE 2010. In chapter 4 you can see the options and sizes of approved cabinets.

•The Holten SAFE 2010/MaxiSAFE 2010 Class II cabinet is/has:

•Microprocessor controller with.

•LCD display indicating fan and alarm status.

•Air velocity (filter service) indicator.

•Clock (7 days) and hour-counter.

•Pre-setting of automatic start-up and UV–timer.

•Alarm for any deviation from safety conditions.

•Ergonomically correct sloping front for maximum operator comfort.

•Motor-driven, double-function front window, with both sliding and hinged modes.

•Side windows, for perfect light conditions and view to the surroundings.

•Negative pressure plenum for highest operator and product safety.

•Key switch to prevent unauthorised starting and stopping of the fan.

•Adjustable FAN speeds. Gives you the opportunity to select FAN off, reduced, or normal air

velocity.

2. Safety precautions

•To avoid unintended or improper operation of the cabinet, please carefully read this manual.

•Also, please pay attention to the short form operating instructions on the label stuck on the

cabinet.

•If you have questions related to the function or control of the cabinet or wish to order spare

parts, please always indicate type and production number from the nameplate on the right

side of the cabinet.

WARNING

The proper function and safety of the cabinet are only secured if personnel

authorised by us to do so perform the required tests, maintenance and repair work.

Please also refer to sections ”Testing” and ”Maintenance”.

The following precautions must be taken for operation of the Holten SAFE 2010/

MaxiSAFE 2010.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 5 of 35

81-09-IM.doc

WARNING

The safety cabinet must not be used for Group 4 pathogens.

Attention is drawn to the risk assessment requirements of the Control of Substances Hazardous to

Health (COSHH) Regulations 1999. (UK).

WARNING

The cabinet is not suitable for HIGH-RISK biological agents.

HIGH RISK biological agents include all etiologic agents designated Class 4 by CDC, and

oncogenic viruses classed high risk by NCI. (USA).

WARNING

Never operate the Holten SAFE 2010/MaxiSAFE 2010 cabinet if the fan

compartment cover is removed.

If this cover is removed, the cabinet will give no protection of the operator or the environment and

the fan will run with openly rotating blades.

WARNING

The Holten SAFE 2010/MaxiSAFE 2010 Class II cabinet will not provide any

protection for operator or environment against harmful gases or vapours.

WARNING

Always keep your hands out of the work chamber before starting the sliding

window.

The airspeed monitoring system needs approximately 5 minutes to warm up and stabilise after the

fan has been switched on.

3. Description

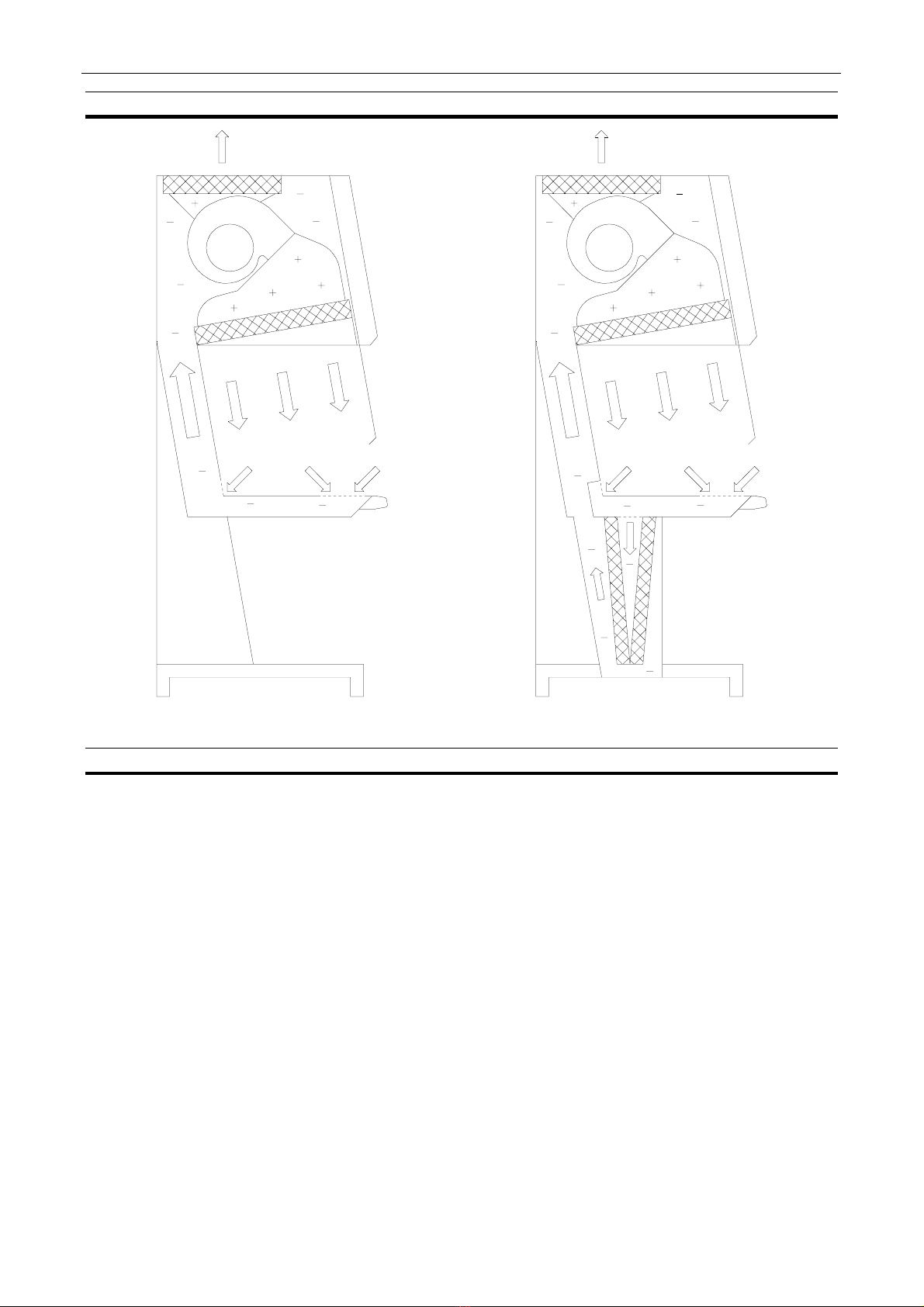

3.1. Working principle

The microbiologic safety cabinet is a modified exhaust cabinet with a turbulence-free (laminar)

vertical displacement flow of clean air in the work chamber protecting the product against particle

contamination. During operation the front window is partly open and the in-going airflow prevents

the escape of particles from the inside of the work chamber thus protecting the operator and the

environment.

3.2. Air filtration

The MaxiSAFE 2010 pre-filter and the main filter and exhaust filter of SAFE 2010/MaxiSAFE 2010

are all high-efficiency HEPA filters.

3.3. Air velocity monitoring

The low turbulence vertical flow and the exhaust flow are monitored by means of air velocity

sensors. Any deviation from safe conditions will be indicated optically and acoustically.

Page 6 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

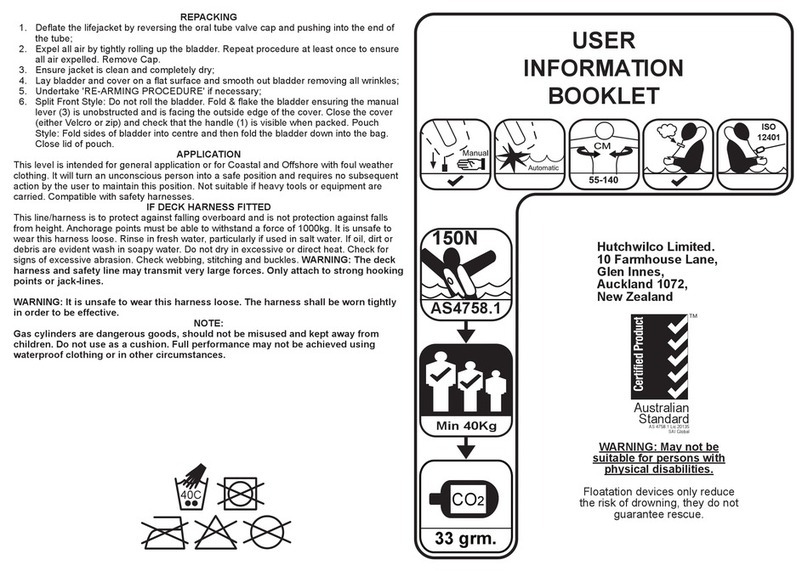

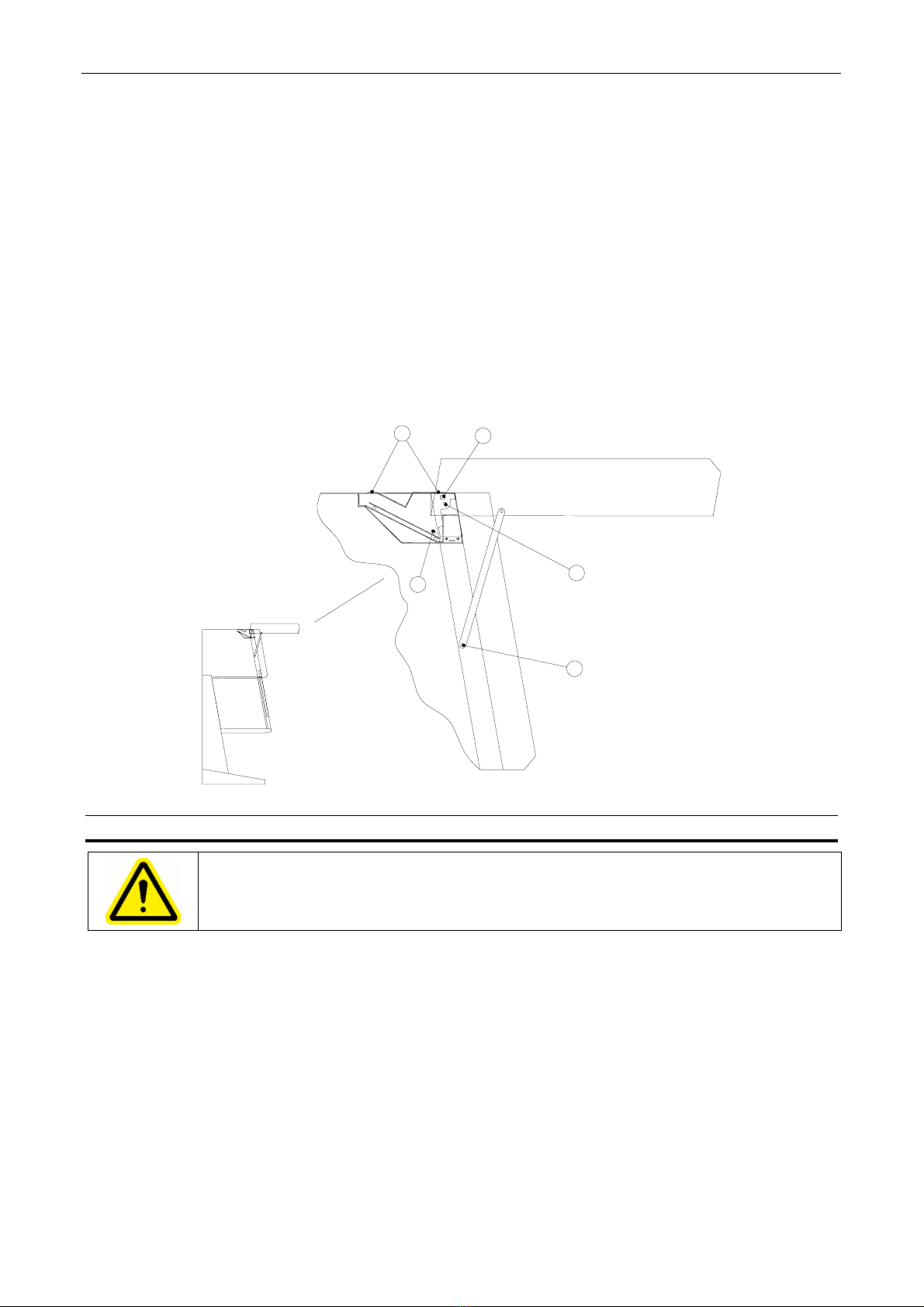

3.4. Airflow diagram

Figure Fejl! Ukendt argument for parameter..

SAFE 2010 Figure Fejl! Ukendt argument for parameter..

MaxiSAFE 2010

3.5. Design

The safety cabinet consists of:

•Fan and filter compartment and return air duct (double back wall) made of polyester coated

sheet steel.

•Support stand made of polyester coated sheet steel and equipped with levelling feet.

•Work chamber with tabletop and trough in stainless steel (AISI 304).

•Side windows and sliding front window all in safety glass.

•Internal ventilation system with negative pressure plenum.

•Microprocessor control and supervision system.

The work chamber is formed by the ceiling (main HEPA filter), side windows, back wall with

installation zones, tabletop and trough; the front is partly closed by the double-action, sliding front

window; the work opening is situated below the front window.

•The outlet opening of the main HEPA filter cover the entire ceiling surface thus giving an

extremely uniform airflow.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 7 of 35

81-09-IM.doc

•The trough will collect and hold any spillage of fluids. A drain valve can be installed

(Standard on MaxiSAFE 2010).

•The installation zones in the back wall can be equipped with electric outlets and a UV-light

fixture.

•The side windows come with holes for installation of valves.

•The stainless steel modular tabletop is easily removed for cleaning.

•The internal light is installed on the front of the work chamber outside the front window. This

secures that the light is glare-free and will cause neither turbulence nor unwanted heating

inside the work chamber.

•Arm rest for air intake efficiency.

Options:

•UV light integrated in the back wall behind a small door.

•Protective ground sockets 230V ∼/ 4A installed in the back wall.

•Valves for various gasses i.e. gas, nitrogen (N2) vacuum, or Carbon dioxide (CO2), a

maximum of 3 installed in each side window.

•Exhaust valve for connection to the exhaust system – consult your dealer for detailed

information.

•Double HEPA-filter exhaust system as specified by BS 5726-(92).

Please contact our sales department for information regarding other available options.

Page 8 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

4. EN 12469 approvals

The SAFE and MaxiSAFE 2010 1.2, 1.5 and 1.5 are approved in different configurations.

The table shows the type and the options:

Approved options for Microbiological Safety cabinets

Maximum 2 electrical outlets in each side

Maximum 3 gas valves in each side window

Alternative filter Camfil H14

UV light

Battery back-up

Multiple processing relay

Cabinet without support stands (Table model)

Only SAFE

Support stand table model

Elevation stand table height 70 – 100 cm

Support stand low 76 - 80 cm ± 2 cm

Support stand high 88 - 92 cm ± 2 cm

Single module table top

2 module table top in the centre

Only SAFE / MaxiSAFE 1.2 and 1.8

3 module tabletop in the centre

Only SAFE / MaxiSAFE 1.5

4 module tabletop in the centre

Only SAFE / MaxiSAFE 1.2 and 1.8

5 module tabletop

Only SAFE / MaxiSAFE 1.5

Stainless steel back wall / sides

Weighting top of marble

Drain valve

Standard on MaxiSAFE

Magnetic valve

Foot contact

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 9 of 35

81-09-IM.doc

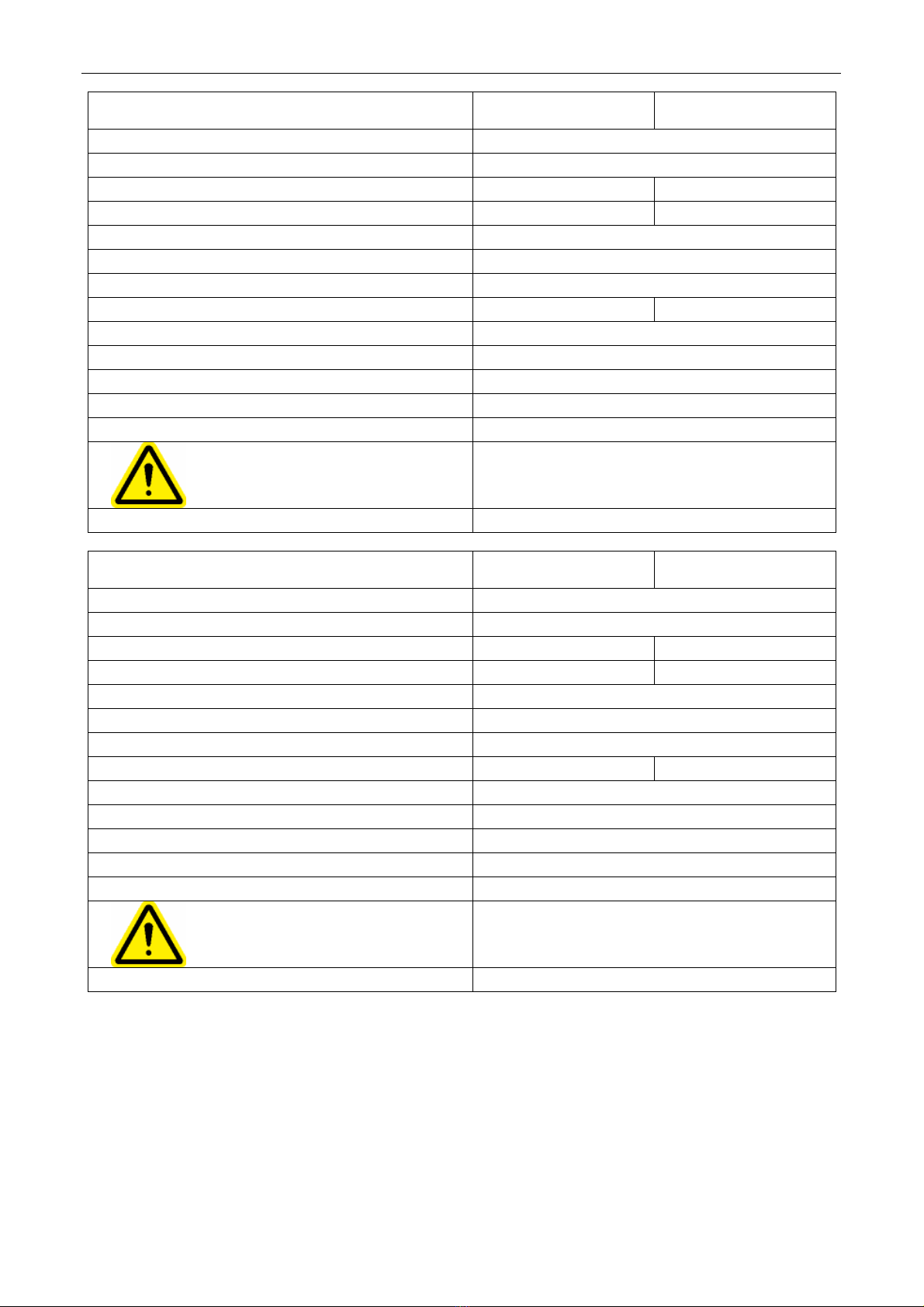

5. Technical specifications

All parts of the cabinet which has a negative pressure is tested in accordance with EN 12469:2000 Annex B,

and meet the LI-C level.

Model 0.9 SAFE MaxiSAFE

External dimensions, DxWxH mm 895x1040x2000

Chamber dimensions, DxWxH mm 580x900x725/650

Weight, kg 200 225

Spillage, litres 13.5 4.5

Exhaust volume, m3/h ±10 % 300

Air velocity in-flow, m/s ≥0.4

Air velocity down-flow, m/s ±20 % 0.4

Noise level, DIN dB(A); EN ISO 3744 55 57

Light intensity, Lux >1200

Supply Voltage/frequency, Volts/Hz 230/50

Power consumption, Watts 500

Required fusing Fuse T16A or circuit breaker 16A

Input current, A 1.6

Socket outlet(s), Volts/Hz/Amps 230/50/4

Maximum leakage current, mA 0.7

Model 1.2 SAFE MaxiSAFE

External dimensions, DxWxH mm 895x1340x2000

Chamber dimensions, DxWxH mm 580x1200x725/650

Weight, kg 225 250

Spillage, litres 18 6

Exhaust volume, m3/h ±10 % 400

Air velocity in-flow, m/s ≥0.4

Air velocity down-flow, m/s ±20 % 0.4

Noise level, DIN dB(A); EN ISO 3744 57 59

Light intensity, Lux >1200

Supply Voltage/frequency, Volts/Hz 230/50

Power consumption, Watts 600

Required fusing Fuse T16A or circuit breaker 16A

Input current, A 1.8

Socket outlet(s), Volts/Hz/Amps 230/50/4

Maximum leakage current, mA 0.7

Page 10 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

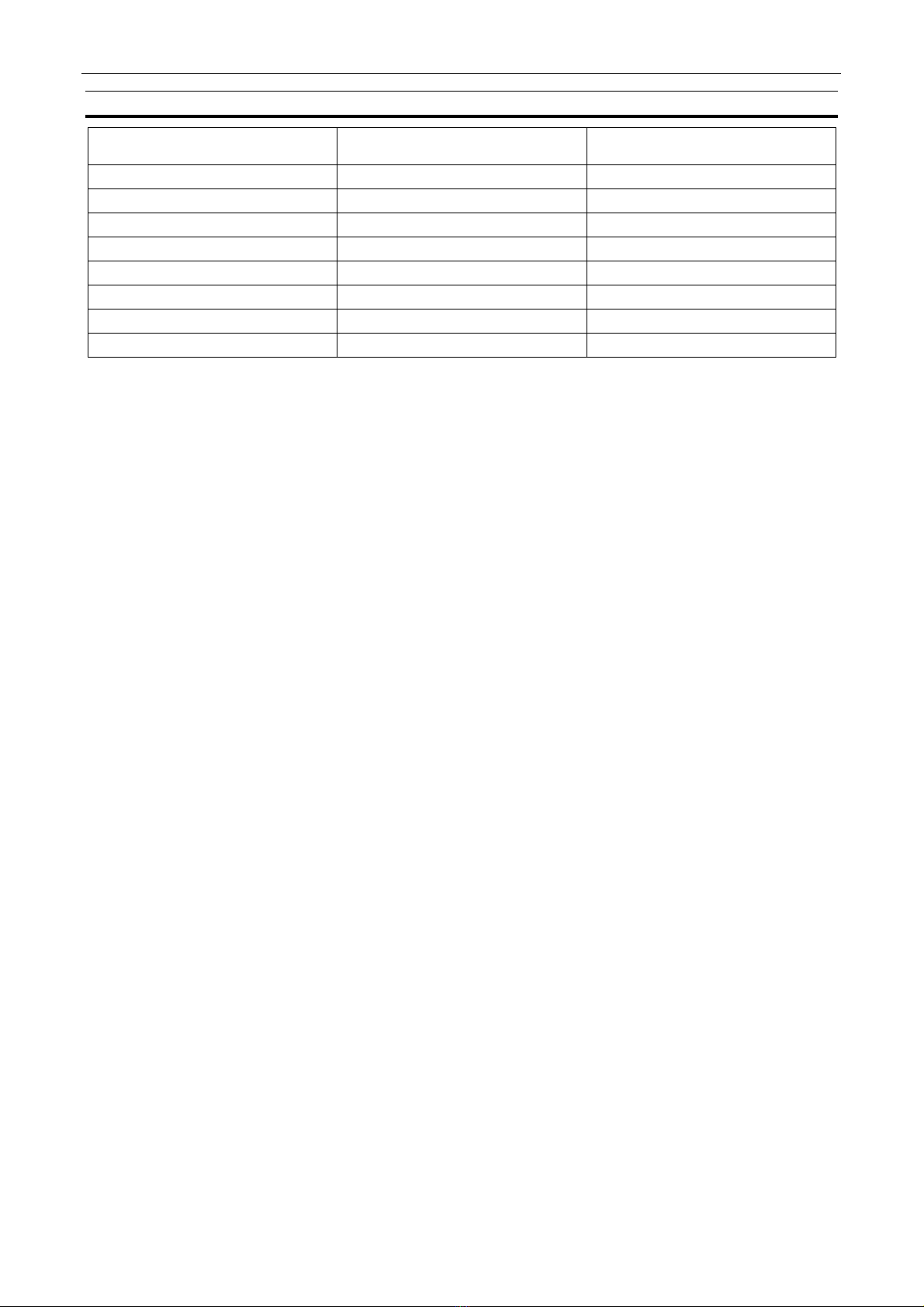

Model 1.5 SAFE MaxiSAFE

External dimensions, DxWxH mm 895x1640x2000

Chamber dimensions, DxWxH mm 580x1500x725/650

Weight, kg 270 315

Spillage, litres 22.5 7.5

Exhaust volume, m3/h ±10 % 500

Air velocity in-flow, m/s ≥0.4

Air velocity down-flow, m/s ±20 % 0.4

Noise level, DIN dB(A); EN ISO 3744 58 59

Light intensity, Lux >1200

Supply Voltage/frequency, Volts/Hz 230/50

Power consumption, Watts 700

Required fusing Fuse T16A or circuit breaker 16A

Input current, A 2.6

Socket outlet(s), Volts/Hz/Amps 230/50/4

Maximum leakage current, mA 0.7

Model 1.8 SAFE MaxiSAFE

External dimensions, DxWxH mm 895x1940x2000

Chamber dimensions, DxWxH mm 580x1800x725/650

Weight, kg 300 355

Spillage, litres 27 9

Exhaust volume, m3/h ±10 % 600

Air velocity in-flow, m/s ≥0.4

Air velocity down-flow, m/s ±20 % 0.4

Noise level, DIN dB(A); EN ISO 3744 58 59

Light intensity, Lux >1200

Supply Voltage/frequency, Volts/Hz 230/50

Power consumption, Watts 800

Required fusing Fuse T16A or circuit breaker 16A

Input current, A 3.0

Socket outlet(s), Volts/Hz/Amps 230/50/4

Maximum leakage current, mA 0.7

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 11 of 35

81-09-IM.doc

5.1. Property of materials

Units Material Treatment

Front and side windows Safety glass Laminated/tempered

Front window frame Stainless steel AISI 304 Polished

Side window frame PVC

Support stand Steel 1203 2 mm Polyester-coated RAL 7038

Front shield Al Mg 3, 2 mm Polyester-coated RAL 7038

All other painted parts Steel 1203, 1.5 mm Polyester-coated RAL 9002

Trough and tabletop Stainless steel AISI 304 Polished

Internal main and exhaust plenum Polystyrene

Page 12 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

6. Installation

Transport of the SAFE 2010/MaxiSAFE 2010 can be carried out by lifting the cabinet using a forklift

either sideways under the support stand or directly under the trough. Furthermore the cabinet can

be moved manually by using hooks in the dedicated holes in the support stand.

WARNING

Whenever transportation of the cabinet is needed, precautions should be taken to

prevent it from overturning due to the high-located mass centre.

WARNING

In order to prevent damage to the cabinet it must be handled as fragile goods.

Storage of the cabinet must be in an environment of maximum 80 % relative humidity and at

temperatures between 5 °C to 50 °C.

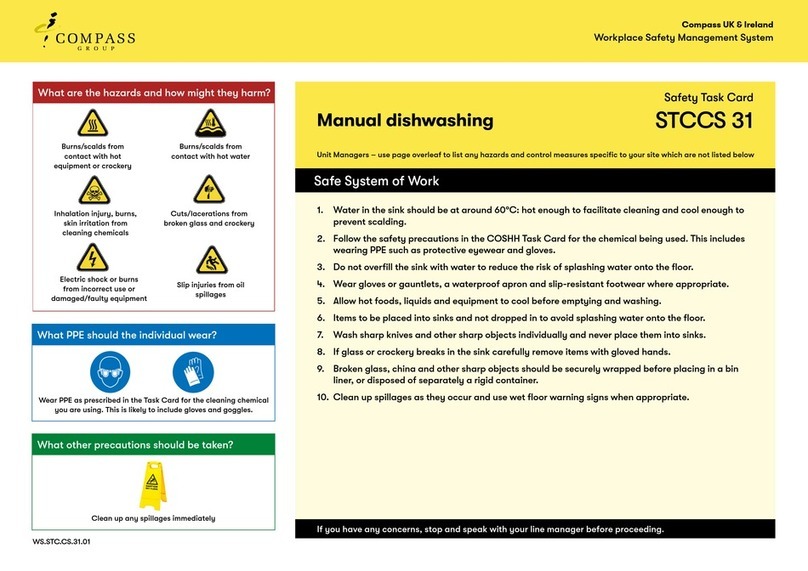

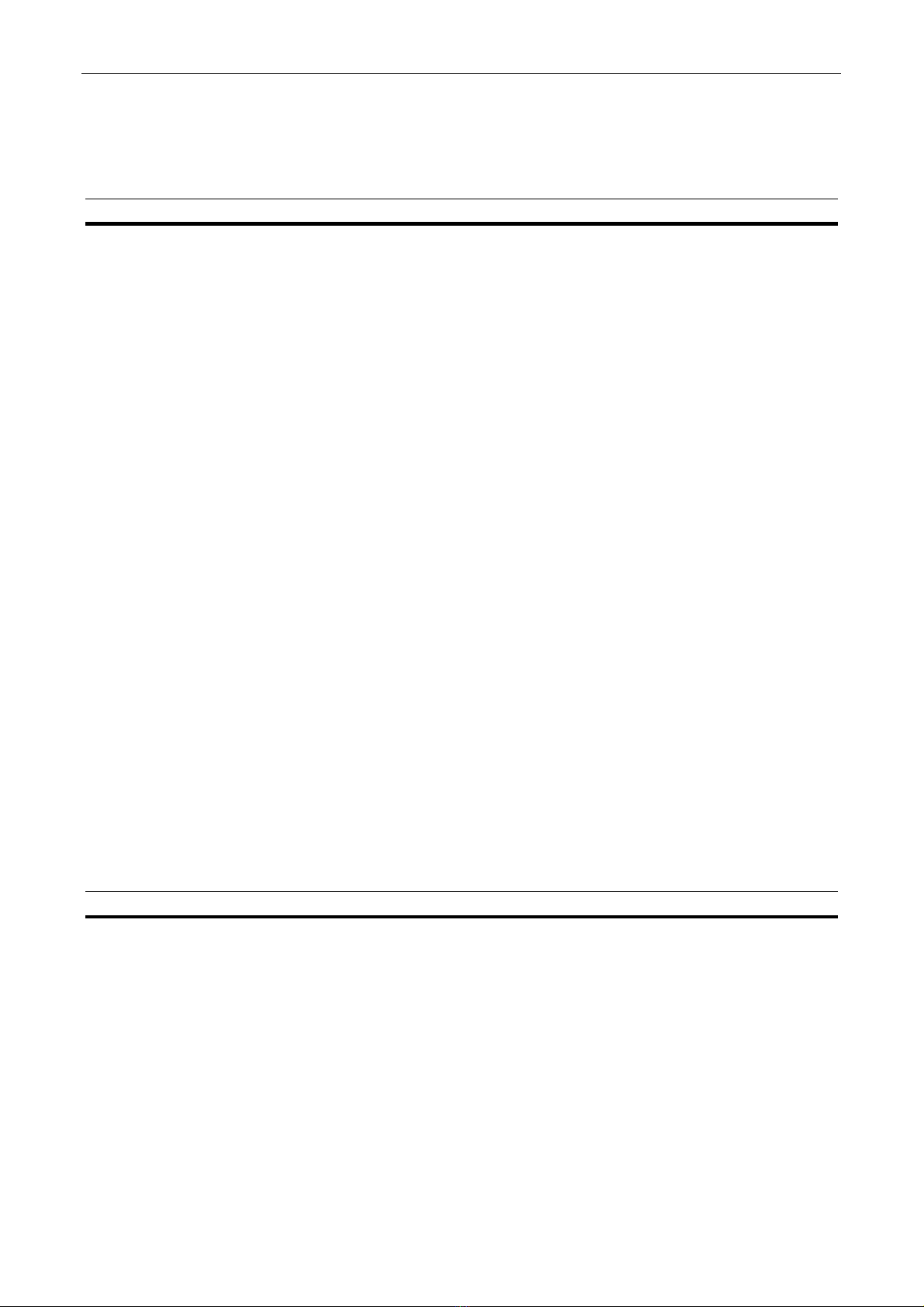

6.1. Transport through passage narrower than 900 mm.

The cabinet may be tilted 10 °, see figure 3 so that the sloping front is in vertical position. If the

passage is narrower than 850 mm you may dismount the front shield with the control panel and the

bracket holding the mains plug on the back of the cabinet, see figure 4.

The cabinet can then be moved through a standard 800 mm wide door.

Space for forklift.

1. Loosen the screw.

2. Screw off and remove the two screws.

3. Tilt the cabinet 10°.

2000 (low support stand)

2110 (high support stand)

850

795

10°

Figure Fejl! Ukendt argument for parameter..How to tilt the cabinet.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 13 of 35

81-09-IM.doc

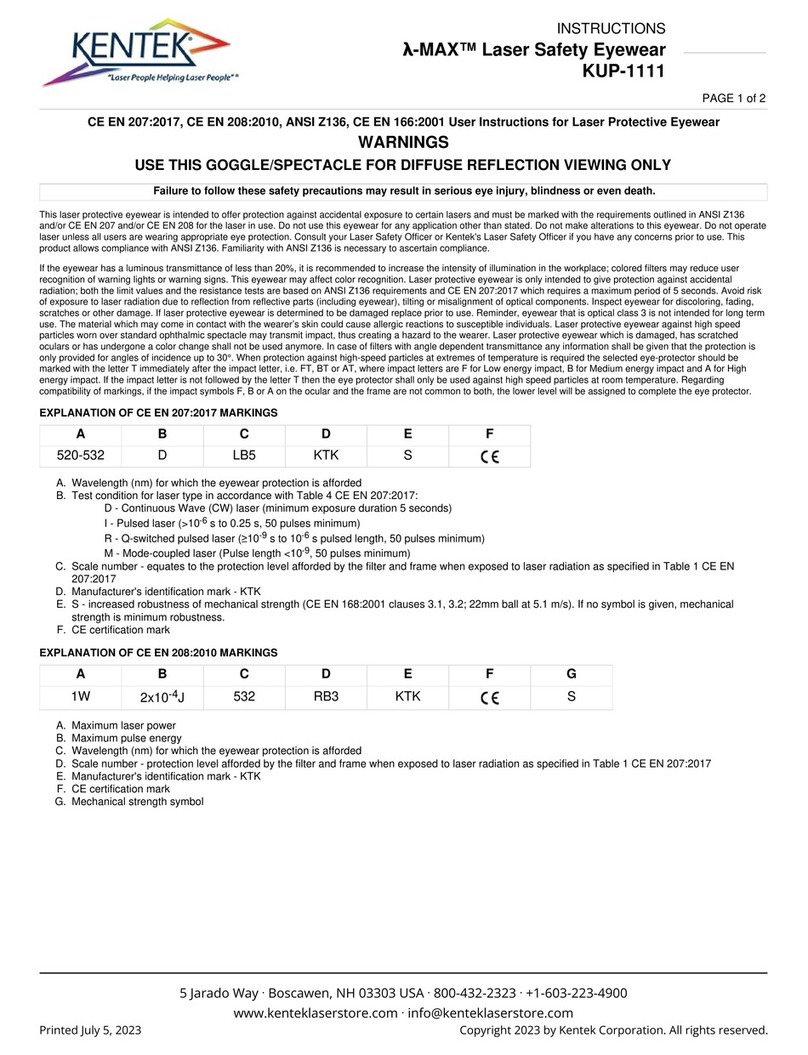

1. Bring the front window to the lowest position.

2. Disconnect the power.

3. Remove the protective cover from the fuses (4 screws) - position 1 figure 4.

4. Pull out the plug - position 2 figure 4 - for the flat cable for the display PCB on the control

PCB.

5. Disconnect the protective earth wire - position 3 figure 4.

6. Unscrew the screws for the gas spring - position 4 figure 4.

7. Unscrew the screws for the front shield - position 5 figure 4.

8. Remount the front shield in the reverse order, and continue with section 6.2 step 1 below:

1

2

3

4

5

Figure Fejl! Ukendt argument for parameter..How to dismount the front shield.

6.2. Preparation

WARNING

The installation site for the unit must be draught-free and should be selected so that

frequent passing of people in front of the work opening is avoided.

1. The tabletops of stainless steel are mounted over the trough.

2. Adjust the levelling screws to assure that the tabletop is in horizontal position and levelled.

3. Valves for gases or vacuum are installed in the side windows. A qualified technician must

make the connections for the supply.

4. For connection of the exhaust air to the exhaust air systems, special precautions which must

be discussed with the cabinet supplier, must be taken.

5. The armrest has to be mounted over the perforated holes.

Page 14 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

When the cabinet has been installed:

1. Check that the front window is in the correct position, i.e. parallel to the front shield.

2. Never lift the front window manually, as this will cause the safety latch to engage.

3. Check that the window slides from top to bottom without any irregular sound.

4. If the window does not move when the UP or DOWN button is pressed, authorised service

personnel must be called to correct the fault.

5. Always keep hands and arms away from the working chamber when activating the front

window.

6.3. Connections

Required fusing: Circuit breaker 16 A or fuse T 16 A.

In addition, the applicable safety requirements of the local power Supply Company shall apply.

WARNING

If an automatic relay for disconnection of power in case of electric fault is needed, it

must be installed in the supply, as it is not built-in.

WARNING

Before connecting the power supply it must be checked that the mains

specifications correspond to those stated on the type plate.

WARNING

The safety cabinet is provided with a flexible power cord. The connection may be

installed hard-wired or by means of a wall outlet with protective ground.

If a hard-wired connection is used, a main switch, which will cut off all poles to the unit, must be

used. This switch must be lockable both in the ON and OFF positions.

If the unit is connected through a protective-ground wall outlet, the connector has the all-pole

insulator function. The wall outlet is to be installed out of reach of operators and may only be

accessible to authorised personnel.

7. Testing

Perform tests after installation or change of location and before the initial start-up.

WARNING

According to the standard EN 12469 and DIN 12980, the following must be tested:

•Check that manufacturer’s specifications are met.

•Air velocity in laminar flow.

•Leakage test of the main and exhaust air filter.

•Air inlet speed in the work opening.

•Check airflow patterns.

•Optionally a KI-Discus test for testing operator protection on site.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 15 of 35

81-09-IM.doc

All tests have to be done by an authorised test technician.

The test results must be entered in a test book.

For more information about testing please consult the service manual.

7.1. Air velocity in laminar flow

Equipment:

The down flow is measured with a calibrated thermo anemometer.

Procedure:

Turn on the cabinet and wait until the airflow has been stabilised.

The thermo anemometer is placed in the measuring spot in a height 50 mm over the upper edge of

the front opening.

The measuring spots are the same at both SAFE and MaxiSAFE.

Measure in 2 rows 150 mm and 350 mm from the sucking holes in the front of the working plate,

starting 150 mm from the left side window and with 300 mm between the measuring spots.

On the left side of the working plate the measuring probe shall point left parallel to the back wall,

and on the right side of the working plate the measuring probe point right parallel to the back wall.

Each point is to be measured in at least 5 sec. and the value is to be recorded.

Calculate the mean value; record it as well as the maximum and minimum airflow.

Acceptance:

Mean downflow 0.40 m/s ± 10 %.

Distribution: All velocities between mean ± 20 % m/s.

Alarms:

The alarms for high and low downflow are set to mean ± 20 % m/s, and the matching voltage is to

be recorded.

7.2. Air velocity in inlet and exhaust opening

Equipment:

The inflow is measured with a suitable volumetric measuring device.

Procedure:

The measuring can take place directly in the opening or directly at the exhaust filter.

Cover the front opening with a plate and seal it so only an opening for the measuring device is free.

Measure the volumetric flow and calculate it into velocity in m/s, and record the result.

Formula for the calculation: X m3/h / (3600s/h x aperture in m2) = Y m/s.

Page 16 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

Acceptance:

Air velocity in inlet ≥0,4 m/s.

S/MS 0,9 S/MS 1,2 S/MS 1,5 S/MS 1,8

0,4 m/s = 258 m3/h 344 m3/h 430 m3/h 516 m3/h

Alarms:

The alarm for inflow velocity is set to 0,4 m/sec, and the matching voltage is to be recorded.

The acoustic alarm is tested in accordance with DIN EN 457, measured 0.5 m from the middle of

the cabinet 1.5 m over the floor. The alarm signal must be at least 13 db(A) higher at 4000 Hz than

the sound of the cabinet.

7.3. Airflow patterns, visualisation

The purpose of the test is to verify that no smoke escapes from the working space to the room, and

that smoke will be drawn into the working space from the room.

Equipment: Smoke stick.

Procedure:

Pass the smoke stick in an easy movement along the front opening outside the cabinet. The

smoke must be drawn into the cabinet without visible turbulence.

Test the laminarity of the downflow and along the side- and back wall. No smoke must come out in

the room and only small turbulence must be observed.

7.4. Test of filters

Equipment:

Aerosol generator capable of producing test aerosol for HEPA filter leak testing. Aerosol

photometer with an upper measuring threshold of 10 ųg/l to 100 ųg/l and a range covering not less

than 5 log rates.

Test aerosol: POA (Poly-Alpha Olefin).

Emery 3004 from Henkel Company or an equivalent material.

Procedure:

Main- and exhaust filter:

Turn on the cabinet and induce the aerosol through the “challenge” valve to the upstream side of

the filter.

Scan the downstream side of the filter over the entire surface. Scan all filter joints and sealant for

leaks.

Pre-filters (Maxi):

Turn on the cabinet in reduced speed mode, and let the airflow stabilise. Remove the tabletop.

Cover half of the pre filters. Adjust the concentration over the “challenge” piece to 0. Every single

pre-filter is “challenged” with test aerosol, and all joints and surfaces are tested.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 17 of 35

81-09-IM.doc

Acceptance:

Maximum local penetration: 0.01 % of upstream concentration.

7.5. Test of the retention at front opening

General:

This test is optional, but useful for determination of the operator protection after installation where

the cabinet is under influence of the laboratory environment.

Equipment:

KI – Discus tester, equipment that with an aerosol challenges the air curtain, established by the

down- and inflow.

Procedure:

With a spinning disc the test aerosol (Potassiumiodide 1.5 % in Ethanol) is spread inside the

cabinet, in a homogeneous aerosol cloud. The particles leave the disc in a horizontal course, and

try to pass the air curtain.

A sucking head with a filter inside, catches particles which pass the air curtain,. With a developing

agent (Palladiumchloride 0.1 %) passing particles will shows up as brown spots. The amount of

spots is to be counted.

Acceptance: Apf ≥1x105.

8. Work rules

8.1. Before start-up

•The cabinets may only be operated at temperatures between 15 °C and 35 °C, at maximum

80 % relative humidity, and at normal air pressure.

•All cabinets are developed and produced for use in clean environments.

•They must not be operated outdoors or in environments with extreme air pollution. The safety

cabinets are not intended to filter vapours containing acids or organic solvents. The safety

cabinets must not be used as a fume hood.

•Approximately 15 minutes before any work in the cabinet, the fan of the unit must be

switched on at normal velocity. The work chamber and the front- and side windows are to be

carefully cleaned and disinfected. Use an ethanol solution or similar. It is recommended to

use special lint-free material. Do not use explosive disinfectants. See also section Fejl!

Ukendt argument for parameter..

•Objects and appliances must be carefully cleaned or disinfected before being introduced into

the work chamber. Do not bring in writing utensils, packing material, etc.

•The front window and the armrest is positioned in working position and kept in that position

during the entire work process.

•Necessary appliances for use during work must be placed within easy reach.

•Secures the appropriate protection of the operator as well as the product (e.g. clothes,

gloves, etc.).

Page 18 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

8.2. While working

WARNING

Important for work with environmentally harmful substances!

•Do not perform work while the fan is running at reduced speed.

•The front window must be in work position during working hours.

•Place the product behind the perforated area of the work surface.

•Work with calm, smooth movements.

•Never overload the work chamber, reduce the number of transfers into and out of the work

chamber.

•Avoid products or agents with high heat emission.

•Avoid a cabinet location where personnel frequently pass and avoid draughts.

WARNING

The efficiency of the laminar airflow in the work chamber is essential for personnel

and product protection. Negative influences of the flow conditions must therefore be

avoided. They primarily arise due to:

•Rapid movements of the operator’s hand, arm, or body both in and in front of the work

chamber.

•Covered vents in the tabletop of the worktable or covered vents at the bottom of the work

chamber back wall.

•Large objects and apparatus.

•Devices making rapid movements e.g. agitators, centrifuges.

WARNING

Do not damage the main filter in the ceiling of the work chamber by mechanical

objects or heat sources, otherwise the microbiological safety is no longer ensured.

The acoustic and optical monitoring devices of the fan and front window must not be deactivated.

The enclosed armrest has to be used in order not to cover the perforated holes.

Devices developing strong heat, e.g. burners. If burners cannot be avoided, use safety burners.

Operate heat sources only with the cabinet fan activated.

8.3. After work

•Remove objects and appliances from the work chamber.

•Clean the work chamber, remove fluids, if any, from the trough and dry it. Disinfect if

required.

•Leave the cabinet fan in operation for about another 10 minutes.

•Close the front window to its lowest position.

SAFE 2010/MaxiSAFE 2010 INSTRUCTION MANUAL Page 19 of 35

81-09-IM.doc

9. Control Panel

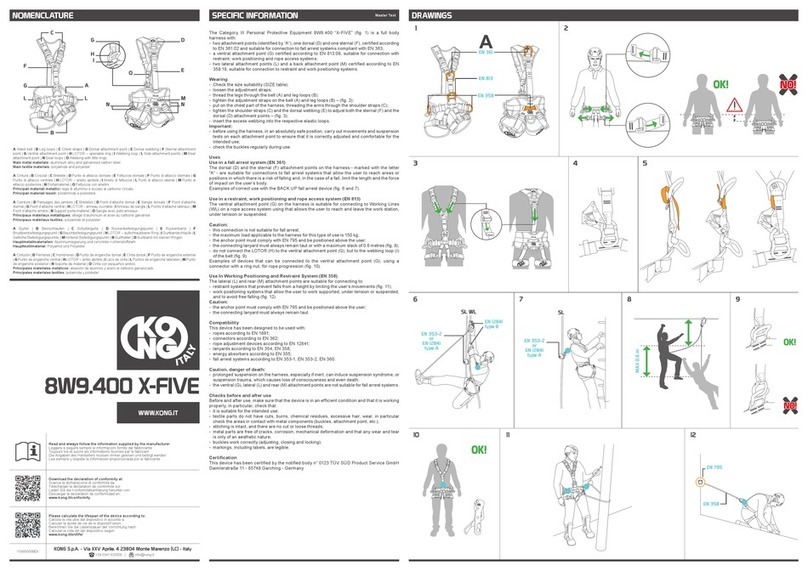

9.1. Control Panel

1. Button with green LED light to select the fan ON/OFF at normal velocity. The green light

indicates that the fan is running at normal velocity, and that conditions are safe.

2. Button to select the fan ON/OFF at reduced velocity.

3. Button with yellow LED light to select UV light ON/OFF. The yellow light indicates that the UV

light is ON. (UV light and matching UV timer for radiation time is optional).

.

NOTE

For increased safety against unintended UV radiation which will harm eyes and

skin: the front window must be closed in the lowest position and normal light must

be switched off before UV light can be switched on.

4. Button for normal light ON/OFF.

.

NOTE

For increased safety reduced velocity will turn the light OFF. When the light is

switched ON at reduced velocity the fan will be forced to normal velocity.

5. Button for programming the clock, automatic start up or the UV timer.

6. Button for entering data.

7. Button to silence the acoustic alarm. The alarm cannot be muted while cabinet is in operation

mode.

NB! Muting of the alarm is possible on the DIN 12950 approved cabinets.

8. Key switch for prevention of any unauthorised switching ON or OFF of the fan.

9. Button to OPEN/CLOSE the solenoid gas valve (optional).

10. Button for opening of the front window. In programming mode used for increasing data value.

11. Button for closing of the front window. In programming mode used for decreasing data value.

Page 20 / 35 INSTRUCTION MANUAL SAFE 2010/MaxiSAFE 2010

81-09-IM.doc

9.2. LCD Display

12. Fan velocity: Normal, Reduced, or Stop.

13. Air velocity not within safe limits. The icon flashes, the acoustic signal sounds and flashing

red light comes on.

14. Front window (sliding sash).

15. Front window not in safe position. The icon flashes, the acoustic signal sounds and flashing

red light comes on.

16. Indication of vertical air velocity in the work chamber (service meter).

17. This icon will illuminate when the UV timer is being programmed.

18. This icon will illuminate when the automatic start-up timer is programmed.

19. Hour counter or clock with fan switch ON or OFF.

20. Indication of weekday.

21. This icon will illuminate when the automatic start-up is programmed and active.

22. This icon will illuminate when the UV timer is activated.

This manual suits for next models

1

Table of contents

Popular Safety Equipment manuals by other brands

Trinity Highway

Trinity Highway SRT 31 System Product Description Assembly Manual

SECUMAR

SECUMAR FREE 100 quick guide

Super Anchor Safety

Super Anchor Safety PD-6101 instruction manual

MSA

MSA BD mini manual

Vertiqual Engineering

Vertiqual Engineering HELI 6 instruction manual

pizzato

pizzato CS MF204 0-P Series manual