Thermon Fastrax User manual

Part No. HF17256.Rev.1 Issued December 2021 Printed in Canada

IMPORTANT INSTRUCTIONS - SAVE THESE INSTRUCTIONS

Read all instructions before installing or using the heater. Please adhere to instructions published in this manual.

Failure to do so may be dangerous and may void certain provisions of your warranty.

Fastrax®is a registered trademark of Thermon.

Copyright©2021. All rights reserved.

ISO 9001

Energy Management

System (EMS)

Installation & Operation Manual

Rail Thermostat

Control Box

ArcticSense

TABLE OF CONTENTS

A. Energy Management System Overview 2

A.1 Overview ............................................................................... 2

B. EMS Installation 3

B.1 Mounting EMS Control Box ..................................... 3

B.2 Mounting Precipitation Sensor............................ 3

B.3 Mounting Rail Thermostat...................................... 3

C. Electrical Connections Overview 5

C.1 Power ..................................................................................... 5

C.2 Control .................................................................................. 5

C.3 Alarm Indication ............................................................ 5

C.4 Aggressive Retry ........................................................... 5

C.5 Operation and Adjustments.................................. 5

C.6 Switches & Dials..............................................................6

C.7 Status LEDs ........................................................................6

D. Spare Parts & Drawings 7

D.1 Schematic - EMS Board Single Unit ..................8

A. ENERGY MANAGEMENT SYSTEM OVERVIEW

A.1 Overview

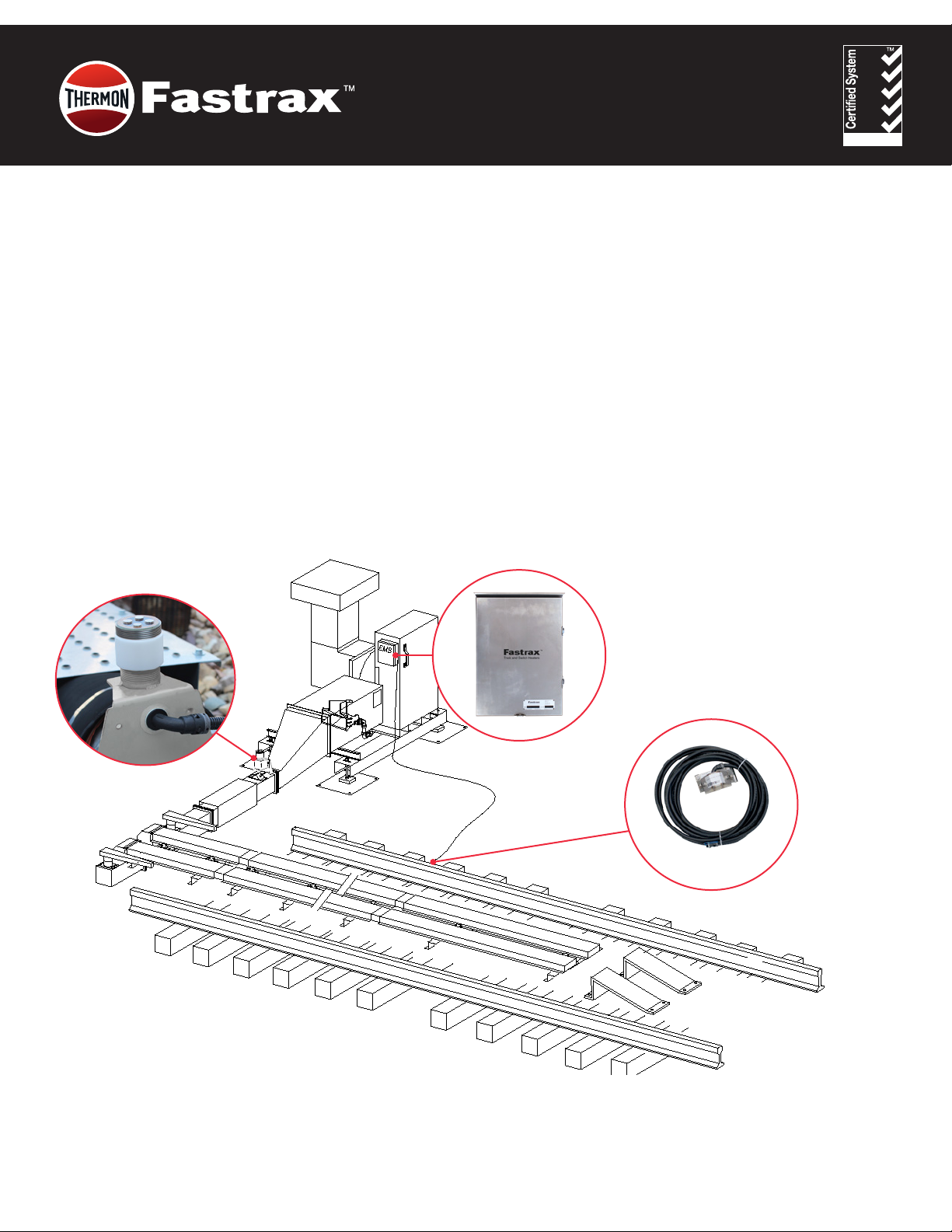

1. The Energy Management System (EMS) allows

automatic control of a railway switch heater. It detects

moisture and senses ambient, and rail temperature,

turning the heater on when it snows and the rail is

cold.

2. The EMS provides an aggressive retry for heaters

equipped with the appropriate remote Flame Safety

Relay reset.

3. The EMS provides a low temperature cut out feature

for use with propane red heaters that do not have

tank heaters and are located in cold environments

where the temperature drops below -30°C (-22°F) to

avoid nuisance shutdowns due to insufcient vapour

pressure.

4. There are two EMS versions, 17255-01 comes with a

precipitation sensor, ambient temperature sensor,

rail thermostat, and control box, as shown. Whereas

version 17255-02, does not include the rail thermostat.

Control Box

Rail Thermostat

ArcticSense

Precipitation Sensor

3

B. EMS INSTALLATION

B.1 Mounting EMS Control Box

1. Mount the EMS control box in a convenient location

on, or next to, the heater.

B.2 Mounting Precipitation Sensor

1. Mount the ArcticSense precipitation sensor on the

sensor duct ange, where it will be exposed to snow

and be in the heated zone. Slotted mounting holes

facilitate attachment to the ange bolts in any of 2

position. Select the position that is most likely to be

exposed to drifting snow.

B.3 Mounting Rail Thermostat

1. Mount the rail thermostat on the eld or gage side

of the stock rail ahead of the points and tie duct,

as shown. Select a location shaded from the sun.

Provide strain relief in the cable, by leaving adequate

slack, as shown, to allow for rail pumping.

Remove the yellow shim washers when installed on

115 lb rail or lighter. Loosen the two mounting bolts

and attach the rail thermostat to the rail ange by

tapping it on with a hammer. Once in place tighten

mounting bolts to maximize grip.

2. Remove the four (4) Phillips screws, the cover, and

the plug from the hole in the rail temperature surge

protection box.

3. Pass the two (2) wires from the rail temperature

sensor through the hole, install the locknut and

tighten.

4. Insert, one each of the bared wires into the two

terminalks on the surge suppression circuit board,

and tighten. There is no polarity.

4

5. Replace the cover, tighten the four (4) Phillips screws.

6. Connect the surge isolator two pin connector with the

mating plug located inside the electrical component

area, hanging immediately under the DSI.

55

C. ELECTRICAL CONNECTIONS OVERVIEW

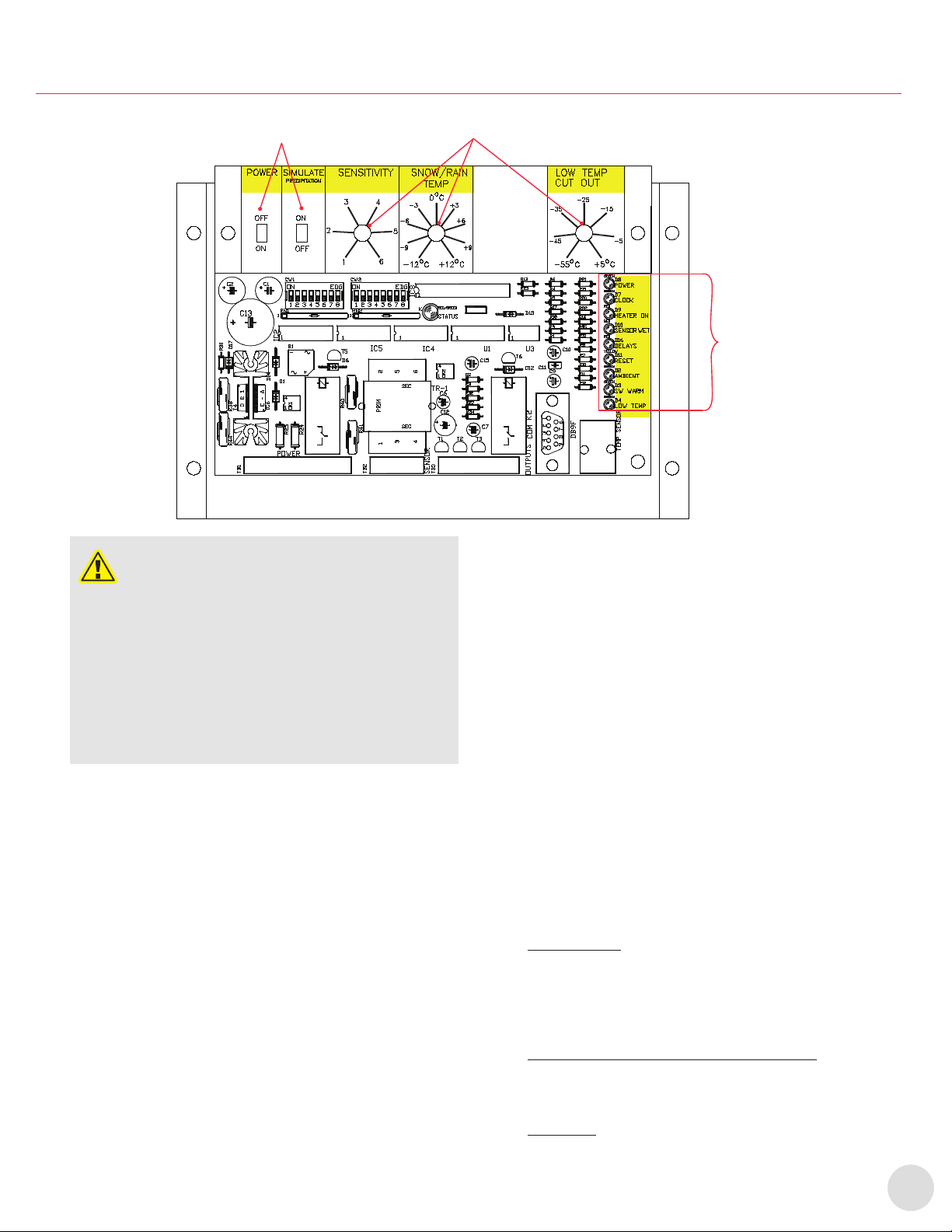

Status LEDs

Power & Simulate

Precipitation Switches Set Point Dials

CAUTION

CAUTION. Disconnect heater from power supply at

integral disconnect or fuse box before opening

closures or servicing heater.

Lock the switch in the “OFF” (open) position and

tag the switch to prevent unexpected power

application.

This heater should only be serviced by qualied

personnel with electrical heating equipment

experience.

Install and use the heater in accordance with local

codes and this Owner’s Manual.

NOTE: Refer to schematic inside door for electrical connections.

C.1 Power

Connect 120V power to terminals 1 and 3, and ground

wire to ground stud.

C.2 Control

Connect heater control to terminals 9 and 8, (Normally

Open, NO) or 9 and 7 (Normally Closed, NC).

C.3 Alarm Indication

1. A 120Vac Alarm signal from the heater can be used to

trigger the aggressive retry feature of the EMS.

1.1 Connect the Alarm Neutral terminal 6 to the

neutral in the heater. Connect the Alarm signal

(120Vac) from the heater to terminal 5 on EMS.

1.2 On a MARK VI heater the alarm signal is

available directly on the “ALARM” relay coil,

contact A1.

1.3 On a MARK VII heater connect the alarm signal

to either Terminal Block 1 terminal 1 or to the

“ALARM” relay terminal 2.

1.4 On a Micro heater the signal is available at the

“ALARM” relay terminal 9.

NOTE: YARDMASTER heaters do not require this connection.

The aggressive retry feature is integrated into the

YARDMASTER controller.

C.4 Aggressive Retry

1. If the heater you are controlling is equipped with a

ame safety relay reset module, connect the reset to

the appropriate terminals 14 and 13 (NO). If the heater

is equipped with Direct Spark Igniter connect the

reset normally closed contact, terminals 12 and 14,

into the wire to the request relay.

NOTE: YARDMASTER heaters do not require this connection.

The aggressive retry feature is integrated into the

YARDMASTER controller.

1.1 Turn on power at electrical service. Ensure 5

amp panel breaker is closed.

C.5 Operation and Adjustments

1. Set Point Dials: The EMS board (15919) monitors

environmental conditions based on various set

points. All set points are easily adjustable by dials

located at the top of the EMS board. These set points,

when triggered by environmental conditions, send

out a signal to the controller to turn the heaters on.

2. Power Switch and Moisture Simulation Switch: The

power switch and a moisture simulation switch

enable resetting or disabling the EMS and aid in

troubleshooting.

LED Lights: On the right side of the EMS board there

are a number of LED lights which indicate the status

of the EMS board.

6

6

C.6 Switches & Dials

1. ‘POWER ON/OFF’

This allows you to turn OFF/ON the EMS. This switch

is also used to reset the EMS in case of a lockout. Four

alarms from the heater within less than 5 minutes.

2. ‘SIMULATE PRECIPITATION ON/OFF’

This is normally OFF. To simulate moisture (snow or

rain) you can switch it ON and the EMS receives a

signal the sensor is wet. Used to test and troubleshoot

the EMS.

3. ‘SENSITIVITY’

This knob is used to adjust the sensitivity of the

precipitation sensor. 6 is maximum sensitivity and 1 is

least sensitive. Factory set at 3.5.

4. ‘SNOW-RAIN TEMP’

Adjustable set point, from -12°C to 12°C (10°F to 54°F).

If the ambient temperature is below this set point,

the EMS sees any moisture as snow and will turn the

heater ON. Above this set point it detects rain and

will not turn on the heater.

5. ‘SWITCH WARM TEMP’

This set point is not used with this EMS. This feature is

used only with the intermediate EMS.

6. ‘LOW TEMP CUT OUT’ 5°C to -55°C (41°F to -67°F)

This set point determines the temperature at which the

heater will be turned OFF. Usually set to -35°C (-31°F).

NOTE: Propane gas does not provide adequate vapour pressure

below -40°C/F. By disabling the heater at temperatures

below the set point, alarm shutdown and manual resets

are avoided.

NOTE: Natural gas red heaters or propane tanks with tank

heaters DO NOT require this feature and the set point

can be lowered to the minimum of -55°C (-67°F).

7. ‘DELAY ON’, ‘DELAY OFF’ DIP SWTCHES ON THE

BOARD

These switches are used to set the DELAY ON and

DELAY OFF times for EMS operation. The value of the

time is calculated by adding the binary code value

of the actual switch. Minimum step is one minute.

The values are 1, 2, 4, 8, 16, 32, 64, and 128 and any

combination between, and up to 255 minutes.

Example shown has 5 minutes delay on and 15

minutes delay off.

8. Heaters equipped with the ‘AGGRESSIVE RETRY

OPTION’

If the heater is equipped with the AGGRESSIVE RETRY

OPTION, the EMS will reset the heater up to three

times within 5 minutes and then lock out.

C.7 Status LEDs

Status LED Description

POWER Indicates 12V DC present on the

board

CLOCK Blinking once a second means clock

is working

HEATER ON Heater relay is energized. Heaters

requested to run

SENSOR WET Indicates when the sensor is wet or

simulated wet

DELAYS

Shows Delay Status:

ࢦDark: No delay time active

ࢦLit: Delay time active. Either delay

off or delay on time

–If ‘HEATER ON’ LED is dark -

delay on time

–If ‘HEATER ON’ LED is lit -

delay off time

ࢦBlinking: Delay time reset to zero

RESET Relay to reset ame safety relay.

(Aggressive retry)

AMBIENT Ambient temperature is below

SNOW/RAIN TEMP and sensor is wet

SW WARM

Ambient temperature is below

SWITCH WARM set point (not

available with this EMS)

LOW TEMP

Ambient temperature is below low

temp cut out set point. EMS will turn

the heater off. LED heater on is dark

(heater on relay de-energized)

7

D. SPARE PARTS & DRAWINGS

EMS Board

Part No. 15919

Transformer

Part No. 9064-0016

Circuit Breaker

Part No. 9042-0014

Metal Oxide Varistor

Part No. 9049-0052

Rail thermostat only, 13340-

03 Enclosure only, 17895

Rail thermostat surge

isolator. Replacement board

only, 15948

Rail thermostat jumper

16422-02

Ambient temperature sensor

16426

ArcticSense, c/w 10’ cable

13849-02

ArcticSense head only

13849-03

Rail thermostat c/w 40’ cable

16442-03

8

D.1 Schematic - EMS Board Single Unit

40

41

41

40

15

1

21

9

44

45

46

47

23

25

24

22

ALARM FSR

4 POLE DEUTSCH

CONNECTOR

TEMPERATURE

SENSOR

TRANSFORMER 24V 75VA

MODULE

44

45

46

47

1

2

3

4

FSR RESETHEATER ON

P1

15935

5

1

2

3

5

6

7

8

9

ELECTRICAL SCHEMA

EMS BOARD SINGLE UNIT

COM

NO

NC

HEATER ON CONTACTS

COM

NO

NC

FSR RESET CONTACTS

9

2

21

1

15

22

23

24

25

GND

10

14

13

12

RAIL TEMP.SWITCH

11

S20K130

S20K130

S20K130

S20K130

VARISTOR

VARISTOR

VARISTOR

VARISTOR

TERMINAL BLOCK

TB

IF RAIL TEMP.SWITCH IS NOT USED

SHORT TB 9 TO 11 WITH A JUMPER

RAIL TEMPSWITCH

INSULATION

BOARD

159361

2

RAIL TEMP. SURGE

PROTECTION BOX

1

2

3

4

15947

DEUTSCH

CONNECTOR

16422-03

WITH SURGE PROTECTION ON RAIL TEMP SWITCH

GRu 10.APRIL 2000

PRODUCTION RELEASE REF ECN 949

B

TB1-1

TB1-2

TB1-3

TB1-4

TB1-5

TB1-6

TB1-7

TB2-1

TB2-2

TB2-3

TB2-4

12 AWG GREEN WIRE

12 AWG GREEN WIRE

TB

4

CONNECT POWER GROUND TO GROUND STUD ON ENCLOSURE

13.NOV.2000CGROUNDING INFORMATION ADDED ECN 1125

PRECIPITATION SENSOR

TO GROUND STUD ONENCLOSURE

TO GROUND STUD ONENCLOSURE

DECN 1122 5.DEC.2000

APPLICATION: EMS 17255-XX , LABEL 17254

G

ETB3 TERM NUMBERING CORRECTED, ECN 1200 2. FEB. 2001GCH

EMS BOARD 15919

TB3-5

TB3-4

TB3-6

FECN 1252 TB1 TERMINAL 13 T0 15 RENUMBERED TO 12 TO 14 27.APRIL 2001

GCH

1

2

P2

NEUTRAL

GSNOW SENSOR REPLACED WITH NEW MODEL 5. NOV 2019

REV

DRAWING NUMBER

TITLE

SHEET: 1/1

Thermon Heating Systems, Inc.

DWN: DATE: CHKD DATE: LTRDATE APP

NOTES: EAGLE A4

DESCRIPTION

H1H2

X1X2

AMP

NEUTRAL

9

9

9

20

20

1

1

1

1

TB1

TB2

99

Section Running Footer

NOTES

10

10

NOTES

1111

NOTES

WARRANTY: Under normal use the Company

warrants to the purchaser that defects in material

or workmanship will be repaired or replaced without

charge (from date of shipment) for a period of:

Any claim for warranty must be reported to the sales

of ce where the product was purchased for authorized

repair or replacement within the contract terms.

Subject to State or Provincial law to the contrary, the

Company will not be responsible for any expense for

installation, removal from service, transportation, or

damages of any type whatsoever, including damages

arising from lack of use, business interruptions, or

incidental or consequential damages.

The Company cannot anticipate or control the

conditions of product usage and therefore accepts no

responsibility for the safe application and suitability

of its products when used alone or in combination

with other products. Tests for the safe application and

suitability of the products are the sole responsibility of

the user.

This warranty will be void if, in the judgment of the

Company, the damage, failure or defect is the result of:

�Vibration, radiation, erosion, corrosion, process

contamination, abnormal process conditions,

temperature and pressures, unusual surges or

pulsation, fouling, ordinary wear and tear, lack of

maintenance, incorrectly applied utilities such as

voltage, air, gas, water, and others or any combination

of the aforementioned causes not speci cally allowed

for in the design conditions

�Or, any act or omission by the Purchaser, its agents,

servants or independent contractors which for

greater certainty, but not so as to limit the generality

of the foregoing, includes physical, chemical or

mechanical abuse, accident, improper installation

of the product, improper storage and handling of the

product, improper application or the misalignment

of parts.

No warranty applies to paint nishes except for

manufacturing defects apparent within 30 days from the

date of installation.

The Company neither assumes nor authorizes any person to

assume for it any other obligation or liability in connection

with the product(s).

The Purchaser agrees that all warranty work required after

the initial commissioning of the product will be provided

only if the Company has been paid by the Purchaser in full

accordance with the terms and conditions of the contract.

The Purchaser agrees that the Company makes no

warranty or guarantee, express, implied or statutory,

(including any warranty of merchantability or warranty

of tness for a particular purpose) written or oral, of the

Article or incidental labour, except as is expressed or

contained in the agreement herein.

LIABILITY: Technical data contained in the catalog

or on the website is subject to change without notice.

The Company reserves the right to make dimensional

and other design changes as required. The Purchaser

acknowledges the Company shall not be obligated

to modify those articles manufactured before the

formulation of the changes in design or improvements

of the products by the Company.

The Company shall not be liable to compensate or

indemnify the Purchaser, end user or any other party

against any actions, claims, liabilities, injury, loss,

loss of use, loss of business, damages, indirect or

consequential damages, demands, penalties, nes,

expenses (including legal expenses), costs, obligations

and causes of action of any kind arising wholly or partly

from negligence or omission of the user or the misuse,

incorrect application, unsafe application, incorrect

storage and handling, incorrect installation, lack of

maintenance, improper maintenance or improper

operation of products furnished by the Company.

PLEASE ADHERE TO INSTRUCTIONS IN THIS MANUAL

Failure to do so may be dangerous and may void certain

provisions of your warranty.

�84 months - SwitchBlade®Heaters

�60 months - DC Heaters

�36 months - DC Control Panels

�36 months - HELLFIRE Heaters, FEB Heaters

�12 months - All other Fastrax®Products

For further assistance, please call 1.855.244.3128

Table of contents

Other Thermon Cables And Connectors manuals

Thermon

Thermon Terminator DP-M Reference guide

Thermon

Thermon Terminator DL Reference guide

Thermon

Thermon Terminator DP Reference guide

Thermon

Thermon Terminator ZP/FAK-1 Reference guide

Thermon

Thermon Terminator ZS Reference guide

Thermon

Thermon Terminator DS/DE Reference guide

Thermon

Thermon Terminator DP/FAK-2 Reference guide

Thermon

Thermon Terminator ZP-M Reference guide

Thermon

Thermon Terminator ZP Reference guide

Thermon

Thermon TraceNet ECM-P/FAK-1 Reference guide