THK Ball Spline User manual

Instruction Manual

No. 1030-T34669

Ball Spline

THK Linear Motion System

www.thk.ru

тел. +7(499) 703-39-86

Table of Contents

i

Ball Spline

1. Introduction 1-1

1-1 Foreword 1-1

1-2 About This Manual 1-1

1-3 Applying This Product 1-2

1-4 Product Support 1-2

1-5 Product Information and THK Information 1-2

2. Precautions on Use 2-1

2-1 Safety Related Warning Displays 2-1

2-2 Handling 2-1

2-3 Precautions on Use 2-2

2-4 Lubrication 2-3

2-5 Storage 2-3

2-6 Disposal 2-3

3. Assembly 3-1

3-1 Mounting the Spline 3-1

3-2 Installing the Spline Nut 3-3

3-3 Installing the Spline Shaft 3-4

4. Lubrication 4-1

4-1 Lubrication Interval 4-1

www.thk.ru

тел. +7(499) 703-39-86

1-1

Ball Spline

1. Introduction

1.

Introduction

1-1 Foreword

Thank you for purchasing this THK product. This manual describes the precautions on use,

assembly method, and lubrication method that apply to a Ball Spline.

1-2 About This Manual

1-2-1 Intended Audience

Persons in charge of product mounting design, installation, wiring, and maintenance, and

persons actually using the product.

1-2-2 Using This Manual

This manual describes the correct handling of this product and precautions on its use.

For maximum product performance and long-term use, read this manual carefully and

understand its contents so that you use this product safely and properly.

When printing this manual for reading, store it in a place where the intended audience can read it

when necessary.

1-2-3 Notice and Attention

zDo not handle or use this product in any way other than as described in this manual.

zNo part of this manual may be duplicated, reproduced, or loaned without permission.

zDue to a continuing process of product improvement, information contained herein is subject

to change without notice.

zEfforts have been made to ensure the accuracy of the information contained herein. If,

however, you notice an error or have a concern, notify THK.

zThe diagrams contained herein are representative examples and may vary from the actual

product.

zTHK will not be liable for the effects resulting from the use of this manual for any reason

whatsoever.

zThis manual also applies to special products, but content specified on the Delivery

*Special products are products that differ from standard products listed in the catalog, in

www.thk.ru

тел. +7(499) 703-39-86

1-2

Ball Spline

1. Introduction

1-3 Applying This Product

zDo not use this product for equipment or systems used in life-threatening situations.

zConsult THK beforehand when considering using this product for special applications such as

in passenger vehicles or in medical, aviation and space, nuclear power, or electrical power

equipment or systems.

zThis product was manufactured under strict quality control, but this does not completely rule

out product failure. When using this product in equipment where failure of this product could

cause a severe accident or damage, install a safety device or backup device to prevent the

occurrence of severe accidents or damage.

1-4 Product Support

you have a concern, notify THK.

1-5 Product Information and THK Information

For the latest product information and company information, we recommend that you regularly

access and view the THK website.

zWebsite URL: https://www.thk.com/eng/

zTechnical support site URL: https://tech.thk.com/

www.thk.ru

тел. +7(499) 703-39-86

2-1

2. Precautions

Ball Spline

2.

Precautions on Use

2-1 Safety Related Warning Displays

This manual uses the following safety related warning displays. Descriptions containing safety

related warning displays are serious and must be followed. The Ball Spline is a precision part, to

be handled with care based on the following information.

Warning "A matter which, if mishandled, could result in

death or serious injury."

Caution "A matter which, if mishandled, could result

in physical injury or material damage."

"Prohibited (never do this)"

"Required (always do this)"

2-2 Handling

CAUTION

Handle with care

zPlease use at least two people to move any product weighing 20 kg or more, or use a dolly or

other conveyance. Failure to do so could cause injury or damage the product.

Do not disassemble

zDo not disassemble the parts. This could impair the product's functions.

Falling objects

zTilting a spline nut or spline shaft may cause them to fall by their own weight.

zTake care not to drop or strike the Ball Spline. This could cause injury or damage the product.

If the product receives an impact, it could impair the product's functions, even if the product

looks intact.

Handle with care

zWhen assembling, be sure not to remove the spline nut from the spline shaft.

zWhen handling the product, wear safety gloves and safety boots, etc., as appropriate to

ensure safety.

www.thk.ru

тел. +7(499) 703-39-86

2-2

2. Precautions

2.

Precautions on Use

Ball Spline

2-3 Precautions on Use

CAUTION

Prevent dust

zPrevent foreign materials, such as cutting chips or coolant, from entering the product. Failure

to do so could damage the product.

zPrevent foreign materials, such as cutting chips, coolant, corrosive solvents or water from

getting in the product by using a bellows or cover when the product is used in an environment

where such a thing is likely.

zIf foreign materials such as cutting chips adhere to the product, clean the product and then

replenish the lubricant.

zSmall strokes can inhibit the formation of an oil film between the raceway and the area of

contact for rolling elements, resulting in fretting. Therefore, be sure to use a type of grease

with high fretting resistance properties. We recommend periodically adding stroke movement

for approximately the spline nut length to help ensure that an oil film forms between the

raceway and the rolling elements.

Maximum temperature

80°C

Max

zDo not use this product if the external temperature exceeds 80 °C. If used in excess of this

temperature, there is a risk that the resin and rubber parts may deform or become damaged

(except the heat-resistant type).

Handle with care

zDo not forcibly drive a pin, key, or other positioning parts into the product. This could create

indentations on the raceway and impair the product's functions.

zIf the spline shaft supporting portion and the spline nut become misaligned or tilted, it may

substantially shorten the service life. Therefore, be sure to pay sufficient attention to the

components that are to be mounted and to the mounting accuracy.

zInserting the spline nut onto the spline shaft while the rolling elements are removed may

cause early damage.

zWhen installing the spline shaft into the spline nut, identify the matching marks on the spline

shaft and the spline nut, and then insert the shaft straight while checking relative positioning.

with a seal or given a preload, apply a lubricant to the outer surface of the spline shaft.

zWhen installing the spline nut into the housing, do not hit the side plate, end cap, or seal;

gently insert it using a jig.

zA lack of rigidity and accuracy of mounting components may cause the bearing load to

the rigidity and accuracy of the housing and base, and the strength of the securing bolts.

z

pin hole, contact THK.

Falling objects

zIf any of the rolling elements fall from the spline nut, discontinue use and contact THK.

www.thk.ru

тел. +7(499) 703-39-86

2-3

2. Precautions

2.

Precautions on Use

Ball Spline

2-4 Lubrication

CAUTION

Check lubricant

zThoroughly remove anti-rust oil and feed lubricant before using the product.

zDo not mix different lubricants. Even grease containing the same type of thickening agent

may, if mixed, interact in an adverse manner due to disparate additives or other ingredients.

zWhen using the product in locations subject to constant vibrations or in special environments

such as in clean rooms, vacuums, and under low or high temperatures, be sure to use a

zWhen lubricating products that do not feature a grease nipple or oil hole, directly coat the

raceway surface with lubricant and perform several warm-up strokes to ensure that the

grease permeates the interior.

zGrease consistency can vary depending on the temperature. Please keep in mind that the

zFollowing greasing, the stirring resistance of the grease can cause the Ball Spline to exhibit

increased sliding resistance. Before commencing operation, be sure to run the unit through

several warm-up cycles to ensure that the grease is adequately integrated and dispersed.

zExcess grease may spatter immediately after lubrication. Wipe off spattered grease as

necessary.

zThe properties of the grease deteriorate over time, thereby degrading the lubricity. It is

necessary to inspect and apply the grease in accordance with the usage frequency.

zHow often grease should be replenished varies depending on the usage conditions and

environment. We recommend greasing the system approximately every 100 km traveled

(three to six months). Final greasing interval/amount should be set at an actual machine.

zWhen using oil lubrication, the lubricant may not be distributed throughout the product

depending on the installation direction of the Ball Spline. Contact THK for details.

2-5 Storage

Ball splines should be stored horizontally in their original packaging in an indoor location where

they are not exposed to abnormally high or low temperatures or high humidity. Please note that if

the product has been kept in storage for an extended period of time, the lubricant inside may

have deteriorated. Please therefore ensure that you replenish the lubricant before re-use.

2-6 Disposal

The product should be disposed of appropriately as an industrial waste.

www.thk.ru

тел. +7(499) 703-39-86

3-1

3. Assembly

Ball Spline

3. Assembly

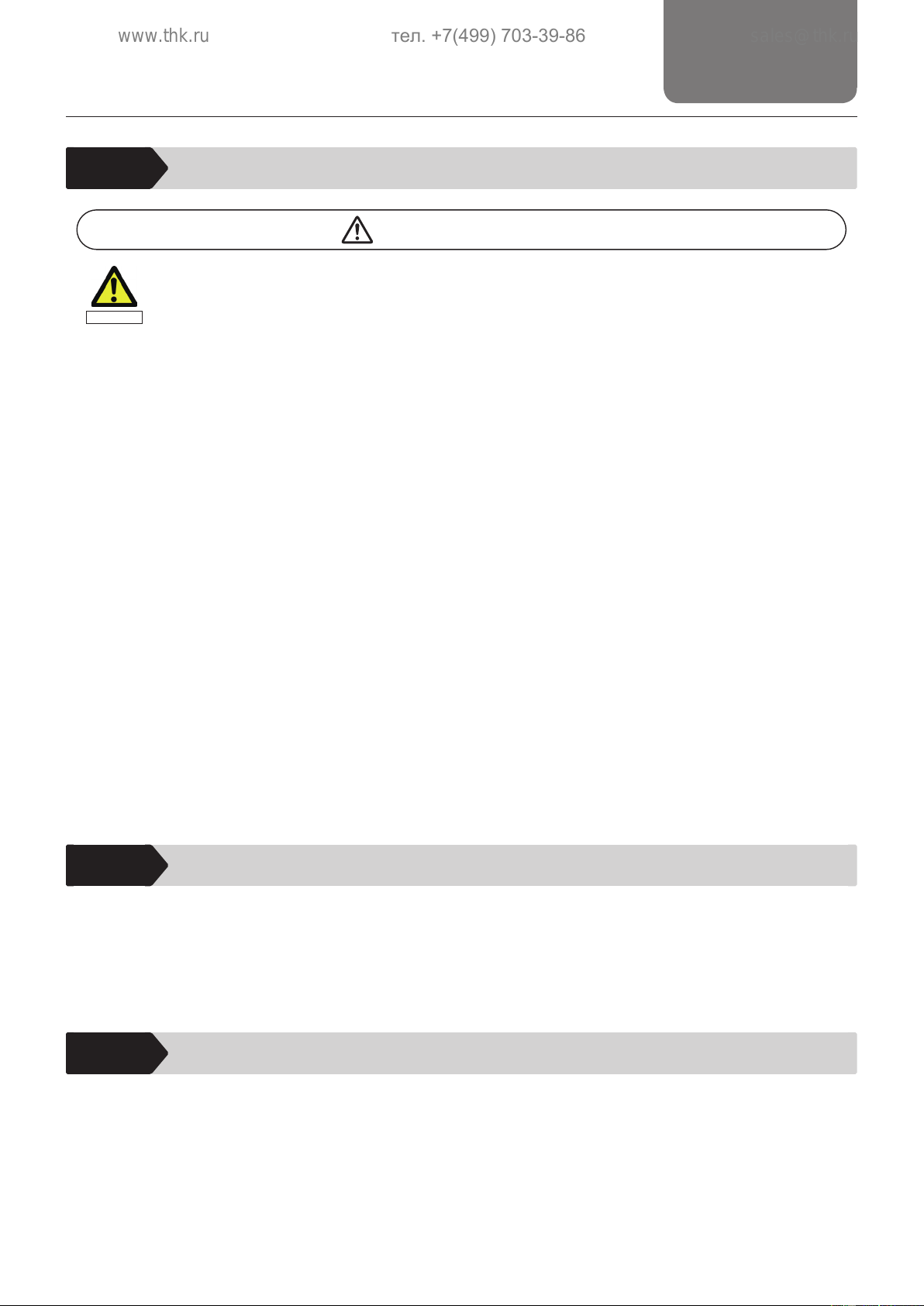

3-1 Mounting the Spline

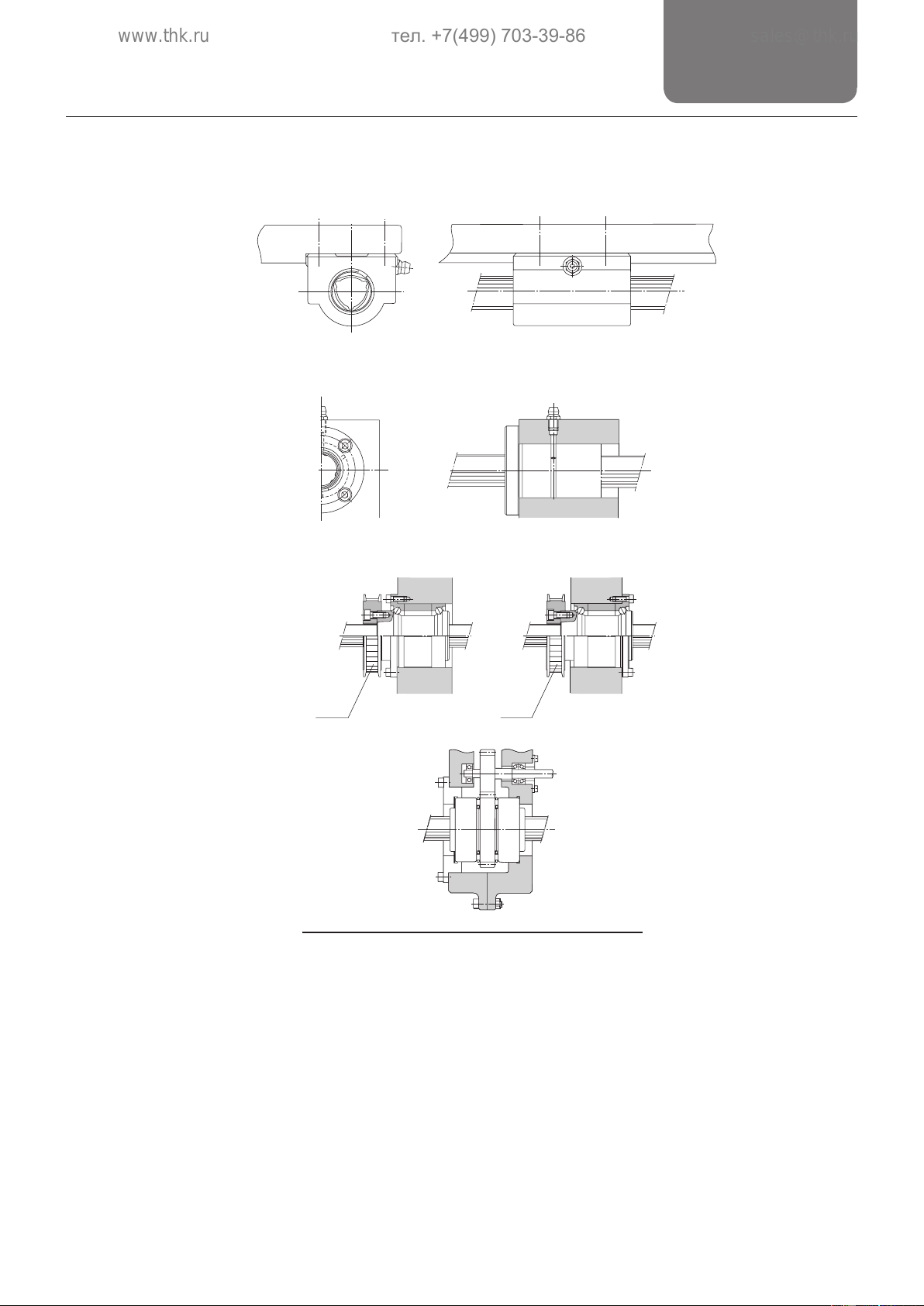

Figure 3-1 and Figure 3-2 show examples of mounting the spline nut. Although the Ball Spline

does not require a large amount of strength for securing it in the spline shaft direction, do not rely

Note: Both ends of the Ball Spline SLS model with a retainer have a resin end cap.

Hammering or forcefully pressing may cause damage. Be careful not to apply an excessive load.

Straight outer cylinder

Figure 3-1 Example of Mounting the Spline Nut

www.thk.ru

тел. +7(499) 703-39-86

3-2

3. Assembly

3.

Assembly

Ball Spline

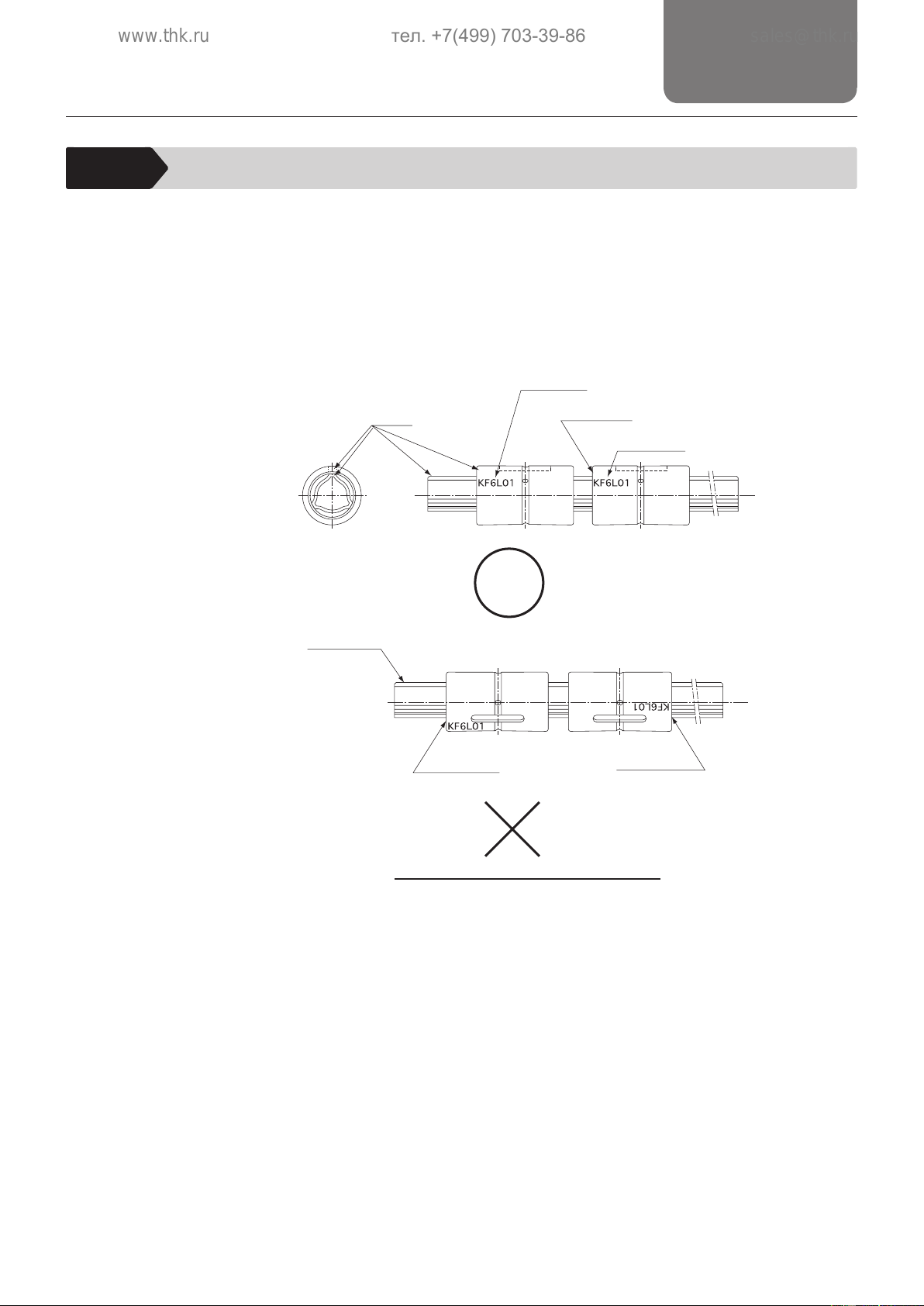

Model LBG

Model LTR

Flanged Type

Model LBH

Pulley Pulley

Figure 3-2 Example of Mounting the Spline Nut

www.thk.ru

тел. +7(499) 703-39-86

3-3

3. Assembly

3.

Assembly

Ball Spline

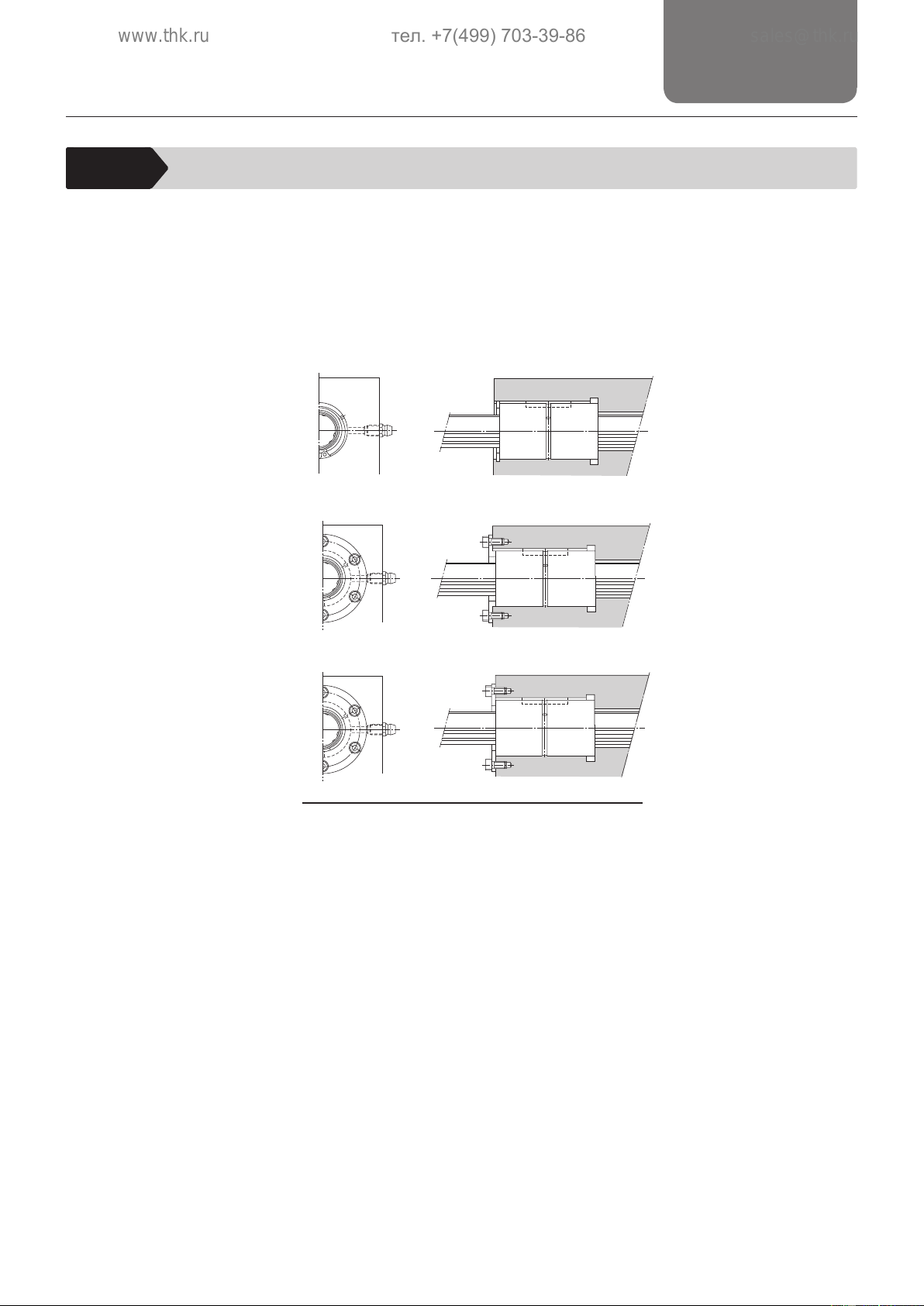

3-2 Installing the Spline Nut

When installing the spline nut into the housing, do not hit the side plate or the seal; gently insert

it using a jig (Figure 3-3).

di

D-0.5

Figure 3-3 Installing the Spline Nut

Table 3-1 Model LBS Jig Dimensions Unit: mm

Nominal

shaft

diameter

15 20 25 30 40 50 60 70 85 100 120 150

di 12.5 16.1 20.3 24.4 32.4 40.1 47.8 55.9 69.3 83.8 103.8 131.8

Table 3-2 Model LT Jig Dimensions Unit: mm

Nominal

shaft

diameter

6 8 10 13 16 20 25 30 40 50 60 80 100

di 5.0 7 8.5 11.5 14.5 18.5 23 28 37.5 46.5 56 75.5 94.5

www.thk.ru

тел. +7(499) 703-39-86

3-4

3. Assembly

3.

Assembly

Ball Spline

3-3 Installing the Spline Shaft

When installing the spline shaft into the spline nut, identify the matching marks (Figure 3-4) on

the spline shaft and the spline nut, and then insert the shaft straight while checking their relative

positions.

If the spline nut is attached with a seal or given a preload, apply a lubricant to the outer surface

of the spline shaft.

Matching

mark Matching mark

Matching mark

Matching mark

Matching mark

Serial number

Serial number

Figure 3-4 Installing the Spline Shaft

www.thk.ru

тел. +7(499) 703-39-86

4-1

4. Lubrication

Ball Spline

4.

Lubrication

A good quality lubricant is required when using Ball Splines. Usage with no lubrication may

increase wear on the rolling elements and shorten the service life.

A lubricant has the following effects.

(1) Minimizes friction in moving elements to prevent seizure and reduce wear.

(2) Forms an oil film on the raceway to decrease stress acting on the surface and extend rolling

fatigue life.

(3) Covers the metal surface in an oil film to prevent rust formation.

To optimize Ball Spline functions, provide lubrication appropriate to the usage conditions.

To prevent foreign material from entering the spline nut and the lubricant from leaking, special

synthetic resin seals with high wear resistance are available for the Ball Spline.

Spline nuts with seals (Seal for Both Ends Type UU, and Seal for One End) are sealed with

lithium soap-based grease No. 2. If using at high speed or with a long stroke, replenish grease of

the same type through the greasing hole on the spline nut after running in.

Afterward, replenish grease of the same type as necessary according to the usage conditions.

The greasing interval differs depending on the usage conditions. Under normal conditions,

replenish (or replace) roughly every 100 km of travel distance (three to six months).

For a Ball Spline model type without a seal, apply grease to the interior of the spline nut or to the

raceway of the spline shaft.

4-1 Lubrication Interval

4-1-1 Grease Lubrication

How often grease should be replenished varies depending on the usage conditions and

environment. We recommend greasing the system approximately every 100 km traveled (three

to six months). Final greasing interval/amount should be set at an actual machine.

Normally, relubricate using the same grease type and through the lubrication hole or grease

nipple provided on the Ball Spline. Mixing different types of grease may deteriorate the system’s

performance due to increased consistency or other such factor.

Lubricant Type Brand name

Grease

Lithium-Based Grease

Urea-Based Grease

Calcium-Based Grease

AFA Grease (THK)

AFB-LF Grease (THK)

AFC Grease (THK)

AFE-CA Grease (THK)

AFF Grease (THK)

AFG Grease (THK)

AFJ Grease (THK)

L100 Grease (THK)

L450 Grease (THK)

L500 Grease (THK)

L700 Grease (THK)

Alvania Grease S No.2 (Showa Shell Sekiyu)

Eponex Grease No.2 (Idemitsu Kosan)

or equivalent

*The recommended grease will vary according to the usage conditions and environment.

www.thk.ru

тел. +7(499) 703-39-86

4-2

4. Lubrication

4.

Lubrication

Ball Spline

4-1-2 Oil Lubrication

LM systems that require oil lubrication are shipped with only anti-rust oil applied. Please indicate

when ordering.

zThe amount of oil to be applied varies depending on the stroke length. For a long stroke,

increase the lubrication frequency or the amount of oil applied so that an oil film is able to form

in the stroke end of the raceway.

zIn environments where coolant may spatter, the lubricant may become mixed with the coolant.

This could result in the lubricant being emulsified or washed away, causing significantly

degraded lubrication performance. In such locations, apply a lubricant with high viscosity

(kinematic viscosity: approx. 68 cst) and high emulsification resistance, and adjust the

lubrication frequency or the amount of the applied lubricant accordingly.

zFor machine tools and similar devices that are subject to heavy loads, require high rigidity, and

operate at high speed, oil lubrication is recommended.

zMake sure that lubrication oil discharges normally from the ends of the lubrication piping; that

is, the oiling ports that connect to your linear motion system.

Lubricant Type Brand name

Oil Raceway Oil or Turbine Oil

ISOVG32 to 68

Daphne Super Multi Oil (Idemitsu Kosan)

Mobil DTE Oil Series (Exxon Mobil)

Shell Tonna S3 M (Showa Shell Sekiyu)

Mobil Vactra Numbered Series (Exxon Mobil)

Mobil Vactra No. 2 SLC (Exxon Mobil)

or equivalent

www.thk.ru

тел. +7(499) 703-39-86

Appendix

Revision History

The instruction manual number is on the back cover.

Publication Date Instruction Manual No. Revisions

December 2017 No. 1030-T34669 First edition

www.thk.ru

тел. +7(499) 703-39-86

No. 1030-T34669

Inquiries

Website URL: https://www.thk.com/eng/

Technical support site URL: https://tech.thk.com/

www.thk.ru

тел. +7(499) 703-39-86

Table of contents

Other THK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Ceriotti

Ceriotti C3000 Assembly instructions

UNITED

UNITED CPC4000 Operation and maintenance manual

deconta

deconta smart dec S 50 Original instruction manual

Graco

Graco 226013 instructions

Milton Roy

Milton Roy YZ Systems NJEX 6300G-PM Instructions & operating manual

Vector

Vector OPT1-FC-HTNV-VC operating instructions