Thies CLIMA 4.387 Series User manual

THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA

Instruction for Use

021546/12/17

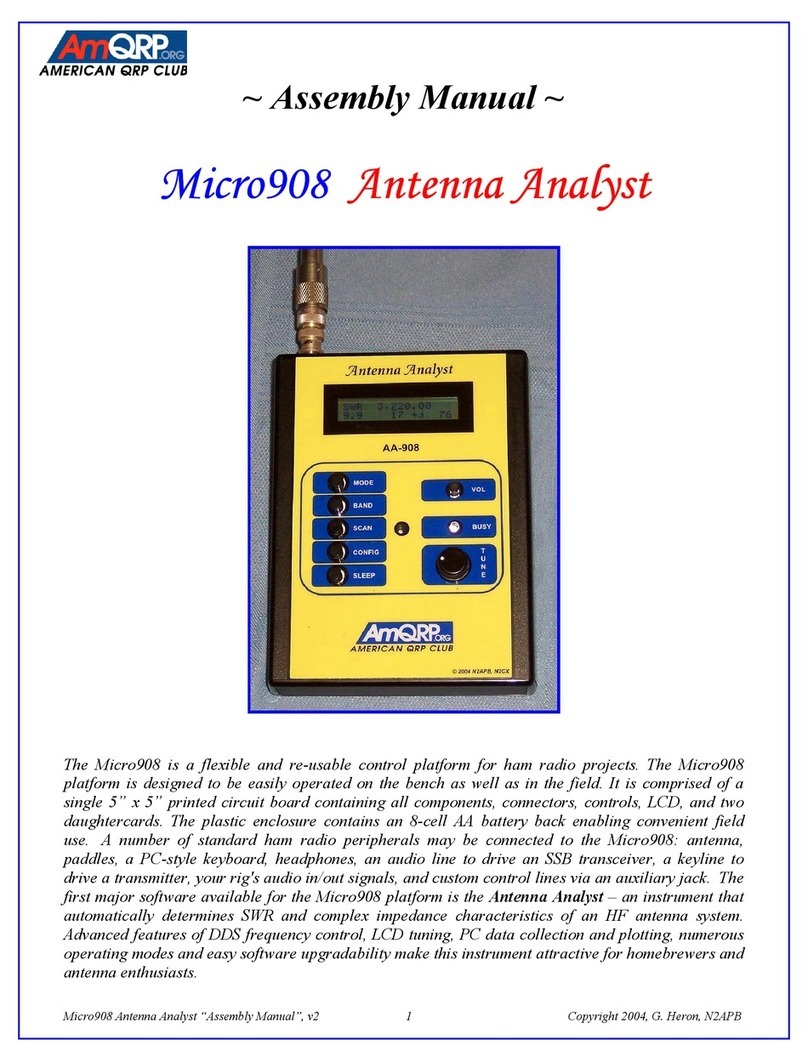

Ultrasonic Anemometer 2D compact

4.387x.xx.xxx

from software version V3.11 Status: 10/2017

ADOLF THIES GmbH & Co. KG

Hauptstraße 76 37083 Göttingen Germany

Box 3536 + 3541 37025 Göttingen

Phone +49 551 79001-0 Fax +49 551 79001-65

www.thiesclima.com inf[email protected]

2 - 68 021546/12/17

Safety Instructions

•Before operating with or at the device/product, read through the operating instructions.

This manual contains instructions, which should be followed on mounting, start-up, and operation.

A non-observance might cause:

- failure of important functions

- Endangering of persons by electrical or mechanic effect

- Damages at objects

•Mounting, electrical connection and wiring of the device/product must be carried out only by a qualified

technician who is familiar with and observes the engineering regulations, provisions and standards applicable

in each case.

•Repairs and maintenance may only be carried out by trained staff or Adolf Thies GmbH & Co. KG. Only

components and spare parts supplied and/or recommended by Adolf Thies GmbH & Co. KG should be used

for repairs.

•Electrical devices/products must be mounted and wired only in voltage-free state.

•Adolf Thies GmbH & Co KG guarantees proper functioning of the device/products provided that no

modifications have been made to the mechanics, electronics or software, and that the following points are

observed:

•All information, warnings and instructions for use included in these operating instructions must be taken into

account and observed as this is essential to ensure trouble-free operation and a safe condition of the

measuring system / device / product.

•The device / product is designed for a specific application as described in these operating instructions.

•The device / product should be operated with the accessories and consumables supplied and/or

recommended by Adolf Thies GmbH & Co KG .

•Recommendation: As it is possible that each measuring system / device / product under certain conditions,

and in rare cases, may also output erroneous measuring values, it is recommended to use redundant systems

with plausibility checks with security-relevant applications.

Environment

•As a longstanding manufacturer of sensors Adolf Thies GmbH & Co KG is committed to the

objectives of environmental protection and is therefore willing to take back all supplied

products governed by the provisions of "ElektroG" (German Electrical and Electronic

Equipment Act) and to perform environmentally compatible disposal and recycling. We are

prepared to take back all Thies products concerned free of charge if returned to Thies by our

customers carriage-paid.

•Make sure you retain packaging for storage or transport of products. Should packaging

however no longer be required, arrange for recycling as the packaging materials are

designed to be recycled.

Documentation

•© Copyright Adolf Thies GmbH & Co KG, Göttingen / Germany

•Although this operating instruction has been drawn up with due care, Adolf Thies GmbH & Co KG can accept

no liability whatsoever for any technical and typographical errors or omissions in this document that might

remain.

•We can accept no liability whatsoever for any losses arising from the information contained in this document.

•Subject to modification in terms of content.

•The device / product should not be passed on without the/these operating instructions.

Explanation of Symbols

•Warning for hot surface

3 - 68 021546/12/17

Patent Protection

This instrument is patent-protected

Patent No.: EP 1 448 966 B1

Patent No.: US 7,149,151 B2

Operating Instructions

These operating instructions describe all possible applications and settings of the instrument. The

Ultrasonic Anemometer 2D compact is factory-set.

Identification for the factory setting derives from the order No. and the respective "Factory Setting"

Order number and Setting

see supplementary sheet

"Factory Setting"

With these detailed operating instructions and via the serial interface of the Ultrasonic Anemometer

2D compact it is possible for the user to adapt the factory-settings to his own requirements.

Shipment

1 x Ultrasonic Anemometer Compact

1 x Operating Instructions

1 x Supplementary Sheet: Factory Setting

1 x Factory certification

4 - 68 021546/12/17

Contents

1Models available............................................................................................................6

2Application.....................................................................................................................7

3Mode of Operation.........................................................................................................8

3.1 Measuring Principle: Wind velocity and direction................................................................8

3.2 Measuring principle: Acoustic virtual temperature...............................................................9

3.3 Measuring principle: Air pressure (optional)........................................................................9

3.4 Heating...............................................................................................................................9

4Preparation for operation.............................................................................................10

4.1 Selection of installation site...............................................................................................10

4.2 Installation of Anemometer...............................................................................................11

4.3 Alignment to north / Positioning ........................................................................................12

4.4 Electrical Installation for Ultrasonic Anemometer..............................................................13

4.4.1 Cables, Cable preparation, Connector Installation......................................................14

4.4.2 Connector Pin Assignment (Examples of Function)....................................................15

5Maintenance................................................................................................................16

6Calibration....................................................................................................................16

7Warranty......................................................................................................................16

8Functional description..................................................................................................17

8.1 Serial communication .......................................................................................................17

8.1.1 Duplex mode..............................................................................................................17

8.1.2 Response Delay.........................................................................................................18

8.1.3 General telegram structure for the Thies Interpreter...................................................18

8.1.4 Saving of the ULTRASONIC Parameters..................................................................19

8.1.5 Return values of ULTRASONIC.................................................................................19

8.1.6 Access Mode..............................................................................................................20

8.1.7 Baud rate ...................................................................................................................21

8.1.8 Instrument ID..............................................................................................................21

8.1.9 Bus mode...................................................................................................................22

8.2Analogue outputs..............................................................................................................22

8.2.1 Scaling of analogue wind velocity...............................................................................23

8.2.2 Correction to North.....................................................................................................23

8.3Instantaneous values and output of raw measured values................................................23

8.3.1 Averaging...................................................................................................................23

8.4 Serial Data Output............................................................................................................24

8.4.1 Data Query.................................................................................................................24

8.4.2 Independent telegram output......................................................................................25

8.4.3 Fixed telegram formats...............................................................................................25

8.4.4 Generation of check sum ...........................................................................................26

8.4.5 Status information......................................................................................................26

8.5 Behaviour of Instrument under extreme Conditions of Measurement Value Acquisition....29

5 - 68 021546/12/17

8.6 Behaviour in Case of Error................................................................................................29

8.6.1 Behaviour of analogue outputs...................................................................................29

8.6.2 Behaviour of telegram output .....................................................................................29

8.7 Output of all system parameters.......................................................................................30

8.8 Enquiry about software version.........................................................................................30

8.9 Forcing a restart ...............................................................................................................30

8.10 Energy-saving mode.........................................................................................................30

8.11 Plausibility ........................................................................................................................30

8.12 Online help.......................................................................................................................31

9Configuration of ultrasonic anemometer by customer..................................................31

10 Thies Command Interpreter.........................................................................................32

10.1 List of Commands Thies Interpreter..................................................................................32

10.2 Command and description................................................................................................33

11 MODBUS RTU Command Interpreter..........................................................................49

11.1 MODBUS RTU Telegram Construction.............................................................................49

11.2 Command Description......................................................................................................50

11.3 Measuring values (Input Register)....................................................................................50

11.4 Commands (Holding Register)..........................................................................................53

12 Appendix 1 Predefined data telegrams........................................................................54

12.1 Telegram 1 VD ................................................................................................................54

12.2 Telegram 2 VDT ..............................................................................................................55

12.3 Telegram 3 VD2 ..............................................................................................................56

12.4 Telegram 00004 NMEA ...................................................................................................57

12.5 Telegram 7 Vx, Vy, VT.....................................................................................................58

12.6 Telegram 8 VDM .............................................................................................................59

12.7 Telegram 9 VDPM...........................................................................................................60

12.8 Telegram 11 PBT .............................................................................................................62

12.9 Telegram 12 Scientific Telegram .....................................................................................62

13 Technical Data.............................................................................................................63

14 Dimension Drawing......................................................................................................65

15 Accessories (available as optional features)................................................................66

16 EC-Declaration of Conformity......................................................................................67

Figure

Figure 1: Connector installation..................................................................................................... 14

Table

Table 1: Restrictions in full and half duplex mode.......................................................................... 18

Table 2: Access key for different command levels......................................................................... 20

Table 3: Config. of analogue outputs WV/RXD- and WD/RXD+ with parameters AO a. SC........... 22

Table 4: List of predefined data telegrams..................................................................................... 25

Table 5: Adjustment of averaging periods with parameter AV........................................................ 34

Table 6: List of baud rates with telegram BR................................................................................. 35

Table 7: Conversion factors between different wind velocities....................................................... 42

6 - 68 021546/12/17

Table 8 : MODBUS Frame............................................................................................................. 49

Table 9 : MODBUS Exceptions ..................................................................................................... 49

Table 10 : MODBUS Input Register............................................................................................... 52

Table 11 : List of commands MODBUS RTU Interpreter................................................................ 53

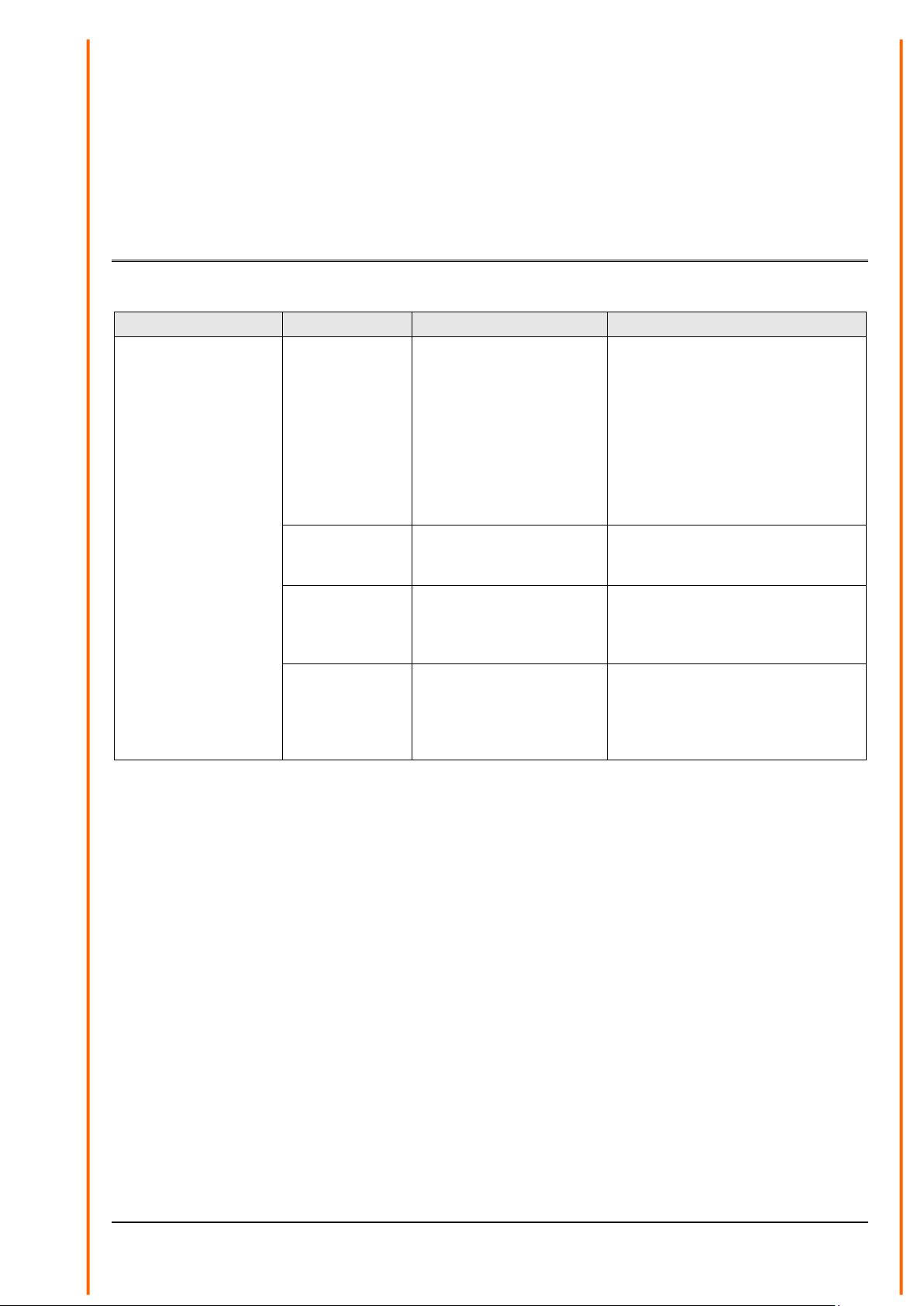

1 Models available

Description

Article- No. *

Parameter

Output / Interface/ Equipment

US-Anemometer 2D

compact

4.3875.0X.XXX Wind velocity

Wind direction

Virtual temperature

- 0 ... 20 mA / 0 ... 10 V

(4 ... 20 mA / 2 ... 10V)

- RS485/ 422

- 8 pole plug connection

- heating for:

base plate

cover plate

Sensor receiving sockets

US-transducer

- hard-anodized housing

4.3875.1X.XXX

Wind velocity

Wind direction

Virtual temperature

- w/o heating for US-transducer

4.3875.2X.XXX Wind velocity

Wind direction

Virtual temperature

Barometric air pressure

- with optionally integrated

Baro-transmitter

4.3875.XX.XXX Depending on article nol. Configuration concerning

- outputs

- data telegrams

- scaling

- etc.

* The complete article-no. results from the arranged equipment and configuration.

7 - 68 021546/12/17

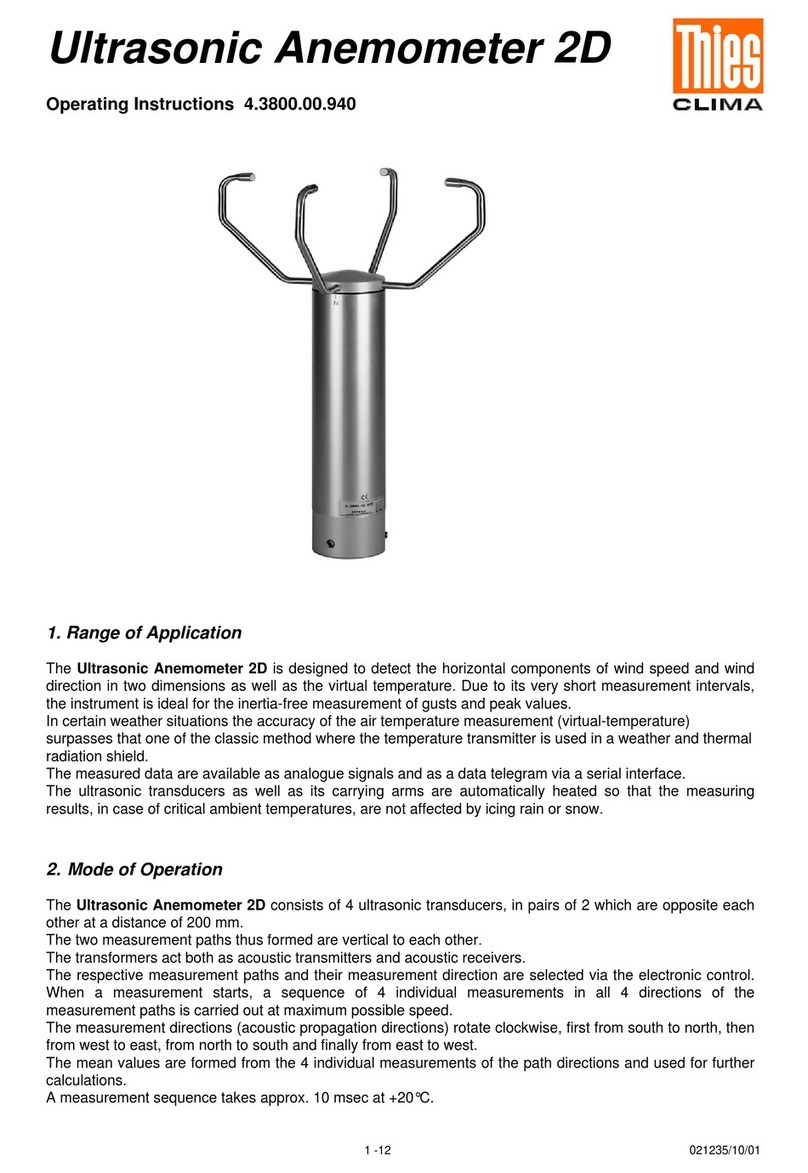

2 Application

The Ultrasonic Anemometer 2D compact is used to detect the horizontal components of wind

velocity and wind direction in 2 dimensions in particular sturdy design. In addition, the virtual

temperature is measured.

Optionally, the measurement of the “atmospheric air pressure (absolute)” is possible.

The instrument is especially suited for application in the fields of

•Industrial automation

•Regenerative power generation (wind power plants)

•Building automation

•Traffic engineering/ control system

•maritime and offshore applications

Due to the measuring principle the instrument is ideal for inertia-free measurement of gusts and peak

values.

Output of the measured values can be either digital and / or analogue.

- analogue, as a standard signal or / and in

- ASCII (THIES format) or

- binary (MODBUS RTU protocol)

The analogue and digital interfaces operate in electrical isolation from supply and housing potential.

Thus, there is no galvanic connection, which might result in a superposition of interference currents

or voltages on the output signals.

Digital output: An RS485/422 is available for serial communication. It can be operated in full or half-

duplex mode. For the output of measured values there are a number of pre-defined telegrams (e.g.

WV, WD, WVx, WVy, NMEA etc.).

A MODBUS RTU protocol is additionally implemented for extended standardised communication.

The device can be switched to MODBUS-RTU mode with the relevant command.

Analogue outputs: Wind velocity and direction are output either as a power or voltage signal.

Individual measuring range scaling of the analogue outputs for WV and WD are selectable.

The serial or analogue output of the data is either as an instantaneous value or as a gliding mean.

The instrument is automatically heated if necessary with critical ambient temperatures. This also

ensures functionality with snowfall and sleet and minimises the risk of malfunctions due to icing-up.

Thanks to the optional integrated ultrasonic converter heating the instrument is especially suited to

cope with difficult icing conditions in high mountains and in other critical locations.

The instrument is equipped with a battery-buffered real-time-clock, so that the data telegrams are

output with date- and time-stamp.

8 - 68 021546/12/17

3 Mode of Operation

The Ultrasonic Anemometer 2D compact consists of 4 ultrasonic transformers, in pairs of two

facing each other at a distance of 200 mm. The two resulting measurement paths are vertical to each

other. The transformers function both as acoustic transmitters and receivers.

The electronic control system is used to select the respective measurement path and its measuring

direction. When a measurement starts, a sequence of 4 individual measurements is performed in all

4 directions of the measurement paths in a basis measuring cycle of one msec.

The measuring directions (sound propagation directions) rotate clockwise.

The mean values are worked out from the 4 individual measurements of the path directions and

used to make further calculations.

The time required for a measuring sequence is exactly 10.0 ms (8 ms measuring sequence +2 ms

analysis) at the maximum measuring speed.

3.1 Measuring Principle: Wind velocity and direction

The speed of propagation of the sound in calm air is superposed by the velocity components of an

airflow in the direction of the wind.

A wind velocity component in the propagation direction of the sound supports the speed of

propagation; i.e. it increases it while a wind velocity component against the propagation direction

reduces the speed of propagation.

The propagation speed resulting from superposition leads to different propagation times of the

sound at different wind velocities and directions over a fixed measurement path.

As the speed of sound greatly depends on the temperature of the air, the propagation time of the

sound is measured on each of the two measurement paths in both directions. This rules out the

influence of temperature on the measurement result.

By combining the two measuring paths, which are at right angles to each other, the measurement

results of the sum and the angle of the wind, velocity vector are obtained in the form of rectangular

components.

After the rectangular velocity components have been measured, they are then converted to polar

coordinates by the µ-processor of the anemometer and output as a sum and angle of wind velocity.

transducer 1

transducer 3

transducer 4

transducer 2

X-Component

Y-Component

Wind direction

9 - 68 021546/12/17

3.2 Measuring principle: Acoustic virtual temperature

The thermodynamic interrelationship between the propagation velocity of sound and the absolute

temperature of the air is defined by a root function. The sound velocity is also more or less

independent of the air pressure and only depends on the absolute air humidity to a minor extent.

This physical interrelationship between sound velocity and temperature is ideal when measuring

the air temperature as long as the chemical composition is known and constant.

The levels of gases in the atmosphere are constant and with the exception of water vapour content

vary at most by a few 100 ppm (CO2) even over lengthy periods.

Determination of gas temperature via its sound velocity is performed directly from measurement of

its physical properties without the step of thermal coupling of this gas to a sensor, which would

otherwise be necessary.

Remark:

Due to warming of the instrument by solar radiation or heating activity the

measuring value can be considered only conditionally as real measuring value,

particularly at low wind velocities.

3.3 Measuring principle: Air pressure (optional)

The air pressure is measured via an MEMS sensor, basing on a piezo-resistive technology. The

sensor is situated on the pc-board.

3.4 Heating

For many applications the continuous output of real measuring data of wind velocity and direction is

an essential requirement to the measurement system even under meteorological extreme

conditions such as icing situations.

The ultrasonic compact is, therefore, equipped with a sophisticated heating system which keeps a

temperature of above +10 °C on all outside surfaces, that might disturb the acquisition of run time

data by ice formation.

Among the heated outside surfaces there are the base plate, sensor receiving sockets of the

ultrasonic transducers, cover plate, and the ultrasonic transducer.

Please pay attention to the fact that the weakest link in the chain determines the complete

functionality. Instruments, which heat only parts of the construction, hardly show advantages over

completely unheated devices in icing situations.

The Ultrasonic Compact is capable to generate measuring data with high accuracy even in

unheated condition with temperatures of up to below -40 °C. There is no temperature dependency

of the measuring data quality. The heating is necessary only for preventing icing formation at the

instrument construction, so that possible disturbances of the run time acquisition can be avoided.

The heating system with a total maximum power of 250 W avoids effectively icing according to the

in-house icing standard THIES STD 012002.

10 - 68 021546/12/17

Thus, icing is safely avoided, for example, at a temperature of -20 °C up to a wind velocity of 10

m/s.

Functionality:

Heating foils and transistors are activated by a temperature sensor at an appropriate position inside

the housing via a two-level-controller, thus providing for a constant temperature at the outside

surfaces of approx. +10 °C. That means, that the total heating power is activated until the required

temperature is reached, and is alternately switched on and off (two-level-control) with a hysteresis

of approximately 1 Kelvin.

The necessary integral heating power depends on the thermal coupling to the surrounding air and

thus to the wind velocity.

With moderate weather conditions the maximum heating power can be pre-selected in several

stages.

See also description of parameter HT (heating), HP (heating power) and HC (heating condition)

The heating can be checked manually by a service technician. If one of the measured distances is

interfered for at least 2 s within the first 10 …190 s after switch-on, the heating switches temporarily

to “HT2”; the heating is activated in consideration of heating capacity “HP” and heating conditions

“HC”, and stays on up to the 190th second.

4 Preparation for operation

Attention:

The working position of the anemometer is vertical (North

arrow on the top).

During installation, de-installation, transport or maintenance of

the anemometer it must be ensured that no water gets into the

bottom and connector or cable gland of the anemometer.

When using a lightning rod take care that it be installed in a

angle of 45 ° to a measuring transducer; otherwise there will be

deviations in the measured values.

4.1 Selection of installation site

As described above, the ultrasonic anemometer transmits sound packages required to measure the

propagation speed. If these sound packages meet surfaces that reflect sound well, they are

thrown back as an echo and can may result in incorrect measurements under unfavourable

conditions.

It is therefore advisable to install the ultrasonic anemometer at a minimum distance of 1 metre to

objects in the measuring level.

The choice of the installation location depends on the task position (e.g., data acquisition for

weather services or for control purposes).

11 - 68 021546/12/17

In general, wind meters should register wind conditions over a wide area. To obtain comparable

values when measuring the ground wind, measurement should be performed at a height of 10

metres above even and undisrupted terrain. Undisrupted terrain means that the distance between

the wind transmitter and the obstruction should be at least ten times the height of the obstruction (s.

VDI 3786, sheet 2). If it is not possible to comply with this provision, the wind meter should be

installed at a height at which measured values are influenced by obstructions located in the vicinity

to the least possible extent (approx. 6 … 10 m above the interference level). On flat roofs the

anemometer should be installed in the middle of the roof and not at the edge to thus avoid any

preferential directions.

The ultrasonic-anemometer has an electro-magnetic compatibility, which is far in excess of the

required standard threshold value.

Within the complete frequency range, required by standard, electro-magnetic fields with 20 V/m

(capacity of the test transmitter) could not affect the measuring value acquisition of the instrument.

In case you intend to install the instrument at transmitter masts or other sources of strong electro-

magnetic radiation, where the local field strength is far above the standard threshold value, please

contact the manufacturer.

4.2 Installation of Anemometer

Mechanical installation

Proper installation of the ULTRASONIC ANEMOMETER 2D compact is carried out using a tube

socket R1½" (Ø 48.3 mm) and at least 40 mm in length. The inside diameter of the tube socket

must be at least 25 mm as the electrical connection of the ULTRASONIC is carried out at the

bottom of the device.

Tool:

Hexagon socket wrench Gr.4

Procedure:

1. Conduct and connect the cable/ plug

connection of the ultrasonic anemometer

through the boring of the mast, tube, bracket

etc.

2. Put the ultrasonic anemometer onto the mast,

tube etc.

3. The ultrasonic anemometer "Positioning".

See chapter 4.3

4. Lock the ultrasonic anemometer afterwards at

the mast by the four M8 hexagon socket

screws.

Caution:.

The allen screws must be tightened to

max. 7 Nm

12 - 68 021546/12/17

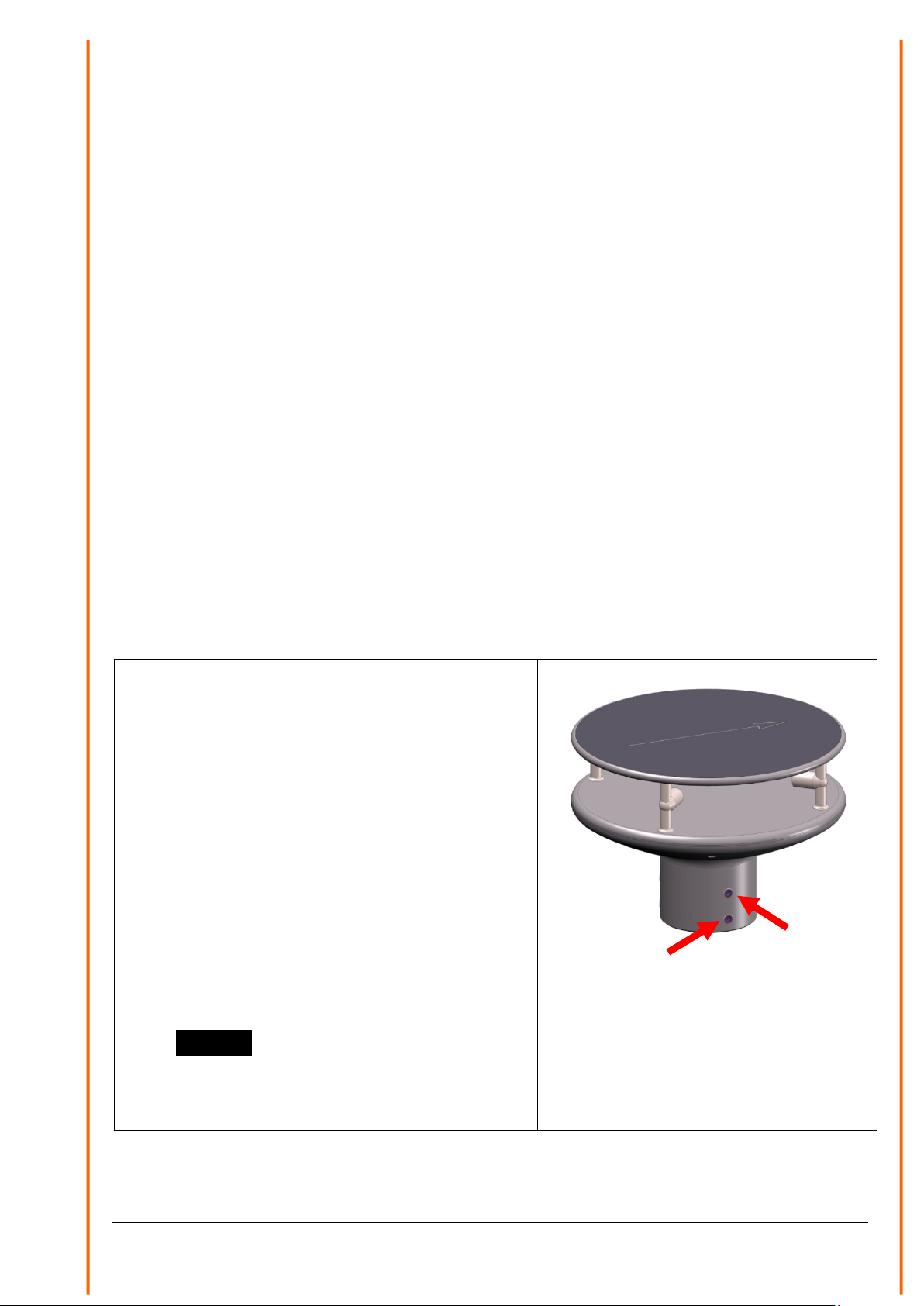

4.3 Alignment to north / Positioning

North Alignment (Positioning) of the Anemometer at a Weather Station

For the accurate determination of the wind direction, the anemometer must be positioned to the

north.

Procedure:

1. „Position“ the ultrasonic anemometer by

rotating on the mast tube until the

Orientation arrow indicates to northern

direction (geographical north).

For this, please choose, in advance, a

prominent point of the land scape in northern

or southern direction by using a compass, und

and rotate the mast or the anemometer until

the Orientation arrow indicates to northern

direction (geographical north).

2. Lock the ultrasonic anemometer afterwards at

the mast by the four M8 hexagon socket

screws.

Caution:.

The allen screws must be tightened to

max. 7 Nm

Note:

When aligning the instrument to north using a

compass, the magnetic variation (= deviation in

direction of compass needle from true north) and local

interfering magnetic fields (e.g. iron parts, electric

cables).

As additional positioning aid, or for a simple change

without re-alignment you may use also the position

drillingin the base. Precondition, however, is a

preparation by user at the mast.

13 - 68 021546/12/17

Positioning of an Anemometer on a Wind Power Plant

For the exact determination of the wind direction the anemometer must be mounted in alignment

with the generator hub.

Procedure (at generator hub north):

1. „Position“ the ultrasonic anemometer by rotating on the mast tube, until the orientation

arrow (in parallel to the generator axis) indicates towards the generator-hub.

2. Lock the ultrasonic anemometer afterwards through the four M6 hexagon socket screw at

the mast.

Caution:.

The allen screws must be tightened to max. 7 Nm

Remark:

In order to avoid the discontinuity of the wind direction at the north leap (360 … 1°) the ultrasonic

anemometer should be aligned oppositely to the generator hub by means of the reference arrow.

Positioning of an Anemometer on a Ship

For the exact determination of the wind direction the anemometer must be mounted in alignment

with the roll-axis, where the bow is related to „0 °“ (north).

Procedure:

1. „Position“ the ultrasonic anemometer by rotating on the mast tube, until the orientation

arrow (in parallel to the generator axis) indicates towards the generator-hub.

Remark:

If the anemometer is far away from the roll-axis (center line bow-rear), a parallel line (bow-

rear) should be assumed.

2. Lock the ultrasonic anemometer afterwards through the four M6 hexagon socket screw at

the mast.

Caution:.

The allen screws must be tightened to max.7 Nm

4.4 Electrical Installation for Ultrasonic Anemometer

The ultrasonic anemometer is equipped with a plug for electrical connection. A coupling socket

(mating) is included in delivery. It is located in the lower part of the transport packing.

14 - 68 021546/12/17

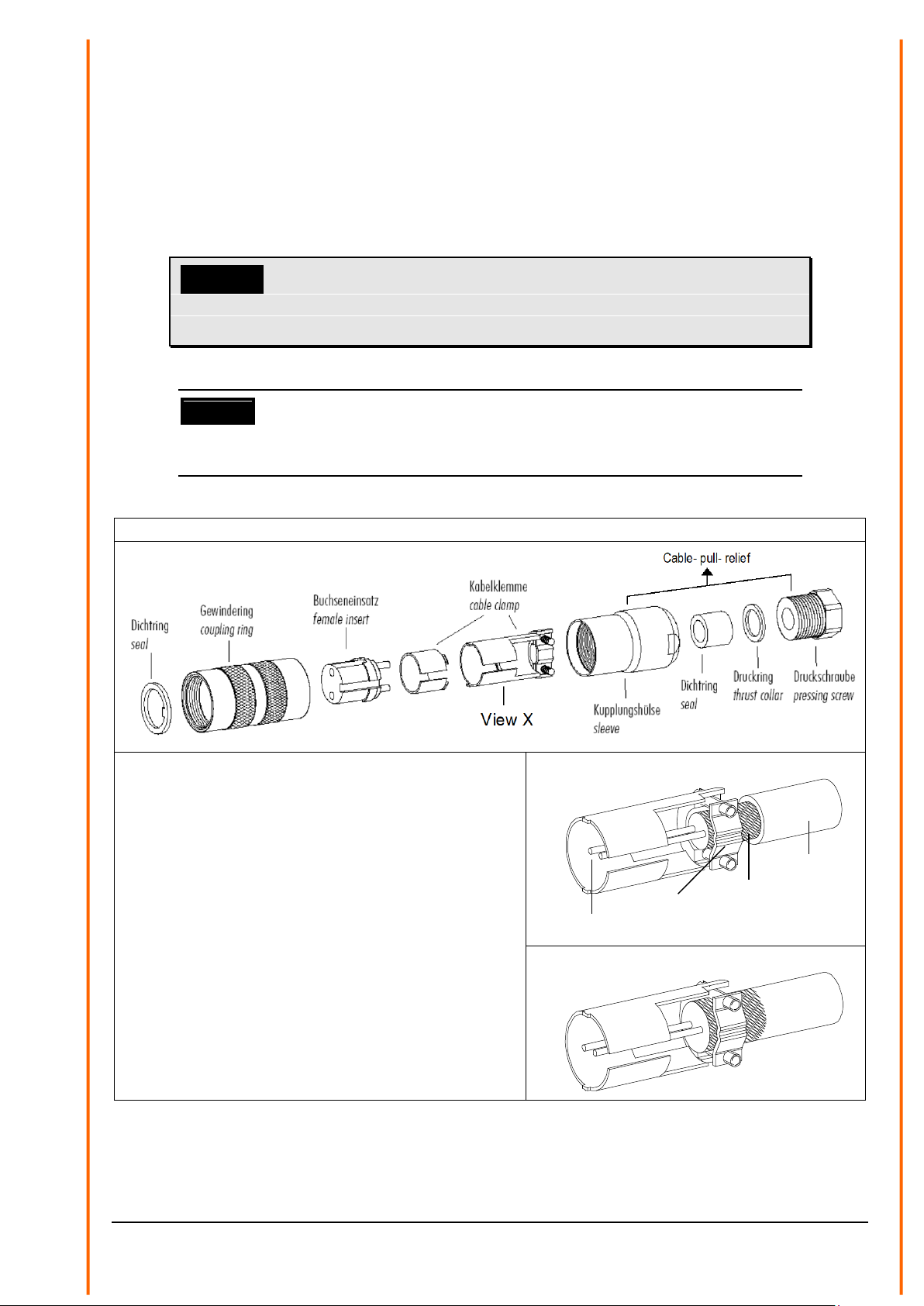

4.4.1 Cables, Cable preparation, Connector Installation

For pin assignment please refer to supplement „factory settings“. Examples see

chapter 3.4.2.

The cable must have the following properties:

8 cores; 0.5 … 0.75 mm² core cross-section for supply ; min. 0.14 mm² core cross-section for data

communications ; 7 … 8 mm cable diameter, resistant to ultraviolet rays, overall shielding.

Coution:

The cable to be connected must be at least the operating

voltage class 01 correspond HAR (100 V).

Remark:

Optionally, a completely converted connecting cable can be included in delivery

for the ultrasonic-anemometer (see accessories).

Coupling socket 507550, 8-pol., (Binder, Serial 423), EMC with cable clamp

1. Stringing parts on cable acc. to plan given above.

2. Stripping cable sheath 20 mm

Cutting uncovered shield 15 mm

Stripping wire 5 mm.

Cable mounting 1

Putting shrink hose or insolating tape between

wire and shield.

Cable mounting 2

If cable diameter permits, put the shield backward

on the cable sheath.

3. Soldering wire to the insert, positioning shield in

cable clamp.

4. Screwing-on cable clamp.

5. Assembling remaining parts acc. to upper plan.

6. Tightening pull-relief of cable by screw-wrench

(SW16 und 17).

Cable mounting 1

Viev X

wire

Cable clamp

shield

Cable shield

Cable mounting 2

Viev X

Figure 1: Connector installation

15 - 68 021546/12/17

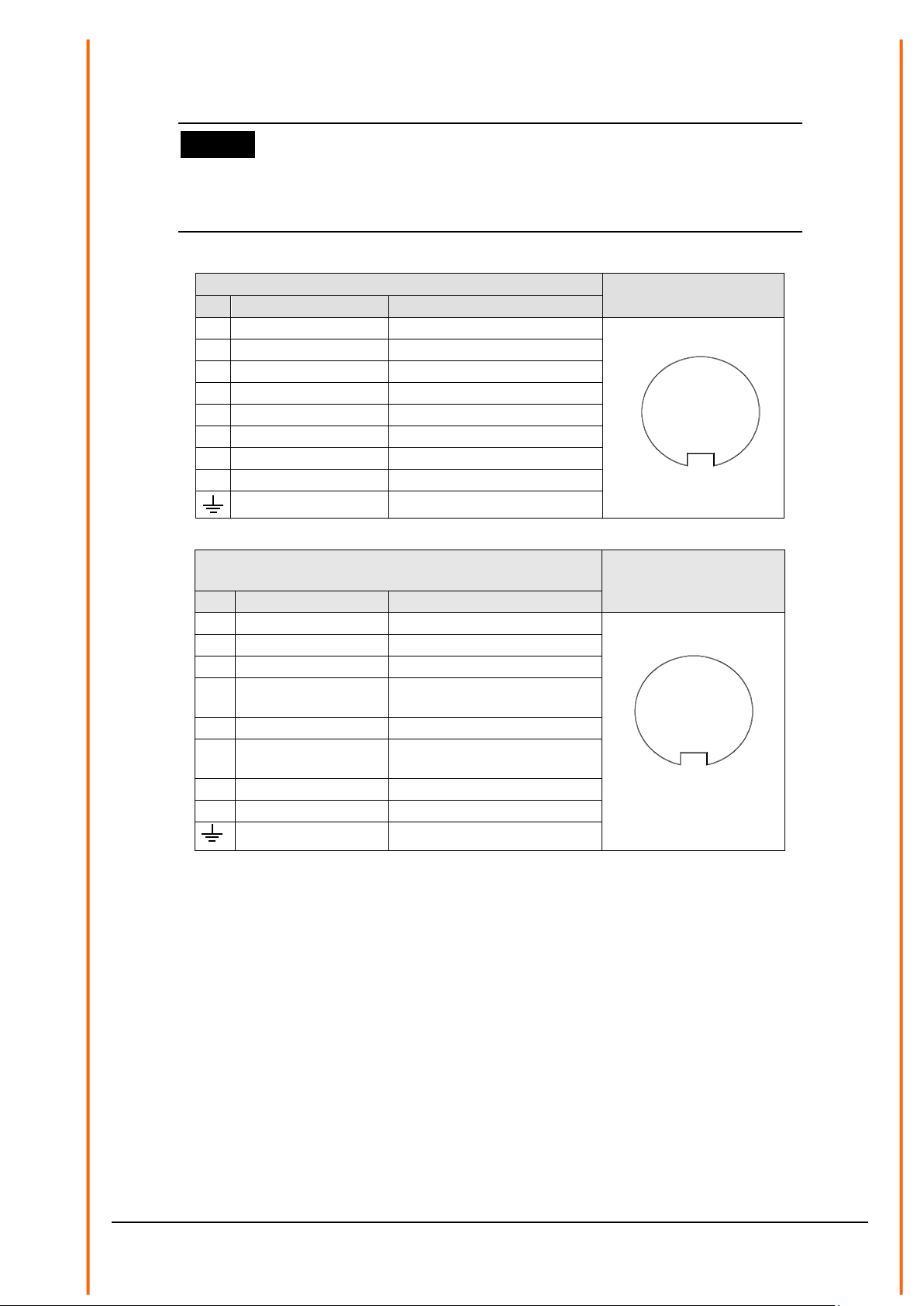

4.4.2 Connector Pin Assignment (Examples of Function)

Remark:

- For exact allocation of function please refer to supplement “Factory Settings”

- The pins 1 – 6 (incl.) are galvanically isolated from the supply voltage and from

housing.

•

Serial Interface, Full-duplex

View of solder terminal

of coupling socket

Pin

Allocation

Function

1

RXD-

Serial interface

2

TXD-

Serial interface

3

CONTROL

Function programmable

4

RXD+

Serial interface

5

TXD+

Serial interface

6

AGND

Ground for serial interface

7

24 V AC/DC nominal

(-) Voltage supply

8

24 V AC/DC nominal

(+) Voltage supply

Shield

•

Serial Interface, Half-duplex and

analogue outputs

View of solder terminal

of coupling socket

Pin

allocation

Function

1

WG

Analogue output wind speed

1

2

3

4

5

6

7

8

2

TXD- / RXD-

Serial interface

3

CONTROL

Function programmable

4

WR

Analogue output wind

direction

5

TXD+ / RXD+

Serial interface

6

AGND

Ground for analogue output

and serial interface

7

24 V AC/DC nominally

(-) Voltage supply

8

24 V AC/DC nominally

(+) Voltage supply

Shield

* reverse-polarity protected

1

2

3

4

5

6

7

8

16 - 68 021546/12/17

5 Maintenance

As the instrument does not have moving parts, i.e. is not subject to wear during operation, only

minimal servicing is required. The instrument is subject to natural pollution, the level of pollution

depends on the location. If necessary the instrument and the sensor surfaces can be cleaned from

soil Cleaning can be carried out as required using non-aggressive cleaning agents in water and a

soft cloth during routine checks.

Attention:

During storage, installation, de-installation, transport or

maintenance of the anemometer it must be ensured that no

water gets into the instrument stand and plug of the

anemometer.

6 Calibration

The ultrasonic anemometer does not contain any adjustable components such as electrical or

mechanical trimming elements. All components and materials used show invariant behaviour in

terms of time. This means that no regular calibration is required due to ageing. Errors in measured

values can only be caused by coarse mechanical deformation of the instrument and associated

changes in measurement path lengths.

The acoustic-virtual temperature can be used to check the effective-acoustic measurement path

length. A change of approx. 0.3 % in the measurement path length and thus a measuring error of

approx. 0.3 % for the wind velocity corresponds to a deviation in the virtual temperature of 1 K at 20

°C; there is a measuring error of approx. 1% for the wind velocity with a deviation of acoustic-virtual

temperature of approx. 3.4 K.

In the event of any change in the measurement paths of the anemometer the manufacturer should

be consulted regarding recalibration.

Important:

Mechanical damages with deformation of the instrument might

lead to measuring value errors.

7 Warranty

Damage caused by improper handling or external influences, e.g. lightning, do not fall under the

warranty provisions. The warranty entitlement expires if the instrument is opened.

Important:

The ultrasonic anemometer must be returned in the original

packaging as the warranty entitlement otherwise expires with

mechanical damage, e.g. deformation of measuring arms.

17 - 68 021546/12/17

8 Functional description

The functioning of the ULTRASONIC instrument is described below. Due to the limited number of

plug connections some functions exclude the simultaneous operation with other functions. Such

dependency is described in each case. There are also restrictions regarding the functional

definition of the cable connector. This is due to the double assignment of individual PINs.

8.1 Serial communication

The ULTRASONIC provides an RS485 / RS422 interface for serial communication. It can be

operated either in full or half duplex mode and at different baud rates.

The communication with the ULTRASONIC can be carried out, for example, by means of a

standard terminal program, in example, you can use the terminal software Tera Term.

On starting the ULTRASONIC the following parameters are output: firmware version, creation date

of firmware, serial number of instrument, system time, instrument ID as well as the duplex-mode of

the serial interface and the used command interpreter. The output is carried out with the last set

and stored baud rate.

Example:

------------------------

THIES-ULTRASONIC-COMPACT

Bootloader: V1.1

Version: 3.00 / RV0000

Feb 2 2016 / 07:40:35

Serial-No.: 000000000

System-Time: 8:57:58

System-ID.: 00

Serial-COM: 4-wire RS422

Interpreter: Thies

------------------------

Help: 00??<CR>

------------------------

The example shows that the ULTRASONIC with the instrument ID 00 is operating in full duplex

mode, and that the Thies interpreter is used, see command CI.

8.1.1 Duplex mode

Duplex mode decides the type of physical connection of the serial interface. In full duplex mode the

send and receive signals are each transmitted via separate pairs of cables. This means it is

possible to send and receive signals at the same time.

In half duplex mode transmission of the send and receive signals is via the same pair of cables in

the time division (successively) (: see Command DM.

For a bus operation in the half-duplex-mode (RS485), where the ULTRASONIC, in general, is

operated as “slave”, it is necessary to switch the line-transmitter into the “high–impedance-state”

during the intermission, so that the replies of the other bus parties are not suppressed.

It might be important with point-to-point-connections in the full-duplex-mode (RS422), depending on

the disturb-ratio on the communication lines, that the line-transmitter remains active during the

intermissions. So, a maximum differential input level leads to a maximum signal/noise ratio.

18 - 68 021546/12/17

A half-duplex-mode can be selected via the Command DM (duplex mode). With this mode, on

principle, the line-transmitter is switched on only when sending. For the full-duplex-operation there

are two modes: one for bus operation (RS485), where the line-transmitter is controlled as in half-

duplex mode, and another one (RS422), where the line-transmitter remains active even in case of

reception. See Command DM.

For the ULTRASONIC there are restrictions on the parameter combination or function of the

terminals depending on the transmission type selected. Due to the limited number of plug

connector contacts multiple assignment of the connections are necessary. The following table

shows the functional options for the modes full and half duplex.

Full duplex mode

Half duplex mode

Bus mode possible (RS 485, DM=1)

Bus mode not possible (RS 422, DM=2)

Bus mode possible (RS 485, DM=0)

No output of analogue values to PIN RXD- and

RXD+

Output of analogue values possible at PIN RXD-

and RXD+

Heating control via PIN CONTROL possible

Heating control via PIN CONTROL possible

Table 1: Restrictions in full and half duplex mode

8.1.2 Response Delay

With the serial communication please take into consideration that the ULTRASONIC responds

immediately to arriving telegrams. The response time of the instrument is in the lower range of

milliseconds. Possibly, the delay between receiving signal and sending signal might be too short for

some interface converters. It is possible that, within this time period, the interface converter has not

yet switched over from the mode ‘sending’ to the mode ‘receiving’. This might lead to absurd

telegrams.

In order to avoid this effect, the ULTRASONIC has the parameter RD (response delay). With this

parameter the response is additionally delayed, on receipt, by the selected value in milliseconds.

The setting of the parameter on state of delivery depends on the instrument number.

8.1.3 General telegram structure for the Thies Interpreter.

For serial communication the ULTRASONIC has a fixed telegram format, which also permits

communication in bus mode. It has the following form:

NNBB<cr> <cr> stands for Carriage return (Enter key)

for a data enquiry or

NNBBPPPPP<cr> <cr> stands for Carriage return (Enter key)

for a parameter change.

The individual letters have the following meaning:

NN: Two-digit ID of the ULTRASONIC. It can be selected in the range from 00 to 99. The

presetting is the ID '00': see also Command ID.

BB: Two-position command. A complete list can be found in section Command list.

PPPPP: The parameter input is always left-justified and can range from 0 to 5-digit

value.

19 - 68 021546/12/17

Examples:

1. Telegram number 2 shall be queried. The respective command is:

00TR2<cr> <cr> stands for Carriage Return (enter button)

alternatively also:

00TR00002<cr> can be entered.

2. Query of baud rate with the command:

00BR<cr> <cr> stands for Carriage Return (enter button)

the selected data record for the baud rate is returned.

!00BR01152 stands for 115200 baud

Requirement in these examples is, that the ULTRASONIC ID has the value ‚00’.

Remark:

The receiving buffer of the ULTRASONIC can be cleared by sending a carriage

return <CR>. If the ULTRASONIC possibly has invalid characters in the receiving

buffer, this buffer can be processed by sending a carriage return. In this case, it is

advisable to send a carriage return at the beginning of the telegram, for example:

<CR>00TR2<CR>

8.1.4 Saving of the ULTRASONIC Parameters

After a change in parameter by the user- or administrator-key, the ULTRASONIC must be reset into

the locked status by the command „00KY0“ (Key „00000“). (In this case the ULTRASONIC ID has

the value „00“).

Only by resetting the key or by storing command (00CS1) the parameters are saved

permanently also beyond a restart.

When restarting the ULTRASONIC without prior saving all changed parameters get lost; therefore,

it is recommendable to save all important parameters after termination of entry by resetting the key

(00KY0), or the by storing command (00CS1).

8.1.5 Return values of ULTRASONIC

After a valid command has been input, the ULTRASONIC sends acknowledgement, e.g.

acceptance of the parameter or output of a data telegram.

For a standard command the response starts with a '!', followed by the ID and the parameter value.

If the input command is TR or TT, the ULTRASONIC transmits a data telegram as the response.

20 - 68 021546/12/17

8.1.6 Access Mode

For configuration the ULTRASONIC has a set of commands, which determine behaviour in terms of

the propagation time. The commands are broken down into three levels:

•Query Mode

•User mode

•Configuration mode

Enquiry mode (“READ ONLY“):

This mode comprises commands, which do not influence the parameters of the ULTRASONIC.

They include for example, output of the system status and interrogation of the data telegram with

TR.

User mode (“USER“):

This mode comprises commands, which affect the behaviour of the ULTRASONIC. These

parameters can be changed by the user. The system behaviour of the instrument is changed with

these commands. This group of commands includes e.g. settings for output scaling and averaging

Configuration mode(“ADMIN“):

This mode comprises commands, which are factory-set for the delivery status.

To distinguish between commands of the three groups when parameterising the ULTRASONIC the

instrument is equipped with an access key KY. Inputting of the key accesses the individual levels.

Access to commands at a higher level includes access to commands at a lower level.

Access key Response from

ULTRASONIC

Command level

00KY00000 READ ONLY

!00KY00000 Query mode (preset)

00KY00001 USER ACCESS

!00KY00001 User mode

00KY04711 ADMIN ACCESS

!00KY04711 Configuration mode

Table 2: Access key for different command levels

After the access key has been changed, the ULTRASONIC transmits a response, which contains

not only the parameter input but also the access mode.

After parameters have been changed with the key '00001' or '04711', the ULTRASONIC must be

reset to the initial position with the command 00KY0, so that the parameter are saved. (see also

chapter 8.1.4).

In case of power supply interruption the instrument is reset automatically to the query mode.

This manual suits for next models

44

Table of contents

Other Thies CLIMA Measuring Instrument manuals

Thies CLIMA

Thies CLIMA First Class Advanced X User manual

Thies CLIMA

Thies CLIMA 4.3223.50 Series User manual

Thies CLIMA

Thies CLIMA Hygro-Thermo Transmitter-compact User manual

Thies CLIMA

Thies CLIMA Ultrasonic Anemometer 2D User manual

Thies CLIMA

Thies CLIMA 5.4110 00 Series User manual

Thies CLIMA

Thies CLIMA 9.2750.xx.90 Series User manual