Thermon FLX Self-Regulating Reference guide

FLXTM Self-Regulating

Winterization/Freeze Protection

INSTALLATION PROCEDURES

FLXTM Self-Regulating

Typical Heat Tracing Installation . . .

A complete electric heat tracing system will typically in-

clude the following components:

1. Electric heat tracing

cable.

2. Power connection kit.

3. Control thermostat (may

be remote ambient

sensing control.)

4. In-line/T-splice

kit (permits two

or three cables to

be spliced together).

5. Cable end termination.

6. Attachment tape (use on 12”

intervals or as required by code

or specication).

7. “Electric Heat Tracing”label (peel-and-stick

label attaches to insulation vapor barrier

on 10’ intervals or as required by code or

specication).

8. Thermal insulation and vapor barrier

(by others).

The absence of any of these items

can cause a system to malfunction

or represent a safety hazard.

FLXTM Self-Regulating

Before Installing Cable . . .

1. Be sure all piping and equipment to be traced is completely

installed and pressure tested.

2. Surface areas where heat tracing is to be installed must be

reasonably clean. Remove dirt, rust and scale with a wire

brush and oil and grease lms with a suitable solvent.

Refer to the“FLX Cable Testing Report” for required recording

of test data and circuit information.

Upon Receiving Cable . . .

1. Upon receiving heating cable, check to make sure the proper

type and output have been received. All cables are printed

on the outer jacket with part number, voltage rating and watt

output.

2. Visually inspect cable for any damage incurred during ship-

ment. The heating cable should be tested to ensure electri-

cal integrity with at least a 500 Vdc megohmmeter (meg-

ger) between the heating cable bus wires and the heating

cable metallic braid. IEEE 515.1 recommends that the test

voltage for polymer insulated heating cables be 2500 Vdc.

Minimum resistance should be 20 megohms. (Record 1 on

Cable Testing Report.)

Connect the positive lead of the megger to the cable bus

wires and the negative lead to the metallic braid.

CAUTION: DO NOT connect power to heating

cable while it is on reel or in shipping carton.

The National Electric Code and Canadian Electrical

Code require ground-fault protection be provided

for all electric heat tracing.

6

5

4

8

71

2

3

2

INSTALLATION PROCEDURES

3

2. Make heating cable allowances for valves, anges, elbows

and supports as per the applicable drawings and table on

pages 2 and 3 of these installation procedures. See product

specications sheet for heating cable minimum bend radius.

Temporary Installation Proposed End-of-Circuit

Location

Proposed Power

Connection Location

Pipe Support

Cable Allowance for

In-Line Heat Sinks

Initial Installation . . .

1. Begin temporary installation at the proposed end-of-circuit

location and lay out heating circuit on the pipe, allowing ex-

tra cable for the power connection and for any splice loca-

tions. Refer to illustration below for temporary installation.

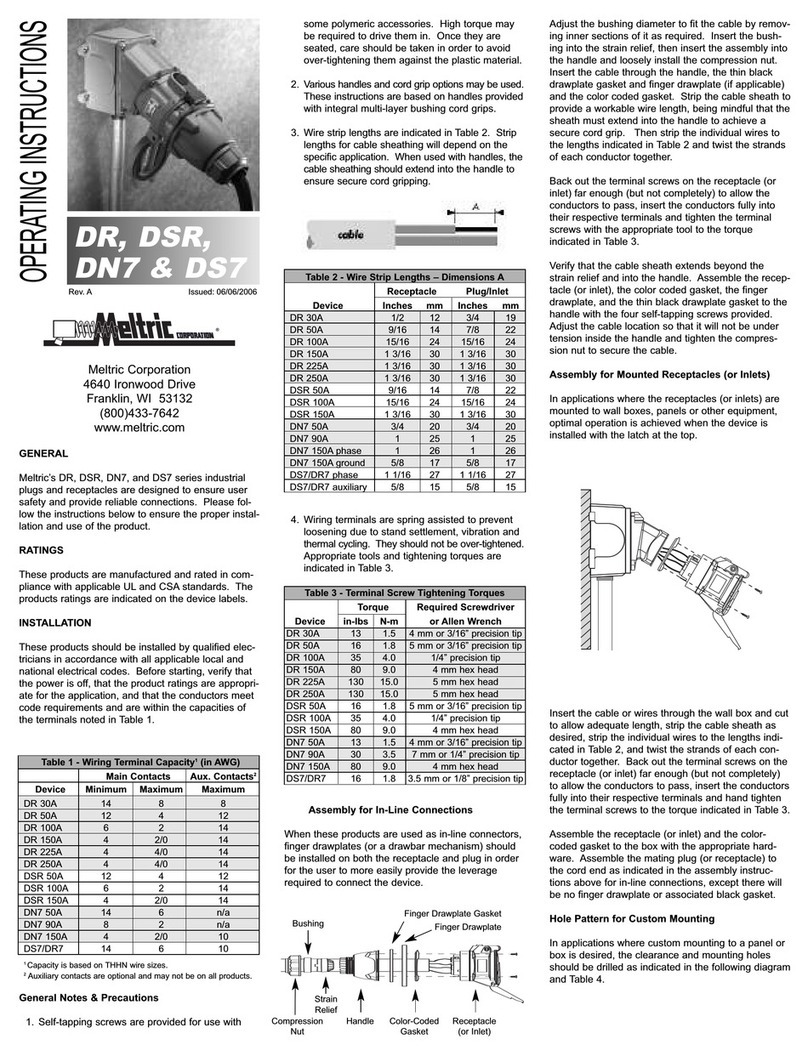

Installation on Fittings and Equipment . . .

1. Install heating cable in accordance with illustrations below.

Secure heating cable to piping using attachment tape.

2. Elbows: Locate the cable on the outside radius of an elbow

to provide sucient heat to compensate for the added pip-

ing material. Secure the cable to the pipe on each side of

the elbow with attachment tape.

Attachment Tape

(Typical)

Heating Cable

Pipe Elbow Pipe Support

Support

Length

Attachment Tape

(Typical)

Heating Cable

3” Min.

(8 cm)

3” Min.

(8 cm)

3. Pipe Supports: Insulated pipe supports require no additional

heating cable. For uninsulated supports, allow two times the

length of the pipe support plus an additional 15”(40 cm) of

heating cable.

FLXTM Self-Regulating

4

Table 1: Valve and Pump Allowances

Heating Cable

12” Max.

(30 cm)

Note:

Flange allowance will vary based on method of insulating ange and adjacent piping.

4. Flanges: Allow cable to be looped around pipe on each side

of and adjacent to the ange. Heating cable must maintain

contact with ange when bending around pipe anges to

compensate for additional heat loss.

Attachment Tape

(Typical)

Heating Cable

Temporary Loop of Cable on Valve

Attachment Tape

(Typical)

Heating Cable Serpentined on Pump

Heating Cable Attachment Tape

(Typical)

Heating Cable Serpentined on Valve

Typical Pump Detail

Heating Cable Attachment Tape

(Typical)

Pipe

Size

Valve Type

Screwed Flanged Welded

Pump Type

Screwed Flanged

½" 6" 1' 0 1' 2'

¾" 9" 1'-6" 0 1'-6" 3'

1" 1' 2' 1' 2' 4'

1¼" 1'-6" 2' 1' 3' 4'-6"

1½" 1'-6" 2'-6" 1'-6" 3' 5'

2" 2' 2'-6" 2' 4' 5'-6"

3" 2'-6" 3'-6" 2'-6" 5' 7'

4" 4' 5' 3' 8' 10'

6" 7' 8' 3'-6" 14' 16'

8" 9'-6" 11' 4' 19' 22'

10" 12'-6" 14' 4' 25' 28'

12" 15' 16'-6" 5' 30' 33'

14" 18' 19'-6" 5'-6" 36' 39'

16" 21'-6" 23' 6' 43' 46'

18" 25'-6" 27' 6'-6" 51' 54'

20" 28'-6" 30' 7' 57' 60'

24" 34' 36' 8' 68' 72'

30" 40' 42' 10' 80' 84'

6. Install heating cable on valves and pumps utilizing a looping

technique (this allows the valve or pump to be removed if

required).

5. Additional cable is required to provide extra heat at valves,

pumps and miscellaneous equipment to oset the in-

creased heat loss associated with these items. Refer to

Table 1 for estimated cable requirements for installation on

typical valves and pumps.

Typical Valve Details

Typical Flange Detail

INSTALLATION PROCEDURES

5

Completing the Installation . . .

1. Begin nal cable attachment by securing the end-of-circuit

termination kit and working back toward the power supply.

• Flexible heating cables are to be installed using attachment

tape. Circumferential bands of tape should be installed at

12” (30 cm) intervals to keep the cable in proper contact

with the pipe. Refer to Table 2 below to calculate the num-

ber of rolls of attachment tape required based on the pipe

diameter1.

• If applicable, refer to installation details provided with the

project drawings or contactThermon for additional infor-

mation regarding installation.

2. In addition to the circumferential tape requirements, a

continuous covering of aluminum foil tape may be required

when:

• Spray or foam urethane2thermal insulation is applied.

• Heat tracing nonmetallic piping.

• Design requirements dictate the use of aluminum tape to

improve heat transfer.

3. Complete splice connections (if required) in accordance

with the installation instructions provided with the splice kit.

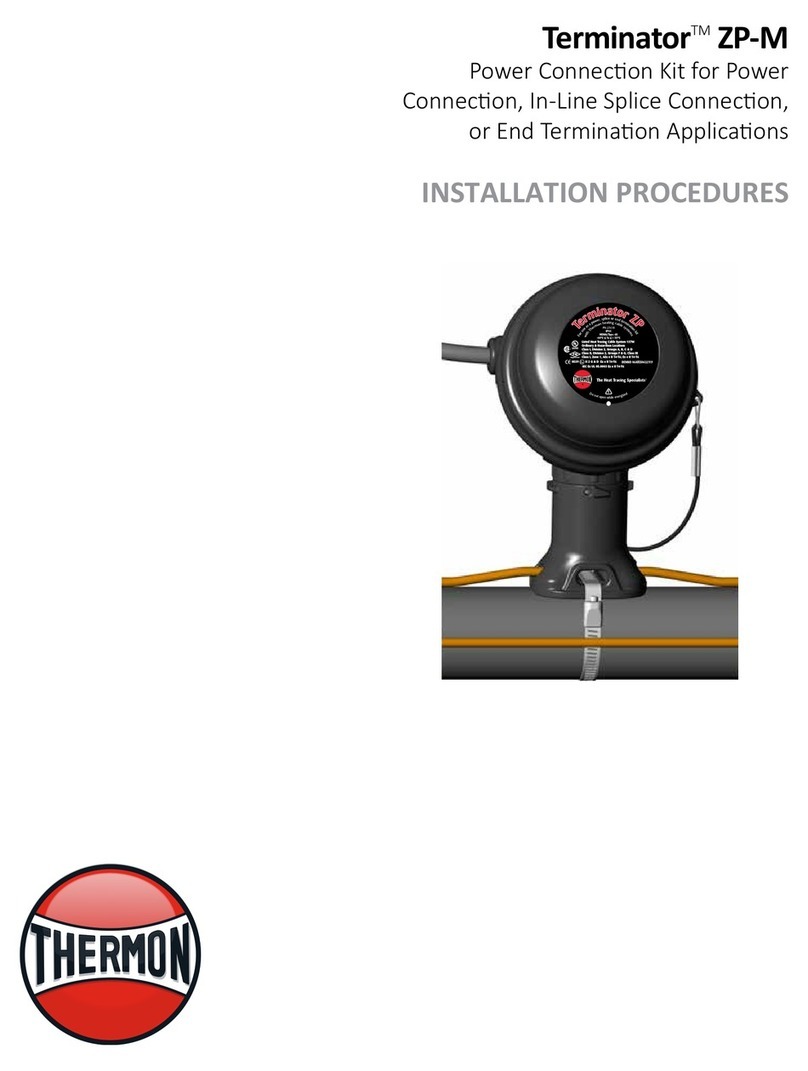

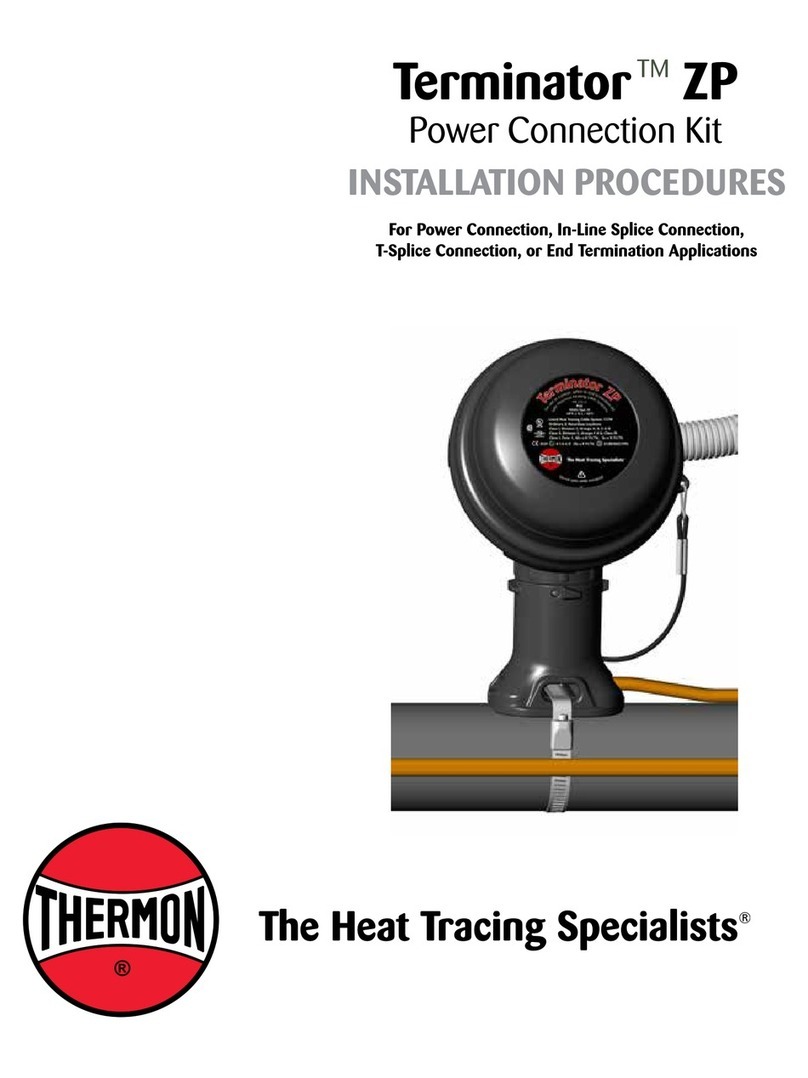

4. Install power connection kit in accordance to the detailed

installation instructions provided with the kit.

5. Before making power connections, repeat the megger test

with at least a 500 Vdc megohmmeter (megger) between

the heating cable bus wires and the heating cable metallic

braid. IEEE 515.1 recommends that the test voltage for

polymer insulated heating cables be 2500 Vdc. The mini-

mum acceptable level for the megger reading for any

polymer-insulated heat tracing cable is 20 megohms.

(Record 2 on Cable Testing Report)

Heating Cable vs. Sensor Location

Temperature Control . . .

1.

When a line sensing controller is specied, the sensor should

be placed at least 90° around the circumference from the

heating cable, or at least 2" (5 cm) from the cable.

Tape

Length

Pipe Diameter in Inches

½"-1" 1¼" 1½" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 30"

36 yd 130' 115' 110' 95' 75' 65' 50' 40' 35' 30' 26' 23' 21' 19' 16' 13'

60 yd 215' 195' 180' 160' 125' 105' 80' 65' 55' 50' 43' 38' 35' 31' 27' 22'

Heating Cable

(Typical)

Temperature

Sensor

Table 2: Attachment Tape (Value Represents Approximate Linear Pipe Length Allowance Per Roll)

Ambient Sensing Thermostat

End Termination

Power Connection

L1

L2/N

Ambient Sensing Control Connection

Temperature Sensor End Termination

Power Connection

L1

L2/N

Heating Cable

Pipewall Sensing Control Connection

Heating Cable

3. When using an ambient sensing temperature controller, the

mounting location should be representative of the coldest

region, and the sensing element should not be exposed to

direct sunlight or any additional heat source.

Notes . . .

1. Table 2 assumes circumferential bands every 12” (30 cm) along the length of the piping.

2. Verify exposure temperature of heating cable versus curing temperature of insulation.

2. For pipewall sensing thermostatic control, the heating circuit

is to be connected in series with the control contacts as

shown in illustration below.The pipewall sensing thermostat

may require more than one support point.

90°

Optional Third

Heating Cable

Optional Second

Heating Cable

FLXTM Self-Regulating

6

Final Inspection and Documentation . . .

1. It is recommended that the circuit be temporarily energized

so that the volts, amps, pipe temperature and ambient

temperature may be recorded. This information may be of

value for future reference and should be maintained for the

historical operating data log (Record 4 on Cable Testing

Report).

2. Once power is connected but before putting the system

into operation, verify all heating cable testing and documen-

tation have been completed for each heat tracing circuit.

This will ensure that the system has been installed per the

manufacturers recommendations.

The National Electric Code and Canadian Electrical

Code require ground-fault protection be provided

for branch circuits supplying electric heat tracing

on xed outdoor electric de-icing and snow-melt-

ing equipment.

Thermal Insulation . . .

1. The need for properly installed and well-maintained thermal

insulation cannot be overemphasized. Without insulation,

heat losses are generally too high to be oset by a conven-

tional heat tracing system.

2. In addition to piping and in-line equipment such as pumps

and valves, all heat sinks must be properly insulated. This

includes pipe supports, hangers, anges and, in most cases,

valve bonnets.

3. Regardless of the type or thickness of insulation used, a

protective barrier should be installed. This protects the

insulation from moisture intrusion, physical damage and

helps ensure the proper performance of the heat tracing

system. Seal around all penetrations through the thermal

insulation.

4. After the installation of the thermal insulation and weather

barrier but BEFORE ENERGIZING THE HEATING CIRCUIT,

the megohmmeter test should be repeated.This should call

attention to any damage to the heating cable that may have

occurred during the insulation installation. (Record 3 on

Cable Testing Report)

5. Apply caution labels to insulation weather barrier at required

intervals along pipe

Thermal Insulation with Weather Barrier

Heating Cable

(Typical)

Temperature

Sensor

Weather

Barrier

Thermal

Insulation

FLX™ Cable Testing Report

1. Refer to Thermon FLX Installation Procedures, FORM CPD1018, for general installation procedures, requirements and guide-

lines.

2. Upon receiving heating cable, check the cable to make sure the proper type and output have been received. All cables are

printed on the outer jacket with part number, voltage rating and watt output.

3. Visually inspect cable for any damage incurred during shipment.

The heating cable should be tested to ensure electrical integrity

with at least a 500 Vdc megohmmeter (megger) between the

heating cable bus wires and the heating cable metallic braid.

IEEE 515.1 recommends that the test voltage for polymer

insulated heating cables be 2500 Vdc. Minimum resistance

should be 20 megohms. (Record 1 on Cable Testing Report.)

A. Connect the positive lead of the megger to the cable bus

wires.

B. Connect the negative lead of the megger to the metallic braid.

C. Energize the megger and record the reading. Readings between 20 megohms and innity are acceptable. Readings

below

20 megohms may mean the electrical insulation has been damaged. Recheck the heating cable for physical damage

between the braid and the heating element; small cuts or scumarks on the outer jacket will not aect the megger

reading unless there was actual penetration through the braid and dielectric insulation jacket.

4. Once the installation is complete, but prior to installation of thermal insulation, recheck the heating cable with at least a

500 Vdc megohmmeter (megger) between the heating cable bus wires and the heating cable metallic braid. IEEE 515.1

recommends that the test voltage for polymer insulated heating cables be 2500 Vdc. Minimum resistance should be 20

megohms. (Record 2 on Cable Testing Report.)

5. After the thermal insulation is installed, the megohmmeter test should be repeated. Minimum resistance should be 20

megohms. (Record 3 on Cable Testing Report.)

6. After the thermal insulation is installed and power supply is completed, record the panel and circuit breaker information.

Ensure all junction boxes, temperature controllers, cable glands, etc. are properly secured. Set the temperature controller

NOTE: To ensure the heating cable warranty is maintained through installation, the testing outlined on

this sheet must be completed on the installed heating cables, and the test results recorded and

mailed/faxed to:

Thermon Customer Service

100 Thermon Drive

San Marcos, Texas 78666

Fax: 512-754-2420

7

Customer: Contractor:

Address: Address:

Phone No: Phone No.

Project Reference:

Record 1: Prior to Installation

Cable Type:

Heater Length:

Heater Number:

Insulation Resistance M Ohms:

Tested By: Date:

Witnessed By: Date:

Record 2: After Installation

Insulation Resistance M Ohms:

Tested By: Date:

Witnessed By: Date:

Record 3: After Thermal Insulation is Installed

Insulation Resistance M Ohms:

Tested By: Date:

Witnessed By: Date:

Record 4: Final Commissioning

Panel Number:

Breaker Number:

Volts:

Ambient Temperature (deg. F):

Recorded Amps:

Tested By: Date:

Witnessed By: Date:

FLX™ Cable Testing Report

Form CPD1018-0716 © Thermon Manufacturing Co. Printed in U.S.A.

Thermon . . . The Heat Tracing Specialists

100 Thermon Dr. •PO Box 609 •San Marcos, TX 78667-0609

Phone: (512) 396-5801 •Facsimile: (512) 396-3627 •800-820-HEAT

www.thermon.com In Canada call 800-563-8461

Other Products . . .

Thermon oers additional cut-to-length cables or

complete turn-key systems for the following

applications:

• Hot Water Temperature Maintenance

• Freezer Floor Frost Heave Prevention

• Tank and Hopper Heating

• Instrument Tubing Bundles

• Control and Monitoring Systems

Table of contents

Other Thermon Cables And Connectors manuals

Thermon

Thermon Terminator ZT-P-WP Reference guide

Thermon

Thermon Terminator DL Reference guide

Thermon

Thermon TraceNet ECM-P/FAK-1 Reference guide

Thermon

Thermon Terminator ZP-M Reference guide

Thermon

Thermon Terminator ZS Reference guide

Thermon

Thermon Terminator DP-M Reference guide

Thermon

Thermon Terminator ZP-XP Reference guide

Thermon

Thermon Terminator ZP Reference guide

Thermon

Thermon Terminator DS/DE Reference guide

Thermon

Thermon Fastrax User manual