6

thermopatch.com

Manual Y151 V. 4.0 ENG EUR from original TPC 47117-MAN Rev 1214 6

V. 4.0 ENG

Oct. 2015

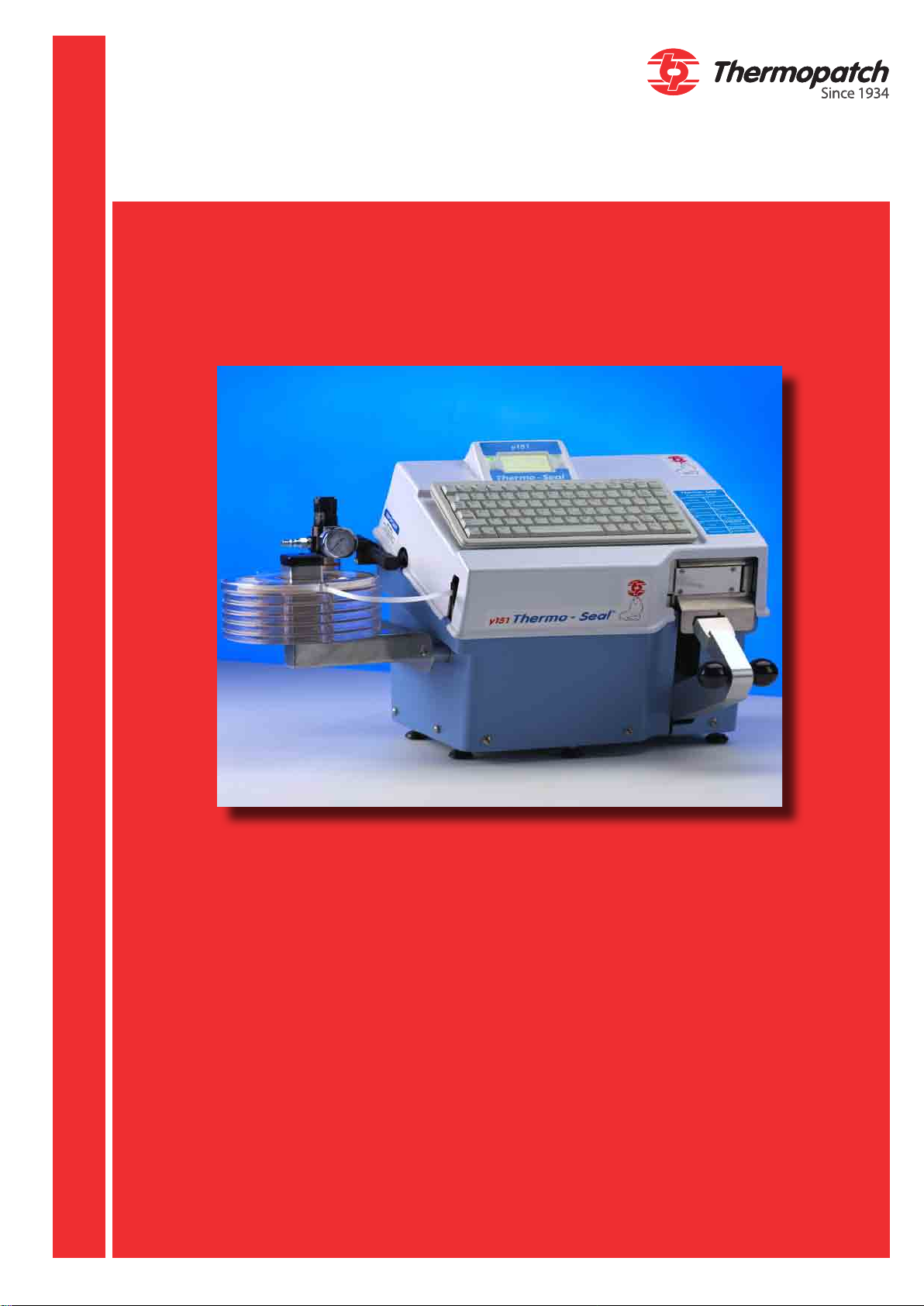

1. General description

The Y151 Thermo-Seal is a machine for the temporary

marking of garments and other textile items.

Temporary marking of a garment or textile item is achieved

without the use of chemical solvents or other harmful

materials. By means of an ink ribbon cartridge, a code

(maximum of 12 characters per label) is printed directly onto

the Thermo-Seal label tape, and it is sealed directly onto the

garment or textile item.

Most garments or textile items can be marked directly.

For garments over very sensitive fabric, there are alternative

methods of xing the temporary label to the garment. The

most common option is to print an extra-long label.

The extra-long label is inserted through the button hole of

the garment, and then the ends are sealed together. Another

option is to seal directly onto a “ag tag”. The ag tag is then

stapled or pinned onto the garment.

The Thermo-Seal label type is specically designed to adhere

to the garment or other textile item through the cleaning

process and then be easily removed without leaving any label

residue on the garment. Thermo-Seal label tape is available

in ten dierent colors.

The colors of the Thermo-Seal label tape, and the printed

code on the label, oer a variety of ways to sort garments.

The Y151 Thermo-Seal machine operates electrically and

pneumatically, through use of compressed air. The code to

be printed on the label tape is entered through the machine

keyboard. Raising the Press Arm engages the pneumatic

system to automatically cut and seal the label tape onto the

garment or textile item.

Time, temperature, and other optional settings can be

entered through the machine keyboard.

The time and temperature, as well as other information, can

be viewed from the Keyboard LCD Panel.

The new heater unit design, as well as electronics, ensures

the consumer of lower energy consumption and a safer work

environment.