Trinity Highway SRT 31 System User manual

Created November 2021

PN 626825

SRT

TMTM 31 System

Flared End Terminal

Product Description Assembly Manual

TrinityHighway.com 1 Part Number: 626825

©2021 Trinity Highway Products, LLC

Created November 2021

SRT™ 31 System

Flared End Terminal

The Slotted Rail Terminal-31 System (“SRT™ 31 System”) has been tested to National Cooperative Highway

Research Program (“NCHRP”) Report 350 criteria and has been deemed eligible for Federal-aid

reimbursement on the National Highway System (“NHS”) by the Federal Highway Administration (“FHWA”).

Product Description

Assembly Manual

15601 Dallas Parkway

Suite 525

Addison, Texas 75001

Warning: The state/specifying agency, distributors, owners, and contractors

are RESPONSIBLE for the assembly, maintenance, and repair of the SRT™ 31

System. Failure to fulfill these RESPONSIBILITIES with respect to the assembly,

maintenance, and repair of the SRT™ 31 System could result in serious injury or

death.

Important: These instructions are for standard assembly specified by the

state/specifying agency. In the event the specified system assembly, maintenance, or

repair would require a deviation from standard assembly parameters, contact a Trinity

Highway Products, LLC (“Trinity Highway”) representative. This system has been

deemed eligible by the FHWA for use on the NHS under strict criteria utilized by that

state/specifying agency.

This manual must be available to the worker overseeing and/or assembling the product at all

times. For additional copies, contact Trinity Highway at (888) 356-2363 or visit

TrinityHighway.com/Products.

The information contained in this manual supersede all previous versions. The instructions, illustrations,

and specifications are based on the latest SRT™ 31 System information available to Trinity Highway at

publication. We reserve the right to make changes at any time. Please visit TrinityHighway.com/product-

category/end-terminals to confirm the latest revision.

TrinityHighway.com 2 Created November 2021

SRT™ 31 System

Flared End Terminal

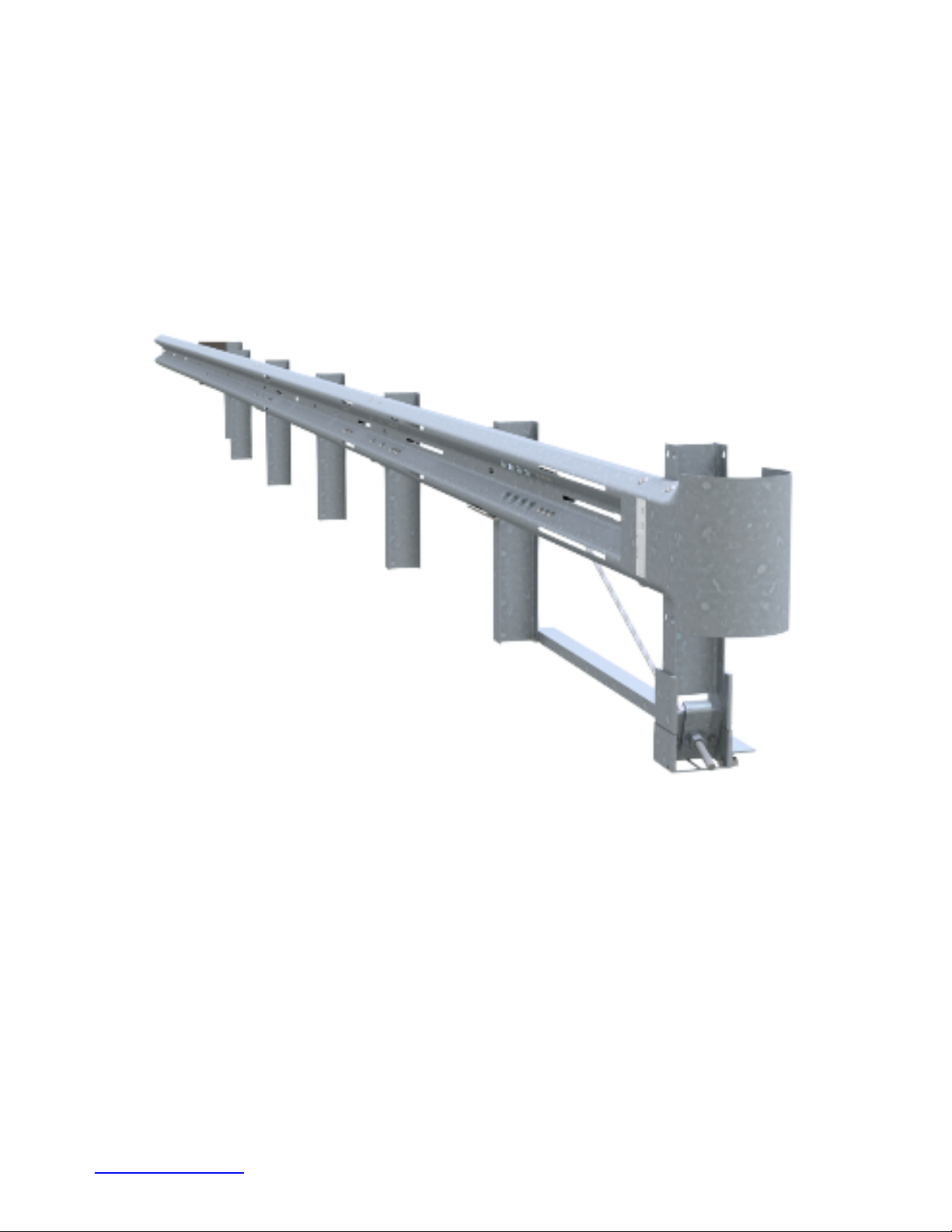

The SRT™ 31 System is a straight flared, single-sided, re-directive, and gating end terminal.

TrinityHighway.com 3 Created November 2021

Table of Contents

Customer Service Contacts ................................................................................................................................. 4

Limitations and Warnings ........................................................................................................................ 5

Overview .................................................................................................................................... 6

Inspect Shipment SRT™ 31 System ....................................................................................................... 8

SRT™ 31 System Components/Hardware ............................................................................................... 9

Recommended Tools ............................................................................................................................. 12

Site Preparation .................................................................................................................................. 13

Post Placement .................................................................................................................................. 14

Rigid Pavement and Rock ..................................................................................................................... 14

Assembly Steps .................................................................................................................................. 14

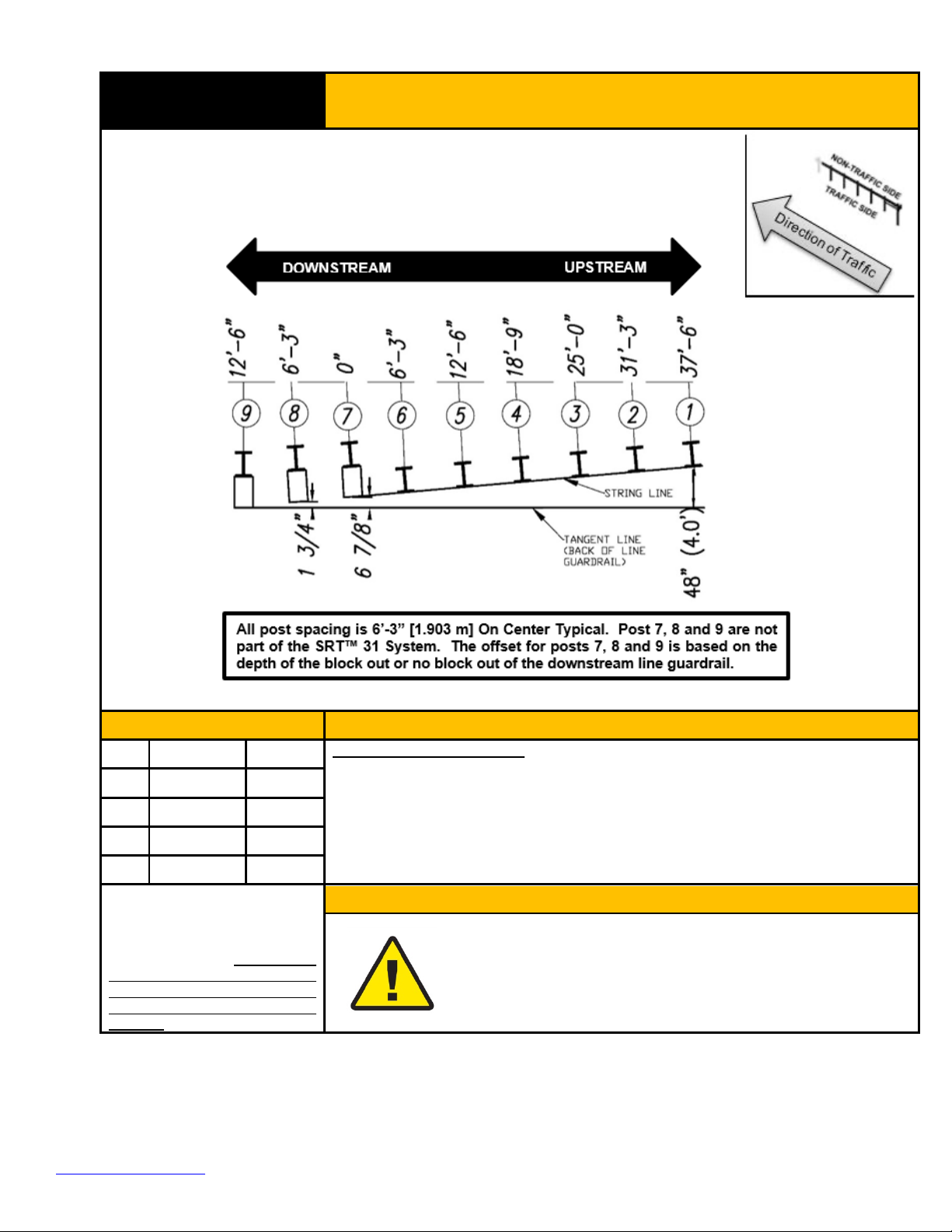

STEP 1A: SRT™ 31 System (34’-4 1/2” Long) Post Layout .......................................................... 15

STEP 1B: SRT™ 31 System (40’-7 1/2” Long) Post Layout .......................................................... 16

STEP 2A: SRT™ 31 System (34’-4 1/2” Long) Post 2-6 Assembly ................................................ 17

STEP 2B: SRT™ 31 System (40’-7 1/2” Long) Post 2-7 Assembly ................................................ 18

STEP 3: CR Post 1 Bottom Assembly … ...................................................................................... 19

STEP 4: CR Post 1 Top Assembly ............................................................................................... 20

STEP 5: SYTP® 2 Assembly ......................................................................................................... 21

STEP 6: SYTP® 4 Assembly ......................................................................................................... 22

STEP 7A: SRT™ System (34’-4 1/2” Long) SRT™-3 Guardrail Assembly ..................................... 23

STEP 7B: SRT™ System (40’-7 1/2” Long) SRT™-3 Guardrail Assembly ..................................... 24

STEP 8 SRT™ Systems SRT™-2 Guardrail Assembly ............................................................... 25

STEP 9: SRT™ Systems SRT™-1 Anchor Guardrail Assembly ................................................... 26

STEP 10: SRT™ Slot Guard Assembly ........................................................................................... 27

STEP 11: SRT™ Anchor Bracket Assembly ................................................................................... 28

STEP 12: SRT™ Anchor Cable Assembly ..................................................................................... 29

STEP 13: SRT™ Angle Strut Assembly .......................................................................................... 30

STEP 14: SRT™ Buffer Assembly .................................................................................................. 31

STEP 15: SRT™ Delineation Assembly .......................................................................................... 32

SRT™ 31 System Assembly Checklist (File With Project Records) ...................................................... 33

SRT™ 31 System Repair Checklist (File With Maintenance Records) .................................................. 34

SRT™ 31 Routine Inspection Checklist (File with Maintenance Records) ............................................ 35

APPENDIX A: AASHTO Roadside Design Guide Grading Detail ......................................................... 36

APPENDIX B: Leave-Outs .................................................................................................................... 37

APPENDIX C: Encountering Rock ........................................................................................................ 38

NOTES ................................................................................................................................................... 39

SRT™ 31 SYSTEM ACRONYMS

AASHTO American Association of State Highway and Transportation Officials

FHWA Federal Highway Administration

CFR Code of Federal Regulation

CR Cable Release

MUTCD Manual on Uniform Traffic Control Devices

NCHRP National Cooperative Highway Research Program

NHS National Highway System

OSHA Occupational Safety & Health Administration

PPE Personal Protective Equipment

SYTP® Steel Yielding Terminal Post®

SRT™ 31 System Slotted Rail Terminal-31 System

TL-X Test Level X; X refers to the different Test Levels; 1, 2 or 3

Trinity Highway Trinity Highway Products, LLC

TrinityHighway.com 4 Created November 2021

Customer Service Contacts

Trinity Highway is committed to the highest level of customer service. Feedback regarding the

SRT™ 31 System, its assembly procedures, supporting documentation, and performance is

always welcome. Additional information can be obtained from the contact information below:

Trinity Highway

Telephone

(888) 356-2363 (USA)

+1 214 589 8140 (International)

Contact Link

TrinityHighway.com\Contact

Website:

www.trinityhighway.com

Trinity Highway Products, LLC

15601 Dallas Parkway

Suite 525

Addison, TX 75001

TrinityHighway.com 5 Created November 2021

Limitations and Warnings

Trinity Highway, in compliance with NCHRP-350,

contracts with ISO 17025 A2LA accredited testing

laboratories to perform crash tests, evaluate tests, and

submit the test results to the FHWA for review.

The SRT™ 31 System has been deemed eligible by

FHWA as meeting the requirements and guidelines of

NCHRP Report 350, Test Level 3 (“TL-3”). These tests

typically evaluate product performance defined by

NCHRP Report 350 involving a range of vehicles on

roadways, from lightweight cars (approx. 800 kg [1800

lb.]) and full size pickup trucks (approx. 2,000 kg [4,400

lb.]) at 100 kph [62 mph].

The SRTTM 31 System is tested pursuant to the test

matrix criteria of NCHRP Report 350 as designated

by FHWA. The FHWA tests are not intended to

represent the performance of systems when

impacted by every vehicle type or in every impact

condition existing on the roadway. Every departure

from the roadway is a unique event.

Trinity Highway expressly disclaims any warranty or

liability for injury or damage to persons or property

resulting from any impact, collision or harmful contact

with its products, other vehicles, or nearby hazards or

objects by any vehicle, object or person, whether or not

the products were assembled in consultation with

Trinity Highway or by third parties.

The SRT™ 31 System is intended to be assembled,

delineated, and maintained within state/specifying

agency and federal guidelines. It is important for the

state/specifying agency specifying the use of a highway

product to select the most appropriate product

configuration for site specifications.

The state/specifying agency’s careful evaluation of

the site layout, vehicle population type and speed,

traffic direction, and visibility are some of the

elements that require evaluation in the selection of

a highway product. For example, curbs could cause

an untested effect on an impacting vehicle.

After an impact with the system, all debris must be

removed from the area immediately in compliance with

the most applicable state/specifying agency policy. The

specified SRT™ 31 System must be evaluated and

restored to its original specified condition or replaced

as the state/specifying agency determines/requires, as

soon as possible. Product selection, approval, proper

installation, and maintenance of any highway product is

the sole responsibility of the state/specifying agency

and the state DOT.

Safety Alert Symbols appear throughout this

manual and indicate Danger, Warning, Caution or

Important statements. Failure to read and follow

these warnings could result in serious injury or

death in the event of a vehicle impact with the

system.

WARNING: Do not assemble, maintain, or repair

the SRT™ 31 System until you have read this manual

thoroughly and completely understand it. Ensure that

all Danger, Warning, Caution, and

Important

statements within the manual are completely

followed. Please call Trinity Highway at (888)

356-2363 if you have any questions about

instructions in this manual.

WARNING: Safety measures incorporating

appropriate traffic control devices and personal

protective equipment ("PPE") specified by the

state/specifying agency must be used to protect all

personnel while at the assembly, maintenance, or

repair site.

WARNING: Ensure the assembly site meets all

appropriate Manual on Uniform Traffic Control

Devices (“MUTCD”) and state/specifying agency

standards.

WARNING: Only Trinity Highway parts that are

specified herein can be used for assembly,

maintenance, or repair on them SRT™ 31 System.

Do not utilize or otherwise commingle parts from

other systems, even if those systems are other

Trinity Highway systems. Such configurations have

not been tested, nor have they been approved for

use.

Assembly,

maintenance or repairs using

unspecified parts or accessories is strictly

prohibited. Failure to follow this warning could result

in serious injury or death in the event of a vehicle

impact with such an UNACCEPTED system.

WARNING: Do NOT modify the SRT™ 31 System in

any way.

IMPORTANT: Trinity Highway makes no

recommendation whether use or reuse of any part

of the SRT™ 31 System is appropriate or acceptable

after system impact. It is the responsibility of the

state/specifying agency and its engineers to make

that determination.

IMPORTANT: It is the responsibility of the applicable

owner, state/specifying agency, or specifier to

inspect the SRT™ 31 System after assembly is

complete to ensure the instructions provided in this

manual have been strictly followed.

TrinityHighway.com 6 Created November 2021

Overview

The SRT™ 31 System is a straight flared, single-sided, re-directive, and gating end terminal. The SRT™

31 System is a 31” [787 mm] high (measured from top of rail to finished grade) end terminal used to

shield 31” [787 mm] high strong post W-beam guardrail.

The SRT™ 31 System consists of one (1) SRTTM Anchor Guardrail, and two (2) SRT Guardrails, Cable

Release (CR) Post at post location 1, Steel Yielding Terminal Post® (“SYTP®”) at post locations 2-6,

SRT™ Angle Strut, SRT™ Cable Anchor Bracket and SRT™ Anchor Cable, SRT™ Shelf Angle at post

2, SRT™ Flange Protector at posts 2, 4, & 6, SRTTM Slot Guards downstream of slots, SRT™ Buffer,

and various other required hardware accessories.

The CR Post 1 Bottom is fabricated from a W6x15# Structural Beam approximately 6’-3 1/2” [1.91 m] in

length from top of the side plates to bottom of the embedded portion. Combined with the CR Post 1 Top,

they become the SRTTM Anchor Post shown below.

SRT™ System (34’-4 1/2” Long - 31” High)

Reference drawing: SS436

TrinityHighway.com 7 Created November 2021

SRT™ 31 System (40’-7 1/2” Long - 31” High)

Reference drawing: SS616

TrinityHighway.com 8 Created November 2021

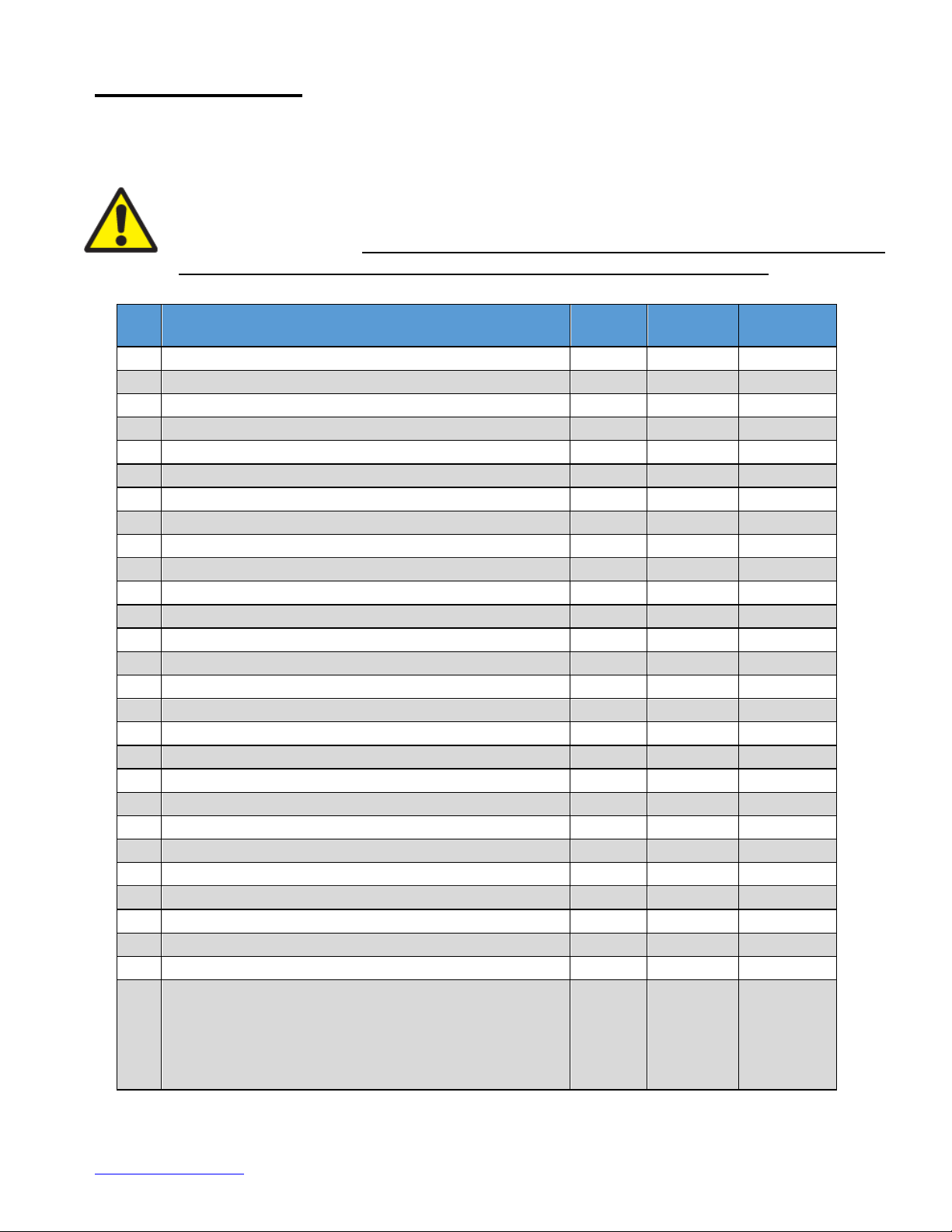

Inspect Shipment

Carefully unpack and inspect all components for damage. Check the received parts against the packing

list supplied with the system. If any parts are damaged, missing, or unspecified; do not attempt to

assemble the system and contact Trinity Highway immediately (p. 4).

Warning: Use only Trinity Highway parts that are specified by Trinity Highway

for use with the SRT™ 31 System for assembling, maintaining, or repairing the

SRT™ 31 System. Do not utilize or otherwise commingle parts from other

systems even if those systems are other Trinity Highway Systems.

ID

SRT™ 31 SYSTEM COMPONENTS/HARDWARE

PN

SS 436

34’-4½”

SS 616

40’-7½”

A

SRT™-1 Anchor Guardrail 12’-6” [3.810 m]

30G

1

1

B

SRT™-2 Guardrail 12’-6” [3.810 m]

39G

1

1

C

SRT™-3 Guardrail 9’-4 1/2” [2.857 m]

10967G

1

0

D

CR Post 1 Bottom W6 x 15# [W6 x 22.5 kg]

34052A

1

1

E

CR Post 1 Top W6 x 8.5# [W150 x 13 kg]

34053A

1

1

F

SYTP® 6’-0” [1.83 m]

15000G

5

5

G

SRT™ Flange Protector at Posts 2,4,6

7G

3

3

I

SRT™ Cable Anchor Bracket

700A

1

1

K

SRT™ Angle Strut 3” x 3” x 1/4” [75 mm x 75 mm x 6 mm]

33875G

1

1

L

SRT™ Shelf Angle (At Post 2)

34054G

1

1

M

SRT™ Buffer

907G

1

1

N

SRT™ Cable Assembly 3/4” x 6’-6”

3000G

1

1

O

5/16” x 1.75” Hex Bolt (At Post 1)

4211G

2

2

P

SRT™ Slot Guard - NOTE Orientation of Arrows

9960G

4

4

Q

SRT™ Cable Anchor Bracket Angle (At Post 1)

33909G

1

1

R

5/8” x 2” HGR Post Bolt (At Posts 1, 2, & 4)

3400G

4

4

S

5/8” x 1.75” Countersunk HD Bolt (At Post 6)

4419G

1

1

T

1” Hex Nut (At Cable Ends)

3910G

2

2

U

5/8” x 1.25” GR Bolt

3360G

52

52

V

1” Round Washer (At Cable Ends)

3900G

2

2

W

5/8” x 1.5” Hex Bolt

3380G

8

8

X

5/8” x 1.75” Hex Bolt (A325) (At Strut)

3391G

2

2

Y

5/16” Round Washer (At Post 1)

3240G

2

2

Z

SRT™-3 Guardrail 15’-7 1/2” [4.762 m]

20442G

0

1

AA

5/8” Round Washer

3300G

12

12

BB

5/8” GR Hex Nut

3340G

67

67

CC

5/16” Hex Nut (At Post 1)

3245G

2

2

DD

EE

DELINEATION OPTIONS: Reflective Sheeting

16” x 16” [400 mm x 400 mm] Striped Yellow/Black

16” x 16” [400 mm x 400 mm] Solid Yellow

Both 6665B and 6666B can be used for Left or Right

applications or use the state standards.

6665B

6666B

1

1

1

1

TrinityHighway.com 9 Created November 2021

SRT™ 31 System Components/Hardware

Below is a pictorial depiction of the components/hardware for SRT™ 31 System Please see the Trinity Highway

drawings and page 8 of this manual for specific lists of components/hardware and quantities required for SRT™

31 System selected to be assembled.

Note: The following components/hardware are not shown to scale.

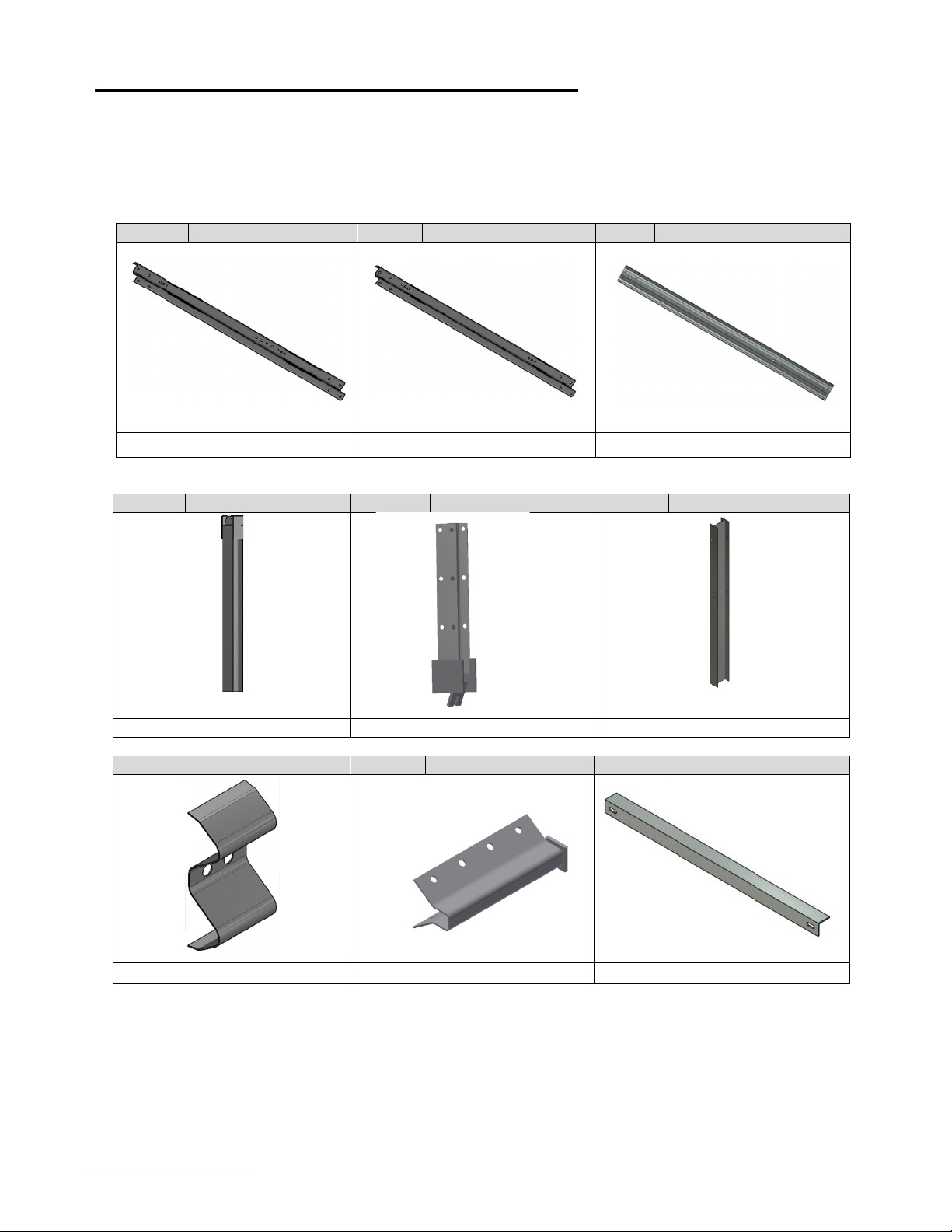

ID: A

PN: 30G

ID: B

PN: 39G

ID: C

PN: 10967G

SRT™-1 Anchor Guardrail 12’-6”

SRT™-2 Guardrail 12’-6”

SRT™-3 Guardrail 9’-4 1/2”

ID: D

PN: 34052A

ID: E

PN: 34053A

ID: F

PN: 15000G

CR Post 1 Bottom

CR Post 1 Top

SYTP® 6’-0”

ID: G

PN: 7G

ID: I

PN: 700A

ID: K

PN: 33875G

SRT™ Flange Protector

SRT™ Cable Anchor Bracket

SRT™ Angle Strut

TrinityHighway.com 10 Created November 2021

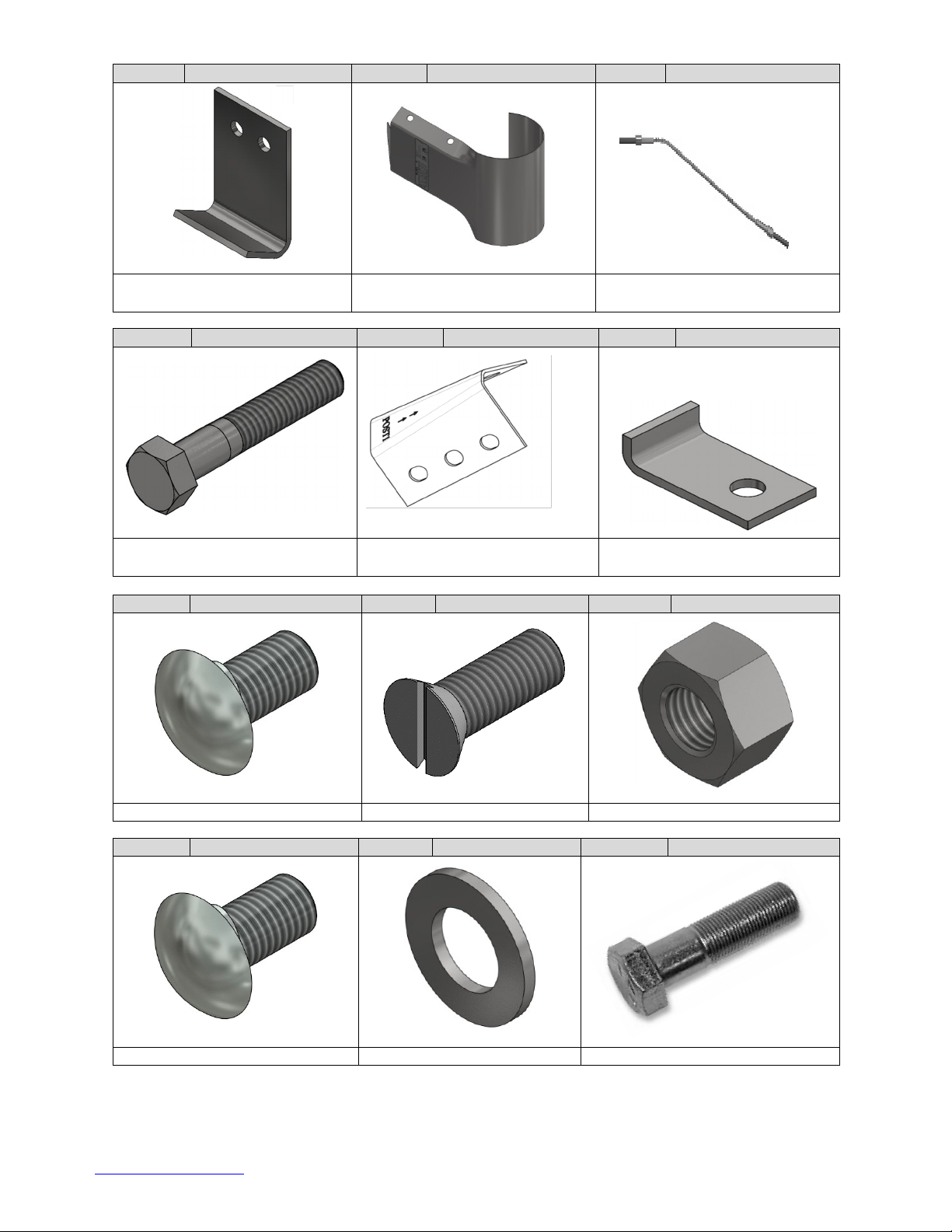

ID: L

PN: 34054G

ID: M

PN: 907G

ID: N

PN: 3000G

SRT™ Shelf Angle

SRT™ Buffer

SRT™ Cable Assembly

3/4” x 6’-6”

ID: O

PN: 4211G

ID: P

PN: 9960G

ID: Q

PN: 33909G

5/16” x 1.75” Hex Bolt

SRT™ Slot Guard

SRT™ Cable Anchor Bracket

Angle

ID: R

PN: 3400G

ID: S

PN: 4419G

ID: T

PN: 3910G

5/8” x 2” HGR Post Bolt

5/8” x 1.75” C.S. HD Bolt

1” Hex Nut

ID: U

PN: 3360G

ID: V

PN: 3900G

ID: W

PN: 3380G

5/8” x 1.25” GR Bolt

1” Round Washer

5/8” x 1.5” Hex Bolt

TrinityHighway.com 11 Created November 2021

ID: X

PN: 3391G

ID: Y

PN: 3240G

ID: Z

PN: 20442G

5/8” x 1.75” Hex Bolt (A325)

5/16” Round Washer

SRT™-3 Guardrail 15’ 7 1/2””

ID: AA

PN: 3300G

ID: BB

PN: 3340G

ID: CC

PN: 3245G

5/8” Round Washer

5/8” GR Hex Nut

5/16” Hex Nut

ID: DD

PN: 6665B

ID: EE

PN: 6666B

Delineation Striped

Yellow/Black

Delineation Solid

Yellow

Both 6665B and 6666B can be used for Left or Right applications

TrinityHighway.com 12 Created November 2021

Recommended Tools

Documentation

•

Manufacturer’s SRT™ 31 Product Description Assembly Manual (Current Version)

•

SRT™ 31 System Drawing(s). Current Version of SS 436 or SS 616

Personal Protective Equipment

•

Eye Protection

•

Work Gloves

•

Safety-Toe Shoes

•

Back Protection

•

Hard Hat

•

Reflective Vest

•

Apron

Miscellaneous

•

Traffic Control Equipment and Plan per local standards and the MUTCD

•

SAE Combination Wrench Set

•

Socket Set & Socket Wrench

•

Hammer

•

Chalk Line

•

Tape Measure

•

Marking Paint and Pen

•

Straight Edge

•

Level

•

Plumb Line

•

Post Pounder (commonly used for driving posts)

•

Auger

•

Soil Tamper

•

5/8” Alignment Tool (Drift Pin)

•

Locking Pliers

Note: The provided list of tools is a general recommendation and should not be considered an

extensive list. Depending on specific site conditions and the complexity of the assembly specified

by the state/specifying agency, the required tools may vary. Decisions as to what tools are needed

to perform the job are entirely the responsibility of the state/specifying agency and the selected

contractor performing the assembly of the system at the state/specifying agency’s site.

TrinityHighway.com 13 Created November 2021

Site Preparation

The SRT™ 31 System is a straight flared, single-sided, re-directive, and gating end terminal. It may be

specified for use by the state/specifying agency in conjunction with strong post W-beam guardrail systems

on the roadside or median of a roadway. The decision to specify the SRT™ 31 System for a particular

project is the responsibility of the state/specifying agency design engineer who must ensure that the most

appropriate end terminal has been selected for the specific site conditions.

The SRT™ 31 System is designed to be attached to strong post W-beam guardrail systems that have been

accepted under NCHRP Report 350 crash test criteria that use either no offset blocks, 8” [203 mm] offset blocks

or 12” [305 mm] offset blocks.

Important: The SRT™ 31 System must not be attached directly to a weak post W-beam

guardrail system without an approved weak-post-to-strong-post transition plus a

minimum of 12’-6” [3.81 m] strong post W-beam guardrail with 6’-3” [1.91 m] post

spacing. The 12’-6” [3.81 m] strong post W-beam guardrail must be placed between the

SRT™ 31 System and the weak-post- to-strong-post transition.

Important: The SRT™ 31 System must not be attached directly to Thrie Beam, Thrie

Beam Transition, or to a post which is stronger/stiffer than a standard W-beam W6x8.5#

[W150x13] or W6x9# [W150x13.5] guardrail post. A minimum of 6’-3” [1.91 m] strong

post single ply W-beam guardrail must be placed between the SRT™ 31 System and the

Thrie Beam transition (or stronger/stiffer post).

Important: Do not attach the SRT™ 31 System directly to a rigid barrier (i.e. concrete

barrier, wall or bridge pier) without the use of a state/specifying agency approved

transition.

Important: Ensure that the SRT™ 31 System application conforms to the AASHTO

Roadside Design Guide.

Important: Trinity Highway does not direct grading. Proper site grading must be

accomplished before assembly of the SRT-31 System in accordance with local

guidelines OR the AASHTO Roadside Design Guide (see Appendix A), whichever is

more stringent. Failure to follow this warning could result in serious injury or death in

the event of a vehicle impact with the system.

Important: The Beginning Length of Need (“BLON”) for the SRT™ 31 System was

established during NCHRP Report 350 Test 3-35 at Post #3, which is 12’-6” [3.81 m] from

the center of Post #1.

Important: A minimum of 75’ [22.86 m] of strong post W-beam guardrail with 6’-3”

[1.90 5m] post spacing must be placed between two SRT™ 31 Systems when installed

with both an approach and departing end on NCHRP Report 350 TL-3 roadway

applications. For roadway applications that meet the NCHRP Report 350 Test Level 2

(TL-2) or Test Level 1 (TL-1) criteria, the SRT™31 TL-3System can be placed “end to

end”, if specified and approved by the state/specifying agency. The minimum installation

length for TL-2 and TL-1 applications is 81'-3" [24.77 m] long consisting of two (2) 40’-7

1/2” Systems or two (2) 34’-4 1/2” Systems plus one (1) 31” high, 12’-6” strong post single

ply 12 gauge W-beam guardrail system.

TrinityHighway.com 14 Created November 2021

SRT™ 31 System Post Placement

The SRT™ 31 System posts may be inserted into the soil using an auger or post pounding equipment

for placement of guardrail posts. If an auger is used, ensure diameter is large enough to allow for proper

compaction of state/specifying agency approved fill material. All SRT™ 31 System posts must be

assembled within established standard construction tolerances, including being plumb. Compaction for

all posts must be within state/specifying agency guidelines.

Danger: It is the responsibility of the installer to ensure all above & below ground utilities

as well as drainage structures are located, marked, and identified prior to using an auger

or post pounding tool in accordance with state/specifying agency guidelines. Failure to

follow this warning could result in serious injury or death.

Rigid Pavement and Rock

If rigid pavement (e.g. concrete or asphalt) of any thickness is encountered within the system pay length,

ensure a proper “leave-out” area (the specified size of open space as defined in the AASHTO Roadside

Design Guide) is provided around the posts and filled with state/specifying agency approved backfill

material. See Appendix B for “leave-out” requirements of the SYTP®.

If rock is encountered within the system pay length, follow the criteria as defined in the AASHTO Roadside

Design Guide. See Appendix C for requirements for the assembly of the CR Post 1 Bottom or SYTP®.

Drilling Holes into Rock

Caution: It is the responsibility of the installer to consult Occupational Safety & Health

Administration (“OSHA”) silica respiratory standard 29 Code of Federal Regulation (“CFR”)

1910.134 for debris removal and ensure compliance.

Assembly Steps

NOTE: The order in which the steps appear in this manual are not necessarily the order

in which they must be followed. ALL STEPS MUST BE COMPLETED.

Important: Trinity Highway does not direct grading. Proper site grading must be

accomplished before assembly of the SRT™ 31 System in accordance with

state/specifying agency guidelines OR the AASHTO Roadside Design Guide (see

Appendix A), whichever is more stringent. Failure to follow this warning could result in

serious injury or death in the event of a vehicle impact with the system.

Note: Below ground portions in the assembly steps are not shown for clarity.

TrinityHighway.com 15 Created November 2021

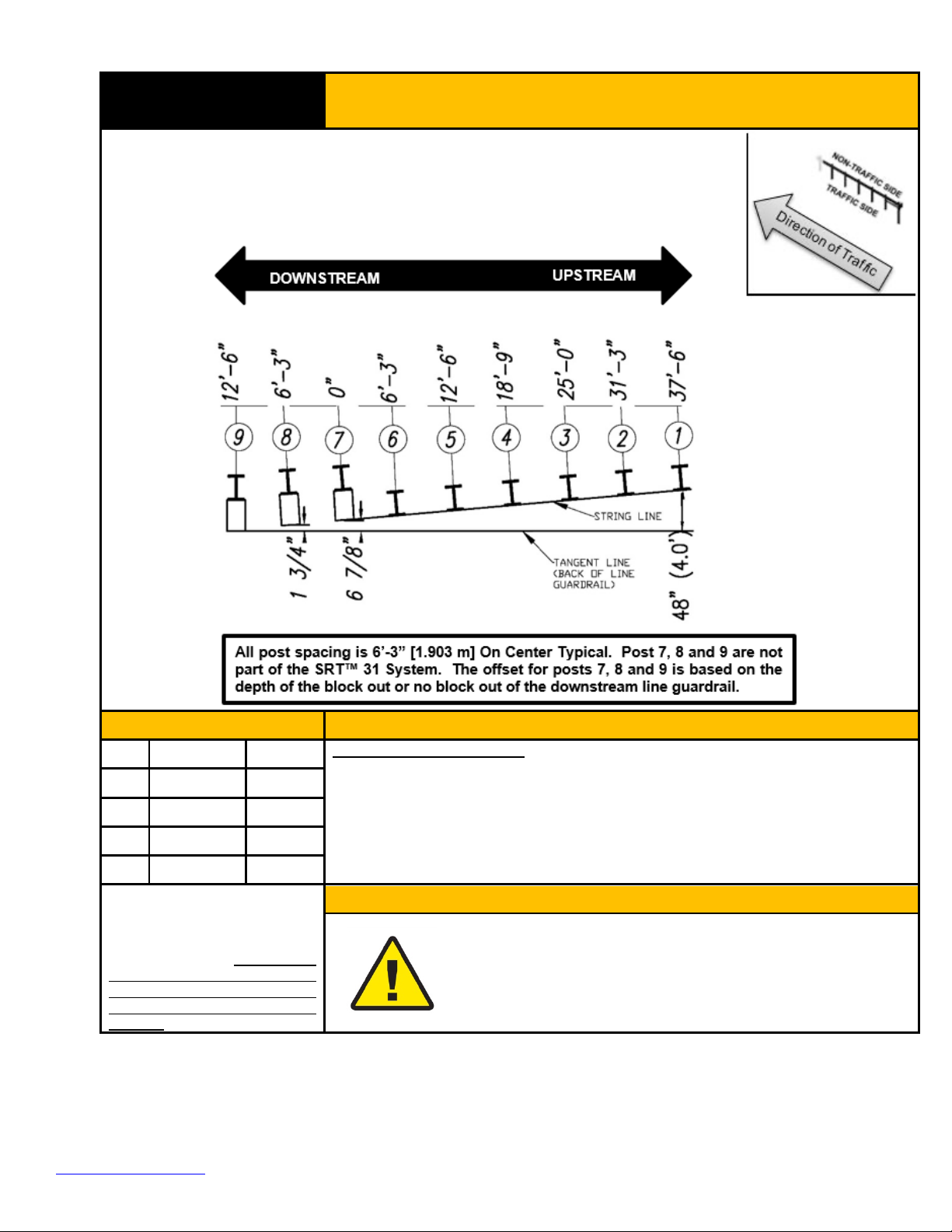

STEP 1A

SRT™ 31 System (34’-4 1/2”Long) Post Layout

PARTS

INSTRUCTIONS

Reference Drawing SS436

1. Layout the post as shown above.

2. Posts 6-2 are to be aligned with the string line between the block face of Post

7 or the face of Post 7 (for no block systems) and the face of Post 1.

3. Layout and placement of the posts are critical to the assembly of the

SRT™ 31.

Use only Trinity Highway parts

that are specified herein for the

SRT™ 31 System for assembling,

maintaining, or repairing the

SRT™ 31 System. Do not utilize

or otherwise commingle parts

from other systems even if those

systems are Trinity Highway

systems.

WARNINGS

Ensure proper site grading in accordance with state/specifying

agency guidelines or the AASHTO Roadside Design Guide,

whichever is more stringent. Failure to follow this warning could

result in serious injury or death in the event of a vehicle impact with

the system.

TrinityHighway.com 16 Created November 2021

STEP 1B

SRT™ 31 System (40’-7 1/2” Long) Post Layout

PARTS

INSTRUCTIONS

Reference Drawing SS616

1. Layout the post as shown above.

2. Posts 6-2 are to be aligned with the string line between the block face of Post

7 or the face of Post 7 (for no block systems) and the face of Post 1.

3. Layout and placement of the posts are critical to the assembly of the

SRT™ 31.

Use only Trinity Highway parts

that are specified herein for the

SRT™ 31 System for assembling,

maintaining, or repairing the

SRT™ 31 System. Do not utilize

or otherwise commingle parts

from other systems even if those

systems are Trinity Highway

systems.

WARNINGS

Ensure proper site grading in accordance with state/specifying

agency guidelines or the AASHTO Roadside Design Guide,

whichever is more stringent. Failure to follow this warning could

result in serious injury or death in the event of a vehicle impact with

the system.

TrinityHighway.com 17 Created November 2021

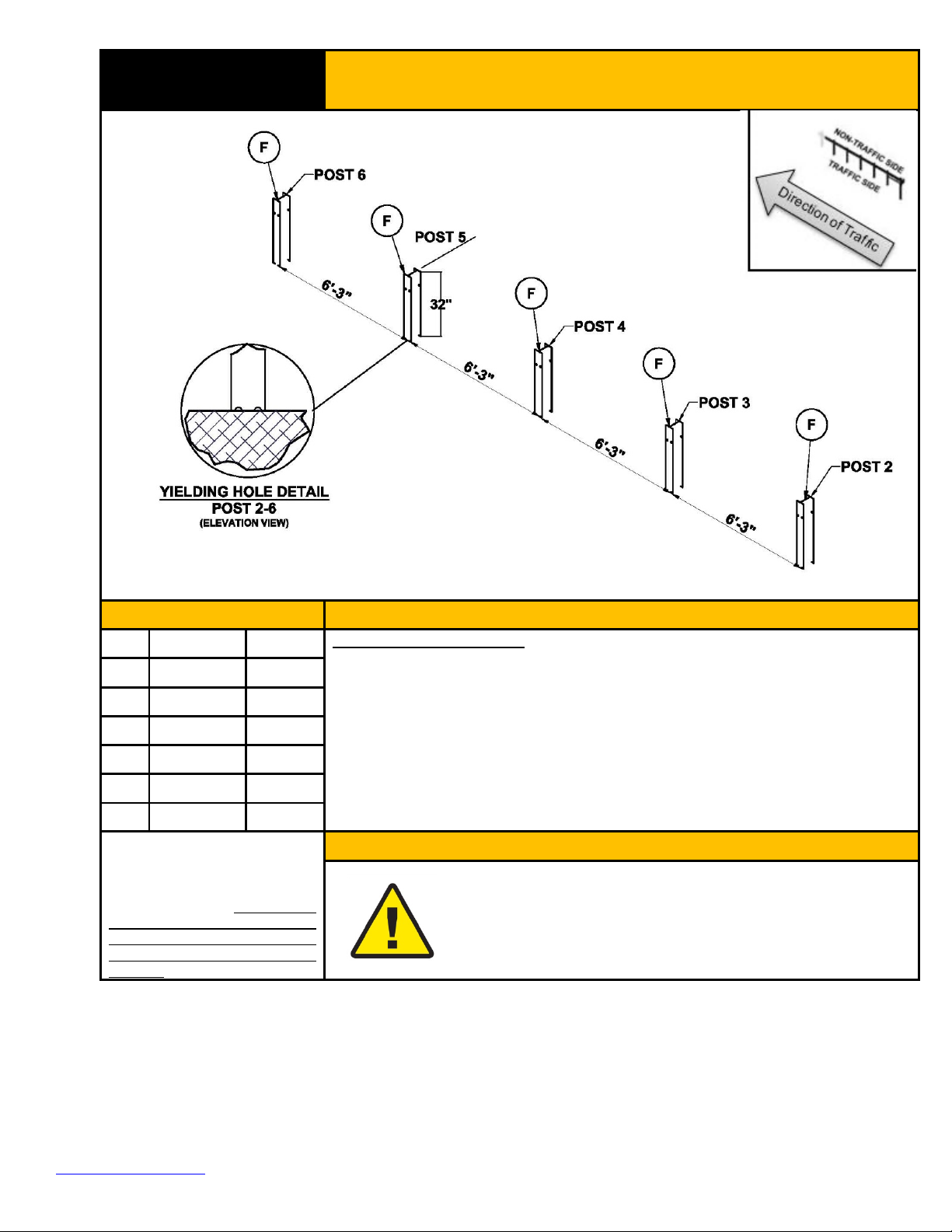

STEP 2A

SRT™ 31 System (34’-4 1/2” Long)

Post 2-6 Assembly

PARTS

INSTRUCTIONS

F

15000G

5 EA

Reference Drawing SS436

1. Assemble all parts in the configuration and orientation as shown above.

2. The SRT™ 31 System must be attached to a 31” [787 mm] high strong post

W-beam guardrail system or to a strong post W-beam guardrail that has

been properly transitioned to 31” [787 mm] rail height per state/specifying

state/specifying agency.

3. Ensure proper post spacing and post height are achieved for 6’ SYTP® 2-6

(Part F) per shown dimensions above.

4. Ensure the center of the SYTP® yielding holes are approximately at finished

grade as shown.

Use only Trinity Highway parts

that are specified herein for the

SRT™ 31 System for assembling,

maintaining, or repairing the

SRT™ 31 System. Do not utilize

or otherwise commingle parts

from other systems even if those

systems are Trinity Highway

systems.

WARNINGS

Ensure proper site grading in accordance with state/specifying

agency guidelines or the AASHTO Roadside Design Guide,

whichever is more stringent. Failure to follow this warning could

result in serious injury or death in the event of a vehicle impact with

the system.

TrinityHighway.com 18 Created November 2021

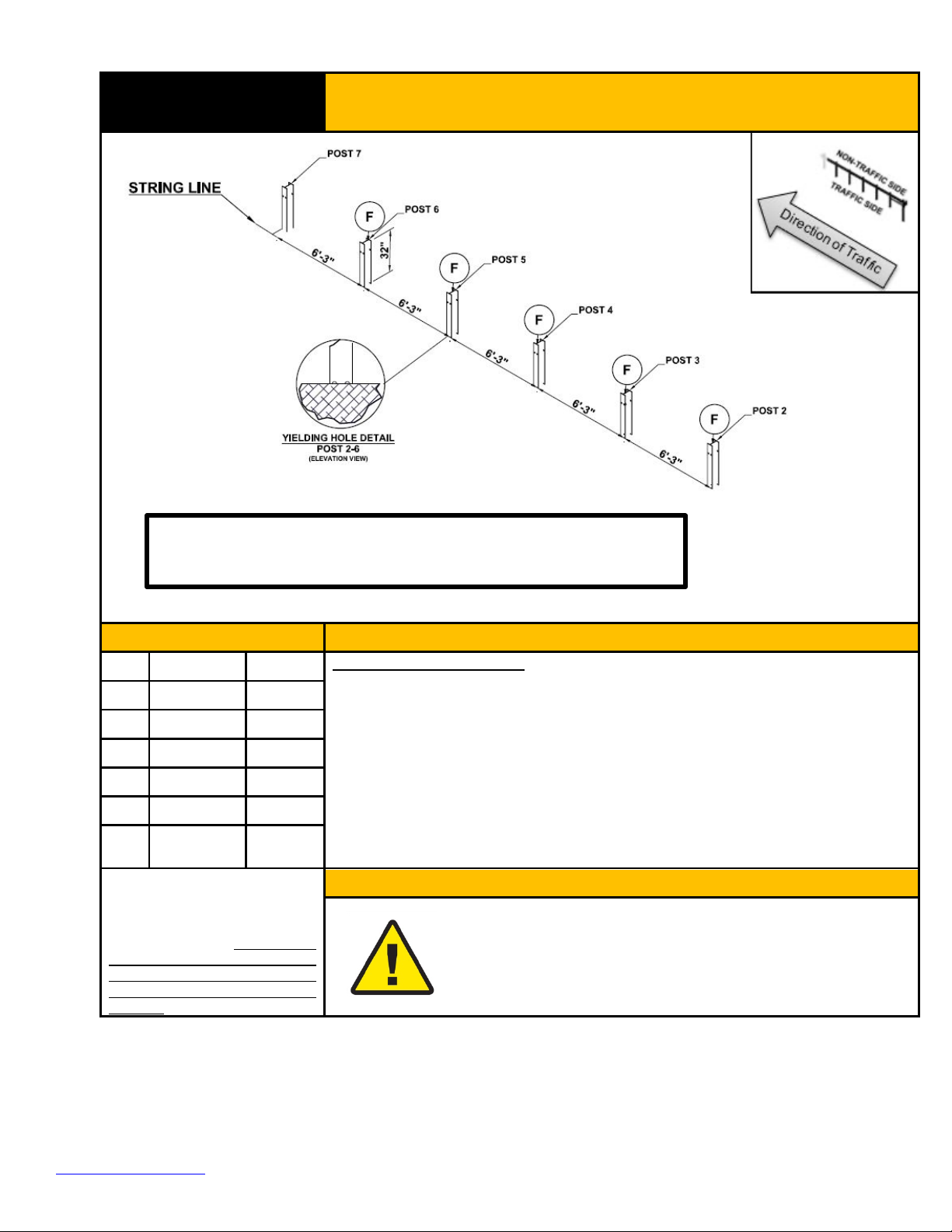

STEP 2B

SRT™ 31 System (40’- 7 1/2” Long)

Post 2-7 Assembly

PARTS

INSTRUCTIONS

F

15000G

5 EA

Reference Drawing SS616

1. Assemble all parts in the configuration and orientation as shown above.

2. The SRT™ 31 System must be attached to a 31” [787 mm] high strong post

W- beam guardrail system or to a strong post W-beam guardrail that has

been properly transitioned to 31” [787 mm] rail height per state/specifying

state/specifying agency.

3. Ensure proper post spacing and post height are achieved for 6’ SYTP® 2-6

(Part F) and post 7 per shown dimensions above.

4. Ensure the center of the SYTP® yielding holes are approximately at

finished grade as shown.

5. Post 7 is a standard 6’ [1.83 m] long W6x8.5# [W150x13 kg] or W6x9#

[W150x13.5 kg] guardrail post.

Use only Trinity Highway parts

that are specified herein for the

SRT™ 31 System for assembling,

maintaining, or repairing the

SRT™ 31 System. Do not utilize

or otherwise commingle parts

from other systems even if those

systems are Trinity Highway

systems.

WARNINGS

Ensure proper site grading in accordance with state/specifying

agency guidelines or the AASHTO Roadside Design Guide,

whichever is more stringent. Failure to follow this warning could

result in serious injury or death in the event of a vehicle impact with

the system.

The offset for posts 7 is based on the depth of the blockout or no

blockout of the downstream line guardrail. Post 7 is not part of the

SRT™ 31 System Bill of Materials. Post 7 is part of the line

guardrail quantities.

TrinityHighway.com 19 Created November 2021

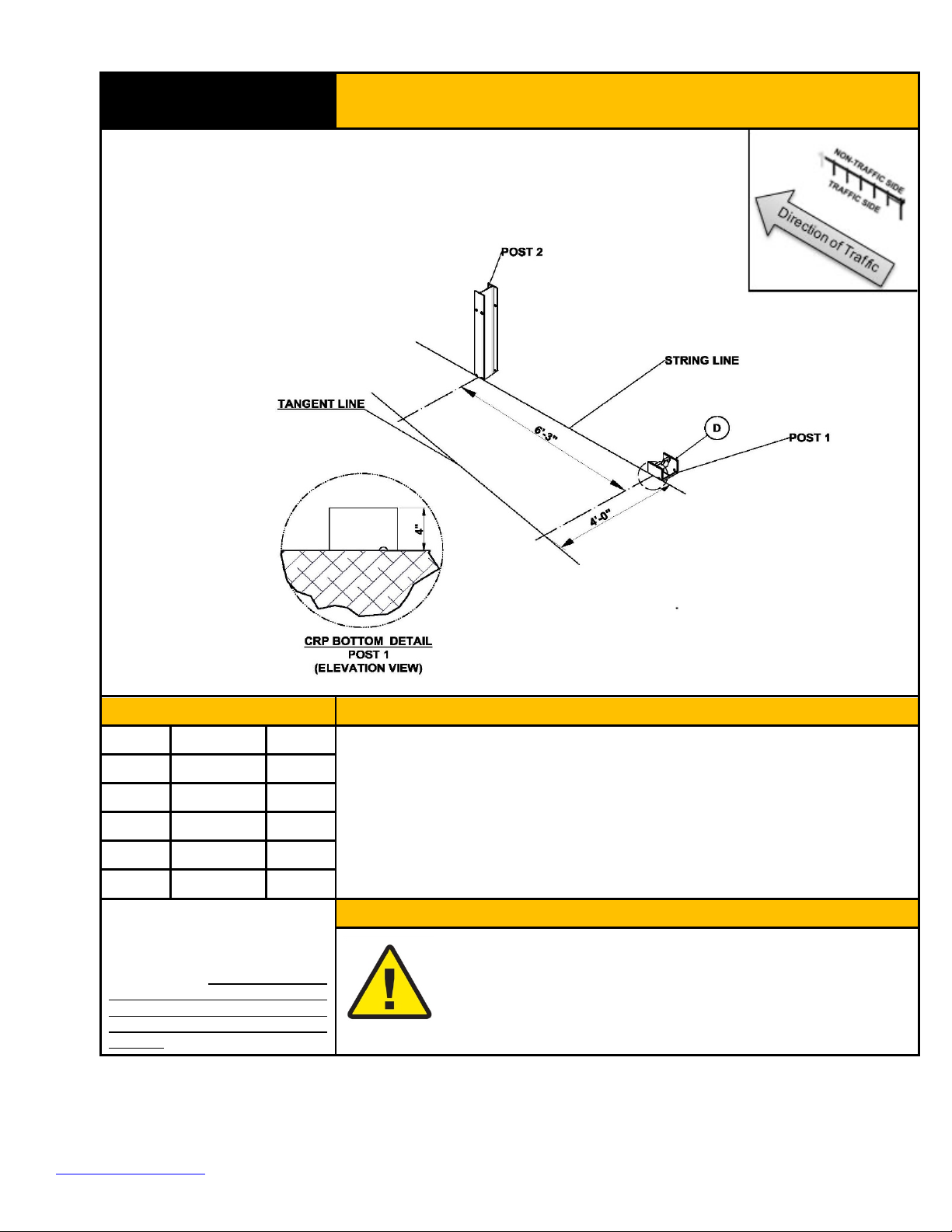

STEP 3

CR Post 1 Bottom Assembly

PARTS

INSTRUCTIONS

D

34052A

1 EA

1. Assemble the CR Post 1 Bottom (Part D) in the configuration and

orientation as shown above.

2. Ensure the CR Post 1 Bottom is installed approximately plumb and

oriented with the hole being closest to the upstream end of the CR Post 1

Bottom.

3. Ensure the top of the CR Post 1 Bottom does not exceed 4” [100 mm] above

finished grade.

Use only Trinity Highway parts that

are specified herein for the SRT™

31 System for assembling,

maintaining, or repairing the SRT™

31 System. Do not utilize or

otherwise commingle parts from

other systems even if those

systems are Trinity Highway

systems.

WARNINGS

Ensure proper site grading in accordance with state/specifying

agency guidelines or the AASHTO Roadside Design Guide,

whichever is more stringent. Ensure the CR Post 1 Bottom is

oriented correctly and the height does not exceed 4” [100 mm]

above finished grade. Failure to follow this warning could result in

serious injury or death in the event of a vehicle impact with the

system

Table of contents

Other Trinity Highway Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual