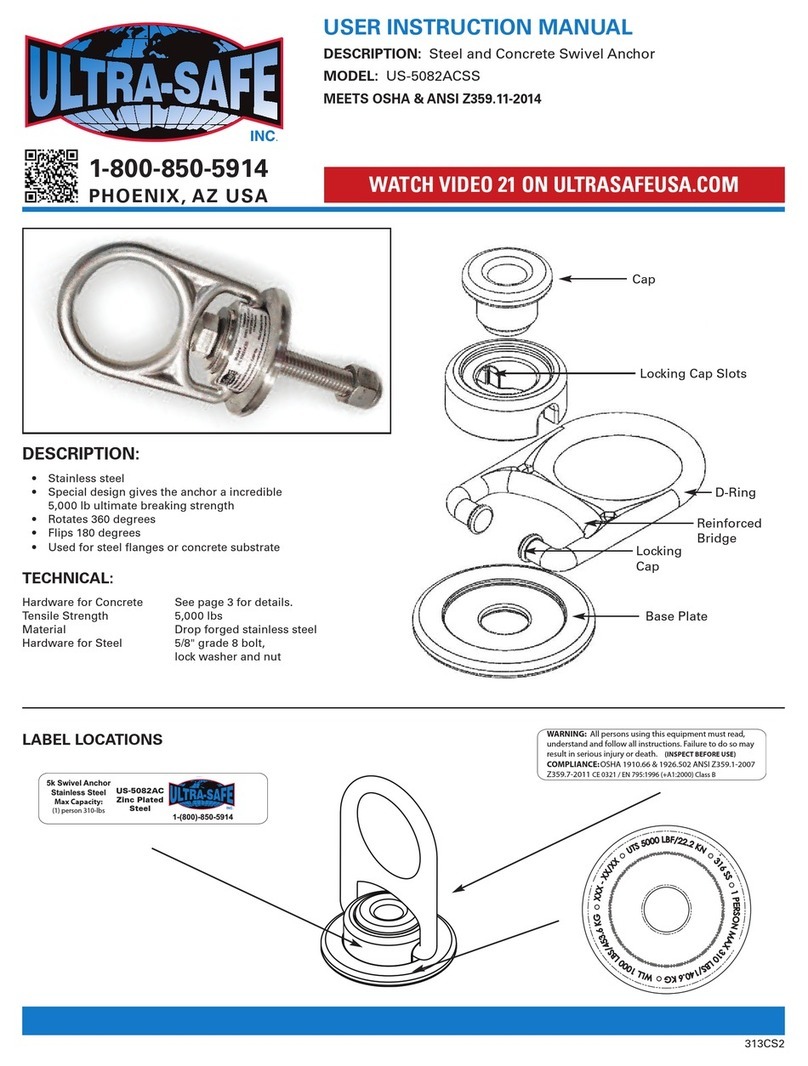

REQUIREMENTS & SPECIFICATI NS:

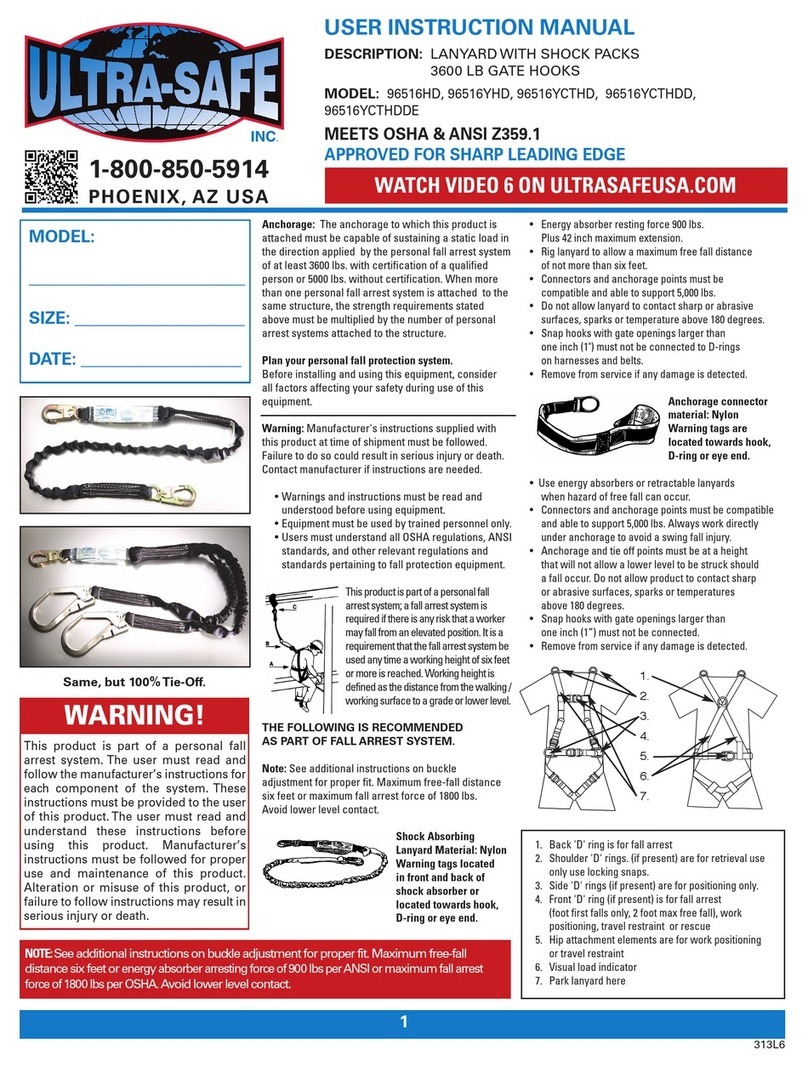

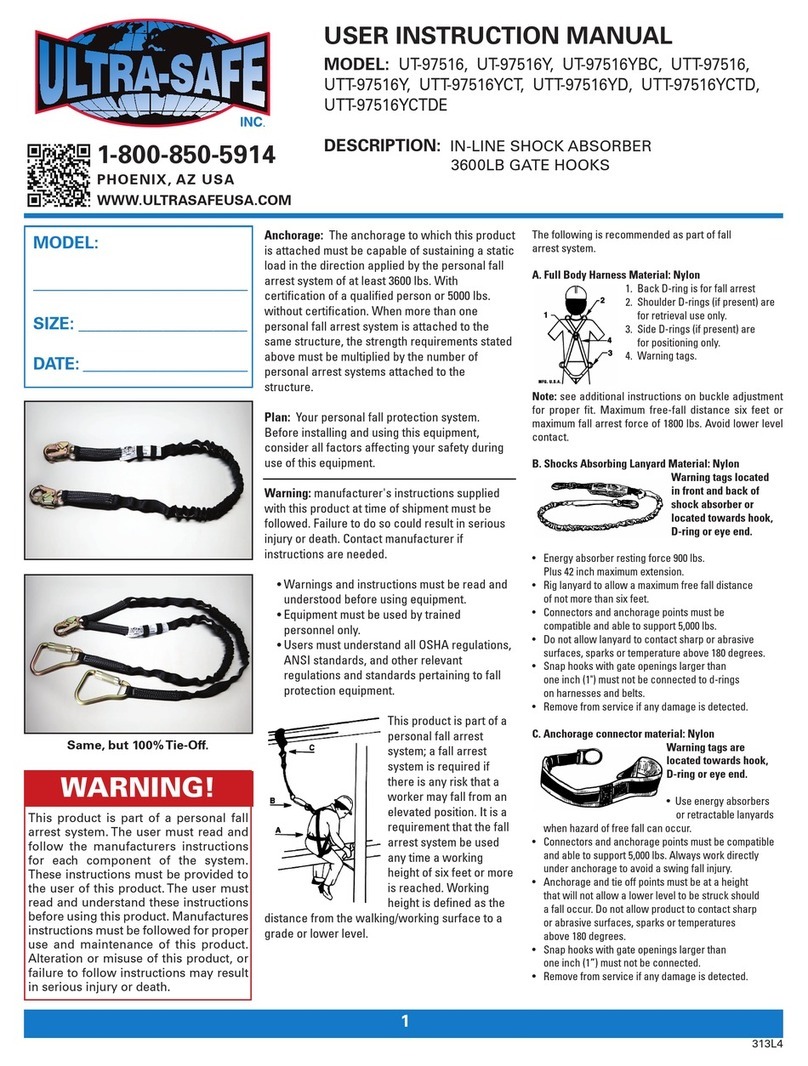

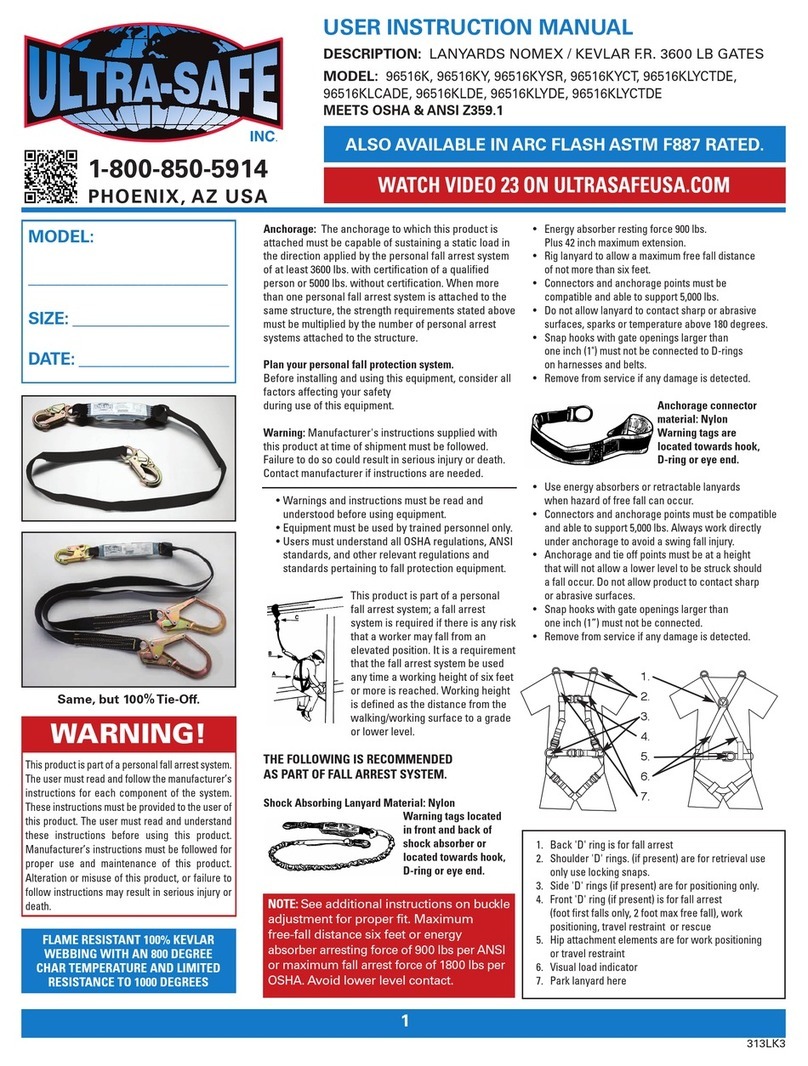

• Follow all manufacturer's instructions.

• For FALL PR TECTI N NLY.

• For use in concrete substrate only.

• D N T use in wet/uncured concrete.

• Concrete must have 3000 psi minimum

compressive strength. .

• Always inspect prior to use.

• For use by qualified fall protection personnel only.

• Use only compatible connectors, snap-hooks or

carabiners with this unit.

• This unit is not to be used for any other

anchoring situation.

• Anchor rated @ 5,000 lbs. for single user

up to 310 lbs.

• D N T use in steel, wood or any substrate

other than concrete.

• For use in horizontal, vertical, or overhead

applications

INSPECTI N:

• Make sure unit is straight and operates smoothly.

• Make sure the Tag is affixed to unit.

• Make sure the Retractor Handle is not

bent or damaged.

• Make sure Retractor Cables are not kinked,

frayed or damaged.

• Make sure metal components are not damaged.

• Make sure Chocks and Wedge operate smoothly,

and no metal burrs occur.

• When reusing a previously drilled hole, always

inspect the hole carefully.

ST RAGE & CLEANING:

• Blow off unit after each use with compressed air.

• Store in clean dry environment.

• Store in secure locked area.

• Store and put away at the end of each day's work.

• Do not pile any objects on top of unit

during storage.

• Keep unit free of grease, oils and dirt.

• Never lend unit to other workers.

DISP SAL:

• Dispose of unit after any fall has occurred.

• Dispose of unit if any cable becomes kinked

or frayed.

• Dispose of unit if Retractor Handle, Stop Ferrule

or Wedge is bent or damaged.

• Dispose of unit if retractor action is rough or sticky.

• Proper disposal requires that both Chocks

are cut off from the Retractor Cables

and all parts thrown away.

H LE DRILLING & PLACEMENT REQUIREMENTS:

• Anchor holes must be drilled using only

industrial grade 3/4” rotary hammer drill bits

and a rotary hammer drill.

• NEVER USE A BENT DRILL BIT.

• Hole must be drilled (bored) straight and parallel

and free of any peaks or valleys on the inner wall.

• Hole must be a minimum depth of 3”

into the substrate.

• Hole must be cleaned with compressed air to

remove any drilling debris

• When reusing a previous hole, inspect carefully

for debris and uniform surface. If necessary

drill another proper hole.

• If concrete is 12” thick x 12” wide (or more) the hole

must be at least 6” from any edge or corner.

• If concrete is 10” thick x 16” wide (or more) the hole

must be at least 8” from any edge or corner.

• If concrete is 8” thick x 20” wide (or more) the hole

must be at least 10” from any edge or corner.

• If concrete is 5” thick (or more) the hole must be

at least 12” from any edge or corner.

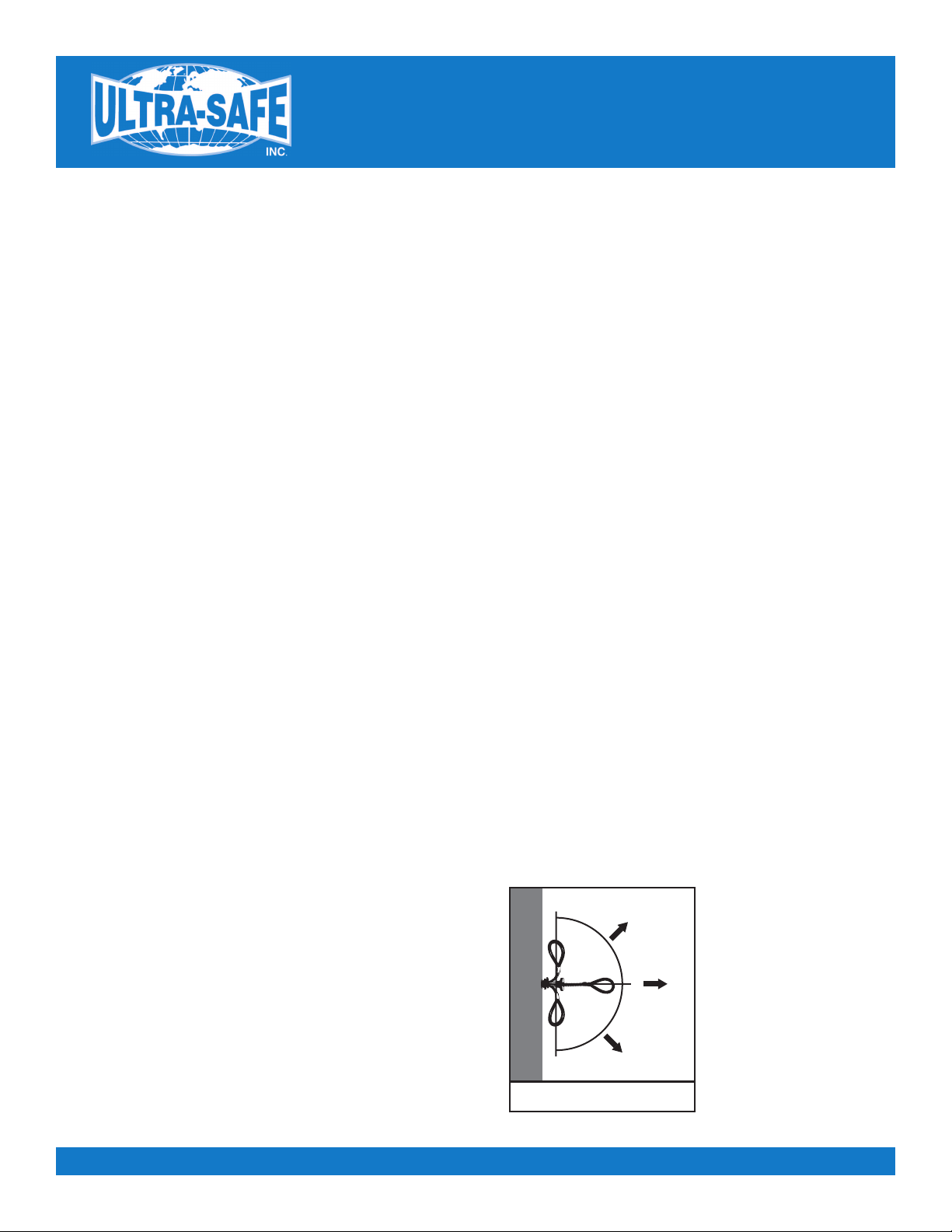

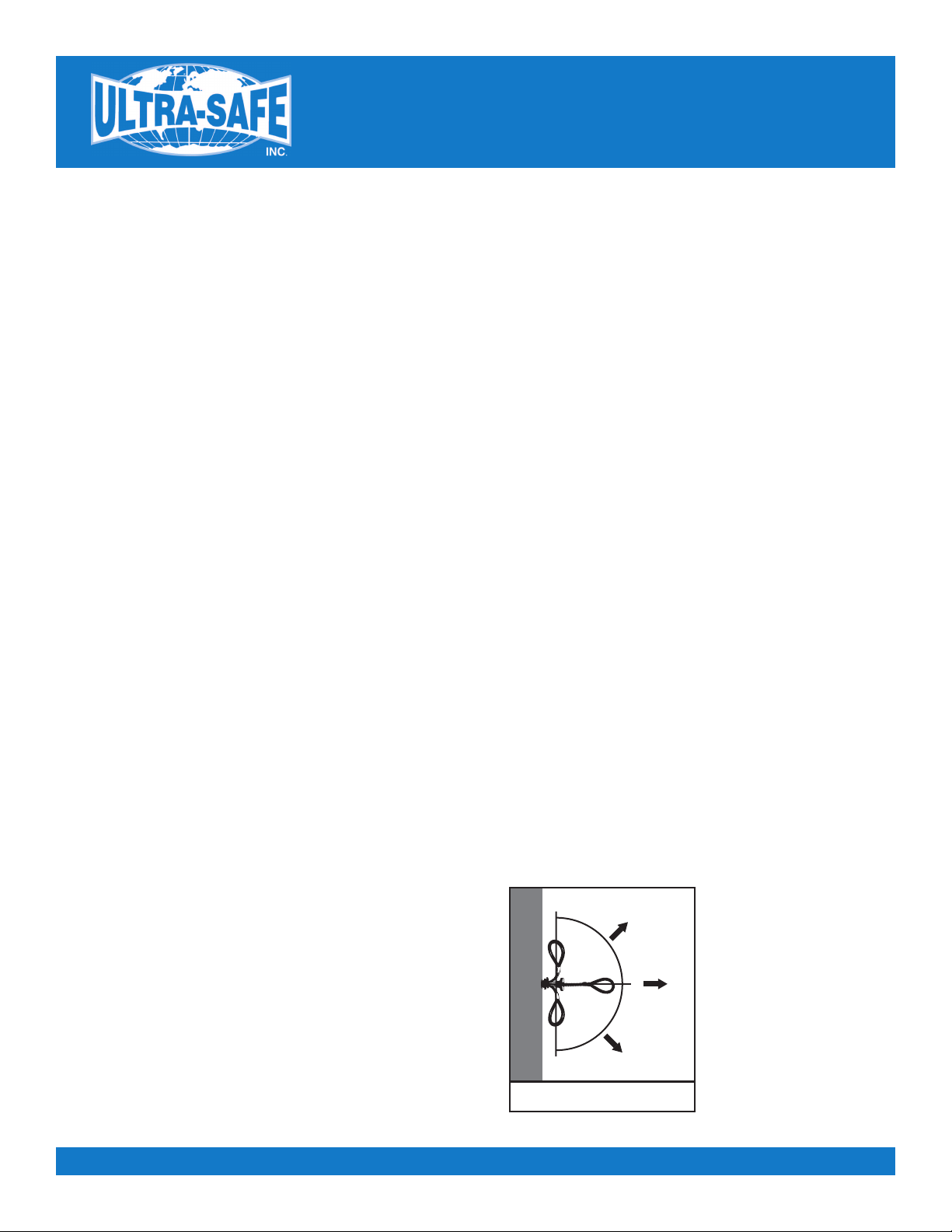

N TE:

Anchor can be used

at a 90 degree angle.

90º

0º

LOAD DIAGRAM

Ok

Good

Best

Ok

Good

90º

2