FC-6S+

Cladding Diameter

125μm

Fiber Count

Coating Diameter

Single fiber

(φ0.25 & φ0.9mm)

Cleave length 5~20mm (single φ0.25mm)

10~20mm (single φ0.9mm)

Blade return function Automatic return

Dimensions

100(W) x 86(D) x 63(H) mm

Weight

Approx. 430g

Items Qty.

Optical fiber cleaver FC-6S+ 1 pc

Carrying case 1 pc

Fiber off-cut collector CU-FC6+ 1 pc (pre-fitted)

Single fiber adapter AP-FC6M 1 pc (pre-fitted or attached)

Items Name

Fiber off-cut collector CU-FC6+

Single fiber adapter AP-FC6M

Spare blade FCP-20BL

OME2126008-1

Optical Fiber Cleaver

FC-6S+

Operation Manual

IMPORTANT SAFETY PRECAUTIONS

This symbol indicates explanations about dangerous matters.

If users ignore this symbol and handle the cleaver the wrong

way, bodily injury and damage to the cleaver could result.

Caution

1. General

2. Structure

This product has been designed and manufactured to assure personal safety.

Improper use can result in bodily injury and serious damage to the fiber cleaver.

Please read and observe all warnings instructions given in this operation manual.

1. Do not disassemble or lubricate any parts of the cleaver. Doing so can cause

serious damage to the cleaver.

2. The FC-6S+ is a precision tool. Do not impact the cleaver by hitting or dropping

it. Doing so can cause personal injury and loss of cleaving performance.

3. Glass fiber fragments are extremely sharp. Handle with care. Wear safety

glasses at all times during cleaving operation for protection from glass fibers.

4. Dispose of glass fiber fragments properly. After use, please empty the off-cut

bin and then store the cleaver in the case. There is a possibility that fiber offcuts

could spill out of the bin during transportation if remain in the bin.

5. The blade of the cleaver is extremely sharp. Do not touch it with bare hands.

6. The FC-6S+ has the “automatic blade return” function. When the clamp cover

is opened after cleaving, the blade carriage returns automatically to the forward.

Be careful not to be hit your fingers by the blade or blade carriage.

7. Do not impact the top clamp lever and switching lever. Doing so can cause

damage to the levers and loss of cleaving performance.

8. If the cleaver is damaged or a problem occurs, please contact our service

department.

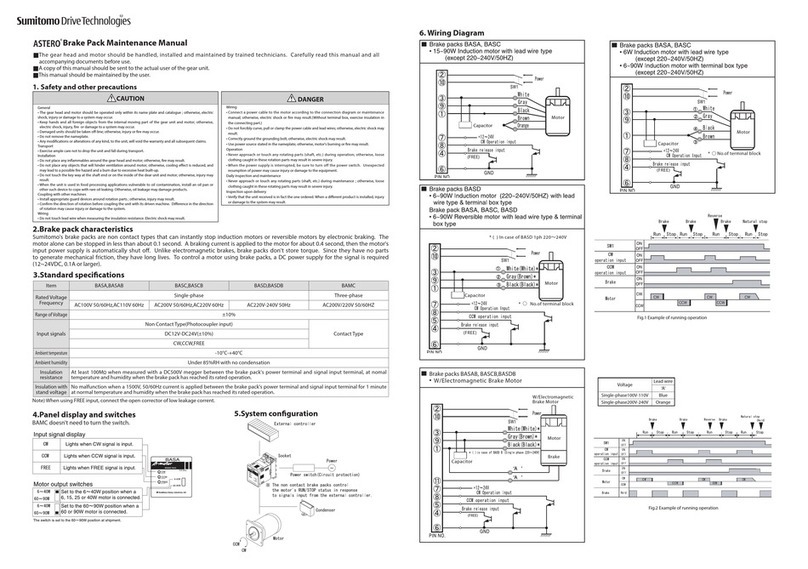

Specification

Standard package

Optional accessories / Consumables

3. Operating procedures

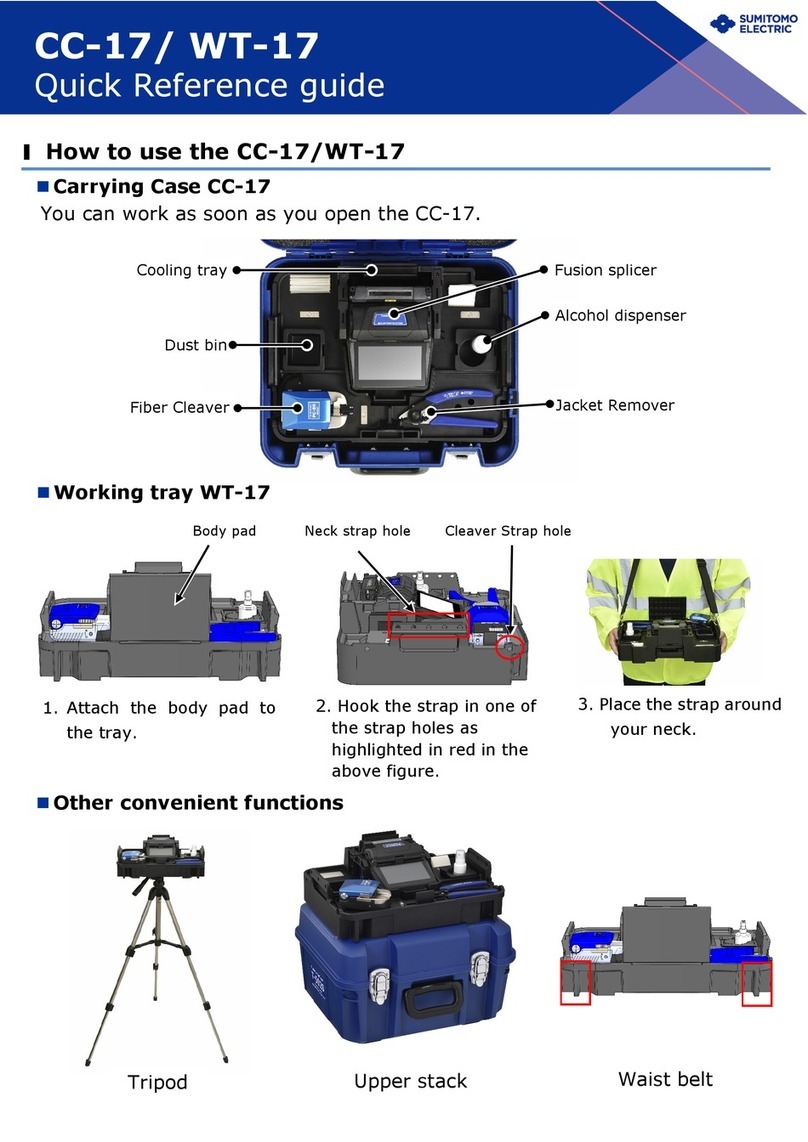

< Single fiber adapter AP-FC6M >

Groove for φ0.9mm fiber

Groove for φ0.25mm fiber

With single fiber adapter

Single fiber adapter

AP-FC6M

Off-cut collector

CU-FC6+

Blade carriage

Blade

Clamp

Fiber holder

receptacle

Clamp cover

Top clamp lever

Clamp

Off-cut bin

< Fiber cleaver FC-6S+ >

1: Open the top clamp lever and the

lid of the single fiber adapter. The

blade carriage sho

forward position.

Lid of single fiber adapter

Top clamp lever

Blade carriage

2: Lower the

correct V-

groove with the end of the

fiber coating (e.g. if the cleave

length is 16mm) at the 16mm mark

on the ruler.

3:

Close the lid of the single fiber

adapter.

4: Lower the

top clamp lever. Slide the blade carriage to the rear of the cleaver.

The fiber will be cleaved.

5:

Open the top clamp lever. Then open the lid of the single

fiber adapter and lift the newly cleaved fiber. Lift the off-

and dispose it properly. (The FC-6S+

collects an off-cut in the off-cut collector.)

carriage returns

automatically after cleave, please refer

"Automatic blade return function".

Cleave

length

Fiber

coating

Bare fiber