Thermon TraceNet ECM-P/FAK-1 Reference guide

TraceNetTM ECM-P/FAK-1

ECM—Electronic Control Module

Mounted on FAK-1 Bulkhead Entry

For Use With TubeTrace® Bundles

INSTALLATION PROCEDURES

2

The following installaon procedures are suggested guidelines

for the installaon of the Terminator ECM/FAK-1 Split Bulkhead

Entry Kit with the ECM Electronic Controller. For translaons other

than English and local language translaon provided here, please

contact Thermon. The English language installaon procedure

shall govern.

Tools Required

TraceNet ECM/FAK-1 Kit Contents

TraceNetTM ECM/FAK-1

Receiving, Storing and Handling

1. Inspect materials for damage incurred during shipping.

2. Report damages to the carrier for selement.

3. Idenfy parts against the packing list to ensure the proper

type and quanty has been received.

4. Store in a dry locaon.

Manuals

For operang and monitoring please refer to ECM operang

manual.

Required: Order Separately for each heater to be fabricated.

PETK Power and End Terminaon Kits (per cable)

PETK-1 for RSX, VSX-HT, BSX

PETK-2 for KSX, HTSX

PETK-3-ECM for HPT, FP

PT-100-3L

RTD Control Sensor

PT-100-3L

RTD Limiter Sensor

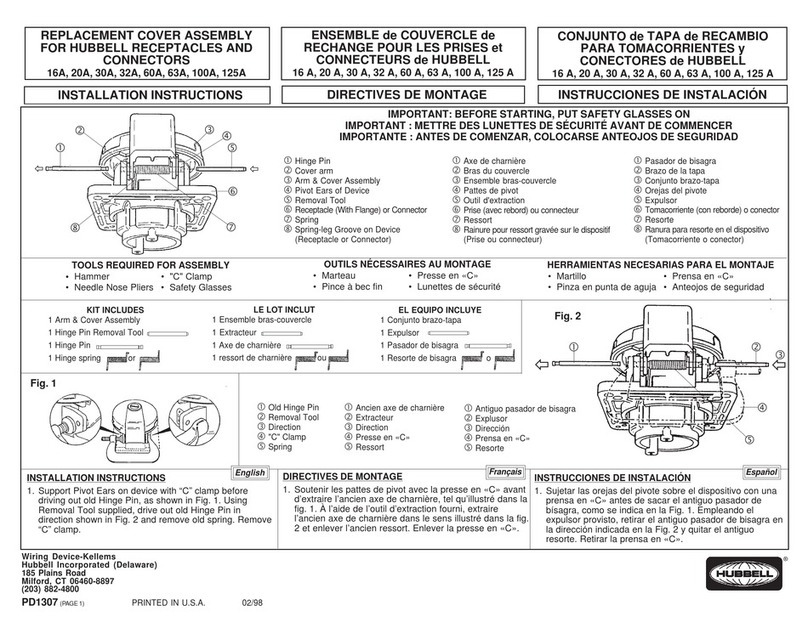

Provided by others — 8 each 8-32 stainless steel bolts, washers

and nuts required.

8

7

Item Quanty Descripon

1 1

Expediter Assembly: Flat Mount Base, Grommet,

Threaded Grommet Compressor, and Support Cap

with O-Ring

2 1 Juncon Box Lid

3 1 Juncon Box Base with O-Ring

4 1 Nut

5 1

Electronic Control Module w/Terminal Blocks

(Refer to terminal specicaons for maximum allowable wire size)

ECM Type

C- Controler

L - Limiter

CL - Controller/Limiter

6 1 Juncon Box Cord

7 1 FAK-1 Cover (Top)

81FAK-1 Cover (Boom)

9 1 Heat Reecve Tape

10 2 RTV Sealant Tube

11 1 Glass Fiber Tape

12 1 Silicone Gasket

13 1 Self-Vulcanizing Tape

14 3 Blind Plug

1 2 4

3

6

5

9 10

11 12

13 14

Dimensions

RTD Sensors

A

mm (inch)

B

mm (inch)

C

mm (inch)

D

inch (mm)

TraceNet

ECM/FAK-1

220 mm

(8-5/8”)

277 mm

(11-7/8”)

107 mm

(4-1/4”)

171 mm

(6-3/4”)

D

B

A

C

3

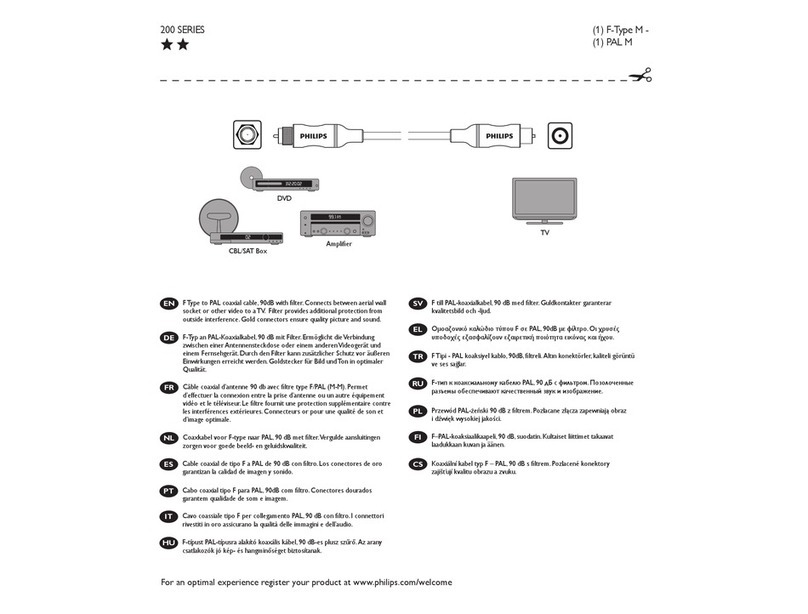

The TraceNet ECM/FAK-1 Split Bulkhead Entry Kit is designed to

provide accurate control with ECM Electronic Control and make

a waterproof seal over the end of TubeTrace and terminate

Thermon electric heat trace in an approved Terminator juncon

box. Review Instrucons prior to installaon. Kit will make one

connecon.

2. Trim heat tracing to within 305 mm–381 mm

of the end of the insulaon. If self-regulang

heat trace proceed to step 3. For Zone-type

heat trace connue with idencaon of bus

connecon on step 2a.

1. Remove outer jacket and insulaon from tubing

bundle to expose the electric heat trace and

tubing. Ensure sucient heat trace is available

for electrical connection. See instructions

included with heat trace PETK kit (purchased

separately).

5. Wrap tubes and heat tracing with pass of heat

reecve tape (25% overlap). Then wrap with 3

passes of glass ber tape (50% overlap), or unl

ber tape is equal to original bundle insulaon

thickness.

Glass Fiber Tape

Heat Reecve Tape

Heat Tracing

Trim as Required

for Connecon Tubing Bundle

Tubing

Heat Tracing

Installaon Precauons

• Keep ends of bundles, heat tracing and kit components dry

before and during installaon.

• To minimize the potenal for arcing on electrical heat tracing

caused by product damage or improper installation, use

appropriate ground-fault circuit protecon.

• Installaon must comply with Thermon requirements and be

installed in accordance with any applicable naonal and local

codes.

• Component approvals and performance rangs are based on

the use of Thermon specied parts only. User supplied power

connecon ngs must be listed or cered for intended use.

• De-energize all power sources before opening enclosure.

• Individuals installing these products are responsible for

complying with all applicable safety and health guidelines.

Proper personal protecve equipment, or PPE, should be

ulized during installaon. Contact Thermon if you have any

addional quesons.

Terminator ECM Cercaons/Approvals

II 2 G Ex e mb [ib]ib IIC T4 Gb SIRA 12ATEX5239X

II 2 D Ex tb IIIC T135°C IP66 Db

Internaonal Electrotechnical Commission

IEC Cercaon Scheme for Explosive Atmospheres

SIR 12.0103X

INSTALLATION PROCEDURES

2a. Strip back bundle insulaon 38 mm to 76 mm

beyond bus connecon heat tracing. If bus

connecon indentaon is less than 305 mm–

381 mm from end of the heat tracing, proceed

stripping the bundle insulaon to the next

indentaon.

180°

RTD

Sensor

Heang Cable

(Typical)

(If Control

Limiter is Used)

Heang Cable vs. Sensor Locaon

4. Insert the RTD(s) into the prepared hole(s) in

the thermal insulaon.

3. Prepare tubing bundle for RTD sensor(s) by

inserng a phillips screwdriver between the

process tube(s) and insulation at a point

opposite the heang cable. The sensor should

be placed 180° around the circumference from

the heang cable. Make sure that the enre

length of the sensor is in inmate contact with

the tube surface. Prevent kinking.

RTD RTD

Tubing

Self-Regulang Heat Tracing

Heat Tracing

305 mm–381 mm

Jacket and

Insulaon

Zone Type Heat Tracing

Tubing

Bus Connecon

Indentaons

(Zone Heater Only)

Jacket and

Insulaon

305 mm–381 mm

4

6. Complete with 1 additional pass of heat

reecve tape.

Heat Reecve Tape

Glass Fiber Tape

Heat Tracing

7. Cut FAK-1 top and base ends to match outside

diameter of tubing bundle and remove end

pieces.

Tubing

RTD

11.For HPT and FP cable, exchange grommet in

Terminator with GRW-GT2 provided in PETK-

3-ECM.

GRW-GT2 GRW

RTD

Tubing Bundle

Cut and Remove

to t

Heat Tracing

Field Drilled

(By Others)

O-Ring

Expediter

Base

Mount Screw

and Washers

Weep Hole

FAK-1 Base

8. Mount expediter base with o-ring to FAK-1 base

using (3) M5 mounng screws and lock washers.

Punch out weep hole.

Silicone

Gasket

9. Install RTV silicone and gasket, cung o excess.

Apply RTV sealant to both halves.

Drilled hole

for bundle

entry

Drilled holes

for securing

FAK-1

Drilled holes for

securing FAK-1 Use as template

14. Field drill required entry hole in wall/plate. Use

the FAK-1 ange as a template and mark and

drill holes for bolts.

12. Apply self-vulcanizing tape around bundle jacket

and work up over FAK ends.

Expediter Base

Heat Tracing

RTD

FAK-1

Boom Cover

FAK-1

Top Cover

13. Terminate heat tracing with appropriate PETK

termination kit. Refer to PETK installation

instrucons for details (not addressed here).

RTD

Power Connecon

Boot

Heat Tracing

Ground Braid

10. Assemble FAK-1 top, tubing bundle, and FAK-1

boom together as shown Snap together rmly.

Inspect ends of tubing splice cover for snug t.

Apply addional RTV sealant where needed.

TraceNetTM ECM/FAK-1

Thermon • 100 Thermon Dr • PO Box 609 San Marcos, TX 78667-0609 • Phone: 512-396-5801 • 1-800-820-4328

For the Thermon oce nearest you visit us at . . . www.thermon.com

© Thermon, Inc. • Printed in U.S.A. • Informaon subject to change.

30°

1725

II 2 (2) GD Ex eb mb [ib] IIC T4, Ex tb I IIC T135°C

SIRA 12ATEX5239X

IP66/Type 4X

-60°C ≤Ta ≤# °C

120 Vac / 240 Vac/ 50-60 Hz

IECEx SIR 12.0103X Ex eb mb [ib] I IC T4, Ex tb IIIC T135°C

PN 27673

D

o

n

o

t

o

p

e

n

w

h

i

l

e

e

n

e

r

g

i

z

e

d

.

S

e

e

i

n

s

t

a

l

l

a

t

i

o

n

i

n

s

t

r

u

c

t

i

o

n

s

.

T

r

a

c

e

N

e

t

E

C

M

F

o

r

u

s

e

a

s

a

n

a

d

j

u

s

t

a

b

l

e

e

l

e

c

t

r

o

n

i

c

c

o

n

t

r

o

l

m

o

d

u

l

e

Ordinary & Hazardous Locations

Class I Division 2, Groups A, B, C, D

Class II Division 2, Groups F, G; Class III; T4

Cl. I, Zn. 1, AEx eb mb [ib] IIC T4; Zone 21 AEx tb IIIC T135°C

14.2709489X, Ex eb mb [ib] IIC T4;

Ex tb IIIC T135°C

# See product specification for ambient temperatures

18. Remove M25 dust cap. Install M25 power

gland (order separately) and M25 blind plug.

20. Use the rotary switches for seling Control

and Limit Temperature, (Celsius or Fahrenheit)

and Auto or Manual reset (Control switches

on Type “C”, Limiter switches on Type “L” and

both on Type “CL”). Refer to ECM user manual

for further details.

21. Install juncon box lid and twist hand ght.

Insert screwdriver into ratchet slot located

on side of juncon box base to ghten. Use

screwdriver to ratchet on juncon box lid. Lid

will rotate 30° for tight seal. To remove lid,

repeat step 21 in opposite direcon.

17. Mount juncon box on expediter making sure

to align slots to properly orient juncon box

base.

19. Install ECM electronic control module and

complete system wiring. Terminal set screws

shall be ghtened to a torque value of 1,4 Nm

(12,4 lb-in). See wiring details. Set ECM

modules electronic control and/or control

limiter at desired setpoints.

Wiring Details

Connecon (for Heat Trace, RTD Sensor Leads,

Alarm and/or Communicaon Connecons)

L LN N C

NO NC

Comm. Port Alarm Relay

Main supply

Heater output

B

B

A

A

B

B

RTD

Limiter Sensor

RTD

Controller Sensor

GND 1 2

22. Apply RTV bead around FAK-1 flange.

Completed Terminator with ECM Electronic

Controller and FAK-1 for bulkhead entry of

Electrically Heated TubeTrace Bundles.

Power Supply

By Others

Align Slots

RTD

INSTALLATION PROCEDURES

RTV Sealant

15. Apply RTV bead to back of FAK-1 ange prior

to securing to bulkhead.

RTV Bead

Backside View

Stainless Steel Bolts

16. Secure FAK-1 to bulkhead/wall using (8) eight

stainless steel bolts. Note: stainless steel

bolts, washers, and nuts provided by others.

Recommended bolt size is 8-32.

Form PN50073-1218

Table of contents

Other Thermon Cables And Connectors manuals

Thermon

Thermon FLX Self-Regulating Reference guide

Thermon

Thermon Terminator ZP-XP Reference guide

Thermon

Thermon Terminator ZT-P-WP Reference guide

Thermon

Thermon Terminator ZP Reference guide

Thermon

Thermon Terminator ZP-M Reference guide

Thermon

Thermon Terminator DP Reference guide

Thermon

Thermon Fastrax User manual

Thermon

Thermon Terminator ZP/FAK-1 Reference guide

Thermon

Thermon Terminator DP-M Reference guide

Thermon

Thermon Terminator DP/FAK-2 Reference guide