3 - 66 021341/07/11

Contents

1Models .......................................................................................................................................5

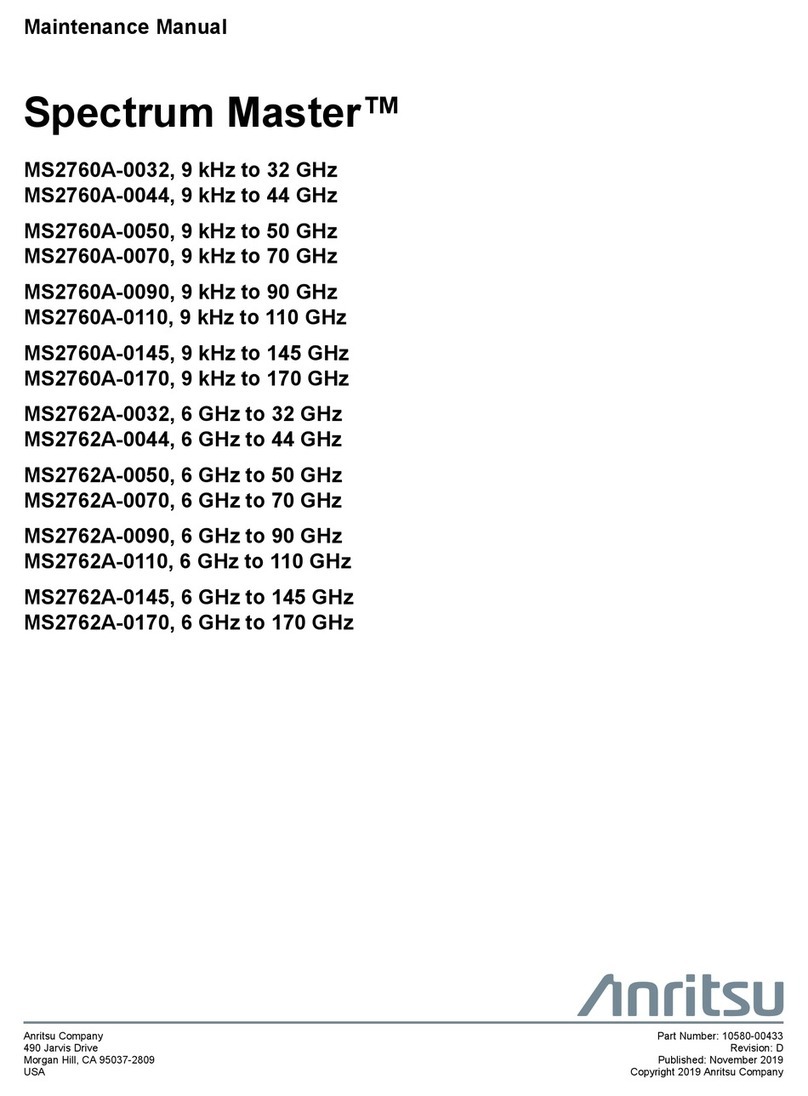

2General......................................................................................................................................5

3Mode of Operation of the Laser Precipition Monitor ..................................................................6

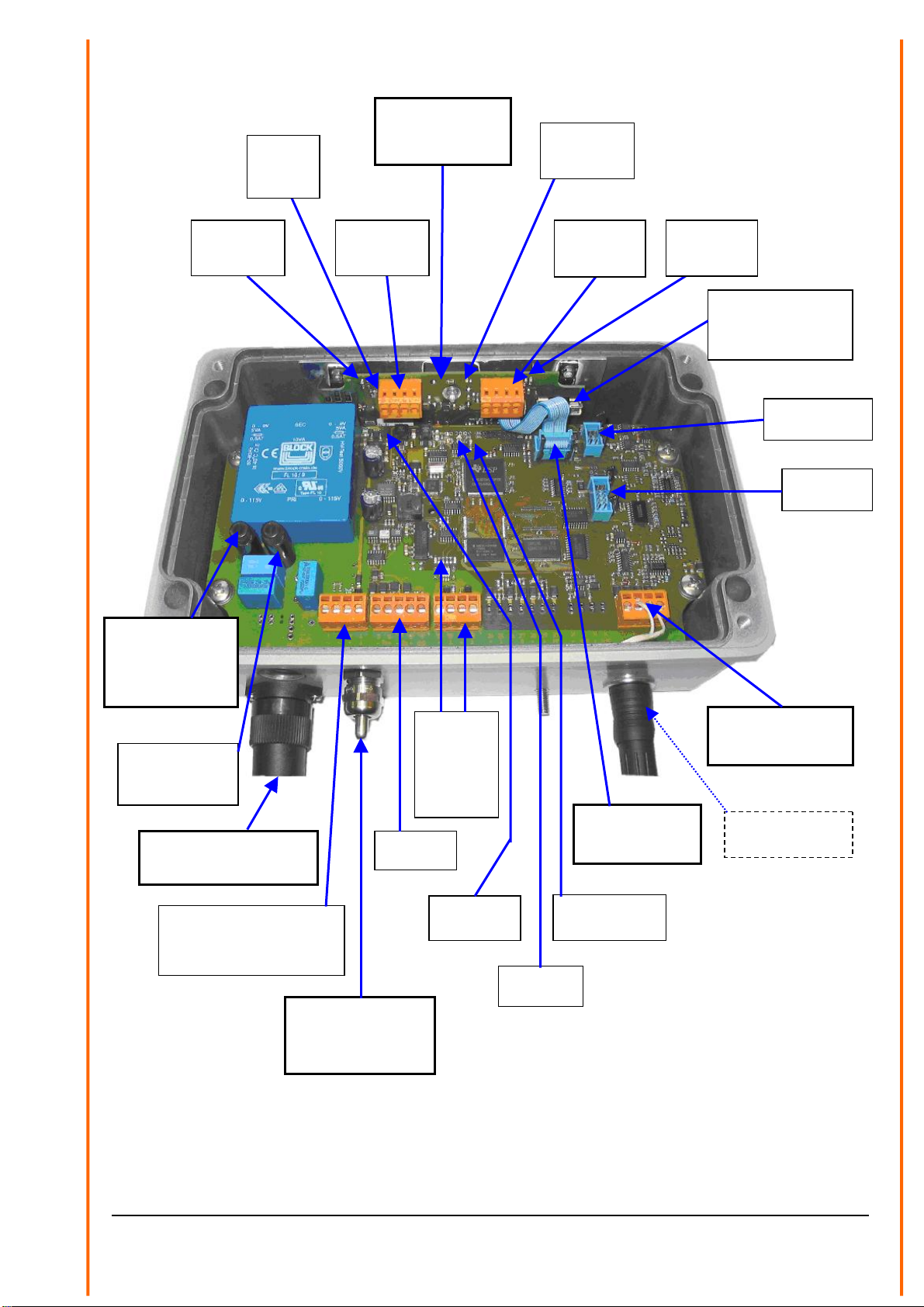

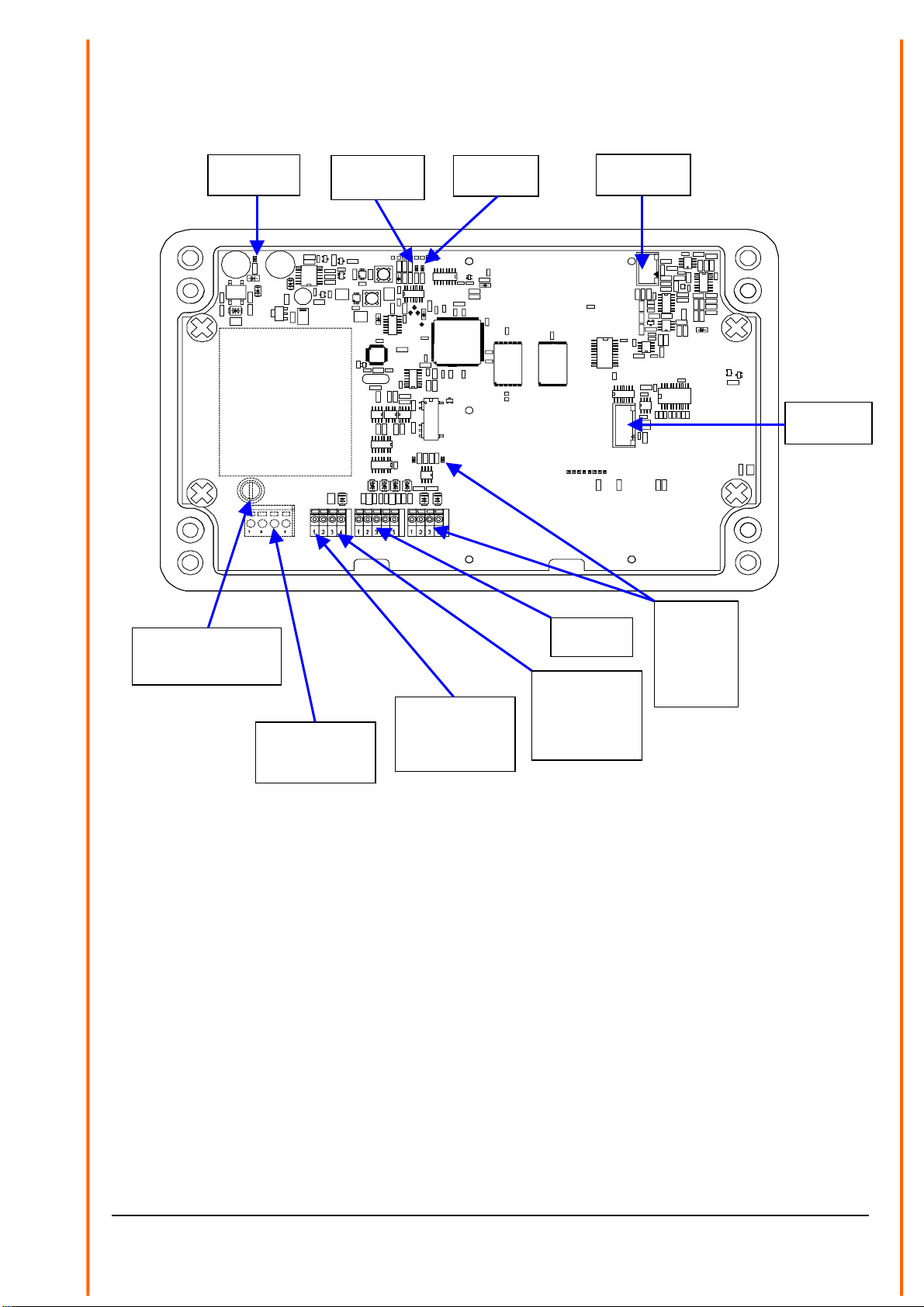

4Construction of the Measuring Instrument.................................................................................8

4.1 Heating..............................................................................................................................12

4.1.1 Variant Extended Heating (5.4110.x1.xxx) .................................................................12

5Installation................................................................................................................................13

5.1 Suggestions for Mounting Place........................................................................................ 13

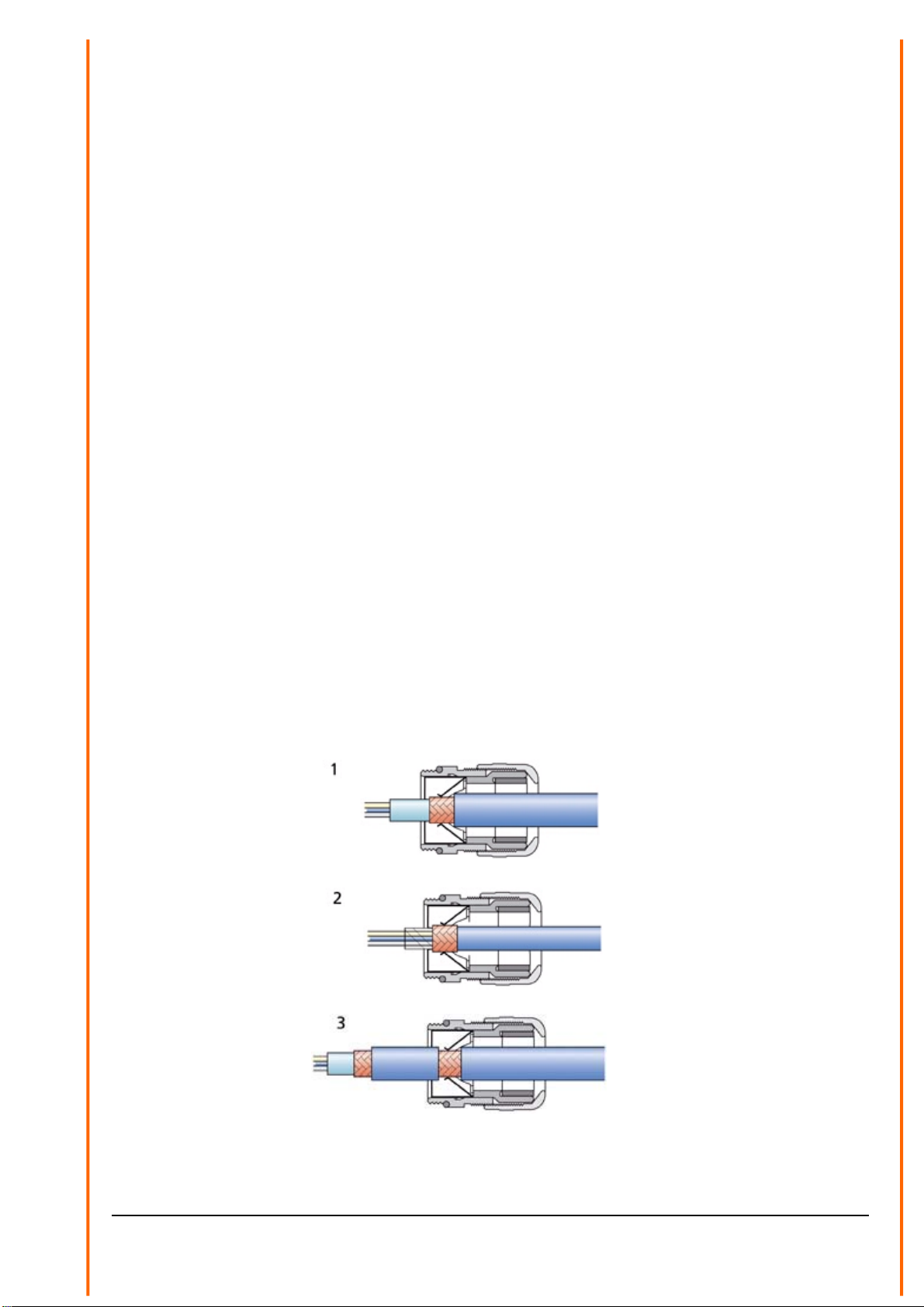

5.2 Mechanical Installation......................................................................................................14

5.2.1 Mounting on Mast.......................................................................................................14

5.2.1.1 Example ...............................................................................................................15

5.2.2 Mounting Angle...........................................................................................................16

5.2.3 Mounting of the Housing Cover .................................................................................. 17

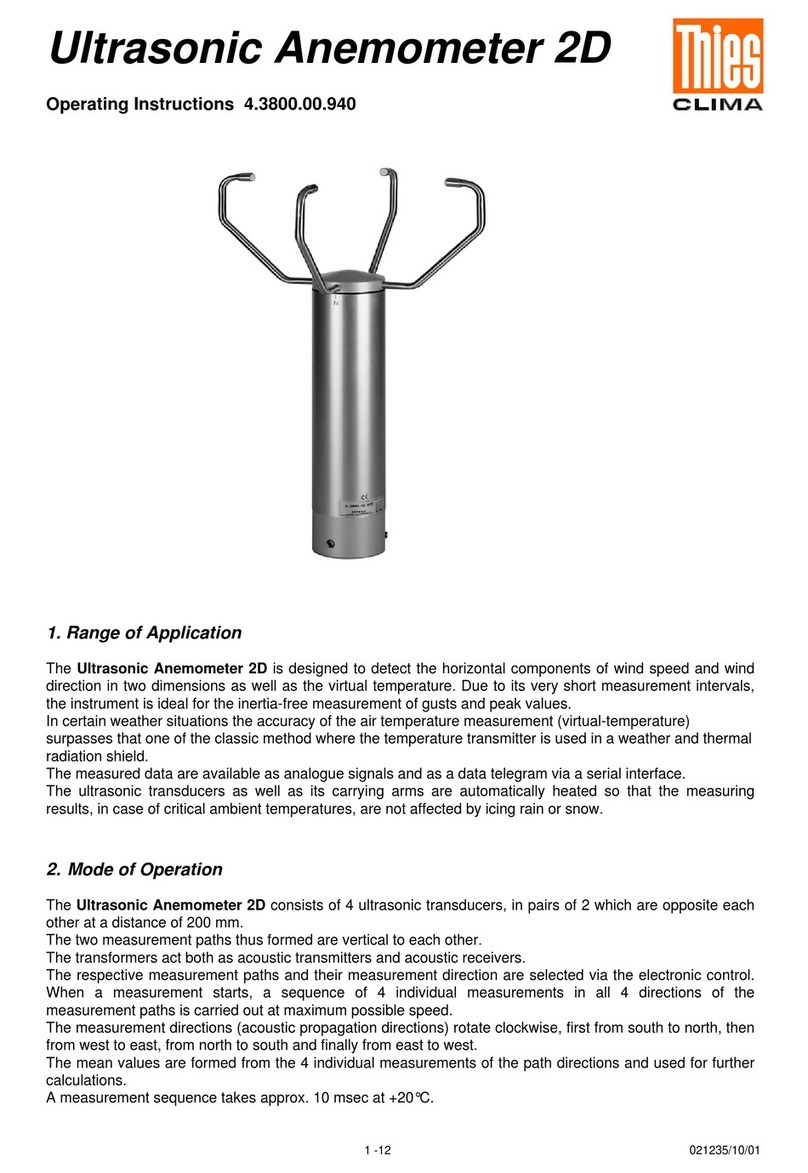

5.3 Electrical Installation..........................................................................................................17

5.3.1 Electrical installation with cable glands.......................................................................18

5.3.1.1 Electrical Installation via Connector ..................................................................... 20

5.3.2 Closing the Instrument Cover ..................................................................................... 20

5.3.3 Optocoupler output.....................................................................................................20

6Maintenance ............................................................................................................................21

6.1 Cleaning............................................................................................................................ 21

6.2 Calibration......................................................................................................................... 21

6.3 Checking the sensor.......................................................................................................... 21

6.3.1 Checking the LED’s....................................................................................................22

6.3.2 Checking by means of a terminal program.................................................................23

7Serial communication...............................................................................................................24

7.1 General telegram format ...................................................................................................25

7.2 List of Commands .............................................................................................................26

7.2.1 Communication commands ........................................................................................27

7.2.2 Reset / Version commands......................................................................................... 28

7.2.3 Data telegrams commands.........................................................................................29

7.2.4 Time / Date commands...............................................................................................30

7.2.5 Diagnostics commands............................................................................................... 32

7.2.6 Calibration commands................................................................................................36

7.2.7 Quantity measurement commands.............................................................................37

7.2.8 Digital output commands............................................................................................ 38

7.3 Data Telegrams.................................................................................................................42

7.3.1 Telegram 4/5: Synop, Metar, Disdrometer, optional measuring channel.................... 42

7.3.2 Telegram 6/7: Synop, Metar, optional measuring channel ......................................... 51