3

BACK TO INDEX For more informaon about our products and how to contact us, please visit thermopatch.com

Contents

Copyrights ..............................................................................................................................................................................2

Introducon............................................................................................................................................................................2

Contents...................................................................................................................................................................................3

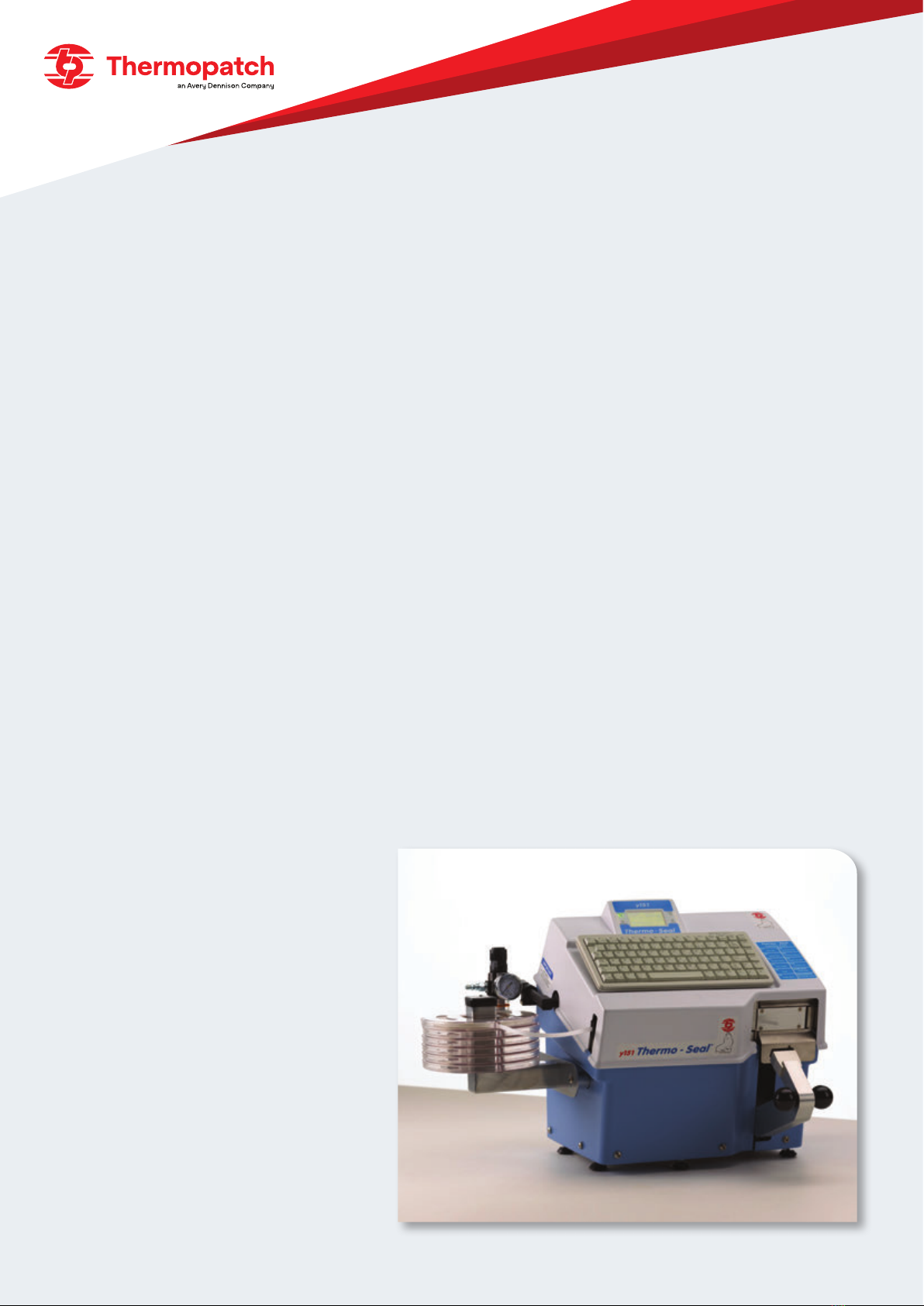

1. General descripon ...........................................................................................................................................5

1.1 Delivery.............................................................................................................................................................................................6

1.2 Condions of warranty ..........................................................................................................................................................6

2. Intended use.........................................................................................................................................................6

3. Technical specificaons ..................................................................................................................................7

4. Overview of safety measures and warnings..............................................................................................8

4.1 Safety.................................................................................................................................................................................................8

5.0 Transport and storage.....................................................................................................................................10

5.1 Transport........................................................................................................................................................................................10

5.2 Storage............................................................................................................................................................................................10

6.0 Operang instrucons.................................................................................................................................... 11

6.1 Starng with the Y-151 Thermo-Seal............................................................................................................................ 11

6.2 Inserng the label marking tape .....................................................................................................................................12

6.3 Machine operaon ..................................................................................................................................................................13

6.4 The control panel......................................................................................................................................................................14

6.5 Customizing the Y-151 Thermoseal...............................................................................................................................15

6.6 Temporary Marking..................................................................................................................................................................17

6.6.1 Sealing Label Tags and Organizaon............................................................................................................................18

6.6.2 Label Tag Marking.....................................................................................................................................................................19

7. Assembly and installaon..............................................................................................................................21

7.1 Installaon ....................................................................................................................................................................................21

7.2 Electrical connecon.............................................................................................................................................................21

7.3 Pneumac requirements.................................................................................................................................................... 22

7.4 Label Tape Storage Rack Installaon.........................................................................................................................23

8. Maintenance instrucons............................................................................................................................. 24

8.1 Maintenance...............................................................................................................................................................................24