THK PPR User manual

Smart Logo

PPR

INSTRUCTION MANUAL

Pick and Place Robot

Support is needed to improve quality and productivity.

Do you have these kinds of

problems at your worksite?

Problems

For solutions to these problems,

see the next page

I want to reduce workpiece damage and aim for zero defects!

Workpieces have gotten progressively more delicate,

so it is difficult to improve production speed without

causing damage.

1

Problem

I want to optimize the cycle time and improve productivity!

If acquisition of sensor information and motor control

are managed by the host, this causes several

milliseconds of downtime.

2

Problem

I want to visualize processes to stabilize quality!

Mounting many sensors results in larger equipment,

and you cannot maintain a short cycle time.

3

Problem

I want to reduce workpiece damage

I want to eliminate cycle downtime

I want to aim for stable quality

Solutions

The PPR Pick and Place Robot

provides the best solutions to

worksite problems.

The PPR solves a variety of issues, such as stabilizing quality and reducing cycle

time.

Uses load control with high-resolution force sensors to

quickly stop the moment the suction nozzle contacts the

workpiece.

This prevents impacts to the workpiece, reducing damage!

1

Solution Reduces workpiece damage

Has integrated control of the various sensors, air devices, and

drives required for pick and place operations.

This reduces the number of communications with the

host, contributing to a shortened cycle time!

Achieves visualization of various sensors for force, flow rate,

pressure, temperature, etc.

This makes it possible to find the source of problems,

which helps achieve stable quality!

2

Solution Shortens cycle time

3

Solution Visualizes pick and place processes

i

Contents

1. Introduction 1

1-1 Acknowledgment 1

1-2 About this manual 1

1-3 How to use this product 2

1-4 About product support 2

2. Safety precautions 3

2-1 About ranks of precautions 3

2-2 About descriptions of precautions 3

2-3 Safety precautions 4

3. Product overview 5

3-1 Checking the product and accessories 6

3-2 Product model numbers 7

3-3 8

3-3-1 8

3-3-2 Selecting peripheral devices 9

3-4 Names and functions of each part 11

3-4-1 Head 11

3-4-2 Controller 12

3-4-3 13

4. Installation 14

4-1 Precautions for installation 15

4-2 Installing the head 17

4-2-1 Installation environment for the head 17

4-2-2 18

4-2-3 Installation standards for the head 20

4-2-4 Installation method for the head 20

4-3 Installing the controller 23

4-3-1 Installation environment for the controller 23

4-3-2 23

4-3-3 Installation standards for the controller 24

4-3-4 Installation method for the controller 26

5. Wiring/piping 29

5-1 Safety precautions for wiring/piping 30

5-1-1 EMC countermeasures 30

5-2 Electrical system wiring 33

5-2-1 Power supply 33

ii

Contents

5-2-2 Wiring the head cables 33

5-2-3 USB connection (PC connection) 34

5-2-4 LAN connection (PLC connection) 34

5-3 Pneumatic system piping 35

5-3-1 Handling method for tubes 35

5-3-2 Mounting nozzles 36

6. PC application program settings 37

6-1 38

6-1-1 PC environment 38

6-1-2 Installation procedure 39

6-1-3 Uninstallation procedure 41

6-1-4 Starting the application 42

6-1-5 44

6-1-6 44

6-1-7 Language setting 45

6-1-8 Clock setting 45

6-1-9 Device name settings 46

6-1-10 Version information 47

6-2 48

6-2-1 Starting/Stopping Trial run mode 48

6-2-2 Trial run mode "Individual motion" tab 50

6-2-3 53

6-2-4 Trial run mode "User origin and limit settings" tab 54

6-3 Sequence programs 58

6-3-1 58

6-3-2 How to create a project 58

6-3-3 How to create a sequence 60

6-3-4 Advanced settings for sequences 67

6-3-5 Target value pointer settings 80

6-3-6 Step complete 82

6-3-7 83

6-4 Trial run/Monitor functions 86

6-4-1 Trial run mode "Sequence" tab 86

6-4-2 Monitor mode 88

6-4-3 Graph area operations 90

6-4-4 95

6-4-5 Present value list display 99

6-4-6 Condition list display 99

6-5 Tuning function 101

6-5-1 Trial run mode "Mass estimation" tab 101

iii

Contents

6-5-2 103

6-5-3 Understanding gain adjustment 106

6-6 Event history function 108

6-6-1 Viewing event history 108

6-6-2 Event code list 109

6-6-3 Acquire present waveform data 110

6-6-4 Status display 110

6-6-5 Initializing event history 110

6-6-6 Event history settings 110

6-6-7 Clear all alarms 112

7. PLC interface settings 113

7-1 Network environment construction 114

7-1-1 "Cyclic communications" and "Message communications" 114

7-1-2 PC application settings 114

7-1-3 PLC settings 117

7-2 Cyclic communications 120

7-2-1 Cyclic communications function list 120

7-2-2 Cyclic communications memory map 121

7-2-3 Cyclic communications timing charts 132

7-3 Message communications 136

7-3-1 Message communications function list 136

7-3-2 Message communications memory map 136

7-3-3 Event history acquisition methods with EtherNet/IP 142

7-3-4

Device information/event history acquisition methods with Ethernet (TCP/IP)

142

7-3-5 Procedure for event waveform data acquisition 143

7-3-6 Message communications timing charts 144

8. Troubleshooting 145

8-1 Event list 146

8-1-1 Event list 146

8-2 Troubleshooting 148

8-2-1 Causes and countermeasures for alarms 148

9. Maintenance and warranty 152

9-1 Maintenance and inspection 153

9-1-1 Precautions for maintenance/inspections 153

9-1-2 Inspection items for the head 153

9-1-3 Maintenance product model number and package contents 153

9-1-4 Greasing the LM Guide 153

9-2 Repair/Replacement 154

iv

Contents

9-2-1 154

9-2-2 Replacing the pneumatic module 155

9-3 Product warranty 156

9-3-1 Free warranty period 156

9-3-2 Usage conditions (range) 156

9-3-3 Warranty scope 156

9-3-4 158

9-3-5 Delivery conditions 158

10. Technical materials 159

10-1 160

10-1-1 160

10-1-2 161

10-2 MECHATROLINK-III interface 163

10-2-1 MECHATROLINK-III communications 163

10-2-2 Communication settings 166

10-2-3 Command list 166

10-2-4 Command format 167

10-2-5 Main commands 172

10-2-6 181

1

1. Introduction

1-1 Acknowledgment

Thank you for purchasing the PPR Pick and Place Robot. This product is a robot optimized for

pick and place applications that supports linear and rotary operation and also has pneumatic

equipment and various sensors built-in.

This is a new product that achieves a reduction in workpiece damage and a shortened cycle

time, which are two important goals for production sites for electronic components and so forth.

We hope that this product, which was created with THK's original ideas and technology, is useful

for further development of your business.

1-2 About this manual

Intended audience

This instruction manual is intended for the following users.

Those who design equipment using this product

Those who perform maintenance of equipment using this product

Those who perform wiring or installation of equipment using this product

Those who actually operate equipment using this product

Using this manual

This manual describes correct handling methods and precautions for this product.

Ensure that you thoroughly understand this manual in order to safely and correctly use the

product.

Also, be sure to keep this manual where the intended audience can refer to it when needed.

Notices and points to remember

Do not use or handle the product in ways that are not described in this manual.

Do not reproduce, reprint, or lend the contents of this manual in whole or in part without

permission.

Please note that the contents of this manual are subject to change in the future without prior

notice, due to product improvements or other reasons.

technical support center.

products should take precedence over this manual.

the standard products in catalogs.

Trademarks

MECHATROLINK is a registered trademark of the MECHATROLINK Members Association.

Windows is a registered trademark of Microsoft Corporation in the United States.

2

1. Introduction

1-3 How to use this product

This product cannot be used for devices or systems that are used under situations that can

If you are considering using this product for special applications such as passenger vehicle,

medical, aerospace, nuclear power, and electric power devices or systems, be sure to consult

with the PPR sales/technology support center in advance.

This product is manufactured under strict quality control. However, that does not mean that

the product is incapable of failure. For applications in which equipment may cause serious

accidents or losses if this product should fail, install safety devices or backup devices in order

to prevent such accidents or losses.

1-4 About product support

▶Product and company information

We recommend that you periodically check the THK website for the latest product and company

information.

Website URL: http://www.thk.com/

3

2. Safety precautions

Before performing the installation and wiring for this product, carefully read the safety

precautions.

are listed in the relevant parts of this manual.

2-1 About ranks of precautions

Danger Incorrect handling has a significant possibility

of causing death or serious injury

Warning Incorrect handling may cause death

or serious injury to a person

Caution Incorrect handling may cause injury

to a person or property damage

2-2 About descriptions of precautions

This mark indicates

"prohibition" of the

action.

This mark indicates

an "instruction" for

the action.

This mark indicates

"caution" about the

action.

Prohibited

Pacemaker wearers

stay back

Do not

disassemble

Instruction Provide

ground wire

Caution Risk of electrical

shock

Flammable

High

temperature

Powerful

magnet

4

2. Safety precautions

2-3 Safety precautions

Always observe the precautions in this section.

Danger

Pacemaker

wearers stay

back

Those who use a pacemaker or

similar medical equipment must

not come within 30 cm of the

product.

The product contains a powerful

magnet that may cause the medical

equipment to malfunction.

Warning

Prohibited

Do not enter the work area,

including the area around the

conveyed object, while the head

is operating or in an operable

state.

Otherwise, you may be injured due to

contact with moving parts.

Instruction

If the product fails or any

abnormality is observed, shut

down the power to the body.

Otherwise, the product may

malfunction, resulting in damage or

injury.

Risk of electrical

shock

Do not touch the internal part of

the controller. Make sure to turn

o the power before touching

the internal part of the head

when performing maintenance.

Otherwise, this may cause electric

shock.

Do not damage, tuck, or apply

excessive stress to the cables.

Otherwise, this may cause electric

shock.

Do not

disassemble

Do not modify, disassemble, or

alter the product with additional

machining. (Excluding the

relevant parts when performing

maintenance on the head)

Otherwise, this may cause injury or

failures.

Powerful magnet

Do not handle magnetic

substances in the vicinity of the

product.

The powerful magnet contained in

the product will attract ferric objects,

which may cause injury or damage

due to a body part being pinned to the

device, etc.

High

temperature

Do not touch the head during

operation or for a while after

turning the power o, as it will

be hot.

Otherwise, this may cause burns.

Caution

Prohibited

Do not apply impacts to the

product, and be sure to avoid

any rough handling such as

throwing it.

Otherwise, this may cause failure or

damage that could result in injury.

Do not apply a load to the

head that exceeds the product

specications.

Doing so may cause motor failure,

accidents. This may also cause

damage to the product.

Instruction

If an alarm is generated,

remove the cause and check

that everything is safe before

deactivating the alarm and

restarting operation.

Otherwise, this could cause injury

due to failure.

Powerful

magnet

Avoid bringing objects subject

to magnetic force, such as

electronic equipment like PCs,

electronic medical equipment,

watches, magnetic tapes, and

credit cards, in the vicinity of

this product.

Otherwise, this may cause these

objects to malfunction or fail, or the

magnetic records to disappear.

Flammable

Observe the specied input

voltage.

failure.

Provide ground

wire

Be sure to perform grounding

for the FG terminal of the

controller.

If the FG terminal is not grounded,

there is a risk that the product could

malfunction.

5

3. Product overview

About this chapter

This chapter introduces the overview of the PPR Pick and Place Robot for customers that will

use this product.

It provides information that you will need to know before you start using the product.

This section describes the package contents

and precautions for the unpacking, storage,

and disposal of this product.

This section describes the product model

numbers for this product.

-

tion and how to select peripheral devices for

this product.

This section describes the names and func-

tions of each part of the body of this product.

3-1 Checking the product and accessories.....................6

3-2 Product model numbers ...........................................7

3-3 ................................................8

3-4 Names and functions of each part..........................11

6

3. Product overview

Caution

Prohibited

Do not stand on this product or the packaging box.

Otherwise, this may cause failure of or damage to the product or packaging, which

could lead to injury.

When carrying the product, do not pull on the cable.

Otherwise, this may cause failure of or damage to the cable, which could lead to

injury.

Do not use the product if you nd any abnormalities.

Using a damaged product may cause malfunctions that could lead to injury or

center.

3-1 Checking the product and accessories

Upon receipt of the ordered product, immediately check the product model and product model

wiring work.

Package contents for each product

▶Head

Head body: 1 unit

Positioning pins: 2 pcs.

Safety precautions: 1 sheet

Precautions on use: 1 sheet

▶Controller

Controller body: 1 unit

Power connector (Plugs into controller body): 1 pc.

Safety precautions: 1 sheet

▶Cable

Dedicated head cable: 1 pc.

7

3. Product overview

Precautions for unpacking

Upon receipt of the ordered product, immediately check the following. If anything is unclear,

please contact the PPR sales/technical support center.

Do the product models, product model numbers, and accessories match what you ordered?

Using an incorrect product may cause malfunctions that could lead to injury or failure.

Are any parts of the product damaged? Using a damaged product may cause injury or failure.

Storage and disposal of products

▶For storage

If the product will not be used for a while, wrap the head and controller in packaging materials,

gas will not be generated or be present in the air, and a location without direct sunlight or

radiant heat

An indoor location with an ambient temperature of -10°C to 60°C (no freezing)

An indoor location where the ambient humidity is 90% RH or less (no condensation)

A location where vibrations or impacts are not transmitted

▶For disposal

When disposing of products, be sure to follow all of the appropriate laws and regulations.

Warning

Do not put the product into a re to dispose of it.

may cause injury.

3-2 Product model numbers

Product Model

Head PPR-LR3 PPR-LR3-LF1*

(for use with position control)

Controller PPR-CTR3

Dedicated head cable PPR-FXC1

(1 m)

PPR-FXC3

(3 m)

PPR-FXC5

(5 m)

* PPR-LR3-LF1 cannot use features that require a force sensor.

8

3. Product overview

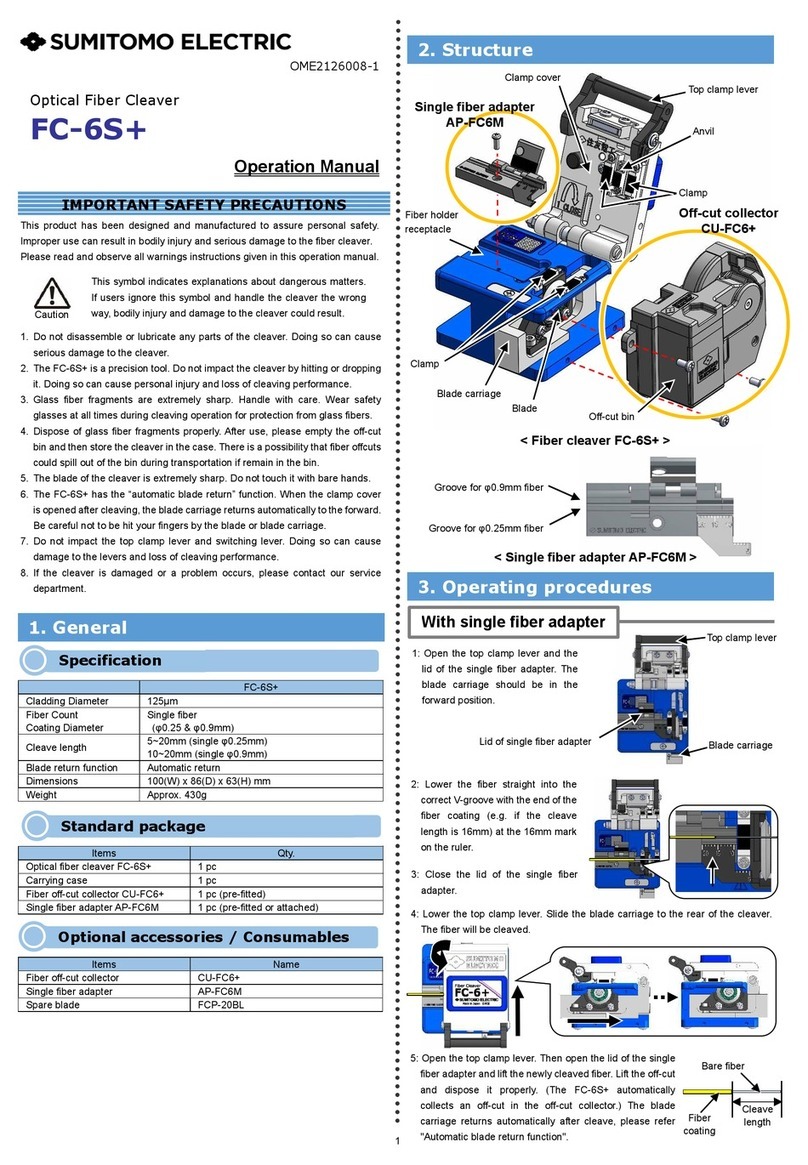

3-3 Systemconguration

to a PC and other necessary peripheral devices.

3-3-1 Systemcongurationexample

3-3-1-1Electricalsystemconguration

LAN cable

LAN cable

USB cable

Next controller or

another slave device

Communication type

• EtherCAT

• MECHATROLINK-III

• EtherNet/IP

• Ethernet (TCP/IP)

T

he peripheral devices marked with a

should be prepared by the customer

as necessary.

PC

Controller

Head

Dedicated head cable

PLC

Emergency stop switch

Power supply for main

circuit, control circuit

24 VDC ± 10%

Electromagnetic

contactor

Noise filter

Power supply

* The required

specifications for

LAN cables differ

depending on the

communication

type.

For details, refer to

"3-3-2 Selecting

peripheral devices."

3-3-1-2Pneumaticsystemconguration

For clean

rooms

Suction air

(negative pressure)

Suction air

(positive pressure)

Air cooling

(IN)

Air cooling

(OUT)

Negative pressure for clean rooms

Negative pressure for suction

(ejector/vacuum pump)

Positive pressure for suction

(compressor/atmospheric release)

Nozzle

* For details on peripheral devices for air

cooling, suction, and clean rooms, refer to

"3-3-2 Selecting peripheral devices." Filter

Filter

Filter

The peripheral devices marked with a

should

be prepared by the customer as necessary.

* A nozzle suitable for workpiece suction

should be prepared by the customer.

Exhaust for air cooling

Positive pressure for air cooling

9

3. Product overview

3-3-2 Selecting peripheral devices

Power supply

Controller power supply capacity

The power supply capacity for one controller is shown below.

Be sure to use this as reference when selecting your own peripheral devices.

Power supply capacity (per 1 unit)

Power supply voltage Output current

24 V ± 10% 4 A or more

Host device

Host device (PLC)

The PPR controller supports four communication types: EtherCAT, MECHATROLINK-III,

EtherNet/IP, and Ethernet (TCP/IP).

LAN cable

the table below.

EtherCAT

Transmission line type Line/Star/Tree

Communication cable length 30 m between stations

Communication cable CAT5e STP (Shielded Twist Pair) cable (cross or straight)

Connector RJ45

MECHATROLINK-III

Transmission line type Cascade type, star type

Communication cable length 30 m between stations

Communication cable CAT5e STP (Shielded Twist Pair) cable (cross)

Connector RJ45

EtherNet/IP

Transmission line type Star/Tree

Communication cable length 30 m between stations

Communication cable CAT5e STP (Shielded Twist Pair cable) cable (cross or straight)

Connector RJ45

Ethernet (TCP/IP)

Transmission line type Star/Tree

Communication cable length 30 m between stations

Communication cable CAT5e STP (Shielded Twist Pair) cable (cross or straight)

Connector RJ45

10

3. Product overview

Pneumatic devices

* Be sure to prepare pneumatic devices for air cooling, suction, and clean rooms in separate

systems.

* For details about handling pneumatic devices, refer to the instruction manuals for each

product.

For air cooling

When using devices in a stacked installation or high-load operations, the internal temperature will

rise. Check the values of the temperature sensors, and cool the environment as necessary.

Observe the following conditions when preparing air for air cooling.

Use dry air.

For suction

The volume of space from the shaft tip to the electromagnetic valve is 1 mL.

When selecting positive pressure pneumatic devices, choose compressors, etc. capable of

breaking the required vacuum. Even if you do not connect anything, atmospheric release will

occur when the release valve is opened.

Observe the following conditions when preparing air for suction (positive pressure).

Use dry air.

Restrict the air pressure to 0.2 MPa (G) or below.

For clean rooms

11

3. Product overview

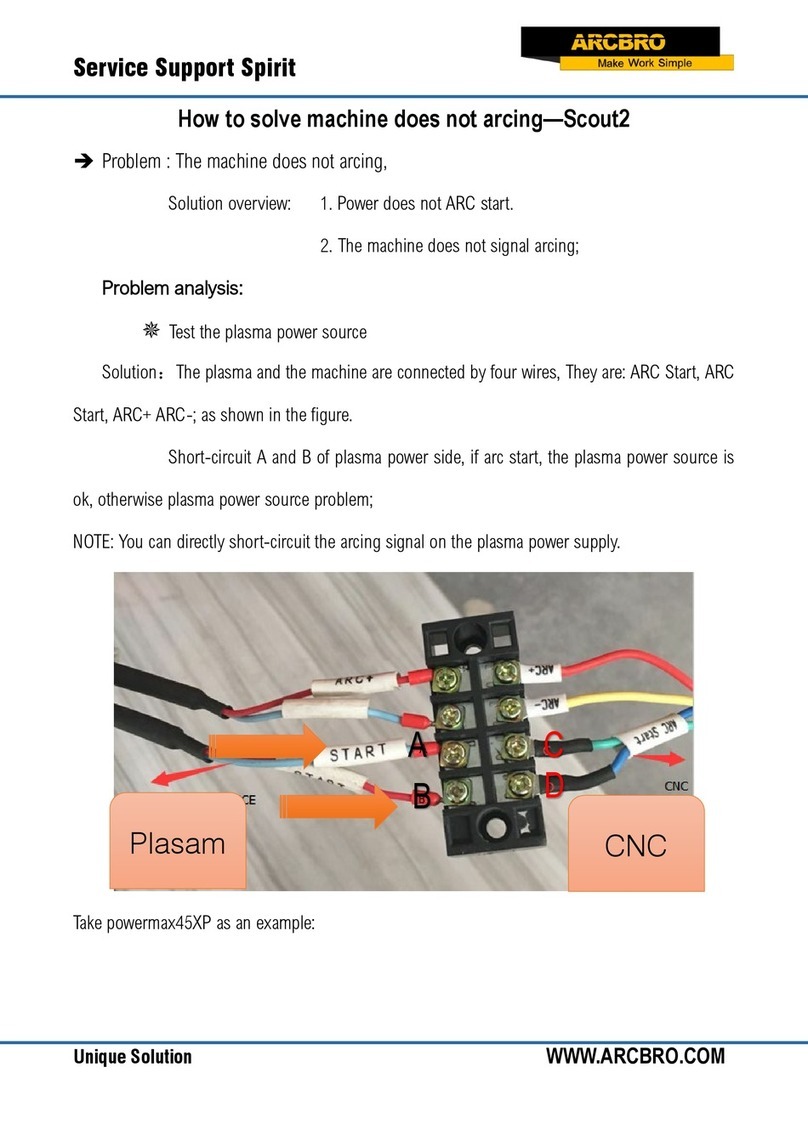

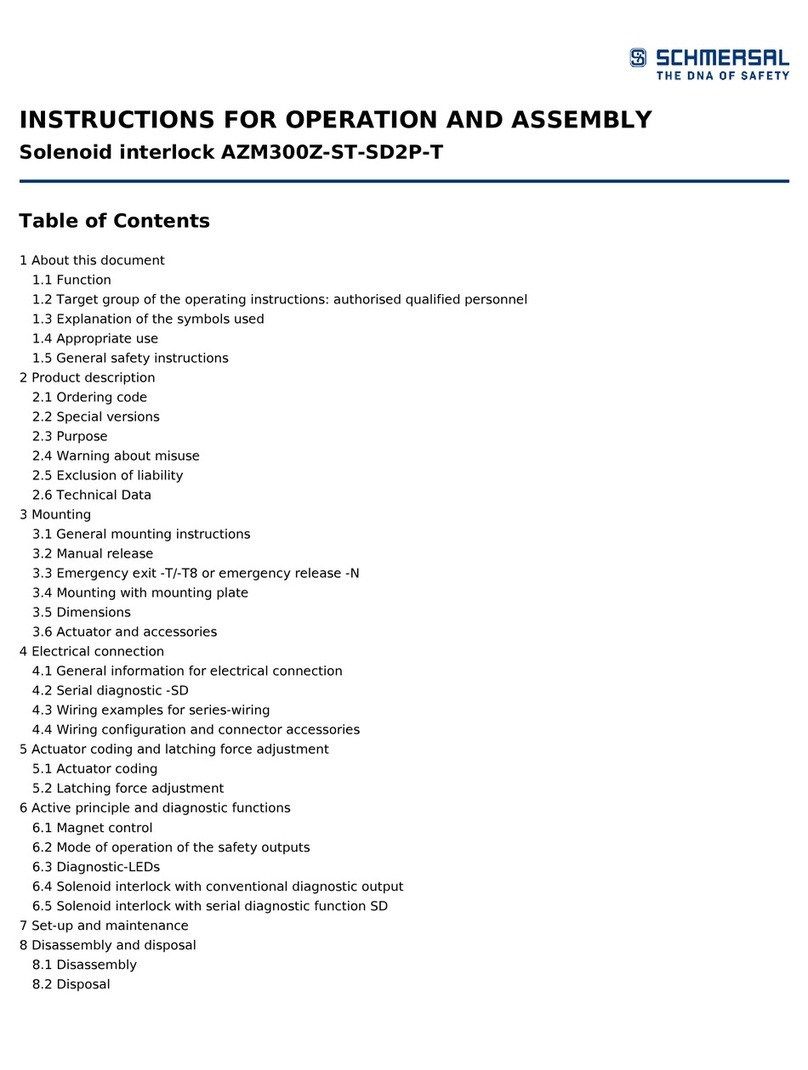

3-4 Names and functions of each part

3-4-1 Head

(4) Fitting for clean rooms

(3) Fitting for suction air

(negative pressure)

(3) Fitting for suction air

(positive pressure)

(2) Fitting for air cooling (IN)

(2) Fitting for air cooling (OUT)

(1) Power/communication connector

(5) Status display

LED

(10) Shaft

(9) Clean cover

(6) Front cover

(7) Filter replacement port

(8) Clean tube

* This image shows a head with the front cover mounted in the standard orientation.

Name Function

(1) Power/communication

connector

A connector that connects to the controller.

For details about the cable connection, refer to "5-2

Electrical system wiring."

(2) Fitting for air cooling

head.

Connect a compressor, etc. on the IN side.

For details about the piping method, refer to "5-3 Pneumatic

system piping."

For details about selecting peripheral devices, refer to "3-3-

2 Selecting peripheral devices."

(3) Fitting for suction air

release valve.

For details about the piping method, refer to "5-3 Pneumatic

system piping."

For details about selecting peripheral devices, refer to "3-3-

2 Selecting peripheral devices."

(4) Fitting for clean rooms

generated inside the head.

For details about the piping method, refer to "5-3 Pneumatic

system piping."

For details about selecting peripheral devices, refer to "3-3-

2 Selecting peripheral devices."

Name Function

(5) Status display LED Displays the status of the head as follows.

Green lit: Servo ON

Red lit: Alarm

(6) Front cover Covers the internal piping used for suction of contamination.

Equipped to the display part of the status display LED.

(7) Filter replacement

port

Collects any contaminants that enter from the shaft tip in a

(8) Clean tube A tube through which contaminants generated inside are

suctioned out.

(9) Clean cover A cover used to suction out contaminants generated inside.

(10) Shaft The output shaft.

The shaft is hollow, and by connecting to suction air, the

shaft end can be changed between release (positive

pressure) and vacuum (negative pressure).

For details about how to mount the nozzle, refer to "5-3-2

Mounting nozzles."

12

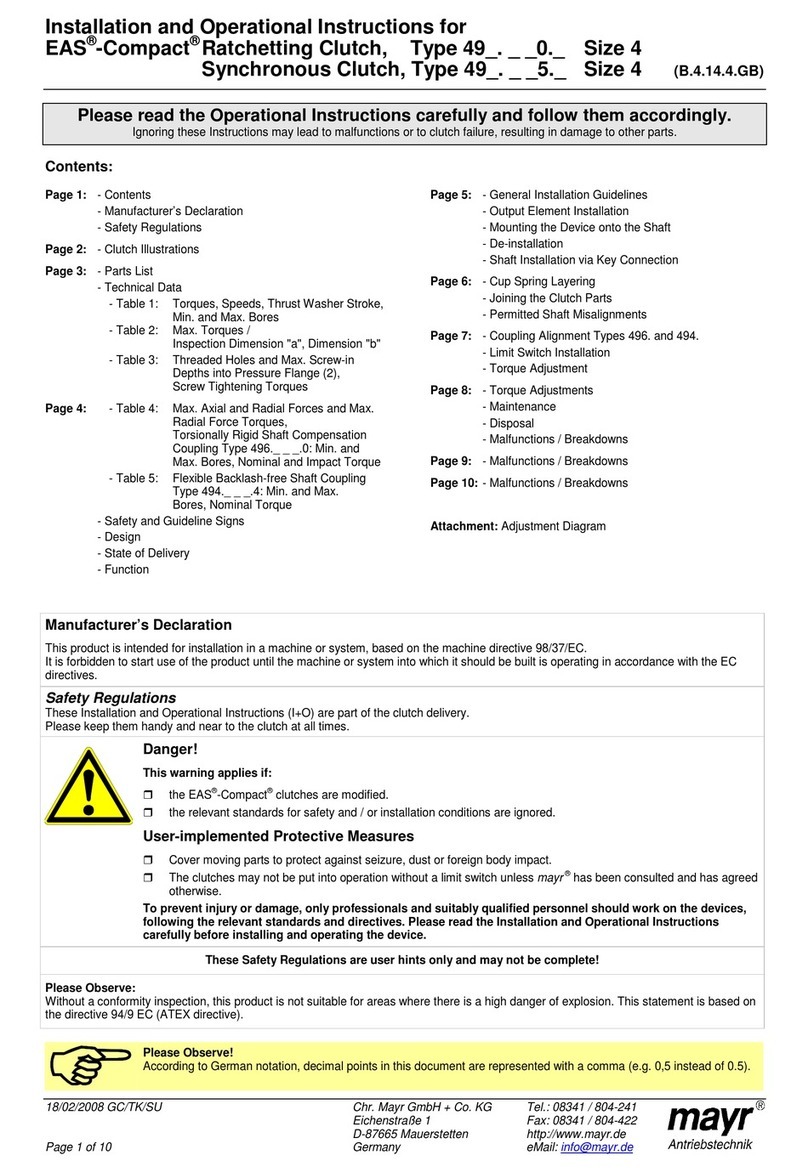

3. Product overview

3-4-2 Controller

(11) Release lever

(7) PLC communication

connector (IN)

(8) PLC communication

connector (OUT)

(9) Head connector

(10) Power connector

(6) USB connector

(12) DIN rail mounting part

(1) POWER LED

(2) CONT/RUN LED

(3) ERR LED

(4) USB LED

(5) LINK/ACT LED

Name Function

(1) POWER LED Shows the power status.

If 24 V of power is being supplied, it lights up green.

(2) CONT/RUN LED Shows the connection status of the PLC network.

of network.

For more details, refer to "3-4-3 PLC network communication

(3) ERR LED Shows abnormal statuses of the PLC network, head, and

controller. It will light up red in the following cases.

・

Head alarm

・

Controller alarm

・

Head and controller are disconnected

・

Disconnection after establishing PLC network

communication

It also shows an abnormal status of the PLC network when

For more details, refer to "3-4-3 PLC network communication

(4) USB LED Shows the USB communication status.

If USB communication is established, it lights up green.

(5) LINK/ACT LED Shows the connection status of the PLC network.

of network.

For more details, refer to "3-4-3 PLC network communication

Name Function

(6) USB connector A USB connector for PC communication.

USB connection (PC connection)."

(7) PLC communication

connector (IN)

A LAN connector for the PLC network connection.

For details about the PLC network connection, refer to "7

PLC interface settings."

(8) PLC communication

connector (OUT)

A LAN connector for the PLC network connection.

For details about the PLC network connection, refer to "7

PLC interface settings."

(9) Head connector A connector that connects the head and the communication

cable.

For details about routing the cables, refer to "5-2-2 Wiring

the head cables."

(10) Power connector A connector that supplies power to the controller.

For details about the wiring, refer to "5-2-1 Power supply."

(11) Release lever Used when mounting to a DIN rail.

For details about mounting to a DIN rail, refer to "4-3-4

Installation method for the controller."

(12) DIN rail mounting

part

13

3. Product overview

3-4-3 PLCnetworkcommunicationLEDspecications

LED Initial value

(init) Pre-Op Safe-Op Operational Cable

disconnect

EtherCAT

CONT/RUN (green) OFF

Blinking Single Flash

ON

Single Flash

Flashing (0.2 s) Flashing (0.2 s/1 s) Flashing

(0.2 s/1 s)

LINK/ACT (green) OFF Flickering Flickering Flickering OFF

(50 ms) (50 ms) (50 ms)

LED Normal Incorrect settings Status error WDT Alarm

ERR (red) OFF

Blinking Single Flash Double Flash

ON

Flashing (0.2 s) Flashing (0.2 s/1 s) Flashing

(0.2 s twice and 1 s wait)

LED Initial value

(init)

Normal

(CONNECT

command)

Normal

(DISCONNECT

command)

Alarm

MECHATROLINK-III

CONT/RUN (green) OFF ON OFF ON

LINK/ACT (green) OFF ON OFF OFF

ERR (red) OFF OFF OFF ON

LED Initial value

(init)

Normal

(No connections)

Normal

(Connected) Connection timeout Duplicate IP

EtherNet/IP

CONT/RUN (green) OFF Flashing

(1 s) ON OFF OFF

LINK/ACT (green) OFF Flashing Flashing Flashing OFF

ERR (red) OFF OFF OFF Flashing

(1 s) ON

LED Initial value

(init)

Normal

(LinkUp)

Normal

(Communicating) Alarm

Ethernet (TCP/IP)

CONT/RUN (green) OFF ON ON OFF

LINK/ACT (green) OFF ON Flashing OFF

ERR (red) OFF OFF OFF ON

Other THK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Datalogic

Datalogic STS400 installation manual

Burkert

Burkert 8695 Series operating instructions

schmersal

schmersal AZM300Z-ST-SD2P-T Operation instructions

Festo

Festo HSP Series Brief overview

Mayr

Mayr EAS-Compact 49 Series Installation and operational instructions

Ruffneck

Ruffneck XL4 Vacucore Series owner's manual